CAR-connect High-Voltage Testing Adapter VAS 6558A/38 User Manual

Document identification

Imprint

[email protected]www.car-connect.cc

1 Concept

The high-voltage testing adapter has been developed according to the latest regulations in measurement and control technology, for use on intrinsically safe high-voltage systems in road vehicles. The testing adapter corresponds with the state of the art and meets all relevant European standards as well as partially meets international standards. Despite high standards for development, production and quality, only careful handling and proper use can ensure that there is no damage and resulting consequences. For this reason, this operating manual should be read and understood in full.

1.1 Read the operating manual

Read this operating manual thoroughly before using the high-voltage testing adapter. In this operating manual, the intended use and hazards of handling the product are described. In addition to this operating manual, other regulations may be binding for diagnosis or troubleshooting of intrinsically safe high-voltage systems in road vehicles. These include, among other things, the manuals of the vehicle manufacturer as well as the instructions of the employers’ liability insurance association. Please ensure that all information on the product and its scope of application is available to you before you use the high-voltage testing adapter. Please use the adapter cable only if you have fully understood all information pertaining to its use.

1.2 Structure of the document

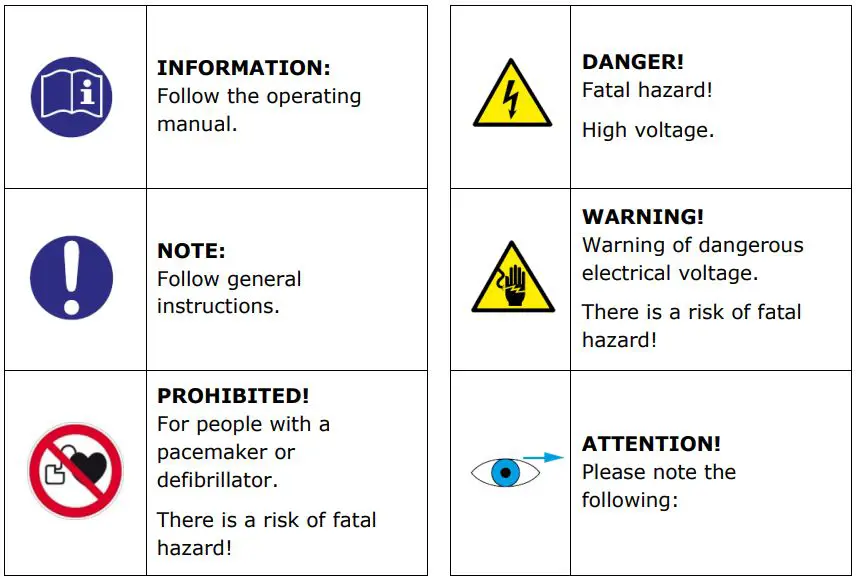

For a better understanding of the information contained in this operating manual, additional descriptive pictograms are used. These markings indicate particularly relevant information and the images indicate the significance within a description or an operation step.

Therefore, please follow the instructions and information in this operating manual, so that there is no bodily injury or property damage when used in the high-voltage section of the vehicle.

The following table contains all the pictograms, warning symbols and symbols that may appear in this manual.

2 Safety instructions

The basic safety instructions given below must be followed to avert bodily injury to people and property damage while using the high-voltage testing adapter.

2.1 General safety instructions

Most incidences of damage to property and personal injury are primarily due to ignorance or negligence and can be avoided from the outset if the following general safety instructions are observed:

- Read the operating manual carefully before use.

- Only people who can provide valid proof of technical knowledge of working on high-voltage systems in motor vehicles may perform measurements on high-voltage systems.

- Follow the instructions in the guided troubleshooting, which is described in the PIWIS Tester.

- Use the high-voltage testing adapter solely in closed and dry rooms.

- Follow the instructions of the trade association or government institutions for the repair of hybrid- and all-battery electric vehicles.

- Check the testing adapter regularly before use in accordance with the specifications of VDE 0701-0702:2010-08 (draft EN 62638).

- Use the testing adapter solely for the intended use, as specified by the vehicle manufacturer.

- Use the product solely for its intended purpose.

- Immediately replace a defective or damaged product.

- Never attempt to modify or manipulate the testing adapter.

- Never attempt to supply current or voltage to other devices through the testing adapter.

- Use only approved test equipment to carry out measurements on the testing adapter.

- Never attempt to repair a testing adapter.

- Do not use aggressive liquids to clean the product.

- Prevent the adapter cable from coming in contact with aggressive operating fluids such as brake fluid and coolant.

- Prevent the product from falling on the floor.

