VTSSC30NSOLDERING STATION WITH CERAMIC HEATER

VTSSC30N

Introduction

To all residents of the European UnionImportant environmental information about this productThis symbol on the device or the package indicates that disposal of the device after its lifecycle could harm the environment. Do not dispose of the unit (or batteries) as unsorted municipal waste; it should be taken to a specialized company for recycling. This device should be returned to your distributor or to a local recycling service. Respect the local environmental rules.If in doubt, contact your local waste disposal authorities.Thank you for choosing Velleman! Please read the manual thoroughly before bringing this device into service. If the device was damaged in transit, do not install or use it and contact your dealer.

Safety Instructions

This device can be used by children aged from 8 years and above, and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning the use of the device in a safe way and understand the hazards involved. Children shall not play with the device. Cleaning and user maintenance shall not be made by children without supervision.

![]() Read and understand this manual and all safety signs before using this appliance.

Read and understand this manual and all safety signs before using this appliance.![]() Indoor use only. Keep this device away from rain, moisture, splashing and dripping liquids. Never put objects filled with liquids on top of or close to the device.

Indoor use only. Keep this device away from rain, moisture, splashing and dripping liquids. Never put objects filled with liquids on top of or close to the device.

![]() Always disconnect mains power when the device is not in use or when servicing or maintenance activities are performed. Handle the power cord by the plug only.Caution! After switching off, leave the power cord plugged in for a few minutes. When you switch off the unit, the automatic cooling function blows cooling air through the heater pipe for a short period. This protects the heater from damage and extends its lifetime. Do not disconnect the mains plug during this cooling process.

Always disconnect mains power when the device is not in use or when servicing or maintenance activities are performed. Handle the power cord by the plug only.Caution! After switching off, leave the power cord plugged in for a few minutes. When you switch off the unit, the automatic cooling function blows cooling air through the heater pipe for a short period. This protects the heater from damage and extends its lifetime. Do not disconnect the mains plug during this cooling process.

Do not crimp the power cord and protect it against damage.Warning! If the power cord is damaged, it must be replaced by the manufacturer, its service agent, or similarly qualified persons in order to avoid any hazard.Make sure that the available voltage does not exceed the voltage stated in the specifications of this manual.Plug the power cord into a suitable, earthed mains outlet.Risk of electroshock when opening the cover. Touching live wires can cause life-threatening electroshocks. Do not disassemble or open the housing yourself. Have the device repaired by qualified personnel. Do not operate the device with wet hands.Never use the device on live electronic circuits. Make sure power to the workpiece is cut and capacitors are discharged.

Do not crimp the power cord and protect it against damage.Warning! If the power cord is damaged, it must be replaced by the manufacturer, its service agent, or similarly qualified persons in order to avoid any hazard.Make sure that the available voltage does not exceed the voltage stated in the specifications of this manual.Plug the power cord into a suitable, earthed mains outlet.Risk of electroshock when opening the cover. Touching live wires can cause life-threatening electroshocks. Do not disassemble or open the housing yourself. Have the device repaired by qualified personnel. Do not operate the device with wet hands.Never use the device on live electronic circuits. Make sure power to the workpiece is cut and capacitors are discharged.

![]() Do not use near inflammable products or in explosive atmospheres. Heat can cause fire to inflammable products even when they are not in sight. Only use in properly ventilated rooms.

Do not use near inflammable products or in explosive atmospheres. Heat can cause fire to inflammable products even when they are not in sight. Only use in properly ventilated rooms.

![]() Incorrect use may cause fire.Do not touch the shafts, tips, or hot air gun as this can cause serious burns. Keep the tips and hot air away from the body, clothes, or other flammable material. Do not aim the hot air gun at the eyes. Use gloves and/or heat-resistant tools to pick up the PCB assembly to prevent burns. Always return the irons and gun to their stands between uses; always let the device cool down after use and before storage. Place the device on a level, stable, and fire-resistant working surface.

Incorrect use may cause fire.Do not touch the shafts, tips, or hot air gun as this can cause serious burns. Keep the tips and hot air away from the body, clothes, or other flammable material. Do not aim the hot air gun at the eyes. Use gloves and/or heat-resistant tools to pick up the PCB assembly to prevent burns. Always return the irons and gun to their stands between uses; always let the device cool down after use and before storage. Place the device on a level, stable, and fire-resistant working surface.

![]() WARNING! – This tool must be placed on its stand when not in use; do not leave the tool unattended when switched on.

WARNING! – This tool must be placed on its stand when not in use; do not leave the tool unattended when switched on.

Do not inhale solder fumes. The vapors that are released during soldering are harmful. Therefore, you shall only use the soldering station in well-ventilated areas or under an exhaust hood (solder fume extractor). Dispose of fume filters and solder residue in accordance with local regulations.

