FORTREX®BOW-MOUNT TROLLING MOTORInstallation Instructions

FORTREX®BOW-MOUNT TROLLING MOTORInstallation Instructions

INTRODUCTION

THANK YOUThank you for choosing Minn Kota. We believe that you should spend more time fishing and less time positioning your boat. That’s why we build the smartest, toughest, most intuitive trolling motors on the water. Every aspect of a Minn Kota trolling motor is thought out and rethought until it’s good enough to bear our name. Countless hours of research and testing provide you the Minn Kota advantage that can truly take you “Anywhere. Anytime.” We don’t believe in shortcuts. We are Minn Kota. And we are never done helping you catch more fish.

REGISTRATIONRemember to keep your receipt and immediately register your trolling motor. A registration card is included with your motor or you can complete registration on our website atminnkotamotors.com.

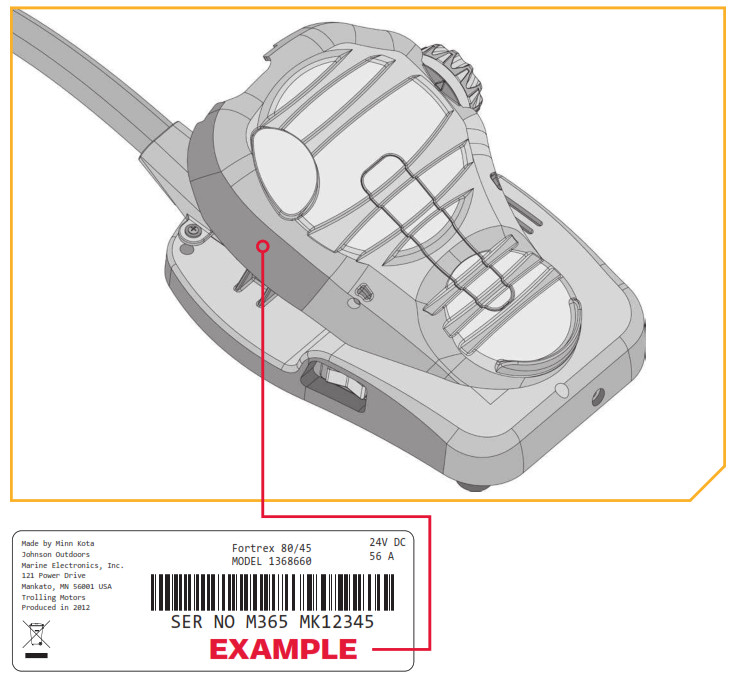

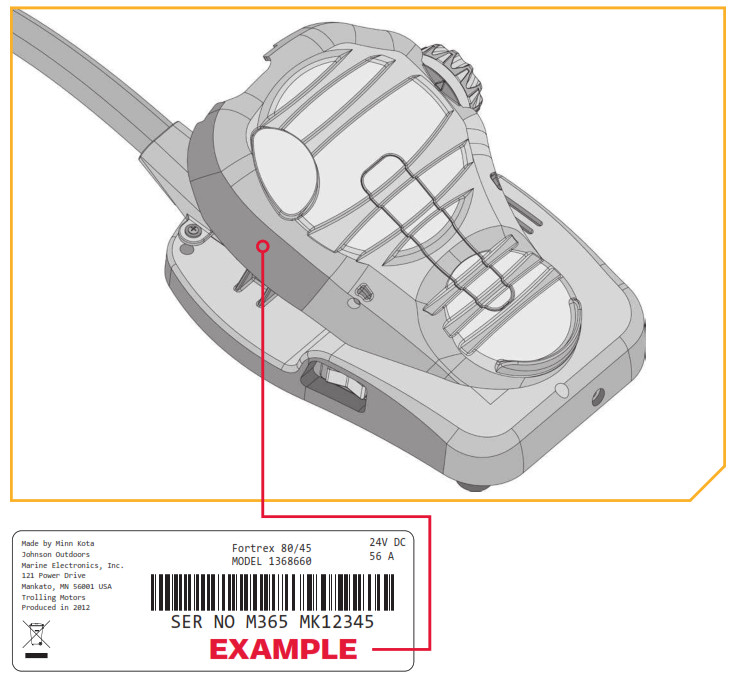

MOTOR INFORMATION (For Consumer Reference Only)Model: ______________________________________Serial Number: __________________________________Purchase Date: _________________________________Store Where Purchased: ________________________

NOTICE: Do not return your Minn Kota motor to your retailer. Your retailer is not authorized to repair or replace this unit. You may obtain service by calling Minn Kota at 800) 227-6433; returning your motor to the Minn Kota Factory Service Center; sending or taking your motor to any Minn Kota authorized service center. A list of authorized service centers is available on our website, at minnkotamotors.com. Please include proof of purchase, serial number, and purchase date for warranty service with any of the above options.

SAFETY CONSIDERATIONS

Please thoroughly read the user manual. Follow all instructions and heed all safety and cautionary notices. Use of this motor is only permitted for persons that have read and understood these user instructions. Minors may use this motor only under adult supervision.

KNOW YOUR BOAT

INSTALLATION

INSTALLING THE FOR TREXYour new Fortrex comes with everything you’ll need to directly install it to the boat. This motor can be directly mounted to the boat or coupled with a Minn Kota quick release bracket for ease of mounting and removal. For installation with a quick-release bracket, refer to the installation instructions provided with the bracket. For compatible quick-release mounting brackets, please visit minnkotamotors.com. To install the motor directly to the boat, please follow the instructions provided in this manual. Please review the parts list, mounting considerations, and tools needed for installation prior to getting started. For additional product support and to locate your nearest dealer, please visit minnkotamotors.com.

