OPERATION AND MAINTENANCE MANUALNOA Medical Industries Inc.Elite 2

Copyright©2008 NOA Medical Industries, Inc. All rights reserved. Publisher reserves the right to make dimension or specification changes, or deletions, consistent with design trends, product improvements, or for reasons beyond our control. The publisher makes no warranties with respect to the accuracy or completeness of the contents of this manual. “Elite Riser ”, “V Riser”, “AP Riser”, “Twin Riser”, and “Onyx” are trademarks of NOA Medical Industries, Inc.; other trademarks used in this document are property of their respective trademark holders.

SPECIAL NOTES

WARNINGS/CAUTION NOTICES in this manual apply to hazards or unsafe practices, which could result in personal injury and/or property damage.

NOTICE

The information in this document is subject to change without notice.Check all parts for shipping damage before using. DO NOT USE IF DAMAGED. ONLY USE AUTHENTIC NOA REPLACEMENT PARTS. Contact NOA Medical Industries Inc. Customer Service 1 (636) 239-7600 and the freight carrier for further instruction.This electric bed has been engineered to provide reliable operation.This bed has been thoroughly tested and inspected prior to shipment.

WARNINGS

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING AND UNDERSTANDING THIS MANUAL. IF YOU ARE UNABLE TO UNDERSTAND THE WARNINGS, CAUTIONS, OR INSTRUCTIONS, CONTACT A HEALTH CARE PROFESSIONAL OR A QUALIFIED TECHNICIAN BEFORE USING THIS EQUIPMENT. OTHERWISE, INJURY OR DAMAGE MAY RESULT.

- The correct bed height when unattended is based on the resident’s knee to floor height, mobility, and cognitive level. For residents with good mobility and cognition, the top of the mattress should be at a height so that the resident’s feet are flat on the floor and the angle between the thighs and calves is 90 degrees. Bed height and the resident’s abilities must be evaluated by a medical professional.

- If the resident’s physical or mental state may lead to entrapment, the sleep deck should be left in the flat position when unattended.

- Do not use near explosive gases.

- Possible fire hazard when used with oxygen administering equipment other than nasal or masked type.

- When using nasal or masked type administering equipment, oxygen or air tubing MUST be routed and secured properly to ensure tubing does not become entangled, kinked, or severed during normal operation of the bed.

- Close supervision by a caregiver is necessary when this product is used near CHILDREN OR PEOPLE WITH DISABILITIES.

- NEVER PERMIT ANYONE UNDER THE BED AT ANY TIME. When operating/moving the bed always ensure that the individual utilizing the bed is positioned properly within the confines of the bed. DO NOT let any extremities protrude over the side or between the rails when performing these functions.

- After installation and before use, make sure all attaching hardware is securely tightened.

- The pendant cord must be routed and secured properly to ensure the cord does not become entangled and damaged during the normal operation of the bed.

- Keep all moving parts free from obstruction (i.e. blankets/sheets, pads, tubing, wiring, etc.) which may get tangled around the bed, side rails, or legs during operation of the bed.

- Beds are equipped with locking casters. Casters should be locked at all times except when moving the bed.

- The mattress should be a hospital-type mattress to allow for proper bed articulation. The mattress must be properly sized to meet entrapment zone dimensional guidelines published by the FDA.

- These side rails are not for pediatric use.

- The side rails are NOT intended and may NOT be used as a restraint. If necessary, a physician or healthcare professional should be consulted for other means of safe restraint.

- When using safety side rails, if excessive side pressure is exerted on them they can be deformed or broken. Do not use side rails as handles to move the bed.

- Never permit more than one person in/on the bed at any time.

- Bodyweight should be evenly distributed over the surface of the bed. The bed’s weight capacity is 600 pounds. This is the total weight of the resident, mattress, bedding, head and footboards, side rails and any other accessories.

- The bed is provided with an additional safety feature of protective earth ground. The electrical cord should only be plugged into a GROUNDED 110/120V outlet. DO NOT ALTER THE PROVIDED PLUG. If the plug does not fit the existing outlet, a licensed electrician should install the correct outlet. Never operate the bed if it has a damaged cord or plug.

- Unplug the power cord when performing any maintenance on the bed.

