EMERSON Pressure Controls Series CS1Instruction Manual

General information:

For application in refrigeration systems in compliance with standard EN 378.A professional and appropriate storage and allocation of the devices is mandatory.

Safety instructions:

- Read operating instructions thoroughly. Failure to comply can result in device failure, system damage or personal injury.

- According to EN 13313 it is intended for use by persons having the appropriate knowledge and skill.

- Before opening any system make sure pressure in system is brought to and remains at atmospheric pressure.

- Before installation or service disconnect all voltages from system and device.

- Do not exceed the specified maximum ratings for pressure, temperature, voltage and current.

Function:

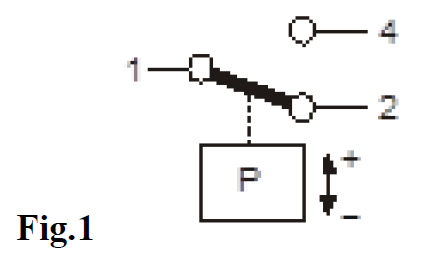

- CS1 Pressure switches are equipped with SPDT snap action contacts switching from 1-2 to 1-4 on rising and from 1-4 to 1-2 on falling pressure. Reaching the preset switch point on rising pressure, contact 1-2 opens while contact 1-4 closes and vice versa on falling pressure.

Mounting direction:

• Any direction except upside down.