INSTALLATION PARTS LIST

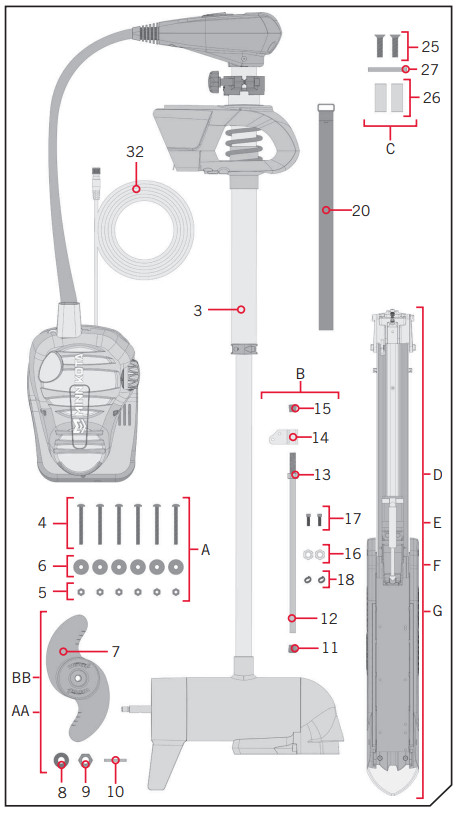

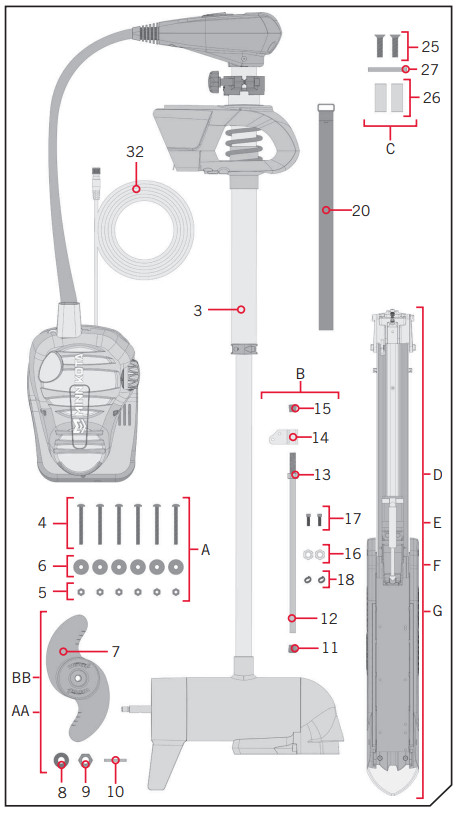

| Item iAssembly | Part # | Description | Qty. |

| 3 | X | MOTOR ASSEMBLY | 1 |

| A | 2994887 | INSTALLATION HARDWARE BAG ASSEMBLY | 1 |

| 4 | 2263468 | 1/4 – 20 X 2.5″ SS PPH SCREW | 6 |

| 5 | 2263103 | 1/4 – 20 SS NYLOCK NUT | 6 |

| 6 | 2261713 | 1/4 FLAT 18-8 SS WASHER | 6 |

| AA | 1378132 | 80# THRUST PROP KIT | 1 |

| BB | 1378160 | I12# THRUST PROP KIT | 1 |

| 7 | 7341160 | PROP-MY? (4 5)W/ADPRING | 1 |

| 8 | 2091701 | WASHER-PROP (LARGE) | 1 |

| 9 | 2093101 | NUT-PROP NYLOC, LG, MX101 3/8 SS | 1 |

| 10 | 2262658 | PIN-DRIVE 1″ 3/16° S/S | 1 |

| B | 29919250 | BRACKET STABLZR ARM ASY (SUB) | 1 |

| 11 | 22655100 | BUMPER STABILIZER | 1 |

| 12 | 2263624 | STABILIZER ROD | 1 |

| 13 | 2263107 | NYLON HEX NUT 3/4 – 10 UNC | 1 |

| 14 | 2281829 | BRACKET | 1 |

| 15 | 2260221 | VINYL CAP | 1 |

| 16 | 2223100 | NUT 5/16-18 NYLONS SS | 2 |

| 17 | 2263422 | BOLT 5/16-18 X 1″ SS CAP SCREW | 2 |

| 18 | 2281700 | 5/16 “ID X .457 OD HIGH COLLAR LOCK WASHER | 2 |

| 20 | 2773806 | STRAP. HOLD DOWN | 1 |

| C | 2994912 | BAG ASSY, FORTREX MOUNT HDW | 1 |

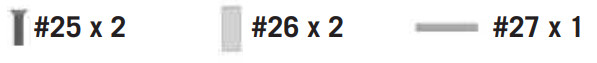

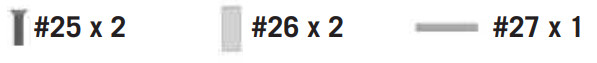

| 25 | 2283410 | SCREW-1/4-20 X .500′ PFH | 2 |

| 26 | 2281710 | SPACER, GAS SPRING, FOR TREX | 2 |

| 27 | 2282610 | PIN. UPPER SHOCK | 1 |

| 2287110 | INSTALLATION GUIDE, FORTREX | 1 | |

| D | 2991650 | MNT /V/ 80# 45″. 112#/1-IC 52 A80 LB45’* “112 LB 52″” | 1 |

| E | 2991652 | MNTASM FIX FW 80# 52/62″ *80 LB 52’* *80 LB 62″* | 1 |

| F | 2991653 | MNT ASM FTX BY I12# 45″ A112 LB 45″A | 1 |

| G | 2991654 | MNT ASM FIX PM 112# 52″ *112 LB 52″* | 1 |

| 32 | 2211415 + | CABLE-EXTENSION, PD/AP 110″ *PRE-INSTALLED” | 1 |

![]()

![]()

![]()

![]()

![]()