- Do not open any actuator, pendant, or control box. If these units are opened the warranty is voided.

- The Safety Lock provides the resident with a stable and secure bed, providing easy access in and out of the bed. Check that the Safety Lock is engaged and that the bed is solidly in place before leaving the bed unattended or before attempting resident transfers into or out of the bed.

- The Safety Lock is not intended to be used on a sloping floor or building access ramp. Use of the Safety Lock on a sloping floor or building access ramp could result in injury or death.

- The Safety Lock should be locked at all times except when the bed is being moved.

- For maximum resident safety, caster locks (if available) should be used in addition to the Safety Lock system.

REDUCING THE RISK OF ENTRAPMENT

The Hospital Bed Safety Workgroup (HBSW) in partnership with the FDA has recognized potential entrapment zones in hospital bed systems and has developed dimensional guidance to reduce the risk of entrapment. The FDA considers the term “hospital bed system” to encompass the bed frame and its components, including the mattress, bedside rails, head and footboards, and any accessories to the bed.The entrapment zones involve the relationship of components controlled by the healthcare facility or individual user. Compliance with the dimensional guidelines for reducing the risk of entrapment is primarily the responsibility of the healthcare facility or the individual user.Anyone having any involvement with hospital bed systems should review and understand the FDA guidelines. These guidelines, entitled “Hospital Bed System Dimensional and Assessment Guidance to Reduce Entrapment – Guidance for Industry and FDA Staff,” are available at the FDA website.

STEPS TO PREVENT BED FIRES

- Inspect the bed’s power cord for damage.

- Connect the power cord directly into a wall-mounted outlet that is in good working order, with no cracks or chips.The plug should fit tightly into the outlet. The ground pin should be intact and secure.

- Do not connect the bed’s power cord to an extension cord or to a multiple-outlet strip.

- Do not cover any power cord with a rug. Heat may build up or the cord may be damaged.

- Inspect the floor beneath the bed for the buildup of dust and lint. Ask housekeeping to clean if necessary.

- Inspect the resident’s bed controls, looking for signs of damage where liquids could leak in.

- Test the bed and its controls, including resident lockout features, to ensure that the bed can move freely in both directions without damaging any cords.

- Check monitors and other resident equipment for signs of overheating or physical damage.

- Keep linens and clothes away from power sources.

- Tell maintenance staff about any unusual sounds, burning odors, or unusual movement of a bed.

- If you suspect overheating, follow your facility’s policy for fire safety and get the resident to a safe area if necessary.

SPECIFICATIONS AND CONDITIONS

Safe Working Load**: 600 lbs.Deck Height Range: 7″ – 30″Maximum Back Angle: 65 degreesMaximum Hip to Knee Angle: 30 degrees

*O.A.L. measure of bumper head and footboards.**The Safe Working Load is the total weight, including the resident, mattress, bedding, head and footboards, side rails, and other accessories evenly distributed on the sleep deck.

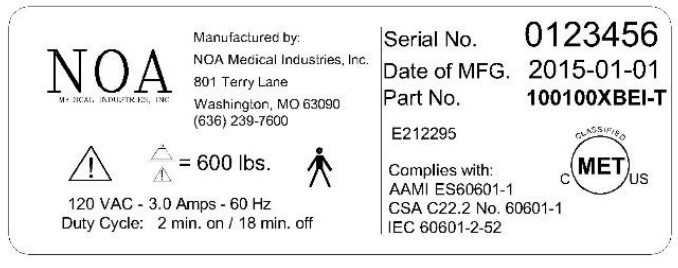

Locating Your Serial Number

The serial number label is located at the foot end of the bed, under the mattress support deck, on the bed frame.Please have the serial number and model of the bed available when calling Customer Service 1(636) 239-7600.

The serial number label is located at the foot end of the bed, under the mattress support deck, on the bed frame.Please have the serial number and model of the bed available when calling Customer Service 1(636) 239-7600.

Environmental Conditions

Ambient temperature range of 50°F to 104°F +10°C to +40°CRelative humidity range of 30% to 75%Atmospheric pressure range of 20.6 to 31.3 inches of Hg.Control Box – IP54Protected against dust and splashing water.Actuators and Pendants- IP66Protected against dust and low-pressure jets of water.

