Pro-Ject Record Cleaning Machine Review Instructions

Record Cleaning Machine Review

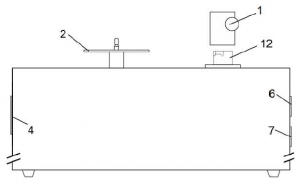

Controls, features and connections

- Vacuum arm* (adhesive velvet strips attached)

- Clamp* (base plate)

- Fixing screw for base part of clamp*

- Sidepanel cover with ventilation outlet and drain hole

- Main switch with mains power cord socket

- Vacuum on/off switch

- Motor on/off direction switch

- Vinyl record (not included)

- Screwable clamp – top plate* with self-adhesive record label seal* with rubber for sealing record label

- Hexagon screw for motor flange height adjustment (see page 6)

- Spindle with motor flange

- Vacuum arm flange

- Self-adhesive record label seal*

Accessories (included, but not shown above)

➢ Wash it vinyl cleaning concentrate (100ml bottle, mixing ratio 1:10 – 1:20)*➢ Goat hair brush*➢ Replacement adhesive strips for vacuum arm*➢ Drain insert (spout)*

Optional accessories (available on request)

➢ Wash it cleaning concentrate, mixing ratio 1:10 – 1:20bottle sizes: 100ml/250ml/500ml/1l (100ml ≙ 135 records / both sides, this average quantity depends on dilution ratio and the amount of ready-to-use cleaning fluid used per application)➢ Goat hair brush➢ Adhesive strips for vacuum arm

AC power cord is not included in the packaging. Use cable with JIS C 8303 and IEC60320 C13 plugs

Dear music lover,Thank you for purchasing a Pro-Ject Audio Systems record cleaning machine.In order to achieve maximum performance and reliability, please study these instructions carefully

Warning of a hazard for the user, the unit or possible misuse.Important notice.

Warning of a hazard for the user, the unit or possible misuse.Important notice.

During assembly and adjustment small parts can be easily lost if they are not carefully placed in a suitable receptacle. Before beginning assembly, please familiarize yourself with the parts listed above which are correspondingly numbered in the technical diagram. Separately packed items are marked with an asterisk*.

Safety instructions

This appliance is not to be used by persons (including children up to 8 years of age) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction. Cleaning and maintenance performed by the user can not be made by children.AC outlet voltages vary from country to country. Before connecting to your wall outlet, make sure that the voltage in your area meets the voltage requirements printed on the device.Hold the end of the plug when unplugging the power cord. Never handle the power cord while your hands are wet or damp. Never place any open flame sources, like burning candles, on or near the device. Do not operate in damp or wet locations, such as near to a bathtub, sink, swimming pool or any other similar locations.

Keep plastic bags away from children to prevent any risk of suffocation. Do not cover any ventilation holes (one is located on the left side and others are on bottom).During operation this unit will generate loud noises, so we recommend the use of hearing protectors during longer cleaning sessions. Check the unit after transportation for signs of damage, if a damage is found, do not operate the unit and contact your dealer! The unit is capable of long time running however in such case platter spindle may get hot and whole platter/clamp area as well as air coming out from the unit may get warm. The temperature of the platter can´t damage vinyl records. In order to keep the temperature as low as possible do not expose the unit to direct sunlight. Motor should not be turned on when not cleaning your records. Extended running time outside of the guideline process can cause over-heating.

Keep plastic bags away from children to prevent any risk of suffocation. Do not cover any ventilation holes (one is located on the left side and others are on bottom).During operation this unit will generate loud noises, so we recommend the use of hearing protectors during longer cleaning sessions. Check the unit after transportation for signs of damage, if a damage is found, do not operate the unit and contact your dealer! The unit is capable of long time running however in such case platter spindle may get hot and whole platter/clamp area as well as air coming out from the unit may get warm. The temperature of the platter can´t damage vinyl records. In order to keep the temperature as low as possible do not expose the unit to direct sunlight. Motor should not be turned on when not cleaning your records. Extended running time outside of the guideline process can cause over-heating.

Setting up the unit

The unit is supplied assembled with the exception of the platter and vacuum arm which are packed separately. Remove all parts from the transport packaging carefully. Please see the diagram above for assembly instructions. Base part of the clamp (2) should be attached by using the screw (3), a Phillips head screwdriver is required but not included. Then apply the self-adhesive label seal (13) on top.

Using the unit

Please ensure that all assembly and set up steps have been followed as outlined in this manual. All 3 rocker switches (“main switch”, “motor” and “vacuum” should be in position “0”). Connect the power cord to the socket on the rear side of VC-S2 and turn the main switch to the “I” position. Place a record on the bottom plate. Using moderate force, thread the top clamp plate on the threaded tip of the centre spindle. Do not over-tighten. If the top plate and screw clamp are too loose, the record will not turn even if the motor is running. While the record is turning apply a generous amount of ready-to-use cleaning fluid (6 – 8ml) to the record while holding the brush horizontally and gently pressing against the record, spread the fluidacross the surface of the record. Use only the necessary amount of fluid (6 – 8ml), enough to cover the record, not the machine!