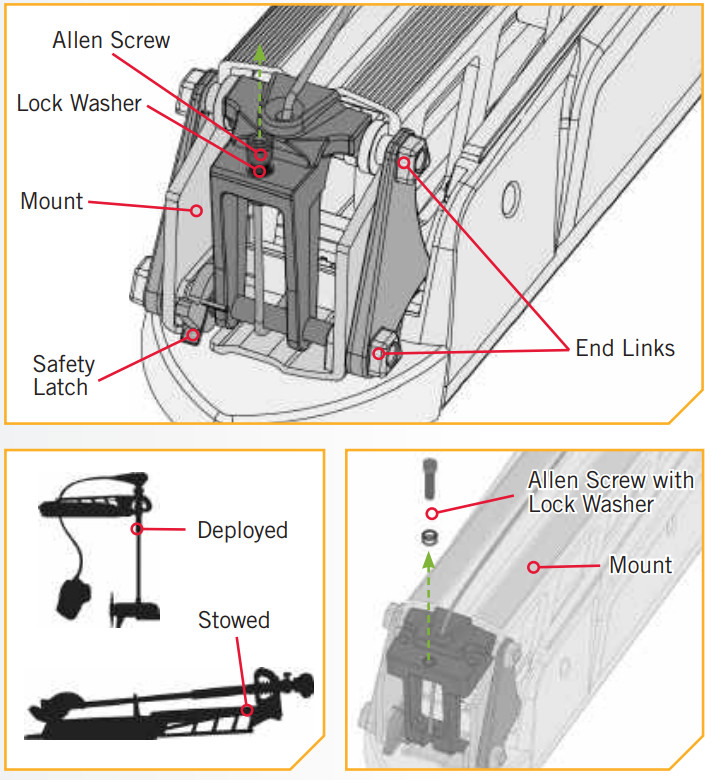

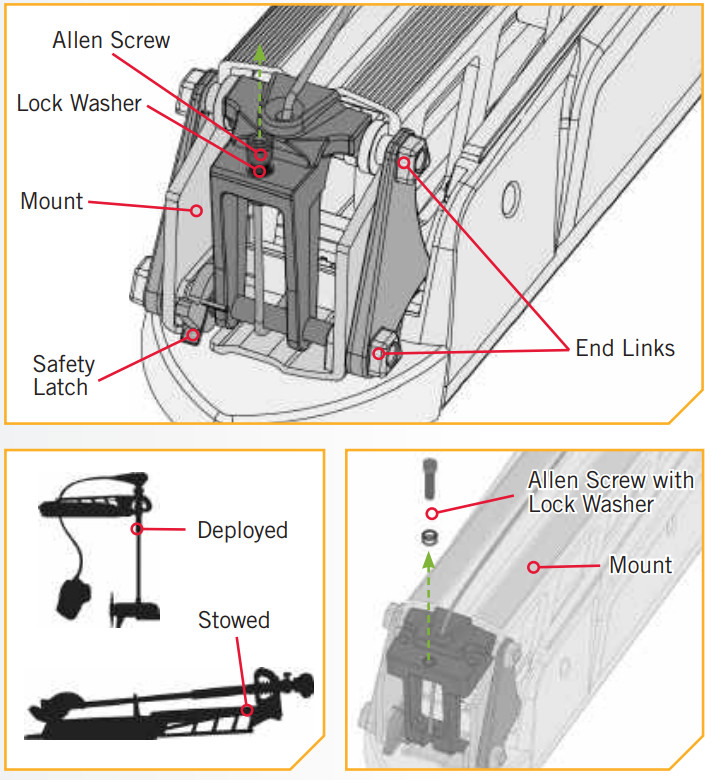

ASSEMBLY OF BOWGUARd TO MOUNT

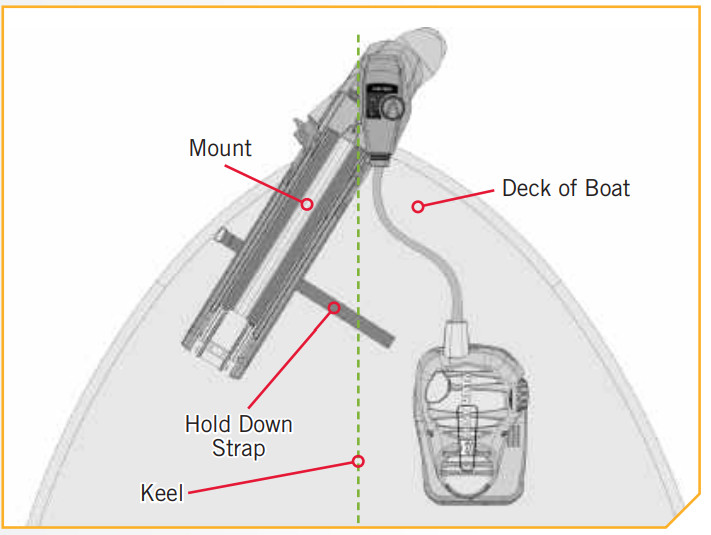

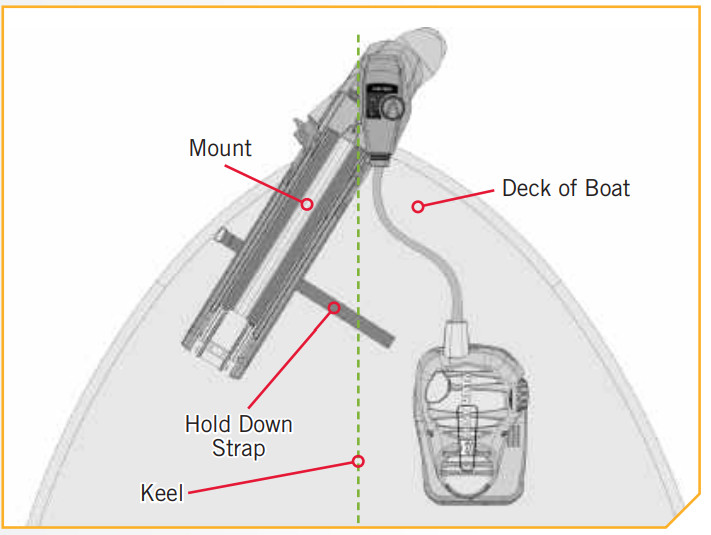

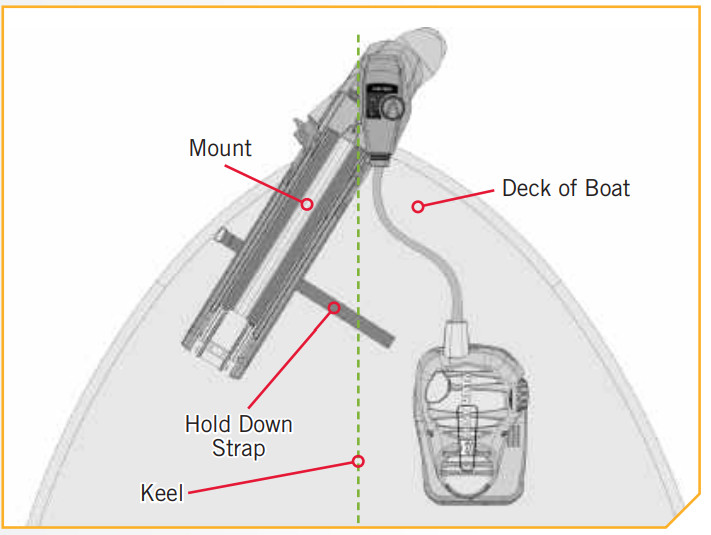

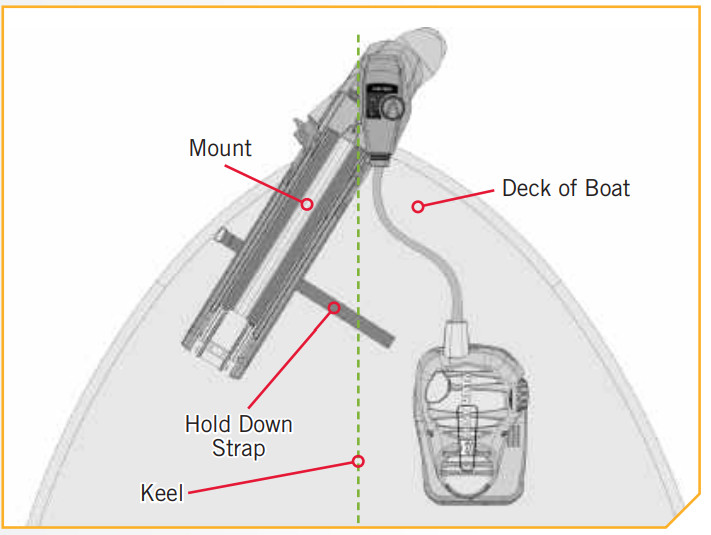

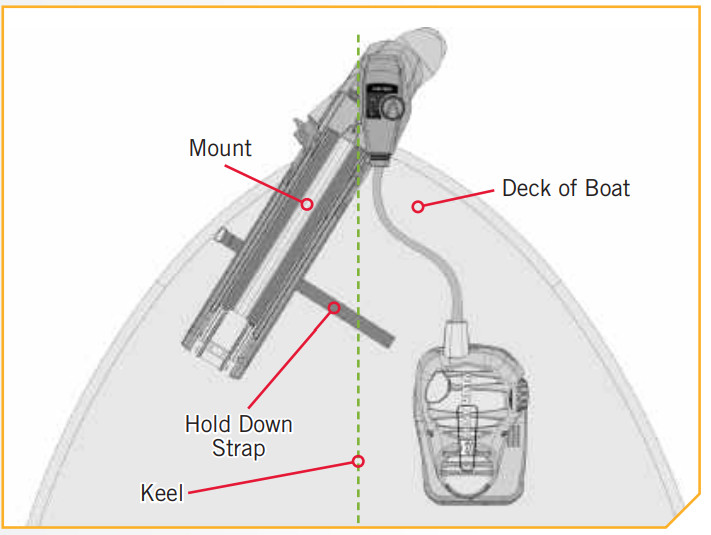

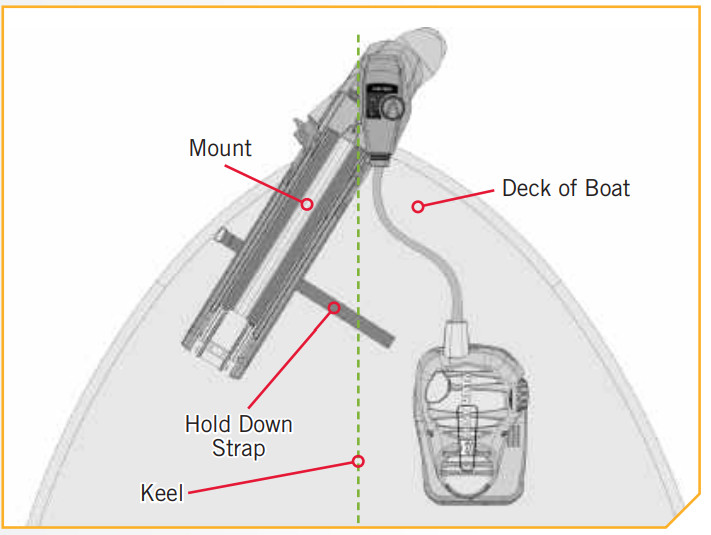

MOUNTING CONSIdERATIONSIt is recommended that the motor be mounted as close to the keel or centerline of the boat as possible. Make sure the area under the mounting location is clear to drill holes and install nuts and washers. Make sure the motor rest is positioned far enough beyond the edge of the boat. The motor must not encounter any obstructions as it is lowered into the water or raised into the boat when stowed and deployed. Consider a quick release or adapter bracket with the installation of your motor. To view a list of accessories, please visit minnkotamotors.com.

TOOLS ANd RESOURCES REQUIRED

| • #2 Phillips Screwdriver• (2) #3 Phillips Screwdriver• 1/4″ Allen Wrench• Drill | • 9/32″ Drill Bit• 7/16″ Box End Wrench• A person to help with installation |

| • Torque Wrench• File or Sandpaper• Hack Saw• Marker or Pencil | • 1/8″ Flat Screwdriver• 1/8″ Allen Wrench• Loctite |

INSTALLATION

Assembly of BowGuard to Mounta. Place the Mount on an elevated, level surface such as a workbench or the tailgate of a pickup. The Mount, as removed from the box, should be in the deployed position.