Electrical Specifications

Power: 110/120 V.A.C.Frequency: 60 HzCurrent Rating: 3.0 AmpsDuty Cycle: 10% Max. (2 min. on/ 18 min. off)

INSTALLATION

Required Tools(1) – #2 Phillips Head ScrewdriverHardware Bag Contents(8) – ¼ – 20 x 1.5” Machine Screws(8) – ¼ – 20 Insert Cap Nuts(1) – Adjustable Cable Clamp(1) – #10-12 x ¾ Wood ScrewUpon receipt of your new bed, carefully inspect the bed and accessory components for any damage received in transit.Notify the NOA Customer Service at 1 (636) 239-7600 immediately if any product or component has been damaged or is missing from your shipment.

Installing the Head and Foot Boards

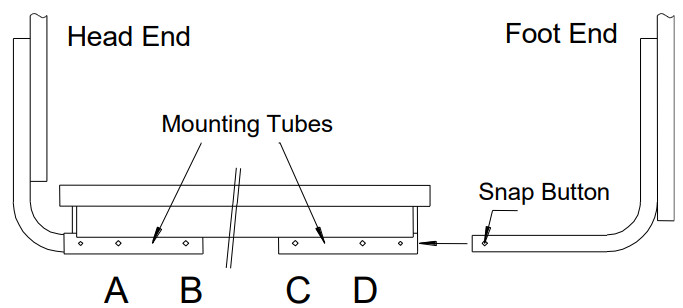

On large orders, beds are shipped with transport legs inserted in the footboard mounting tubes. Remove and discard these legs and replace them with footboard brackets. Insert brackets into the mounting tubes until snap buttons align in the holes as indicated below. Ensure that snap buttons are seated in the proper holes prior to bed use.

| Bed Length | Head Board Bracket Hole | Foot Board Bracket Hole |

| 80″ | B | C |

| 84″ | B | D |

Normally the cap nuts are installed in the head and footboards at the factory. If they are not installed at the factory insert the cap nuts provided in the hardware bag into the pre-drilled holes in the head and footboards using a rubber mallet. If laminate on one side only, install the nuts on the laminated side of the board. Attach head and footboardsto the front face of the vertical bracket using the provided screws. Tighten all hardware.

Securing the Power Cord

Approximately 8 feet of the exposed power cord is provided with the bed. A cable tie has been supplied so that excess cord can be maintained and secured to the back of the headboard. When securing the power cord, ensure that an adequate loose length is maintained to allow for the full range of motion of the bed.

Installing the Corner Mattress Retainers

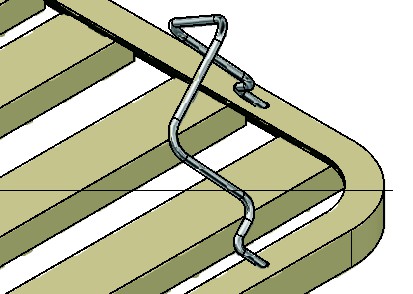

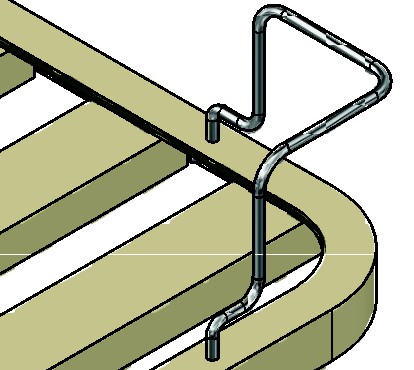

Corner Mattress Retainers (PN 3040025) should be installed at each corner of the bed to assist in maintaining the proper alignment of the mattress during bed use. In order for the retainers to be effective, beds should be used in conjunction with a hospital-grade mattress designed to allow for bed articulation. The mattress should be 6” thick with a width and length conforming to the sleep deck size. Mattress retainers should be installed prior to installation of any deck-mounted side rails or assist bars.

- Locate (2) ¼” holes at each bed corner in the outer angle of the head and foot deck. Insert each leg of the Mattress Retainer.

- With the leg of each side of the Mattress Retainer positioned in the ¼” holes, rotate the Retainer towards the corner of the bed while slowly inserting the legs further into the holes.

