AIR CAT 1″ Composite Straight Impact Wrench Instruction Manual

IMPORTANT! Read carefully before operating this tool.Failure to operate any power tool properly can result in personal injury and/or property damage!

7.2.2.3 GENERAL SAFETY RULES

7.2.2.3 GENERAL SAFETY RULES

- Multiple hazards. Read and understand the safety instructions before installing, operating, repairing, maintaining, changing accessories on, or working near the power tool. Failure to do so can result in serious bodily injury.

- Only qualified and trained operators should install, adjust or use the power tool.

- Do not modify this power tool. Modifications may reduce the effectiveness of safety measures and increase the risks to the operator.

- Do not discard the safety instructions – give them to the operator.

- Do not use a tool if the tool has been damaged.

- Warnings shall be given against the risk of explosion or fire due to the material being processed.

- Warnings shall be given against the risk of cutting.

7.2.2.4 PROJECTILE HAZARDS

7.2.2.4 PROJECTILE HAZARDS

- Failure of the work piece, of accessories, or even of the tool itself may generate high velocity projectiles.

- Always wear impact-resistant eye protection during operation of the tool. The grade of protection required should be assessed for each use.

7.2.2.5 ENTANGLEMENT HAZARDS

7.2.2.5 ENTANGLEMENT HAZARDS

- Entanglement hazard – choking, scalping and/or lacerations can occur if neck ware hair or gloves are not kept away from tool and accessories. ‘

7.2.2.6 OPERATING HAZARDS

7.2.2.6 OPERATING HAZARDS

- Use of the tool may expose the operator’s hands to hazards including crushing, impacts, cuts and abrasions and heat. Wear suitable gloves to protect hands.

- Operators and maintenance personnel must be physically able to handle the bulk, weight and power of the tool.

- Hold the tool correctly: be ready to counteract normal or sudden movements – have both hands available.

- Maintain a balanced body position and secure footing.

- Keep hands away from rotating or reciprocation accessories, spindles or other moving parts.

- Release the start and stop device in the case of an interruption of the energy supply

- Use only lubricants recommended by the manufacturer. e 7.2.2.7 REPETITIVE MOTIONS HAZARDS

- When using a power tool, you may experience discomfort in your hands, arms, shoulders, neck, or other parts of your body.

- While using a power tool, position your body in a comfortable posture. Maintain secure footing and avoid awkward or off-balanced postures. Changing your posture during extended tasks may help avoid discomfort and fatigue.

- If you experience symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling, numbness, burning sensation, or stiffness, do not ignore these warning signs. Promptly tell your employer and consult a qualified health professional.

7.2.2.8 ACCESSORY HAZARDS

- Only use sizes and types of accessories and consumables that are recommended by the power tool manufacturer.

7.2.2.9 WORKPLACE HAZARDS

7.2.2.9 WORKPLACE HAZARDS

- Slips, trips and falls are major causes of workplace injury. Be aware of slippery surfaces caused by use of the tool and also of trip hazards caused by the air line or hydraulic hose.

- Proceed with care in unfamiliar surroundings. Hidden hazards may exist, such as electricity or other utility lines.

- This power tool is not intended for use in potentially explosive atmospheres and is not insulated from coming into contact with electric power.

- Make sure there are no electrical cables, gas pipes etc. that could cause a hazard if damaged by use of the tool.

7.2.2.10 DUST AND FUME HAZARDS

7.2.2.10 DUST AND FUME HAZARDS

- Dust from some work processes can cause cancer, birth defects or other respiratory diseases. Risk assessment of these hazards and implementation of appropriate controls is essential.

- If the pneumatic tool is used in a dust filled environment exhaust air can cause a dust hazard.

- Dusts and fumes generated when using power tools can cause ill health (for example: cancer, birth defects, asthma and/or dermatitis); risk assessment of these hazards and implementation of appropriate controls of is essential.

- Risk assessment should include dust created by the use of the tool and the potential for disturbing existing dust.