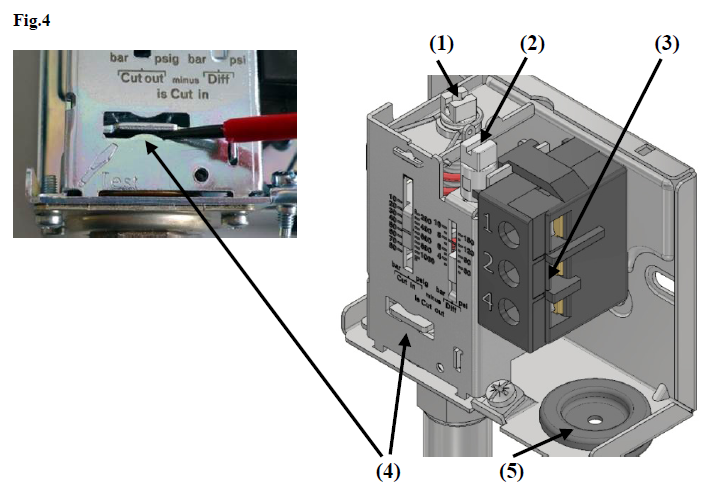

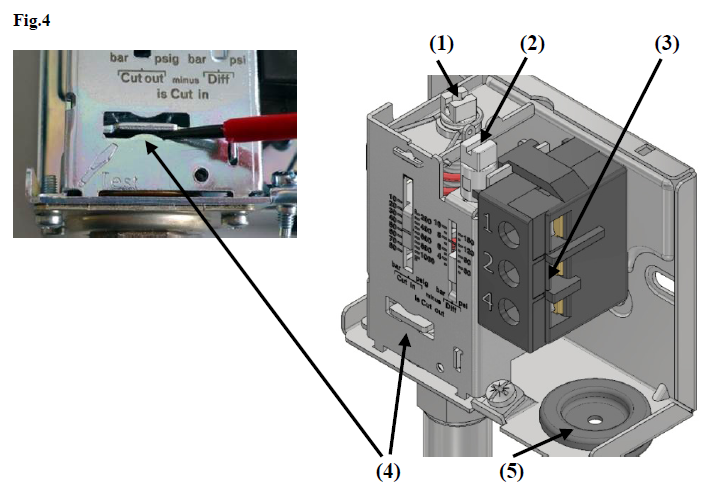

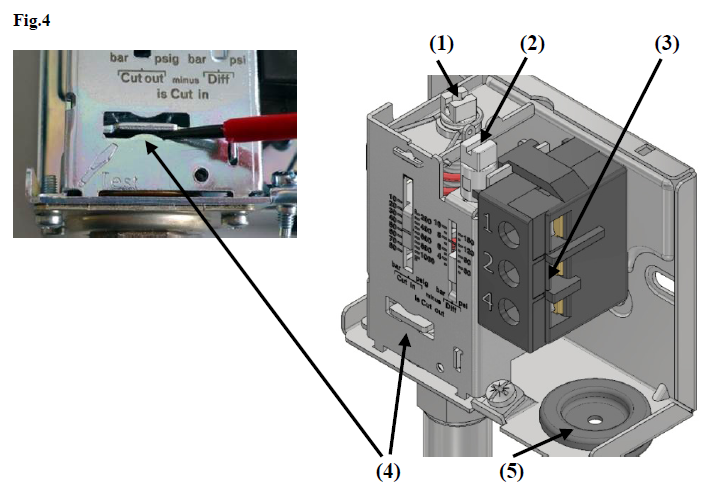

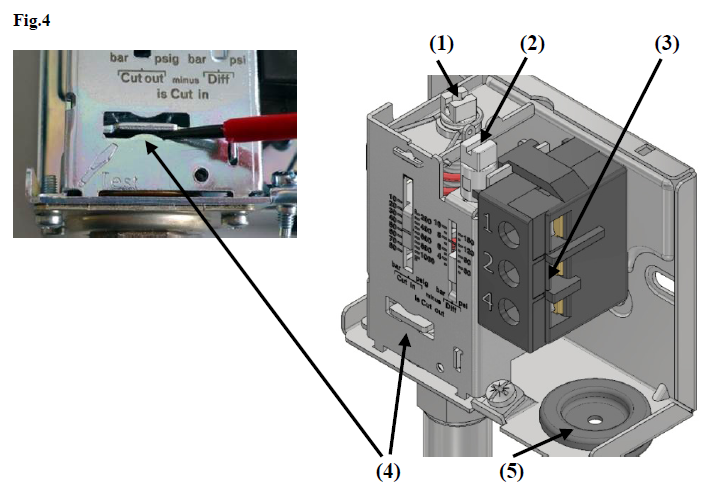

Installation (Fig.2&4):

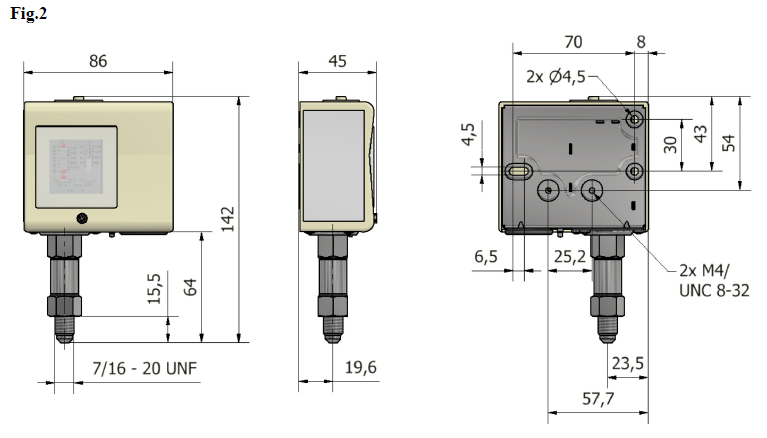

- CS1 may be installed by using a mounting plate or as a wall-mounted device against a flat surface.

- Use universal thread M4 or UNC8-32 mounting holes for installation via mounting plate.

- Use the standard mounting holes at the backside for wall mounting.

- Use mounting screws supplied with control.

- Mounting screws must not penetrate control backside by more than 8 mm to ensure proper operation.

- Do not use CS1 in pulsating operating conditions! Minimize vibrations in the piping lines by appropriate solutions.