- When fully rotated, press the Mattress Retainer into position and then place the mattress on the rib-deck sleep surface. Check that all corners of the mattress are within the Retainers. A slightly compressed fit is desired.

Ensure that the Retainers hold the mattress securely to prevent mattress slippage during head and foot deck articulation.Install accessory components as per their instructions.Verify that there are no gaps between the mattress, head, and footboards, side rails, or any other accessories wide enough to entrap a resident’s head, neck, or body. Additional information regarding bed entrapment may be obtained from the U.S. Food and Drug Administration Center for Devices and Radiological Health website.Your bed is ready for use. The bed should be located and casters locked while the bed is in its lowest position. Adequate spacing must be maintained between the wall and the bed to prevent damage to the bed or walls while raising or lowering the bed. Check to be sure that the vertical movement of the bed does not interfere with the power cord or plug.

Bed Transport:

The bed features a patented rolling base that allows it to be rolled or locked at any bed height. In order to lock the bed, activate the brakes located on the twin wheel casters at the head of the bed and safety lock. To roll the bed, disengage brakes. Activating caster brakes does not disengage bed functions.

CautionIf casters are not locked swivel and wheel rotation can allow for bed motion with little or no resistance. This can result in loss of balance, fall, and personal injury. Ensure that the casters are locked to prevent any bed movement during resident transfer and/or treatment.

BED OPERATION

Bed Positioning

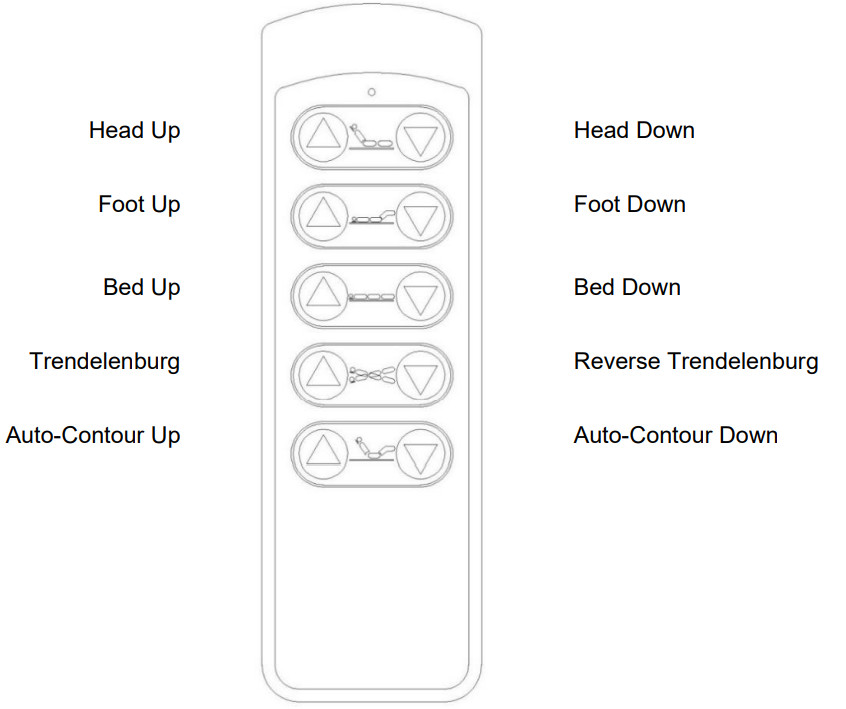

Bed functions are operated with a 10 button pendant (4040137). Button functions on the handheld pendant control are clearly identified with universal icons. The hand control is provided with an attached bracket for suspending the control from side rails or bed ends. PRIOR TO RAISING OR LOWERING THE BED AND/OR SIDE RAILS, CHECK TO ENSURE THAT THE CORD FOR THE PENDANT CONTROL HAS NOT BECOME ENTANGLED IN BED PARTS. THE CORD SHOULD BE KEPT CLEAR OF MOVING PARTS AT ALL TIMES.