2.2 Proper use

The high-voltage testing adapter is a passive, non-self-indicating measuring medium used for diagnosis on the high-voltage systems of road vehicles. With the testing adapter, the high-voltage connector (Rosenberger HPK-2-pole) is adapted in such a way that it is touch-proof. Special laboratory safety sockets in the adapter ensure safe access to the high-voltage system. Necessary measurements such as manual deenergizing control can be carried out safely on the testing adapter. The operating and test instructions of the vehicle manufacturer must be followed and are included in the PIWIS Tester.

2.3 Improper use

Any use of the product deviating from the intended use is considered improper use. Use of a manipulated or defective testing adapter will be considered in exactly the same way as disregarding or disobeying the instructions of the operating manual. This behavior, in addition to limiting the guarantee and the loss of warranty claims, can also lead to bodily injury to people or damage to property under certain circumstances.

2.4 Obligations of the operator

The operator must ensure that appropriate and capable staff is appointed by them to work on vehicle-specific high-voltage system. The proof of qualification required for this is based on successful participation in appropriate training. The operator must ensure that the measuring equipment and accessories are in a faultless condition and they do not have any defects.Regular inspection periods for the measuring equipment, accessories and testing adapters are set out in an instruction manual. Also, it is the operator’s responsibility to note the replacement of the high-voltage testing adapter on reaching the number of operation cycles. The operator must ensure that servicing staff regularly participate in refresher training courses for repairs of high-voltage systems and pass these successfully as well.

2.5 User’s qualifications

The user has proven expertise to carry out work on high-voltage systems of fully battery-operated, plug-in hybrid or e-traction road vehicles. In addition, the user should have experience in taking cascade measurements, whereby active and passive measurements are taken simultaneously.

3 Transport

The product comes in recyclable disposable packaging, which is not suitable for storing the product after use.

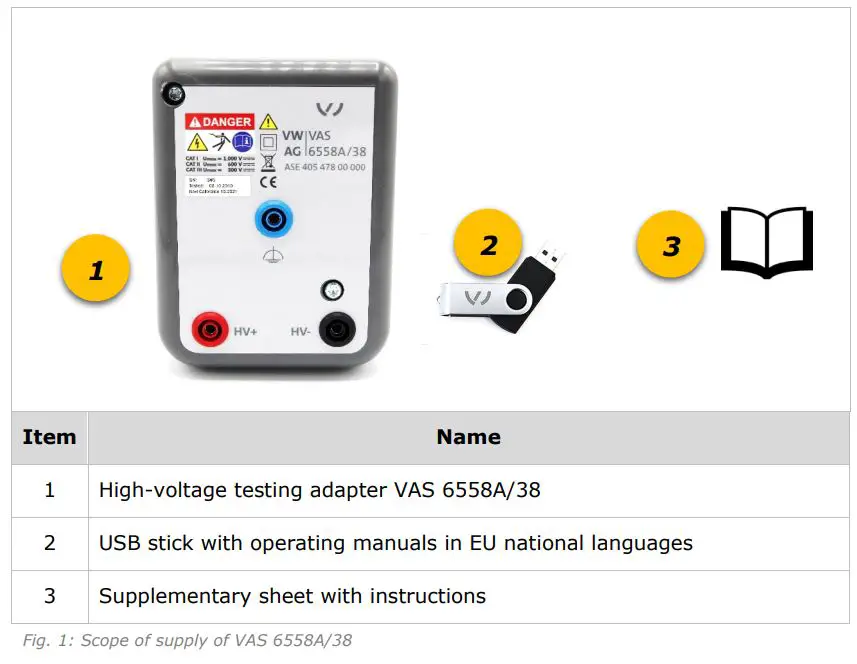

3.1 Unpacking and checking for completeness

Check the condition and completeness of the contents based on the shipping documents and the delivery note. In case of any damage or defective components, contact the manufacturer immediately.

3.2 Transport during normal working hours

The high-voltage testing adapter is used along with an activated measuring module and should be transported after diagnosis in a suitable transport container. Please ensure that moisture and metal dust do not enter the container.

3.3 Safekeeping and storage

In order to avoid damage to the high-voltage testing adapter or to prevent the loss of accessories, always keep the measuring equipment in a transport case. This approach ensures a quick overview of a completed task, if all the parts are once again placed in the case in their designated places.

4 High-voltage testing adapter

The high-voltage testing adapter is a passive, non-self-indicating measuring medium, to which the high-voltage connector (Rosenberger HPK 2-pole) is adapted. This adaptation provides standardized access to the high-voltage cables and the shielding. Special laboratory safety sockets located on the front of the testing adapter allow user-specific measurements to be carried out safely, protected against touching.