The motor can turn both directions or can be stopped during the application of the fluid, depending on your personal preference. To change direction, choose the “I” position for clockwiserotation or to the “II” position for counter-clockwise rotation. It is recommended that you use the brush to clean the record in both directions before vacuuming. For better dissolving of impurities, wait a few seconds (longer in the case of heavily soiled records) before starting the vacuuming process. Once the record has been thoroughly cleaned in both directions, place the vacuum arm above the record pointing at the spindle until it reaches its lock position. Turn the Vacuum motor to the “I” position. After the cleaning fluid has been thoroughly vacuumed, switch off the vacuum, followed by the motor. Return the vacuum arm into its rest position and wait a few seconds for the record to dry thoroughly. Unscrew the top clamp plate, turn the record over and repeat steps for the opposite side of the record.

Maintenance and cleaning

Your record cleaning machine requires little to no regular maintenance. A water level gauge is located on the left side of the unit, below the air outlet hole. The internal tank has a substantial capacity and subsequently takes a very long time to reach full capacity. Common home use of the unit DOES NOT require to empty the tank. The tank is there to catch the drained cleaning liquid, and the large surface on the inside and oversized capacity allows the drained liquid to evaporate faster than in a much smaller tank. In rare cases when the water levelreaches the point marked ” ←MAX”, the tank should be emptied:

- Disconnect the mains cable

- remove ventilation outlet grille (4)

- Place the drain insert spout into the hole (drain insert is included in the accessories) and make sure it sits there tightly, so no fluid can reach the inside of the device.

- Lift the opposite side of the VC-S2 ALU up to drain the unit reservoir to a big container.

- Remove the spout and attach the ventilation outlet grille back to its place

Regularly check the velvet strips on the arm. Make sure they are clean, no dirt or debris is present

Technical specifications Vinyl Cleaner VC-S2 ALU

Nominal speed 30 r.p.m.Power consumption 100V/250WDimensions (W x D x H) 415 x 325 x 272 mm (fully assembled)Weight 8kg (netto)Fuse T6,3A

Potential incorrect use and fault conditions

Pro-Ject products are manufactured to the highest standards and undergo strict quality controls before leaving the factory. Faults that may possibly occur are not necessarily due to material orproduction faults but can sometimes be caused by incorrect use. Some of these faults are as follows:The platter doesn’t turn although the unit is switched on:

- The power cord is not connected to the unit.

- The power cord is not plugged in to the AC wall outlet.

- Broken fuse in the main switch.

- Overheating protection is active.

- Top clamp plate is not tightened properly.

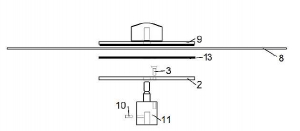

How to adjust the height of VC-S2 ALUs record clamp

The VC-S2 ALU is pre-adjusted to spec for standard 80 – 180 g records. There is enough headroom, so that the arm is optimally pressed against the record and the cleaning fluid can be completely removed. The vacuum arm works best when it is parallel to the record when operating and the adhesive strips is pressed gently on the surface of record. If the vacuum suction arm is not in the correct distance from the record it may not be able to completely vacuum the cleaning fluid. In this case it may be necessary to adjust the height of the clamp. You will need a Phillips screwdriver (to unscrew the set screw of the clamp base part) and a 2.5mm hexagon key (to loosen motor spindle):

- Disassemble the clamp (2) by unscrewing the set screw (3) from the motor flange spindle (11)

- Insert the 2.5mm hexagon key into the hole on the side of motor flange (11)

- Loosen the hexagon screw, until the flange can be moved up or down

- When the correct height position is found, fasten the hexagon screw and mount the clamp (2)

![]()

![]()

Service

Should you encounter a problem which the above information does not able to alleviate or identify, please contact your dealer for assistance. Guarantee repairs will only be affected if the unit is returned correctly packaged. For this reason we recommend keeping the original packaging. Never return a record cleaning machine without making sure that is it safely disassembled and co

rrectly packaged in the original packaging.

Warranty

Pro-Ject Audio Systems is a Registered Trademark ofH. Lichtenegger.This guide was produced by: Pro-Ject Audio SystemsCopyright © 2020. All rights reserved.

The information was correct at the time of printing. The manufacturer reserves the right to make changes to the technical specification without prior notice as deemed necessary to uphold the ongoing process of technical development

Read More About This Manual & Download PDF:

[xyz-ips snippet=”download-snippet”]