Installing the Mount

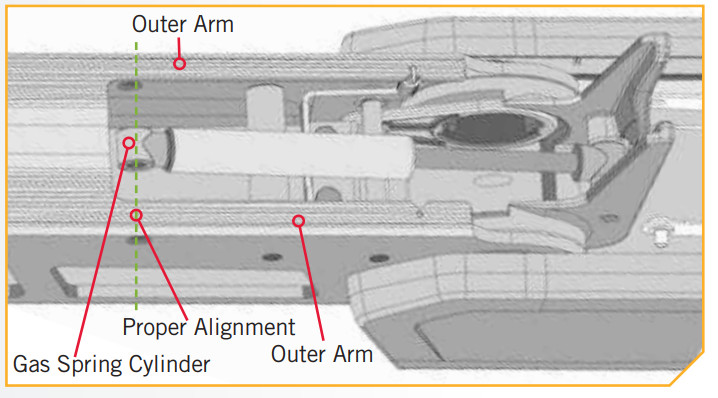

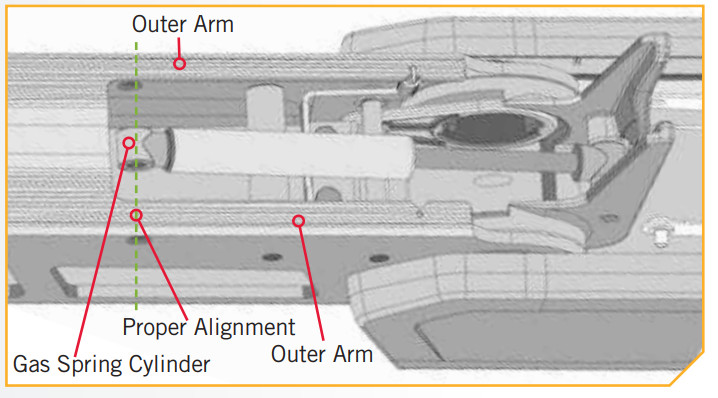

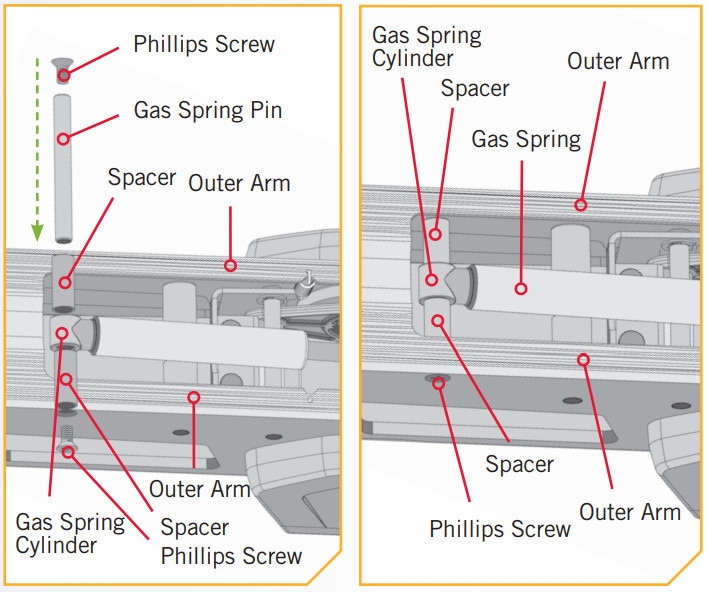

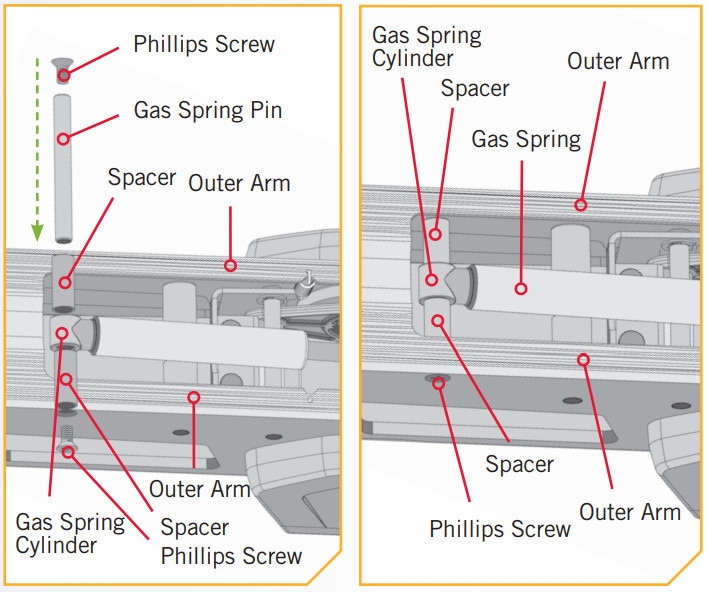

During installation, it is recommended to mount the motor to the boat before installing the Gas Spring Pin. The Gas Spring Pin is installed in the Gas Spring Cylinder. The Gas Spring Cylinder is located on the inside of the Outer Arm, which is a part of the Mount. At this point in the installation, the Gas Spring Cylinder is not fully installed and may move around inside the Mount when stowing and deploying the motor. The Gas Spring Cylinder can become damaged while deploying the motor and the damage will prevent the Lift-Assist feature from operating correctly once fully assembled. Make sure that the Gas Spring Cylinder does not get damaged in the Mount.

ITEM(S) NEEDED

![]()

![]()

a. Review the mounting considerations at the beginning of the Installation section for proper placement. Place the Mount as close to the centerline or keel of the boat as ossible, with the motor in the stowed position, on the deck of the boat. Check placement with the motor in the stowed and deployed positions.

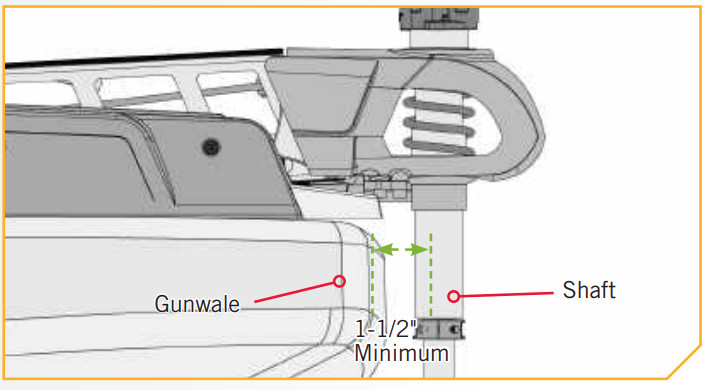

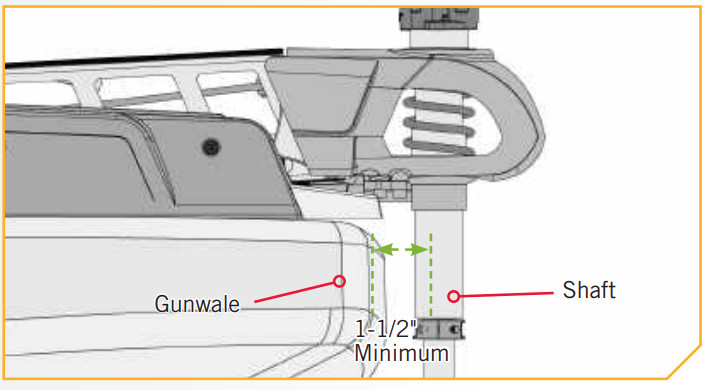

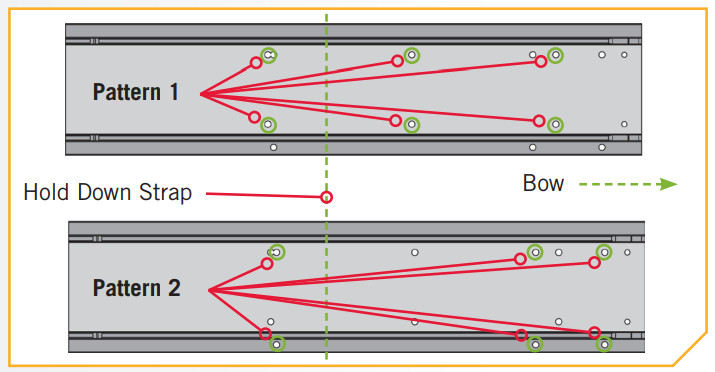

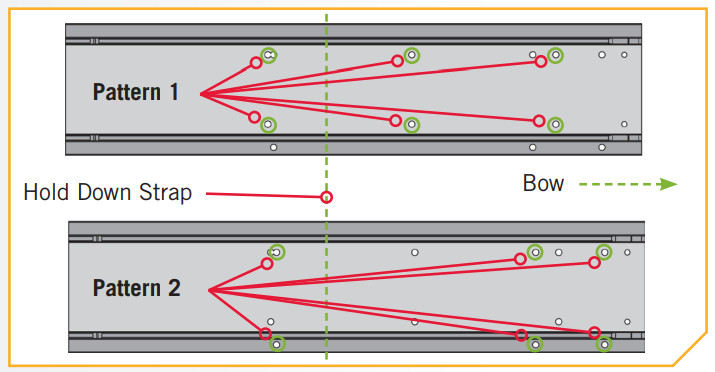

e. Check the placement with the motor in the deployed position. When the motor is in the deployed position, make sure that the Shaft is 1-1/2″ out past the Gunwale of the boat. The lower unit, when stowed and deployed must not encounter any obstructions.f. Check the placement of the Hold-Down Strap when the motor is in the stowed and deployed position and adjust if necessary.

INSTALLING THE GAS SPRING PIN

ITEM(S) NEEDED

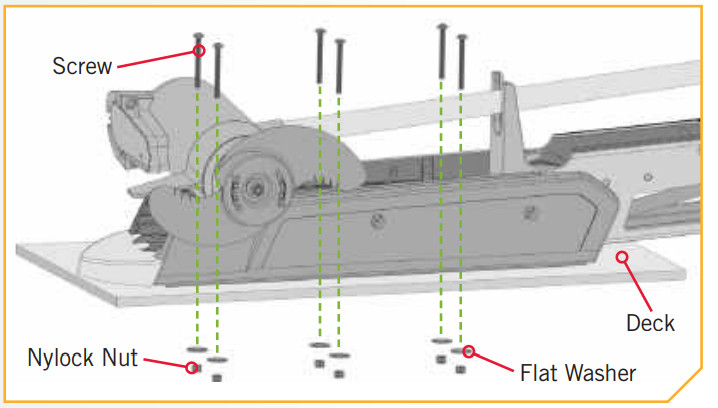

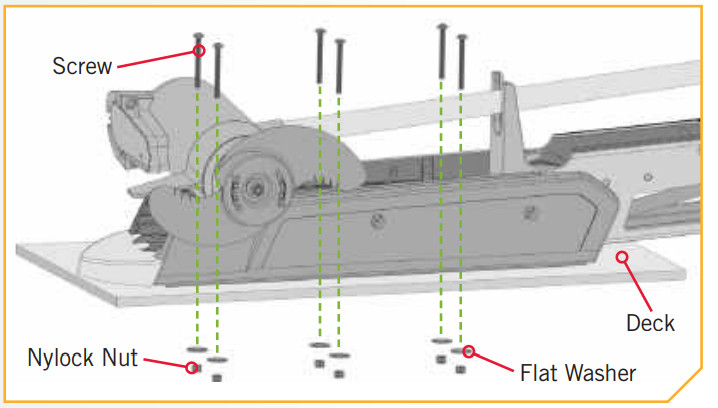

k. Put a 1/4-20 x 2 1/2″ Screw (Item #4) in each of the drilled locations. The Screw should pass through the Mount Plate and the boat deck.l. Place a Flat Washer (Item #5) and then a Nylock Nut (Item #6) at the end of each screw as shown and secure. Make sure all hardware is secure.