Sub Acute Care

Trendelenburg/Reverse Trendelenburg Positioning – This feature allows for the immediate adjustment of the bed into an incline of up to 13 degrees in either Trendelenburg or Reverse Trendelenburg positions. Trendelenburg positioning is controlled with two buttons located on the twelve-button pendant. To return to a normal horizontal bed position press the opposite button, the bed will stop when it is level.Cardiac Chair Positioning – The cardiac chair position can be achieved by positioning the bed in Reverse Trendelenburg and raising the head and foot sections to desired levels.Attention: Ensure the head end of the bed is free to roll and at least 7 inches away from any obstructions before operating Trendelenburg or Reverse Trendelenburg features.

ACCESSORIES AND OPTIONS

Optional Foot Board Control

An optional Lock Out Foot Board Control (4040148) with Sub Acute functions is available.

Connecting the Optional Foot Board Control Cable

Connecting the Optional Foot Board Control Cable

- Plugin the Junction Y Cable (4040112) to the handset socket on the Control Box.

- Plug the Foot Board Control Cable (4040111) and the handset (4040137) into the Junction Y Cable.

- Plug Foot Board Control into the Foot Board Control Cable (4040111).

SERVICING

Troubleshooting

| SYMPTOM | POSSIBLE CAUSE(s) | ACTION | ||

| No Power

|

1. | The bed is not plugged into NC power. | 1. | Check plug to the receptacle. |

| 2. | Cut/damaged power cord. | 2. | Check the power cord for damage. | |

| 3. | Loose plug for the pendant. Cut/damaged pendant cord. | 3. | Check pendant cord for damage. | |

| 4. | The actuator plug is not connected. | 4. | Check actuator connection to control box. Inspect the actuator cord for damage. | |

| Actuators operate. but the wrong movement occurs | 1. | Cut/damaged pendant cord. | 1. | Inspect pendant cord for damage. |

| One or more actuators do not function

|

1 | Loose or unplugged connection of actuator cord to control box. | 1. | Check actuator plug to control box. |

| 2. | Cut/damaged actuator cord. | 2. | Inspect the actuator cord for damage. | |

| 3. | Defective actuator. | 3. | Replace actuator. | |

| 4. | Defective control box. | 4. | Replace the control box. | |

| Bed is not level when operating Hi/Low functions | 1. | Actuators are out of synchronization. | 1. | Run bed to the full down position and continue to hold the button for 3 seconds (after bed reaches full down position). |

| No Function/Handset Blinking | 1. | The bed needs reset. | 1. |

If the handset is flashing, press the elevation down button until bed moves to the lowest position. Continue holding the elevation down until the handset backlight stops flashing. The bed is now reset. |

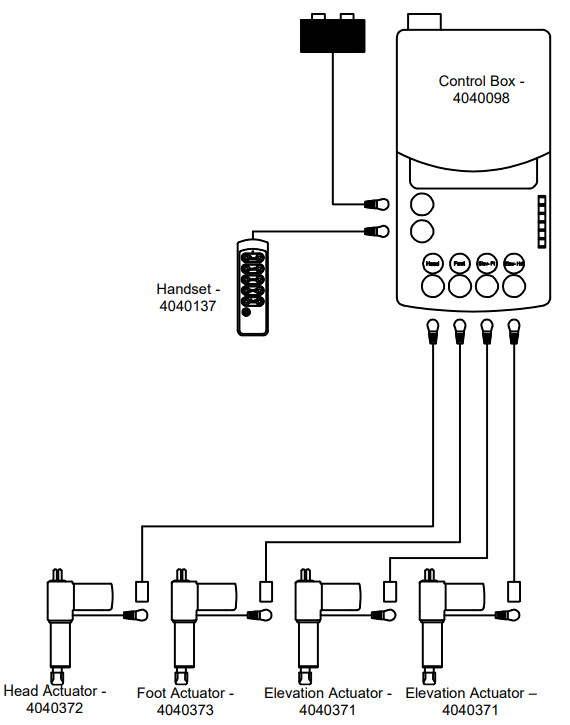

Control Box Socket Identification

NOTE: To install Foot Board Control (4040148), a junction y cable is plugged into the control box instead of the handset, and the handset (4040137) and Foot Board Control cable (4040111) is plugged into the junction y cable. The Foot Board Control will get plugged into the Foot Board Control Cable.Steps for Isolating Electrical Problems

- Check all connections.

- Exchange pendant with a known working pendant.