- Operate and maintain the power tool as recommended in these instructions, to minimize dust or fume emissions

- Direct the exhaust so as to minimized disturbance of dust in a dust filled environment

- Where dusts or fumes are created, the priority shall be to control them at the point of emission.

- All integral features or accessories for the collection, extraction or suppression of airborne dust or fumes should be correctly used and maintained in accordance with the manufacturer’s instructions.

- Select, maintain and replace the consumable/inserted tool as recommended in these instructions, to prevent an unnecessary increase in dust or fumes.

- Use respiratory protection as instructed by your employer or as required by occupational health and safety regulations;

7.2.2.11 NOISE HAZARDS

7.2.2.11 NOISE HAZARDS

- Unprotected exposure to high noise levels can cause permanent, disabling, hearing loss and other problems such as tinnitus (ringing, buzzing, whistling or humming in the ears).

- Risk assessment of these hazards and implementation of appropriate controls of is essential.

- Appropriate controls to reduce the risk may include actions such as damping materials to prevent work pieces from ‘ringing’

- Use hearing protection as instructed by your employer or as required by occupational health and safety regulations;

- Operate and maintain the power tool as recommended in these instructions, to prevent an unnecessary increase in noise levels;

- Select, maintain and replace the consumable/inserted tool as recommended in these instructions, to prevent an unnecessary increase in noise.

7.2.2.12 VIBRATION HAZARDS

7.2.2.12 VIBRATION HAZARDS

- Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms;

- Wear warm clothing when working in cold conditions and keep your hands warm and dry.

- If you experience numbness, tingling, pain or whitening of the skin in your fingers or hands, stop using the power tool, and tell your employer. You should also seek medical advice from a qualified occupational health professional.

- Operate and maintain the power tool as recommended in these instructions, to prevent an unnecessary increase in vibration;

- Select, maintain and replace the consumable/inserted tool as recommended in these instructions, to prevent an unnecessary increase in vibration levels;

- Support the weight of the tool in a stand, tensioner or balancer, because the operator can then use a lighter grip to support the tool.

- Hold the tool with a light but safe grip taking account of the required hand reaction forces, because the risk from vibration is generally greater when the grip force is higher.

7.2.3 ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC POWER TOOLS – AIR SUPPLY & CONNECTION HAZARDS

- Air under pressure can cause severe injury.

- Never direct air at yourself or anyone else.

- Whipping hoses can cause severe injury. Always check for damaged or loose hoses and fittings.

- Whenever universal twist couplings (claw couplings) are used, lock pins must be installed.

- Do not exceed the maximum air pressure stated on the tool.

- Use whip check safety cables to safeguard against possible hose to tool and hose to hose connection failure.

- Never carry an air tool by the hose.

Important Warnings – Impacts

- Eye protection and hearing protection and safety gloves must always be worn when operating an impact wrench or impact driver.

- When using heavy impact sockets or sockets on impact wrenches with 3/4” drive anvils or larger, a socket retaining ring and pin should be used to prevent the socket falling off and causing injury.

- Use only impact sockets and accessories. Only use sockets designated “FOR USE WITH IMPACT WRENCHES”, hand tool damage and replace when necessary.Accessory Hazards

- Disconnect the assembly power tool for threaded fasteners from the energy supply before changing the inserted tool or accessory.

- Do not touch sockets or accessories during impacting as this increases the risk of cuts, burns or vibration injuries.

- Use only sizes and types of accessories and consumables that are recommended by the assembly power tool for threaded fasteners manufacturer; do not use other types or sizes of accessories and consumables.

WARNING:This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or . other reproductive harm.For more information go to www.P65Warnings.ca.gov