PLACING THE BOW-MOUNT STABILIZER

ITEM(S) NEEDED

c. Locate the upper Gas Spring Pin (Item #27) and Spacers (Item #26) in the bag assembly. Align the end of the Gas Spring with the holes in the Outer Arm.d. Install the Gas Spring Pin through the Outer Arm, then through a Spacer, the end of the Gas Spring Cylinder and another Spacer.e. Install one Phillips Screw (Item #25) on each end of the Gas Spring Pin and secure with two #3 Phillips screwdrivers.f. Tighten Phillips Screws until the heads are flush with the Outer Arm.

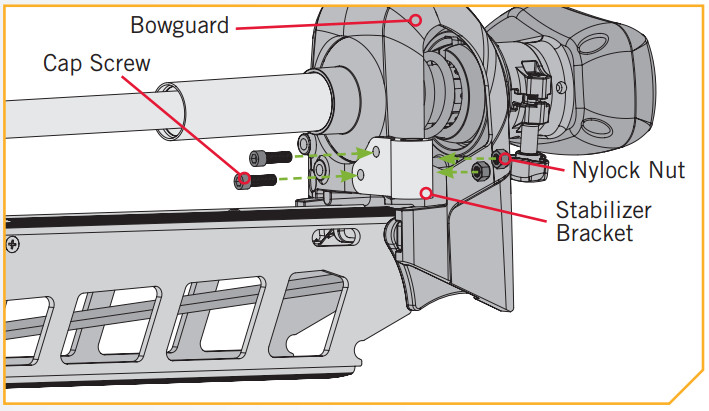

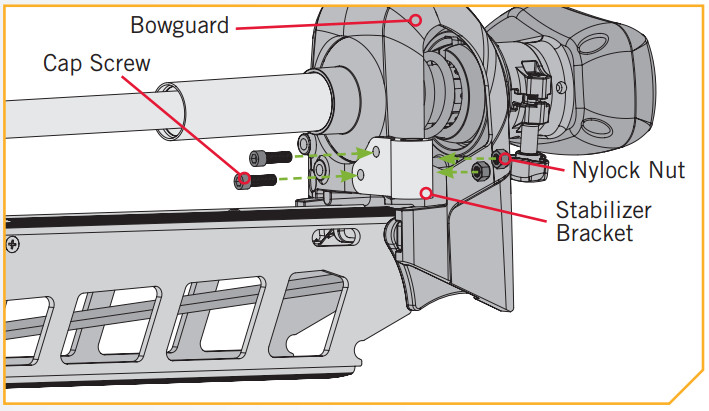

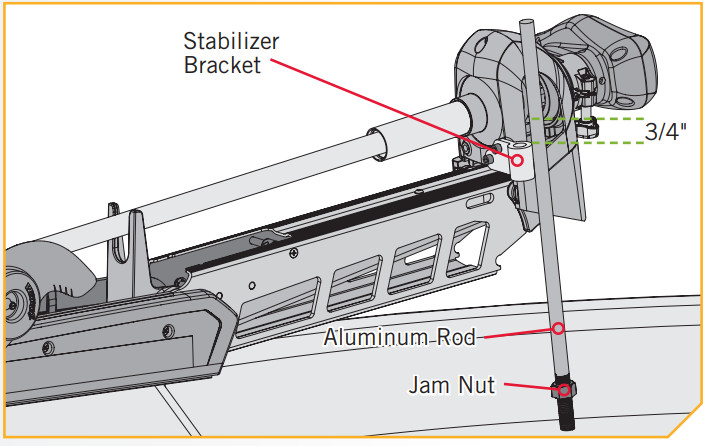

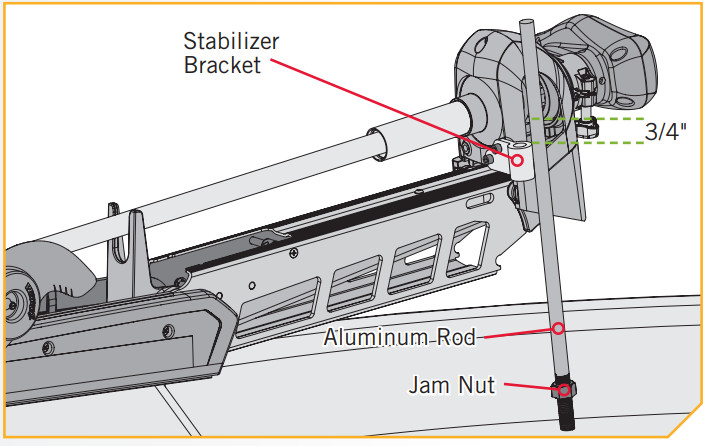

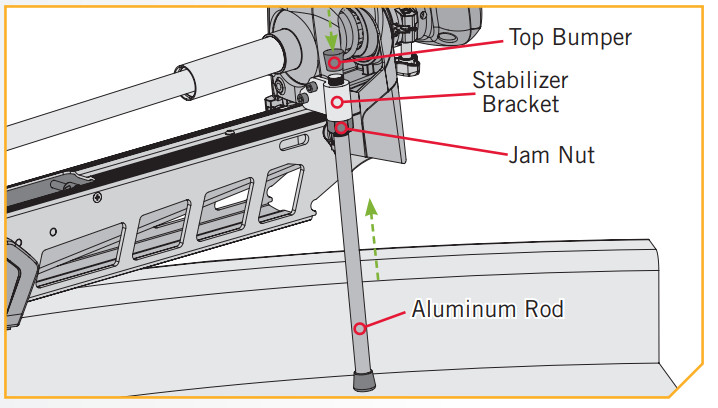

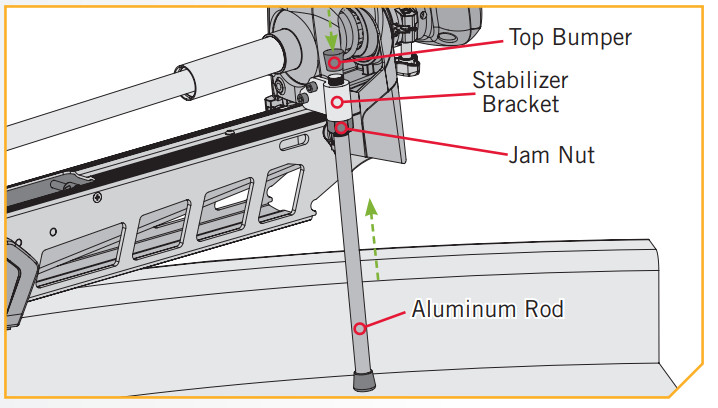

Placing the Bow-Mount StabilizerThe Bow-Mount Stabilizer Bracket is used to stabilize the Bowguard and reduce bouncing when the motor is stowed and transported. Attention to detail is needed for the successful installation of the stabilizer. We recommend having the stabilizer bracket installed by a qualified marine installer.NOTICE: The Bow-Mount Stabilizer is not required or included on the 80lb 45” Fortrex.

ITEM(S) NEEDED

![]()

![]()

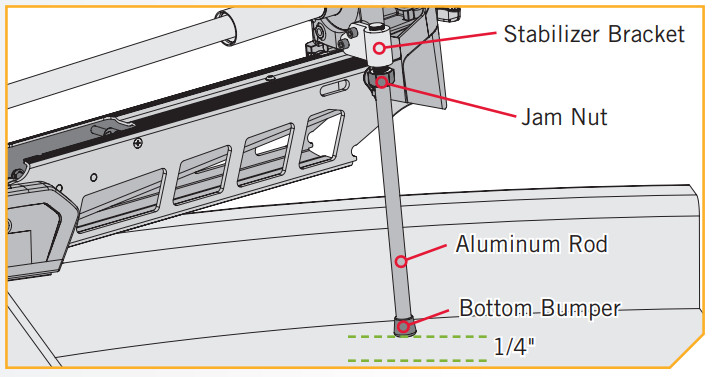

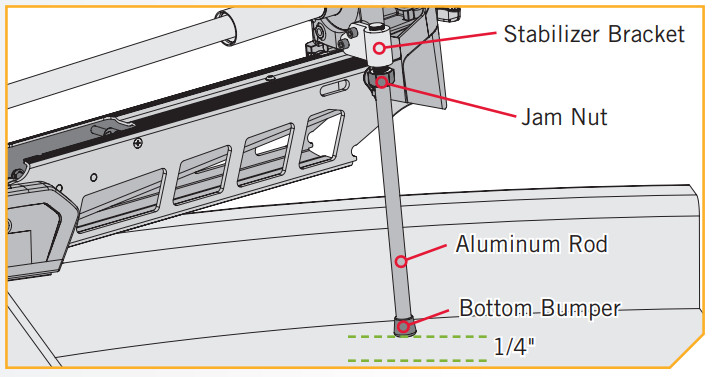

a. Place the motor in the stowed position.b. Un-thread the Aluminum Rod (Item #13) from the Stabilizer Bracket (Item #12) by removing the Top Bumper (Item #11) and unscrewing the bracket. Also remove the Bottom Bumper (Item #15). Keep the Jam Nut (Item #14) in place.