The appropriate mating connector, on which the vehicle-mounted high-voltage cable with the Rosenberger connector is used, is located in the high-voltage testing adapter. In addition to the compatibility with the high-voltage connector, the following contacts are possible on the testing adapter:

A series of measurements (e.g., insulation, potential and continuity measurements) can be carried out with an activated measuring device using the laboratory safety sockets. The testing adapter is designed for measurements under voltage.

The high-voltage testing adapter VAS 6558A/38 consists of a two-part, rectangular and screwed plastic housing. The two dimensionally stable and accurate housing halves are joined together almost seamlessly, which meet the requirements of protection class IP20.

The plastic material used makes the housing resistant to impacts typically encountered in everyday use, plays a repellent function against aggressive substances, and prevents a static charge thanks to its composition.

The smooth, non-porous and glossy surface minimizes dust adhesion and thereby reduces the effort required in cleaning. The top of the housing has two test sockets for the two-pin Rosenberger plug, which can only be inserted in one plug-in direction due to the reverse polarity coding.

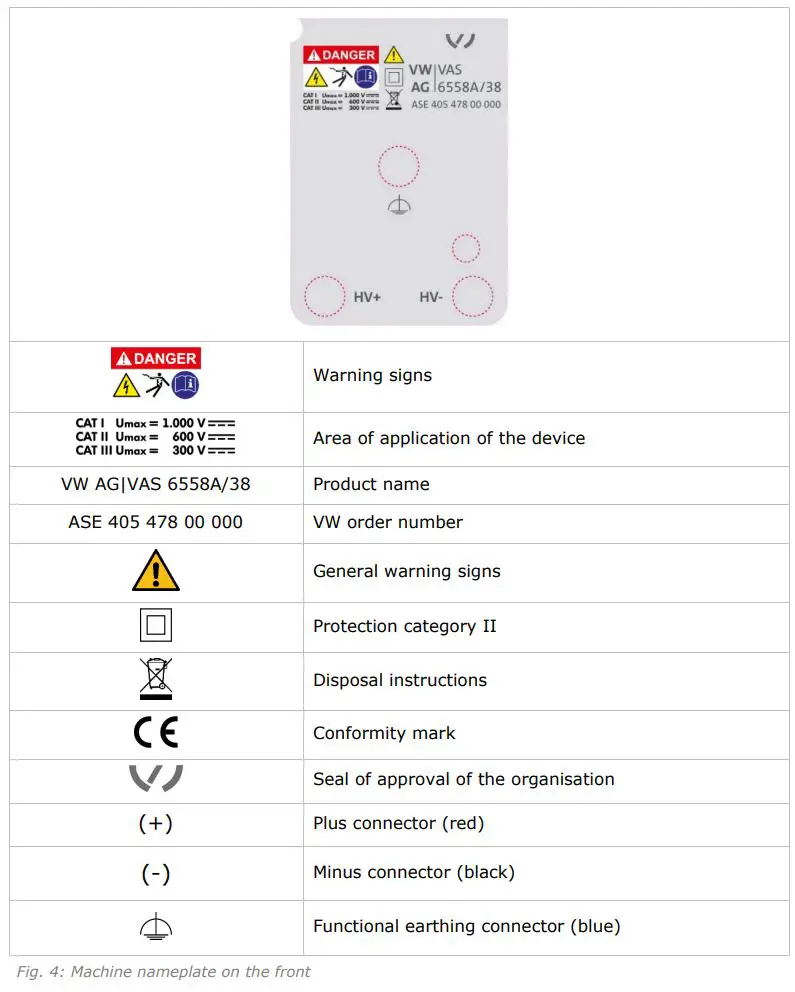

4.1 Product labelling

Product labels are attached to the testing adapter. The following tables describe each label and explain the signs shown. The machine nameplate contains the following symbols and signs.

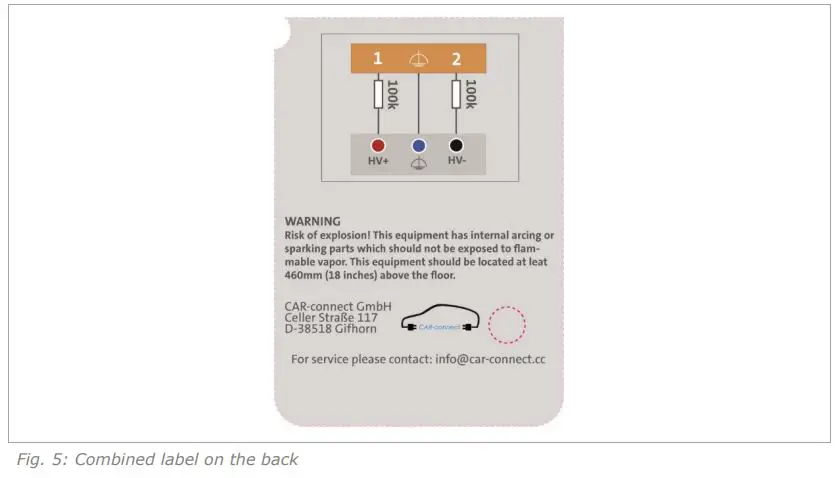

The combined label on the back side contains the wiring diagram, a warning with instructions, and the manufacturer’s address.

