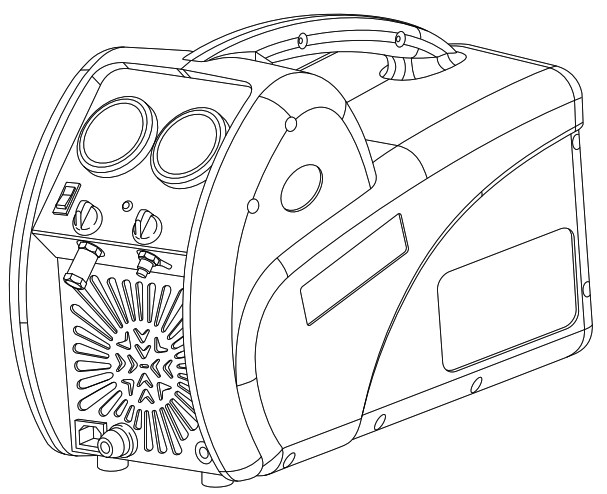

Refrigerant Recovery Machine

Model-No. 25700

Model-No. 25700

Operating ManualManuel utilisation

Safety Precautions

![]() WARNING : TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

WARNING : TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Additional health and safety information may be obtained from refrigerant and lubricant manufacturers.

Explanation of Safety Signal WordS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

underStanding refrigerant recovery

Refrigerant recovery is the process of taking refrigerant out of a system and storing it in a tank. The following information is critical to achieving the best refrigerant recovery results.

The 25700 refrigerant recovery machine is capable of recovering either contaminated R1234yf or R134a systems.

- The 25700 is built and shipped ready to service contaminated R1234yf systems.

- The 25700 also includes the hose and connections to service contaminated R134a systems. When anR134a system needs to be serviced, refer to the parts list in this manual to determine the necessary components.

- Refer to the Maintenance section of this manual to remove the hose and filter assembly and replace them with the appropriate components for the refrigerant being serviced.

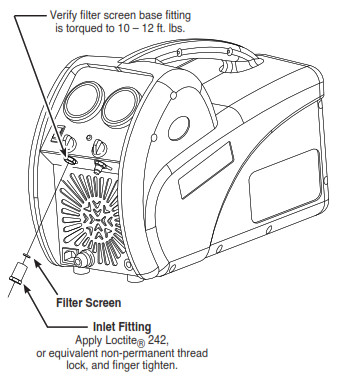

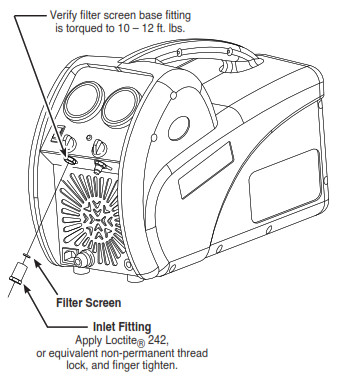

FiltersCAUTION: Filters prevent contamination from entering the unit, which reduces the risk of damage to the unit and the system being serviced. The 25700 unit is shipped with a filter screen installed behind the inlet fitting. Robinair recommends the user clean the filter screen regularly for optimal unit performance. Failure to use a filter screen will invalidate your warranty.

Valves![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Isolate large amounts of refrigerant and close valves after use, so if a leak should develop anywhere in the system, the refrigerant will not escape to the atmosphere.

Storage Tanks![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

This unit is provided with an 80% capacity shut-off float cable. Do not use the 25700 unit without correctly attaching the float cable to a storage tank with an internal float switch. The unit will automatically shut down when the storage tank reaches 80% capacity if the float cable is used correctly. Use only Robinair tank p/n 17990 with this machine.

Shut-off SwitchThis unit has an internal, high-pressure, shut-off switch. If system pressure rises above 435 psi, the unit shuts off. The shut-off switch automatically resets itself after the pressure drops below 320 psi.MaintenanceCAUTION :

- Keep all connections to the refrigeration system dry and clean. Damage will occur if moisture is allowed to enter the system.

- The 25700 unit is built and shipped ready to service contaminated R1234yf systems. When a contaminated R134a system needs to be serviced, see the parts list and Maintenance sections in this manual to install the necessary components.

Standard Operating instructions

The 25700 is specifically designed to recover contaminated refrigerant from an R1234yf RRR (recover, recycle, recharge) cart or a contaminated vehicle. For specific instructions and information on the identification and recovery of such refrigerant within the R1234yf RRR cart, refer to the user manual supplied with that machine.

Setup Procedure

- Place the 25700 unit on a flat, level surface.

- Verify a clean filter screen is installed behind the inlet fitting.

- Connect the float cable to the float switch connection on the storage tank.