ITEM(S) NEEDED

![]()

![]()

c. Determine the desired orientation of the Stabilizer Bracket and attach it to the bottom of the Bowguard.NOTICE: The Bow-Mount Stabilizer Bracket can be installed on the left or right side of the Bowguard.d. Put the 5/16” Cap Screws (Item #17) through the Stabilizer Bracket and the mounting holes on the guard. Secure the 5/16” Cap Screws with the 5/16-18 Nylock Nut. The Nylock Nuts fit into a hex pocket on the inside of the Bowguard behind the spring. Secure with a 1/4” Allen Wrench. Tighten to 10 ft-lb.

NOTICE: The two Lock Washers (Item #16) are not used when installing on the Fortrex.

e. Measure the proper length of the Aluminum Rod by standing it, with the threaded end down, onto the deck surface so that it sits vertically right next to the Stabilizer Bracket.f. Mark the Aluminum Rod with a pencil or marker 3/4″ past the top of the Stabilizer Bracket.

MOUNTING THE FOOT PEDAL

k. Once in the correct position, tighten the Jam Nut upwards against the Stabilizer Bracket. This will prevent the Aluminum Rod from turning.l. Install the Top Bumper if there are threads exposed on the Aluminum Rod above the Stabilizer Bracket.

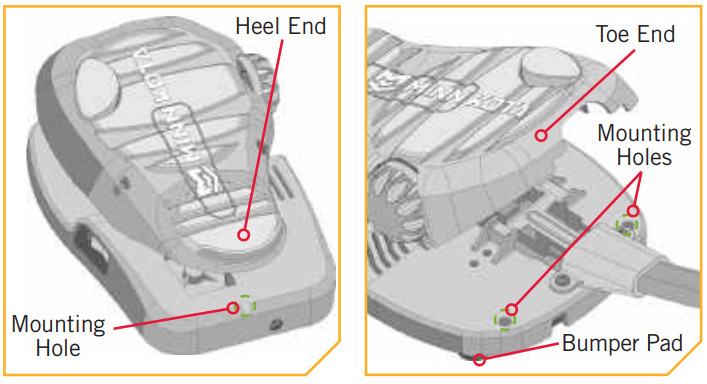

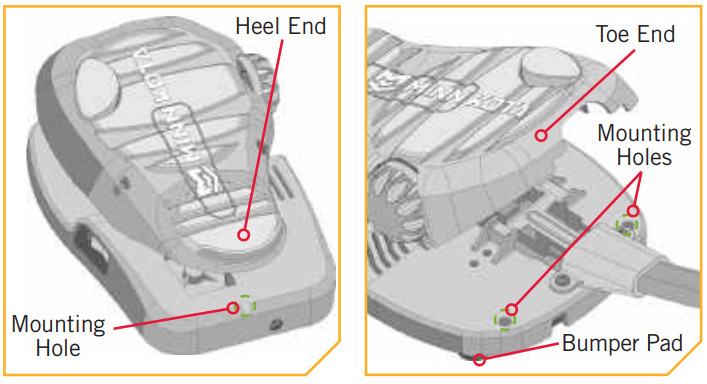

We recommend securing the Foot Pedal to the boat deck to prevent it from being damaged during transport and to make motor operation more efficient. It is recommended to use the Mounting Holes on the Foot Pedal for a secure mount. The Foot The pedal has three Mounting Holes. One Mounting Hole is located under the Heel End of the Foot Pedal. he other two are located under the Toe End of the Foot Pedal. We recommend using a 1/8″ or 3/16″ diameter screw and only tighten enough to slightly compress the Bumper ads underneath the Foot Pedal.

ROUTING CONNECTION CABLES

Please follow these instructions for routing any and all of the cables present for any of the pre-installed features that may come with your trolling motor. This routing should be followed no matter the type of connection cable present.

a. Locate the Universal Sonar cable, at the base of the Foot Pedal.

b. Identify where the Universal Sonar Cable needs to be connected and route along with an established routing system in your boat.c. Use cable ties to loosely secure cables if needed.NOTICE: After the cable(s) exit(s) the Foot Pedal, it should be routed through an established routing system on the boat, in an area with minimal interference. Power cables or other elements that may produce interference for the sonar signals. Inspect the selected route carefully to ensure that there are no sharp edges, obstacles, or obstructions that may damage the cables.

UNIVERSAL SONAR

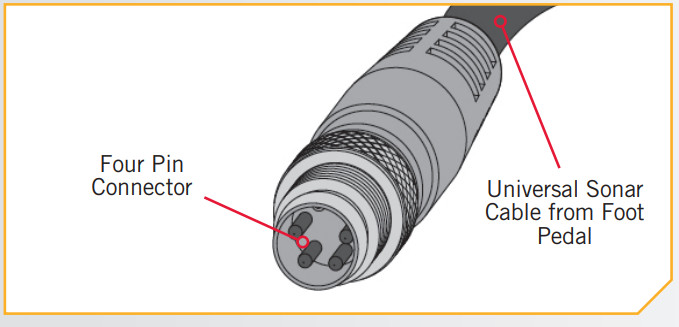

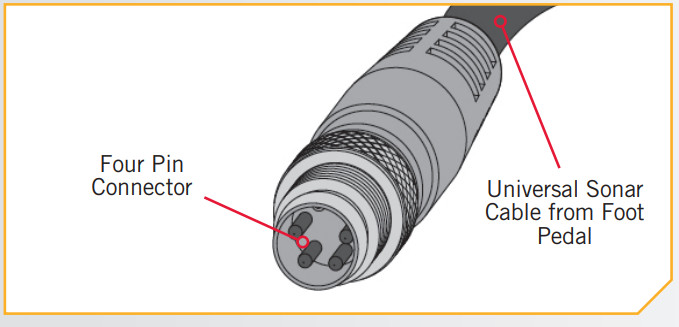

Your trolling motor may be pre-installed with a Universal Sonar transducer system. Universal Sonar is a 2D sonar transducer with a temperature sensor that is integrated into the ower unit of the trolling motor. It has an operating frequency of 83/200 kHz. Connecting this transducer to a compatible fishfinder gives you a 2D sonar view of what is happening directly below your trolling motor. The integrated design protects the transducer from underwater hazards and prevents tangles and damage to the transducer cables. All Universal Sonar motors are equipped with an internal bonding wire, incorrect rigging will cause sonar interference and can damage your trolling motor, electronics and other boat accessories. To minimize trolling motor interference, ensure that the fish finder and trolling motor are powered by separate batteries. Please refer to the Battery & Wiring Installation and Motor Wiring Diagram sections of this manual for correct rigging instructions.The Universal Sonar Cables are shielded to minimize interference. To protect this shielding the cables should not be pulled tight against sharp angles or hard objects. If using cable ties, do not over-tighten. Any excess cable should be bundled in a loose loop of no less than 4” in diameter. In certain situations, air bubbles may adhere to the surface of the Universal Sonar transducer, and affect the performance. If this happens simply wipe the surface of the transducer with your finger.NOTICE: Universal Sonar does not support imaging screens that require higher frequencies such as 455 kHz or 800 kHz (Down Imaging, Side Imaging, etc.). Down Imaging (DI) specific units are not compatible with Universal Sonar. See the compatibility chart for a list of compatible fish finders at minnkotamotors.com.The connector for Universal Sonar exits the trolling motor at the base of the Foot Pedal and consists of a 4 pin plug. An adapter cable (MKR-US2) that is sold separately is required for all installations. For a current list of compatible fish finders and the correct adapter cable, or more information on Universal Sonar, please visit minnkotamotors.com.

a. Locate the Universal Sonar, if equipped, at the base of the Foot Pedal.b. Locate the Universal Sonar four-pin connector at the end of the Universal Sonar Extension Cable. The connector is black with a stainless steel threaded locking collar.NOTICE: Your fish finder should be turned off until this procedure is complete.