Do not inhale solder fumes. The vapors that are released during soldering are harmful. Therefore, you shall only use the soldering station in well-ventilated areas or under an exhaust hood (solder fume extractor). Dispose of fume filters and solder residue in accordance with local regulations.

• Use the soldering iron on a heatproof workbench.• Place the soldering iron in its holder after use.• Let a hot soldering iron cool down naturally and do not immerse in water.

General Guidelines

Refer to the Velleman® Service and Quality Warranty on the last pages of this manual.

|

Indoor use only. Keep this device away from rain, moisture, splashing and dripping liquids. Never put object filled with liquid on top. |

|

Keep this device away from dust and extreme heat. Make sure the ventilation openings are clear at all times. |

|

Protect this device from shocks and abuse. Avoid brute force when operating the device. |

- Familiarise yourself with the functions of the device before actually using it.

- All modifications of the device are forbidden for safety reasons. Damage caused by user modifications to the device is not covered by the warranty.

- Only use the device for its intended purpose. Using the device in an unauthorized way will void the warranty.

- Damage caused by disregard of certain guidelines in this manual is not covered by the warranty and the dealer will not accept responsibility for any ensuing defects or problems.

- Do not switch the device on immediately after it has been exposed to changes in temperature. Protect the device against damage by leaving it switched off until it has reached room temperature.