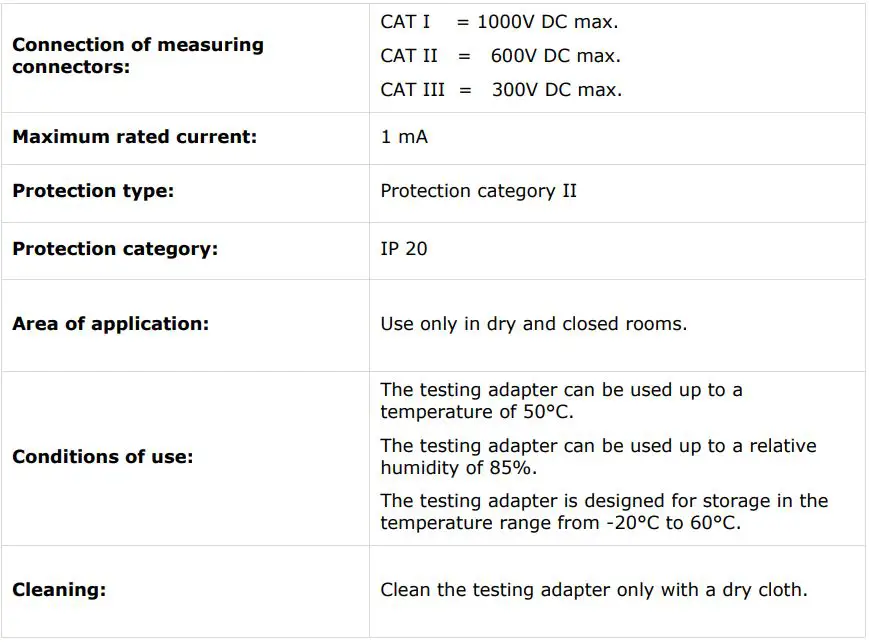

4.2 Technical specifications

5 Operation

Before you can start testing the high-voltage components, ensure that the vehicle is in de-energized state. Follow the instructions given in the guided diagnostics of the vehicle manufacturer. Additionally, observe the following safety rules.

![]()

5.1 Insert the high-voltage testing adapter

The high-voltage testing adapter is inserted and used as per the vehicle manufacturer’s specifications. Follow the handling instructions in the guided vehicle diagnostics of the relevant brand of the company.

6 Maintenance/self-testing

![]() INFORMATION: In addition to this operating manual, also read the operating instruction on the topic of maintenance/self-testing from the vehicle’s manufacturer and operator.

INFORMATION: In addition to this operating manual, also read the operating instruction on the topic of maintenance/self-testing from the vehicle’s manufacturer and operator.

6.1 Maintenance of the device

No provisions are made by the device manufacturer for preventive maintenance of the testing adapter.

![]()

![]()

6.2 Recurring testing of the device.

To comply with the requirements for electrical safety of electrical equipment and work equipment in accordance with VDE 0701-0702: 2008 (draft EN 62638), the corresponding test instructions for an annual inspection are available on the manufacturer’s homepage.

![]()

![]()

![]()

6.3 Clean the device.

The adapter cable should only be cleaned with a dust-absorbing cloth made of antistatic material. Avoid contact with liquid cleaners, aggressive cleaning agents or water in any form (splash water, dripping water, high-pressure cleaning water). Immediately replace the testing adapter, if it comes in contact with liquids or chemicals.

7 Disposal

![]()

![]()

7.1 Product life cycle

![]()

![]()

7.2 Environmentally responsible waste disposal

As soon as the testing adapter’s life cycle come to an end, it must be sent for sorted disposal. The testing adapter’s operator bears the responsibility for this as the owner responsible for disposal. The sale or gratuitous licensing for the purpose of disposal must be documented.

8 Customer service

If you have any questions about the product or need additional service information, then you can contact Customer Service at:

CAR-connect GmbH Caller Str. 117D-38518 GifhornTelephone: +49 (0) 5373 92197- 0Fax: +49 (0) 5373 92197-88[email protected]www.car-connect.cc

References

[xyz-ips snippet=”download-snippet”]