- Connect the hose (provided) from the inlet fitting of the unit to the contamination port of the R1234yf RRR cart (or low-side port of the system being serviced).

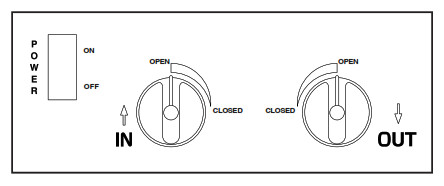

- Verify the inlet and outlet valves on the 25700 unit are closed.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The 25700 will perform at its peak when voltage entering the machine (while operating) is between 115V AC and 122V AC. Lower supply voltages may result in difficulty starting under high head pressure, reduced performance, and/or motor overheating. Use an outlet that does not have other appliances (such as lights, machines, etc.) plugged into it. Do not use an extension cord unless needed. If an extension cord is used, it must be 14 AWG minimum and as short as possible to reduce voltage drops.

Recovery Procedure

- Connect the unit to a 115V outlet.

- Slowly open the liquid valve of the storage tank while watching hoses and connections for leaks.

- Open the outlet valve on the 25700 unit.

- Toggle the power switch to the ON position.

- Slowly open the inlet valve on the unit. Note: If the unit begins to “knock”, slowly throttle back (close) the inlet valve until the noise stops.

- Run the 25700 until the desired vacuum is achieved.

- Toggle the power switch OFF.

- Close the outlet valve of the 25700.

- Allow the machine to sit for 5 minutes.

- Monitor the inlet pressure gauge to determine the presence of any remaining refrigerant.

- If the inlet gauge displays a vacuum for the entire 5 minutes, turn the inlet valve on the 25700 to the CLOSED position.

- If the inlet gauge displays a pressure above atmospheric pressure, repeat Steps 2–11 until vacuum is achieved. This will indicate no refrigerant remains in the system being serviced.

Storage tank information

Type of Tank Use only authorized, refillable, refrigerant storage tanks. Federal regulations require refrigerants to be transported only in containers meeting DOT specs. 4BW or 4BA. Cylinders used in conjunction with this equipment must be permanently marked with 20 mm black print that says: “CONTAMINATED REFRIGERANT — DO NOT USE. MUST BE RECLAIMED or DESTROYED by an EPA authorized facility”.

Only use Robinair tank, p/n 17990, with this machine.

NEVER use a standard disposable 30 lb. storage tank (the type of container in which new refrigerant is sold) to recover refrigerant.

Working PressureStorage tanks are designed for different working pressures. Robinair strongly recommends the use of 400 psi cylinders.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TroubleShooting

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

| Symptom | Possible Cause | Possible Solution |

| Unit will not turn on | 1. Power cord not plugged in.2. Bad power outlet.3. Machine is in high-pressure shut-off.4. Motor is in thermal overload.5. Blown or bad fuse. | 1. Check power cord at wall and unit.2. Try a different outlet.3. Reduce head pressure to below 320 psi.4. Allow motor/unit to cool down.5. Check/replace fuse. |

| Compressor tries to start, but just buzzes | 1. Low voltage at power source.|2. Extension cord too long, or too small. | 1. Locate/use better outlet.2. Reduce length of an extension cord.Increase size (gauge) of extension cord (14 AWG minimum). |

| Machine pumps into the high-pressure shut-off | 1. Output valve on machine is closed.2. Recovery cylinder valve closed.3. Head pressure too high. | 1. Check output valve.2. Check recovery cylinder valve.3. Check output hoses for restrictions or kinks. Reduce head pressure. |

| Slow recovery | 1. Trapped liquid in system.2. Restriction in refrigerant flow path. | 1. Momentarily cycle system compressor to move trapped refrigerant.2. Check inlet hose for restrictions or kinks. Remove Schrader valves and core depressors from hoses (if possible). Use larger hoses. |

| Blown fuse | 1. Electrical short of float cable.2. Electrical short of tank float switch. | 1. Replace float cable.2. Replace tank float switch. |

Replacement Parts

| Item No. | Part No. | Qty. | Description |

| 1 | 564651 | 1 | Case Kit (includes both case halves |

| 2 | 564650 | 1 | Interface Kit (includes compressor bracket, motor bracket, motor- compressor interface, coupler w/ hardware, spacers) |