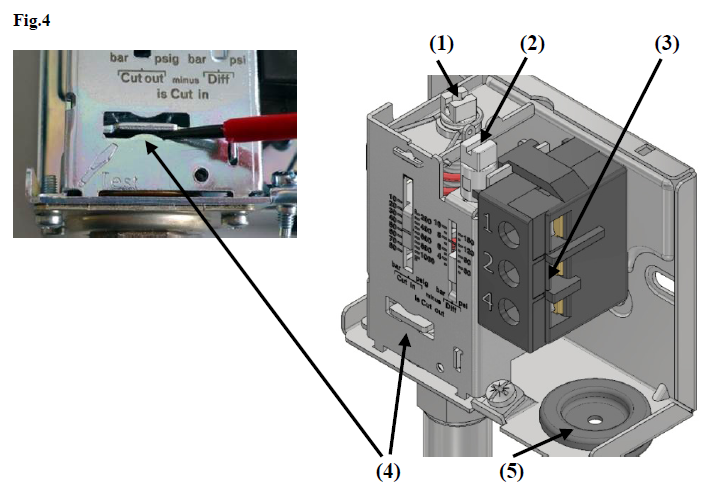

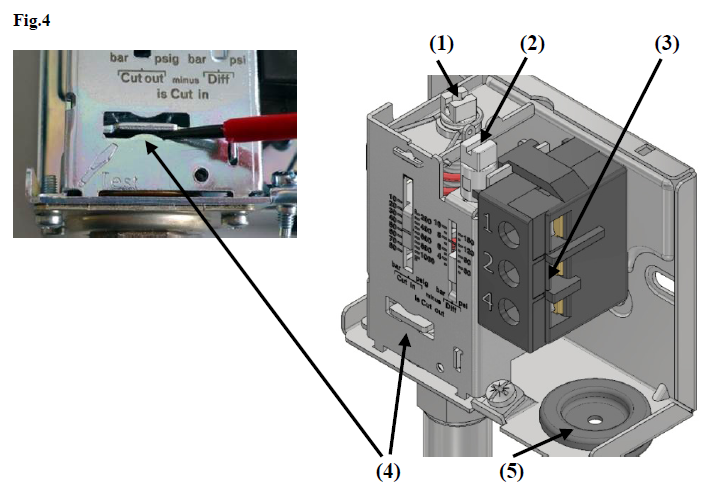

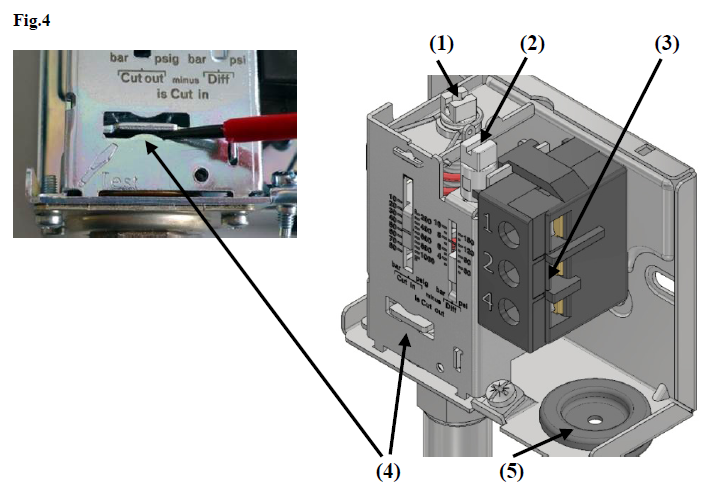

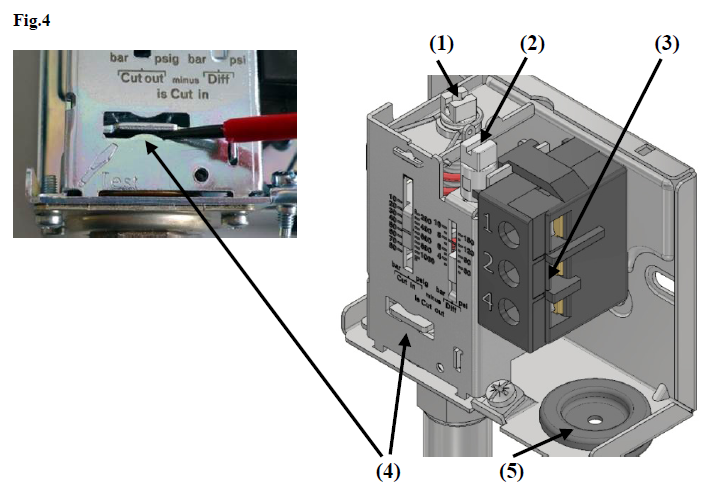

- In order to achieve protection class IP33, the following instructions must be observed:1. Cover must be closed and cover screw fastened.2. Control must be mounted against a flat surface so that all openings on the housing backside are fully covered.3. Cable grommet (Fig.4, No.5) is sealing the cable entry to the housing