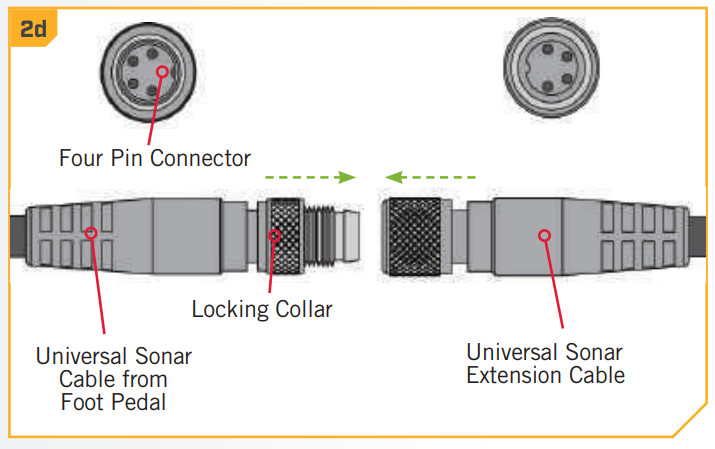

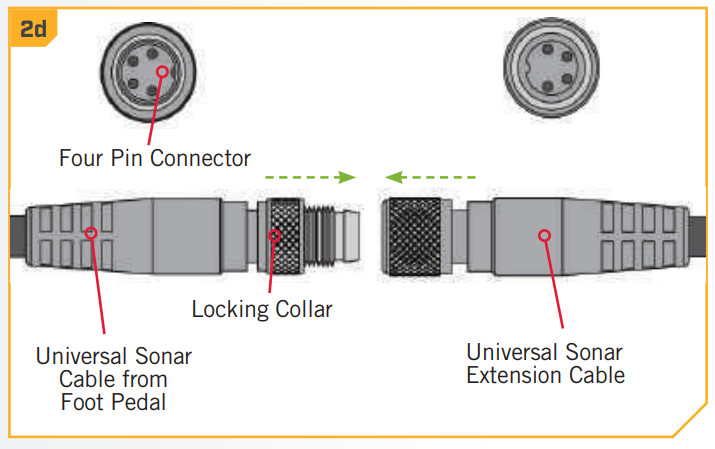

NOTICE: If the cable length does not reach the desired fish finder installation location, a 14.5’ extension cable is available (MKR-US2-11) (sold separately).

NOTICE: The Universal Sonar Cable may not be long enough to reach the fish finder. If the cable length does not reach the desired fish finder installation location, a 14.5’ extension cable is available to purchase. Minn Kota recommends using the MKR-US2-11.c. Take the Universal Sonar Extension Cable, if needed, and attach it to the Universal Sonar Cable exiting the Foot Pedal. Firmly push the plug together and twist the locking collar until it is snug.d. Install the Universal Sonar Cable that exists the Foot Pedal or the Universal Sonar Extension Cable (if used) to the appropriate Universal Sonar Adapter Cable. Install the Adapter Cable to your fishfinder. Refer to your fishfinder manual for complete installation instructions.NOTICE: If any cables need to be routed, please follow the guidelines in the Routing Connection Cables section of these installation instructions.

NOTICE: The connectors are keyed to prevent reversed installation.

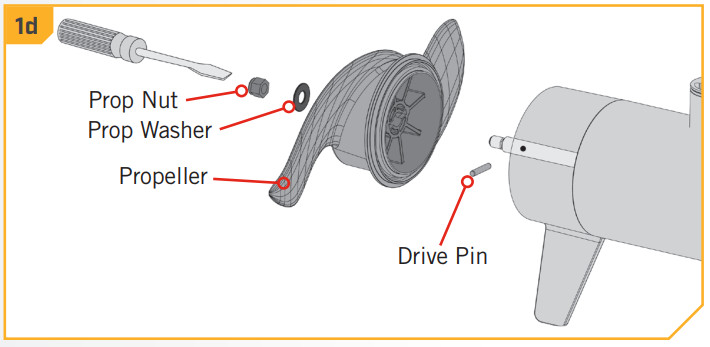

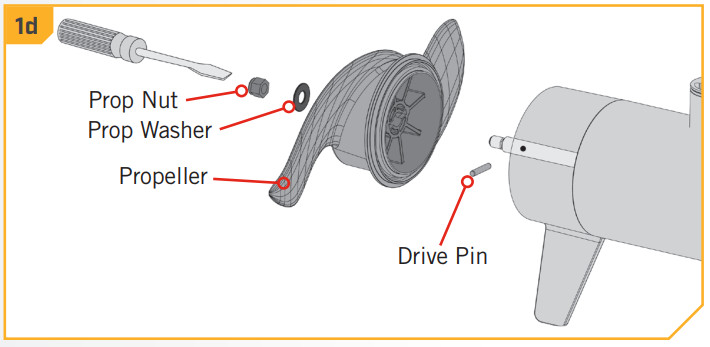

INSTALLING THE PROP

ITEM(S) NEEDED

![]()

![]()

BATTERY & WIRING INSTALLATION

BOAT RIGGING & PROdUCT INSTALLATIONFor safety and compliance reasons, we recommend that you follow American Boat and Yacht Council (ABYC) standards when rigging your boat. Altering boat wiring should be completed by a qualified marine technician. The following specifications are for general guidelines only:

- No more than 2 conductors are bundled together inside of a sheath or conduit outside of engine spaces.

- Each conductor has 105° C temp-rated insulation.

- No more than 5% voltage drop allowed at full motor power based on published product power requirements.

| Motor Thrust / Model | MaxAmp Draw | Circuit Breaker | Wire Extension Length | ||||

| 5 feet | 10 feet | 15 feet | 20 feet | 25 feet | |||

| 301b. | 30 | 50 Amp @ 12 VDC | 10 AWG | 10 AWG | 8 AWG | 6 AWG | 4 AWG |

| 40 lb., 451b. | 42 | 10 AWG | 8 AWG | 6 AWG | 4 AWG | 4 AWG | |

| 50 lb., 55 lb. | 50 | 60 Amp @ 12 VDC | 8 AWG | 6 AWG | 4 AWG | 4 AWG | 2 AWG |

| 701b. | 42 | 50 Amp @ 24 VDC | 10 AWG | 10 AWG | 8 AWG | 8 AWG | 6 AWG |

| 801b. | 56 | 60 Amp @ 24 VDC | 8 AWG | 8 AWG | 8 AWG | 6 AWG | 6 AWG |

| 101 lb. | 46 | 50 Amp @ 36 VDC | 8 AWG | 8 AWG | 8 AWG | 8 AWG | 8 AWG |

| Engine Mount 101 | 50 | 60 Amp @ 36 VDC | 8 AWG | 8 AWG | 8 AWG | 8 AWG | 8 AWG |

| 1121b. | 52 | 60 Amp @ 36 VDC | 8 AWG | 8 AWG | 8 AWG | 8 AWG | 8 AWG |

| Engine Mount 160 | 116 | (2) x 60 Amp @ 24 VDC | 6 AWG | 6 AWG | 4 AWG | 2 AWG | 2 AWG |

| E-Drive | 40 | 50 Amp @ 48 VDC | 10 AWG | 10 AWG | 10 AWG | 10 AWG | 10 AWG |

NOTICE: Wire Extension Length refers to the distance from the batteries to the trolling motor leads. Consult the website for available thrust options. Maximum Amp Draw values only occur intermittently during select conditions and should not be used s continuous amp load ratings.ReferenceUnited States Code of Federal Regulations: 33 CFR 183 – Boats and Associated Equipment ABYC E-11: AC and DC Electrical Systems on Boats

SELECTING THE CORRECT BATTERIES

The motor will operate with any lead-acid, deep cycle marine 12-volt battery/batteries. For best results, use a deep cycle, marine battery with at least a 105 amp-hour rating. Maintain battery at full charge. Proper care will ensure having battery power when you need it, and will significantly improve the battery life. Failure to recharge lead-acid batteries (within 12-24 hours) is the leading cause of premature battery failure. Use a multi-stage charger to avoid overcharging. We offer a wide selection of chargers to fit your charging needs. If you are using a crank battery to start a gasoline outboard, we recommend that you use a separate deep cycle marine battery/batteries for your Minn Kota trolling motor. For more information on battery selection and rigging, please visit minnkotamotors.com. Minn Kota trolling motors can run on Lithium-Ion batteries. However, they are specifically designed to run on traditional lead-acid batteries (flooded, AMG, or GEL). Lithium-Ion batteries maintain higher voltages for longer periods of time than lead-acid. Therefore, running a Minn Kota trolling motor at speeds higher than 85% for a prolonged period could cause permanent damage to the motor.

AddITIONAL CONSIdERATIONSUsing Alternator ChargersYour Minn Kota trolling motor may be designed with an internal bonding wire to reduce sonar interference. Most alternator charging systems do not account for this bonding wire and connect the negative posts of the trolling motor batteries to the negative posts of the crank/starting battery. These external connections can damage connected electronics and the electrical system of your trolling motor, voiding your warranty. Review your charger’s manual carefully or consult the manufacturer prior to use to ensure your charger is compatible. Minn Kota recommends using Minn Kota brand chargers to recharge the batteries connected to your Minn Kota trolling motor, as they have been engineered to work with motors that include a bonding wire.Additional Accessories Connected to Trolling Motor BatteriesSignificant damage to your Minn Kota motor, your boat electronics, and your boat can occur if incorrect connections are made between your trolling motor batteries and other battery systems. Minn Kota recommends using an exclusive battery system for your trolling motor. Where possible, accessories should be connected to a separate battery system. Radios and sonar units should not be connected to any trolling motor battery systems as interference from the trolling motor is unavoidable. If connecting any additional accessories to any trolling motor battery system, or making connections between the trolling motor batteries and other battery systems on the boat, be sure to carefully observe the information below.