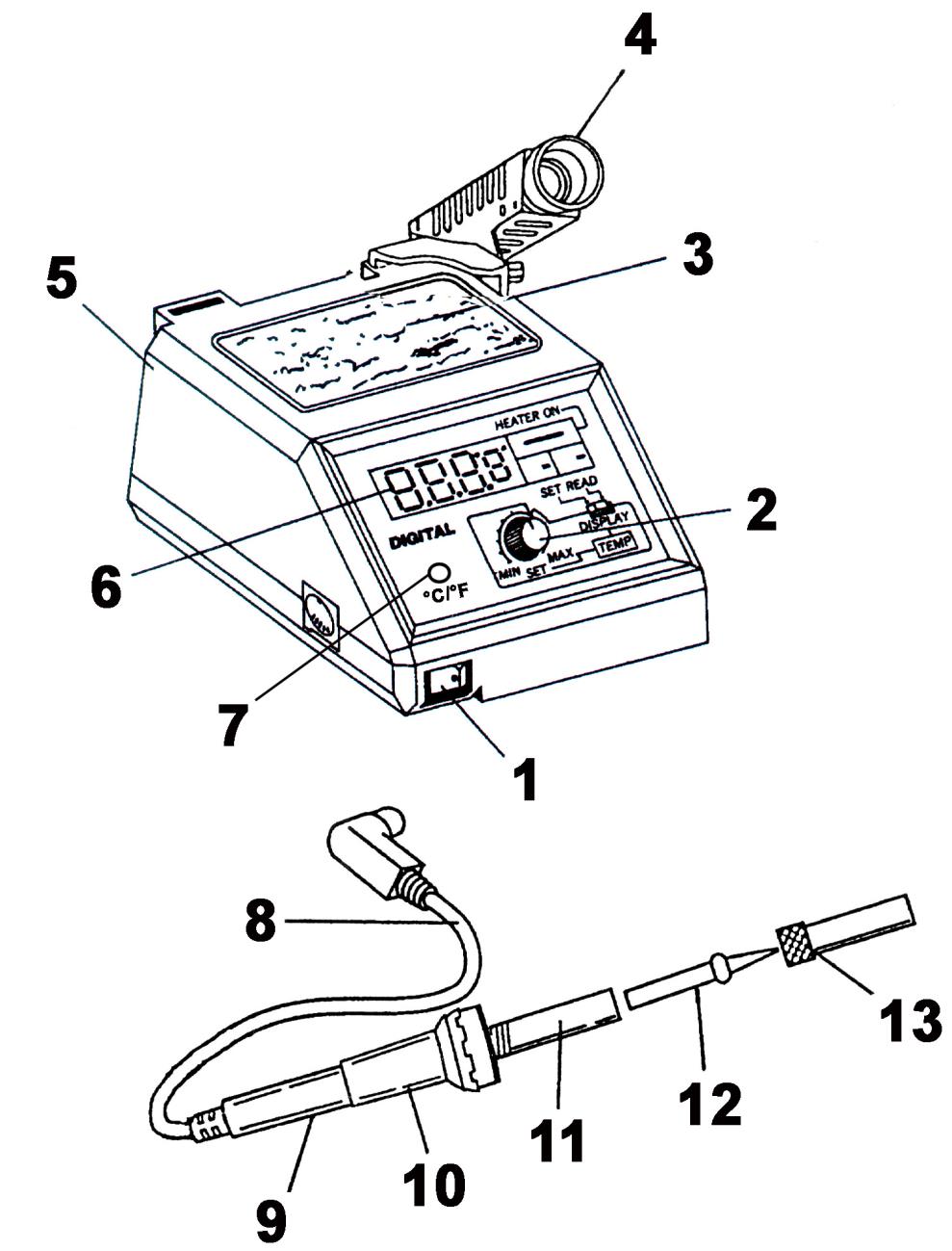

Overview

| 1 | ON/OFF switch |

| 2 | temperature control |

| 3 | sponge |

| 4 | iron stand |

| 5 | fuse holder |

| 6 | temperature read-out |

| 7 | °C/°F button |

| 8 | rubber cable |

| 9 | handle |

| 10 | antiskid rubber |

| 11 | heating element with incorporated temperature sensor |

| 12 | bit |

| 13 | bit holder |

Working Temperature

The most common soldering alloys used in the electronics industry consist of 60 % tin and 40 % lead. The operating temperature of this type of solder is detailed below and can vary from manufacturer to manufacturer. However, to meet RoHS requirements, these solders are no longer allowed and are replaced by lead-free solders that require a working temperature, which is ± 30 °C (54 °F) higher.

| leaded solder | lead-free | |

| Melting point | 215 °C (419°F) | 220 °C (428°F) |

| Normal Operation | 270-320 °C (518-608 °F) | 300-360 °C (572-680 °F) |

| Production Line Operation | 320-380 °C (608-716 °F) | 360-410 °C (680-770 °F) |

Tip Maintenance

The soldering uses extremely high temperatures. Make sure that the unit is switched off for maintenance purposes.Remove the tip and clean it after heavy or moderate use. We recommend cleaning the tip daily if the station is used frequently.

- Always tin the tip before returning it to the holder, prior to turning off the station or to storing it for long periods of time. Wipe the tip on a wet sponge or use our tip cleaner before activating the device.

- Using excessive temperatures (more than 400 °C or 750 °F) will shorten the life span of the tip.

- Do not exercise excessive pressure on the tip while soldering, as this may cause damage to the tip.

- Never clean the tip with a file or with abrasive materials.

- Do not use flux containing chloride or acid. Use only resinous fluxes.

- If an oxide film has formed, you should remove it by buffing carefully with a 600-800 grit emery cloth or by using isopropyl alcohol and consequently applying a new protective layer of solder.

- Set the desired temperature after allowing the unit to idle at 250 °C for three minutes. The station will be ready for use once the set temperature is reached.

- Wet the sponge with nothing but water.

![]() IMPORTANTRemove and clean the tip daily. Remove excess solder from the barrel nut assembly when installing a new tip.

IMPORTANTRemove and clean the tip daily. Remove excess solder from the barrel nut assembly when installing a new tip.

Cleaning and Maintenance

- Soldering tips can be replaced simply by unscrewing the barrel nut assembly. Turn off the station and allow it to cool down first. Damage to the soldering station may occur if the system is left on and the removed tip has not been replaced.

- After removing the tip, you should blow out any oxide dust that may have formed in the tip receptacle. Be careful not to get dust in your eyes. Replace the tip and tighten the screw. Pliers can be used to avoid contact with hot surfaces BUT SHOULD BE USED WITH CAUTION because overtightening may cause damage to the element or fuse the tip to the element.

- The outer cover of the iron and station may be cleaned with a damp cloth using small amounts of liquid detergent. Never submerse the unit in liquid or allow any liquid to enter the case of the station. Never use any solvent to clean the case.

- If the iron or station should become faulty or, for some reason does not operate normally, the system should be returned to the service department of your authorized dealer or service agent.

Technical Specifications

max. heater power for soldering iron ………………………………………………………. 48 Wpower supply ………………………………………………………………….. 220-240 V~, 50 Hztemperature range …………………………………………………………………….. 160-480 °Coperating voltage ……………………………………………………………………………….. 24 Vweight …………………………………………………………………………………………. 1.75 kgdimensions ……………………………………… 120 x 170 x 90 mm (without stand and iron)replacement bits1.0 mm ………………………………………………………………………………….. BITC10N23.0 mm ………………………………………………………………………………….. BITC10N32.0 mm ………………………………………………………………………………….. BITC10N4replacement soldering iron ………………………………………………………… VTSSC10N/SP

Use this device with original accessories only. Velleman nv cannot be held responsible in the event of damage or injury resulting from (incorrect) use of this device. For more info concerning this product and the latest version of this manual, please visit our website www.velleman.eu. The information in this manual is subject to change without prior notice.

© COPYRIGHT NOTICEThe copyright to this manual is owned by Velleman nv. All worldwide rights reserved. No part of this manual may be copied, reproduced, translated or reduced to any electronic medium or otherwise without the prior written consent of the copyright holder.

Made in PRCImported by Velleman nvLegen Heirweg 33, 9890 Gavere, Belgiumwww.velleman.eu

References

[xyz-ips snippet=”download-snippet”]