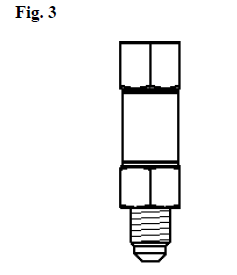

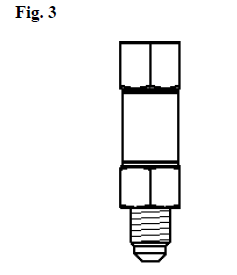

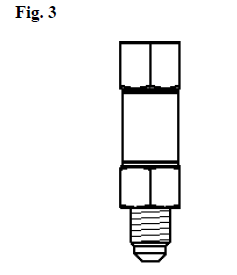

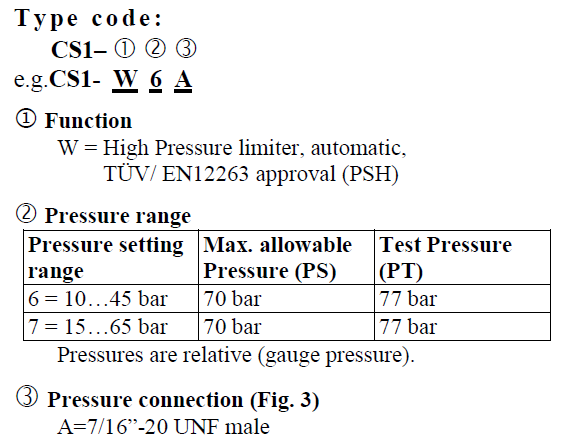

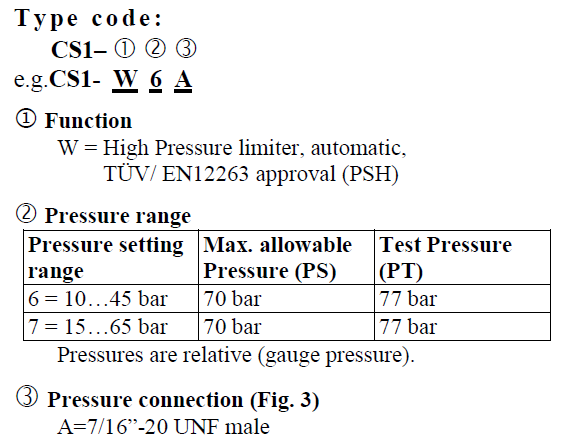

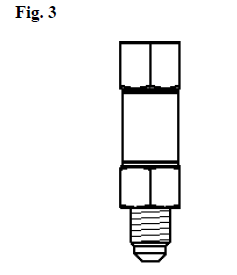

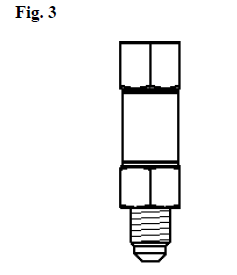

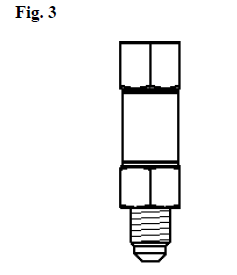

Pressure connection (Fig.3):

- Do not apply torsional load to pressure connector; use second spanner to counter-balance torque when tightening pressure connection. High pressure versions are equipped with a snubber to dampen pulsations.

- When connecting CS1 to the hot gas line of a refrigeration system, a pipe or high-pressure hose of at least 80 mm shall be used to allow sufficient temperature drop between refrigeration line and pressure switch bellows.

Pressure test:

After completion of installation, a test pressure must be carried out as follows:

- according to EN378 for systems which must comply with European pressure equipment directive 2014/68/EU

- to maximum working pressure of system for regions out of Europe

Warning:

- Failure to do so could result in loss of refrigerant and personal injury.

- The pressure test must be conducted by skilled persons with due respect regarding the danger related to pressure.