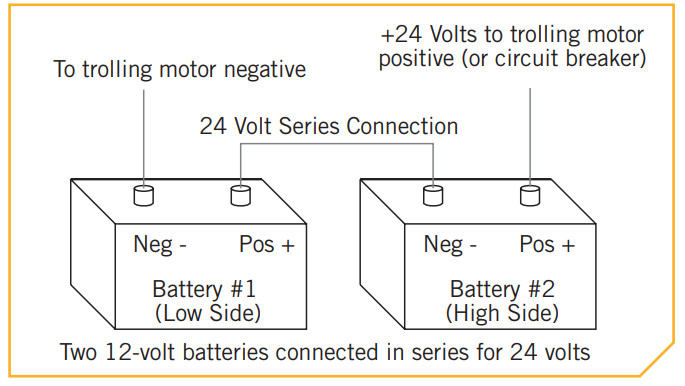

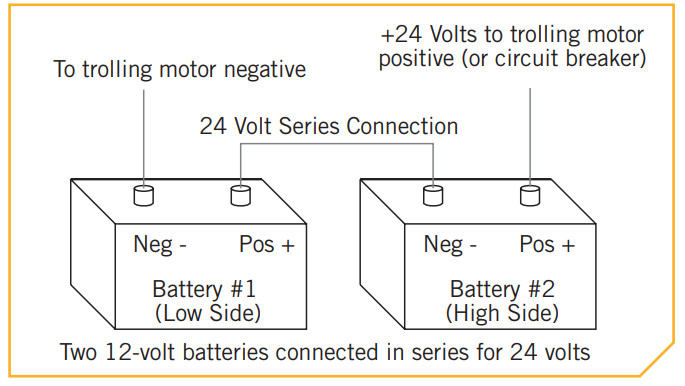

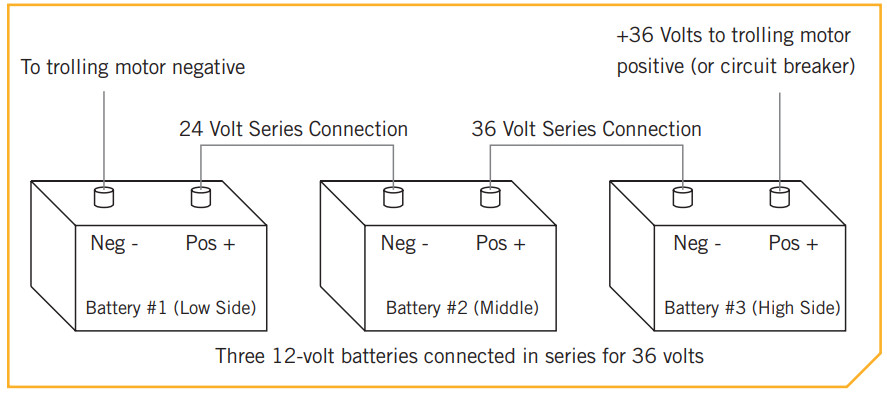

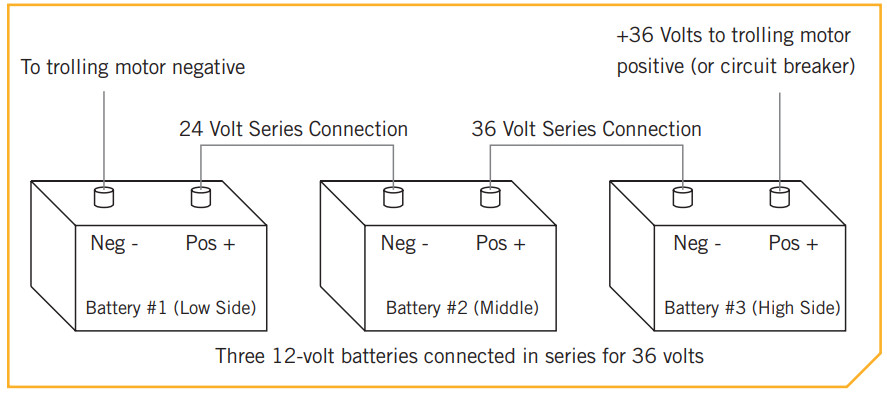

CONNECTING THE BATTERIES IN SERIES

The negative (-) connection must be connected to the negative terminal of the same battery that the trolling motor negative lead connects to. In the diagrams below this battery is labeled “Low Side” Battery. Connecting to any other trolling motor battery will input positive voltage into the “ground” of that accessory, which can cause excessive corrosion. Any damage caused by incorrect connections between battery systems will not be covered under warranty.Automatic Jump Start Systems and Selector SwitchesAutomatic jump start systems and selector switches tie the negatives of the connected batteries together. Connecting these systems to the “High Side” Battery or “Middle” Battery in the diagrams below and will cause significant damage to your trolling motor and electronics. The only trolling motor battery that is safe to connect to one of these systems is the “Low Side” Battery.NOTICE: The internal bonding wire is equipped with a 3 amp fuse. Improper connections described above carrying in excess of 3 amps will blow this fuse and no further damage will be exhibited. If this occurs, RF interference from the trolling motor affecting sonar units and other electronics will be more significant. If the fuse is blown the wiring error should be found and addressed prior to replacing the fuse. The replacement fuse should be 3 amps or less. An intact fuse does not imply correct rigging; significant damage can be done by incorrect wiring without approaching 3 amps of current.

CONNECTING THE BATTERIES IN SERIES (IF REQUIREd FOR YOUR MOTOR)24 Volt Systems

Two 12 volt batteries are required. The batteries must be wired in series, only as directed in a wiring diagram, to provide 24 volts.

- Make sure that the motor is switched off (speed selector on “0”).

- Connect a connector cable to the positive ( + ) terminal of battery 1 and to the negative ( – ) terminal of battery 2.

- Connect positive ( + ) red motor lead to positive ( + ) terminal on battery 2.

- Connect negative ( – ) black motor lead to negative ( – ) the terminal of battery 1.

- For safety reasons, disconnect the motor from the battery or batteries when the motor is not in use or while the battery/batteries are being charged.

- Improper wiring of 24/36 volt systems could cause battery explosion.

- Keep lead wire wing nut connections tight and solid to battery terminals.

- Locate the battery in a ventilated compartment.

36 Volt Systems

- Make sure that the motor is switched off (speed selector on “0”).

- Connect a connector cable to the positive ( + ) terminal of battery 1 and to the negative ( – ) terminal of battery 2 and another connector cable from the positive ( + ) terminal of battery 2 to the negative ( – ) terminal of battery 3.

- Connect positive ( + ) red motor lead to positive ( + ) terminal on battery 3.

- Connect negative ( – ) black motor lead to negative ( – ) terminal of battery 1.

- For safety reasons, disconnect the motor from the battery or batteries when the motor is not in use or while the battery/batteries are being charged.

- Improper wiring of 24/36 volt systems could cause battery explosion.

- Keep lead wire wing nut connections tight and solid to battery terminals.

- Locate the battery in a ventilated compartment.

This completes the installation of your Fortrex. A Complete Owner’s Manual can be downloaded at minnkotamotors.com.

NOTES

_______________________________________________

_______________________________________________

________________________________________________

RECOMMENDED ACCESSORIES

ON-BOARd & PORTABLE BATTERY CHARGERSStop buying new batteries and start taking care of the ones you’ve got. Many chargers can actually damage your battery over time – creating shorter run times and shorter overall life. Digitally controlled Minn Kota chargers are designed to provide the fastest charge that protects and extends battery life.

TALON SHALLOW WATER ANCHORIntroducing the all-new, sleek redesigned Talon. Talon is the only shallow water anchor with up to 15’ of anchoring depth, multiple anchoring modes, and control from the bow, transom, console, remote or mobile device.

BUILT-IN WORK LIGHT

- Control Panel

- Wireless Remote

- Mobile App

- Wireless Foot Switch

- Humminbird® Connectivity

- i-Pilot®& i-Pilot Link ™Remote

MINN KOTA ACCESSORIESWe offer a wide variety of trolling motor accessories, including:

| • 60-Amp Circuit Breaker• Mounting Brackets• Stabilizer Kits• Extension Handles | • Battery Connectors• Battery Boxes• Quick Connect Plugs |

minnkotamotors.comPart #2287110

Minn Kota Consumer & Technical Service Johnson Outdoors Marine Electronics, Inc. PO Box 8129Mankato, MN 56001

121 Power Drive Mankato, MN 56001Phone (800) 227-6433Fax (800) 527-4464

©2021 Johnson Outdoors Marine Electronics, Inc.All rights reserved.

References

[xyz-ips snippet=”download-snippet”]