| 3 | RA17416 | 1 | Fan Replacement |

| 4 | SK-6005 | 1 | Motor Kit (includes motor, relay, capacitor, hardware) |

| 5 | 563640 | 1 | Compressor Replacement |

| 6 | GA1000 | 1 | Gauge Lens (1 ea.) |

| 7 | 564649 | 1 | Manifold Knob Kit (includes red and blue manifold knobs) |

| 8 | EL1500 | 1 | Relay |

| 9 | SK-6003 | 1 | Low-side Gauge Kit (includeslow-side gauge, lens) |

| 10 | SK-6022 | 1 | High-side Gauge Kit (includeshigh-side gauge, lens) |

| 11 | 563627 | 1 | Manifold Assembly Replacement |

| 12 | 564648 | 1 | Panel Kit (includes front and back panels) |

| 13 | 564647

SK-6001 |

1 | Inlet Fitting / Filter Screen Kit (For R1234yf only; includes inlet fitting, filter screen, o-ring) Filter Screen Replacement Kit (For R134a only; includes inlet fitting, filter screens, o-ring) |

| 14 | 564256 | 1 | Black Recovery Hose Assembly |

| 15 | 563996

577869 |

1 | Blue Low-side Recovery Hose Assembly (For R1234yf only) Blue Low-side Recovery Hose Assembly (For R134a only) |

| 16 | 564040 | 1 | Tank Connection Harness |

| 17 | 551628 | 1 | Power Cord |

| 18 | 564646 | 1 | Hardware Kit (includes all unit

hardware, fan screen) |

| 19 | 555385 | 1 | High-Pressure Switch |

| 20 | 564613 | 1 | Fuse |

| 21 | 564645 | 1 | Tube Kit (includes inlet/outlet tubes) |

| 22 | RA19343 | 1 | Power Switch |

Rebuild kits and accessories

| Part No. | Description |

| SK-6005 | Motor Replacement Kit |

| SK-6006 | Compressor Rebuild Kit (includes piston seals, valves, springs, o- rings) |

| SK-6007 | Valve Rebuild / Replacement Kit (includes inlet /outlet valves and springs, o-rings) |

| RA17416 | Fan Replacement Kit |

| 564648 | Panel Replacement Kit |

| SK-6003 | Low-side Gauge Replacement Kit |

| SK-6022 | High-side Gauge Replacement Kit |

| 17990 | 30 lb. Contaminated Refrigerant Tank |

| 577867 | R134a Conversion Kit (includes low-side recovery hose assembly and inlet fitting & filter) |

Maintenance

CAUTION : To prevent personal injury,

- Disconnect the 25700 from the power supply before performing maintenance.

- Slowly and carefully remove the inlet hose from the unit to maintain the filter. All hoses may contain liquid refrigerant under pressure. Contact with refrigerant may cause personal injury. Wear correct protective equipment, including safety goggles and protective gloves. Disconnect hoses using extreme caution.

Inspect and Install the Inlet Filter

- Before performing a refrigerant recovery, inspect and clean the filter screen in the inlet fitting on the 25700 unit. Replace the filter screen, if necessary. Ensure the correct inlet fitting and filter is used for the type of refrigerant being serviced.A filter screen greatly reduces the risk of damage to the unit by preventing foreign material from entering the unit and the system being serviced. Failure to use a filter screen will invalidate the warranty.

Storage

- Empty refrigerant from the unit into a storage cylinder. Liquid refrigerant left in the unit’s condenser may expand, causing damage to components.

- Completely evacuate the 25700 of any residual refrigerant, and purge it with dry nitrogen before putting it in storage for a long period of time.

Full one-year limited Warranty

Unit Serial No.

This product is warranted to be free from defects in workmanship, materials and components for a period of one year from date of purchase.

The following restrictions apply:

- This warranty is non-transferable. All warranty claims must be made within the warranty period. Proof of purchase must be supplied with the product when returned.

- The warranty applies to products in normal use only, as described in this operating manual. The product must be maintained and serviced as specified.

- If the product fails, it will be repaired or replaced at the option of the manufacturer. Warranty service claims are subject to factory inspection for product defects. The manufacturer is the sole determiner of warranty coverage. If during the warranty evaluation it is determined that proper maintenance was not performed, or that the product has been used in any way other than the purpose for which it was designed, the manufacturer reserves the right to void the warranty.

- Normal wear items (seals, filters, etc.) are specifically excluded from this warranty unless found by the manufacturer to be defective.This warranty does not apply if the product or product part is damaged by accident, misuse, tampering with, or modifying in any way. The manufacturer is not responsible for any additional costs associated with a product failure including, but not limited to, loss of work time, loss of refrigerant, or unauthorized shipping and/or labor charges.Use of this product with any unauthorized refrigerants or chemicals will void the warranty.Warranty Service:1. Outside of the United States of America, contact your local Robinair distributor.2. Inside the United States of America, call 1-800-327-5060 for a Return MaterialAuthorization (RMA) number. Instructions on where to send the product will be provided.

Owatonna, MN 55060Telephone: 800.327.5060Fax: 866.287.722www.robinair.com

© Bosch Automotive Service Solutions Inc.

References

[xyz-ips snippet=”download-snippet”]