Tightness test:

Conduct a tightness test according to EN 378-2 with appropriate equipment and method to identify leakages of external joints. The allowable leakage rate must be according system manufacturer’s specification.

Electrical connection:

- Entire electrical connections have to comply with local regulations.

- Wire size must match the electrical load connected to the switch contacts.

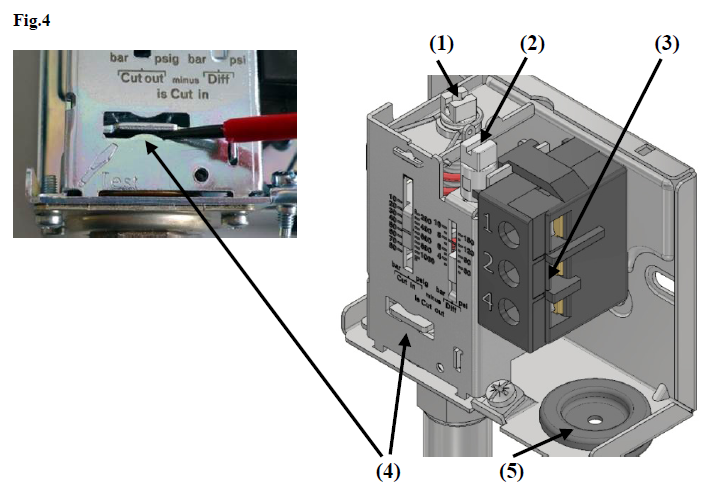

- Feed cables through rubber grommet at switch bottom (Fig.4, No.5).

- Optionally, the rubber grommet may be replaced by a standard PG 13.5 cable gland.

- Connect wires to terminals (Fig.4, No.3) by taking into account switch functions as shown in Fig.1

- Fasten terminal screws with torque 1.2 Nm max.

- Warning: CS1 might not be suitable for connection to electronic controllers with low electrical loads (voltage <24 V and current <50 mA).

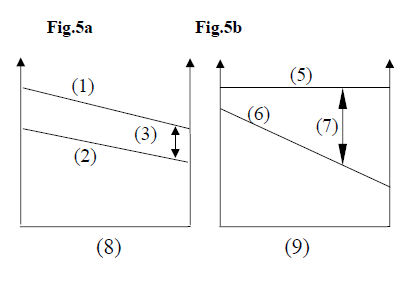

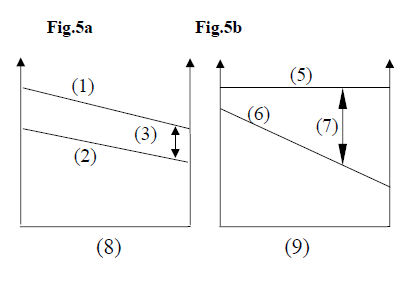

Setpoint adjustment (Fig.4&5):

- CS1 pressure switches come with individually adjustable range and differential depending on the exact model.

- Use a flat screw driver or a ¼” refrigeration (square) wrench to adjust setpoints as described below.

- Adjust upper setpoint using the range spindle (Fig.4, No.1).

- Adjust lower setpoint by turning the differential spindle (Fig.4, No.2).

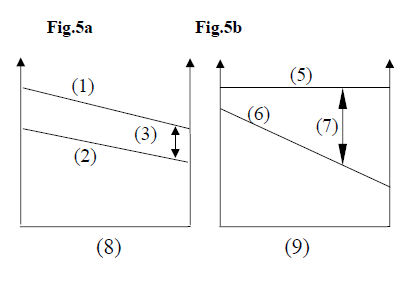

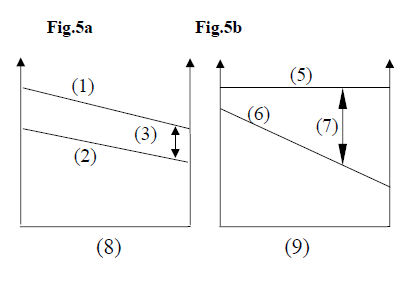

Upper setpoint – Differential = Lower setpoint Fig.5a/5b

(1) Upper setpoint(5) Upper setpoint(2) Lower setpoint(6) Lower setpoint(3) Differential(7) Differential = variable(8) Turning range spindle(9) Turning differential spindle

- A separate accurate gauge must be used for exact adjustment of the setpoints. The integrated display scale can only be used for obtaining approximate settings. Maximum cut-out level must be as follows:1. System with single protection device: At PS of system minus tolerances.2. System with two individual protection devices: At 0.9*PS of system.