- Exchange actuator plugs at known working control box ports.

- Check the actuator with a known working control box.

IF THE USE OF THIS TROUBLESHOOTING GUIDE DOES NOT CORRECT THE PROBLEM PLEASE CALL CUSTOMER SUPPORT AT 1 (636) 239-7600.

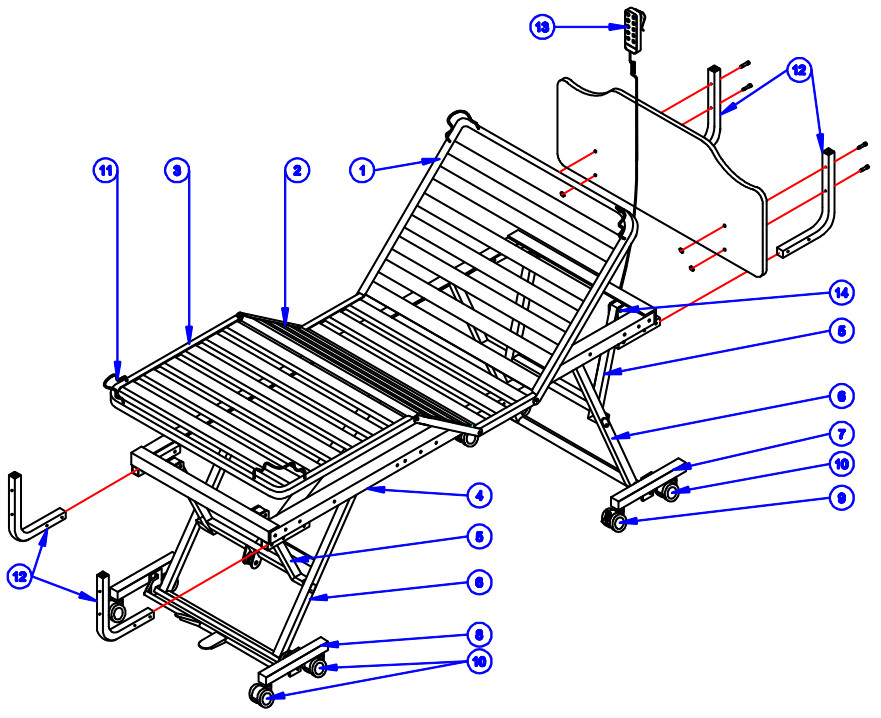

Bed Diagram

Part List

| Item No | 80″ | QTY | DESCRIPTION |

| 1001001BEI-T | Bed Model | ||

| 1 | 5250060BE1-T | 1 | Head Deck |

| 2 | 5250061BEI-T | 1 | Knee Deck |

| 3 | 5250062BE1-T | 1 | Foot Deck |

| 4 | 5250063BE1 | 1 | Bed Frame |

| 5 | 5240201BEI-T | 2 | Elevation Arm |

| 6 | 5240202BE1-T | 2 | Elevation Leg |

| N.S. | 4040237 | 2 | Support — Foot Deck |

| 7 | 5240199BE1-T | 1 | Head Caster Assembly |

| 8 | 5240200BE1-T | 1 | Foot Caster Assembly |

| 9 | 4040344 | 2 | Caster – Twin Locking |

| 10 | 4040343 | 6 | Caster – Twin Non-Locking |

| 11* | 3040025 | 4 | Mattress Retainer |

| 12′ | 1540001BE1 | 4 | Head/Foot Board Bracket |

| N.S. | 4040372 | 1 | Actuator — Head |

| N.S. | 4040373 | 1 | Actuator — Foot |

| N.S. | 4040371 | 2 | Actuator — Elevation |

| 13 | 4040137 | 1 | Pendant |

| N.S. | 4040098 | 1 | Control Box |

| 14 | 4000341 | 12 | Clevis Pin — 3/8″ X 2-1/4″ |

| N.S. | 4000342 | 12 | Cotter Pin (Rue Clip) |

| N.S. | 4020069 | 8 | Screw — #10-16 x 3/4″ |

| N.S. | 4030033 | 4 | Rubber Bumper |

Note:

- N.S. – Not Shown

- *Indicates part is shipped in hardware box (PN 7000043BEI)

- BEI means Beige

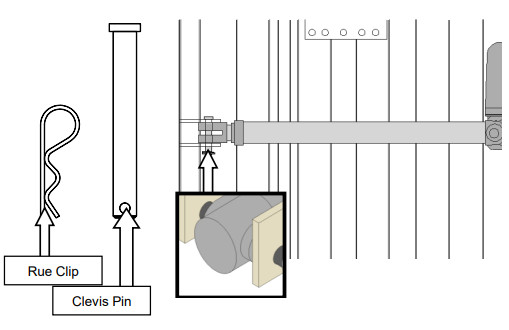

Replacement of Actuators

![]() CautionUnplug the bed before beginning work.

CautionUnplug the bed before beginning work.

- With help, roll the bed onto its side.

- Unplug the actuator cord from the control box.

- Remove hairpin and clevis pins. Save these parts for reuse.

- Lift actuator(s) out of brackets. Install new actuator in reverse order.

- Place actuator(s) in brackets.

- Put hairpin and clevis pin through bracket and actuator.

- Plug the actuator cord into the control box.

- With help, roll the bed right side up.

MAINTENANCE AND CLEANING

Maintenance and cleaning procedures should be performed at least once a year or as required.

Cleaning and Disinfecting The Bed

- Unplug the power cord before cleaning or performing maintenance on the electric bed.

- Do not submerge the pendant in liquid.

- Do not steam or pressure wash the bed or any of its components.

- Wipe down actuators, control box, and pendant with a damp, well wrung out cloth or with a disinfecting wipe.

- Excess water or liquid may damage electrical parts and poses a shock hazard.

- Wipe down the remainder of the bed with a disinfectant.

- Allow the bed to dry completely before using.

Periodic Inspection

- Perform the procedure “STEPS TO PREVENT BED FIRES” listed in this manual.

- Review “REDUCING THE RISK OF ENTRAPMENT” listed in this manual.

- Review and inspect for compliance to the “WARNINGS” listed in this manual.

- Check casters to ensure they lock, if applicable, and roll properly.

- Inspect all bed components for damage or excessive wear.

- Visually examine all welds for cracks.

- Inspect the deck components for bending or damage.

- Check the motor actuator shaft and its connections for bending damage, or excessive wear.

- Check actuator ends and its mounting hardware for bending or excessive wear.

- Inspect all bolts and fasteners. (Do not overtighten bolts at pivot points.)

- Check all cords for cuts or other damage.

- Make sure all plugs are fully seated.

- Make sure all cords are free of moving parts.

LIMITED WARRANTY

The Manufacturer warrants to the original user (Customer) all products manufactured by the manufacturer to be free from defects in material and workmanship under normal use and service for a period as specified below. If such a defect appears and Customer has given immediate written notification of same, the Manufacturer shall replace or repair such part at the Manufacturers option. The Manufacturer will require the return of the defective part to establish the claim. The Manufacturer’s obligation under this warranty shall be limited to said replacement and/or repair. Installation and freight costs for replaced or repaired items remain the responsibility of the Customer. This warranty does not cover failure due to negligence, accident, deliberate abuse, nor improper installation and/or maintenance. Modifications made to products (including modifications without the expressed written consent of the Manufacturer) shall void this warranty in its entirety. NO FURTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE NOT SPECIFIED HEREIN, ARE MADE BY THE MANUFACTURER, AND THIS WARRANTY SETS FORTH THE FULL EXTENT OF THE LIABILITY ARISING FROM THE MANUFACTURE, USE OR SALE OF THE PRODUCTS AND MATERIALS SOLD HEREUNDER. No allowances will be made for delays or loss of profit, nor for any other special, indirect or consequential damages or injuries, whether based on tort or contract.Applicable warranty periods commencing from date of shipment from NOA are as follows:Welds ……………………………………………………………………………. 15 yearsElectrical components ……………………………………………………………. 4 yearsMechanical components …………………………………………………….. 4 yearsSide Rails…………………………………………………………………………………… 2 yearsWood products ……………………………………………………………………… 1 yearManual Number 1100185_4Save these instructions

[xyz-ips snippet=”download-snippet”]

Connecting the Optional Foot Board Control Cable

Connecting the Optional Foot Board Control Cable