- When changing the upper setpoint the lower setpoint must be re-checked.

- Refer to the Technical Bulletin for standard factory settings.

Check-out lever (Fig.4, No.4):

- Use the check-out lever to manually override the electrical contact position for testing out the system.Service / Maintenance:

- Defective CS1 must be replaced, they cannot be repaired.

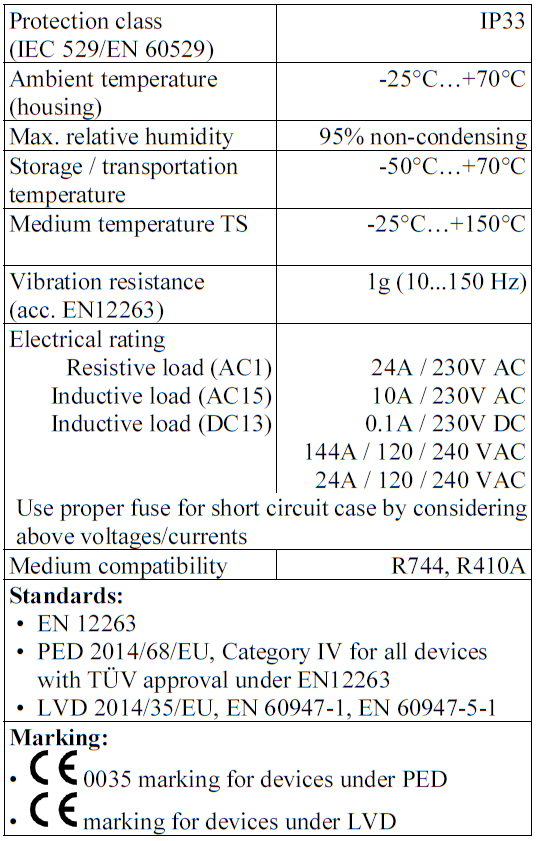

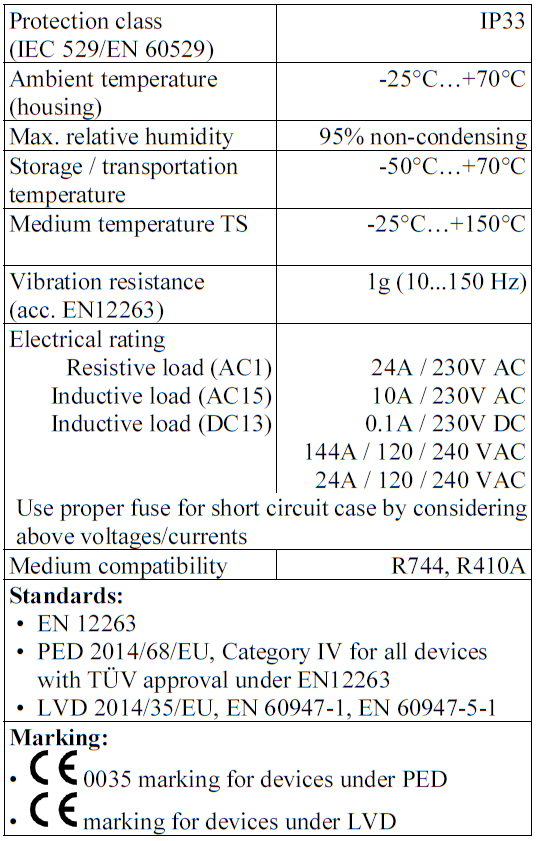

Technical data:

Emerson Climate Technologies GmbHwww.climate.emerson.com/en-gbDate: 06.03.2020Am Borsigturm 31 I 13507 Berlin I Germa

References

[xyz-ips snippet=”download-snippet”]