SPECIFICATIONS

|

Model No. |

Free Speed(RPM) |

BoltCapacity(in.) |

Square Drive(in.) |

ImpactsPer Minute |

Max. Torque(ft-lb)@90 psi |

Weight(lbs.) |

Length(in) |

Air Cons.(CFM) |

Rec. HoseSize(in.) |

Air Inlet(in.)NPT/BSP |

|

1993-VXL |

6000 |

1-1/4 |

1 x 7 |

950 |

2100 |

20.2 |

18.7 |

10 |

1/2 |

1/2 |

| 1993-1-VXL | 6000 | 1-1/4 | 1 | 950 | 2100 | 18.5 | 13.4 | 10 |

1/2 |

1/2 |

Tools of this class operate on a wide range of air pressure. It is recommended that air pressure of these tools measures 90 PSI at the tool while running free. Higher pressure and unclean air will shorten the tool’s life because of faster wear and may create a hazardous condition and void the warranty. Water in the air line will cause damage to the tool. Drain the air tank daily. Clean the air inlet filter screen on at least a weekly schedule. The recommended hookup procedure can be viewed in the illustration below. The air inlet, used for connecting air supply, has standard 1/4” NPT/BSP Thread. Line pressure should be increased to compensate for unusually long air hoses (over 25 feet). Minimum hose diameter should be 1/2” I.D. and Sittings should have the same inside dimensions.

Operating Instructions

This impact wrench should never be used to set torque. Use a torque wrench to set the torque.To remove nuts, set the regulator to the maximum setting. To install nuts, set the regulator to the minimum to medium setting. Do not over tighten the nuts.Warning: Never trigger the tool when not applied to a work object. Attachments such as torque socket bars or extensions will reduce the life of the tool, however, if used, they must be securely attached. Loose attachments can cause serious injury.

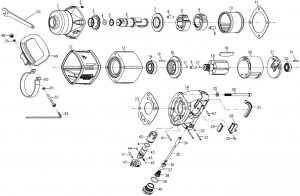

MODEL: 1993-1-VXL 1″ COMPOSITE STRAIGHT IMPACT WRENCH 1993-VXL (6″)Exploded View & Parts List

| Ref No. |

Part No. |

Description |

Qty |

Ref No |

Part No. |

Description |

Qty |

Ref No |

Part No. |

Description |

Qty |

|

1 |

2826Q-002 |

Hmmer Case |

1 |

19 |

2824-008 |

Rotor Blade |

6 |

38 |

315S-029 |

Spring |

1 |

|

2 |

00-4303 |

Helicoil |

4 |

20 |

2826Q-006 |

Cylinder |

1 |

39 |

00-4188 |

O-Ring |

1 |

|

3 |

2824-010 |

Anvil Bushing |

1 |

21 |

2826Q-009 |

Rear End Plate |

1 |

40 |

315F-025A |

Air Inlet |

1 |

|

4 |

00-4124 |

O-Ring |

2 |

22 |

00-2304A |

Ball Bearing |

1 |

40 |

315F-025B |

Air Inlet |

1 |

|

5 |

310-038 |

Anvil Collar |

1 |

23 |

2826Q-032 |

Rear Gasket |

1 |

40 |

315F-025C |

Air Inlet |

1 |

|

6 |

2824-011A8 |

Anvil |

1 |

24 |

2826Q-004 |

Hand Frame |

1 |

41 |

00-3338 |

Spring Pin |

2 |

|

6 |

2824-011B8 |

6” Anvil |

1 |

25 |

00-1808 |

Spring Washer |

6 |

42 |

328-020 |

Reverse Valve Bushing |

1 |

|

7 |

2824-019 |

Hammer Cage Cover |

1 |

26 |

00-0158 |

Cap Screw |

4 |

43 |

315S-021 |

Reverse Valve |

1 |

|

8 |

2824-016 |

Hammer Pin |

3 |

27 |

00-3321 |

Spring Pin |

1 |

44 | 00-3307 | Spring Pin | 1 |

|

9 |

2824-017 |

Hammer |

2 |

28 |

315S-024 |

Inner Trigger |

1 |

45 |

322-023-B |

Spring |

1 |

|

10 |

2824-012 |

Hammer Cage |

1 |

29 |

315S-025 |

Trigger Rubber |

1 |

46 |

00-3802 |

Steel Ball |

1 |

|

11 |

2826Q-030 |

Front Gasket |

1 |

30 |

00-3312 |

Spring Pin |

1 |

47 |

315S-022 |

Reverse Knob |

1 |

|

12 |

2826Q-043 |

Housing Band |

1 |

31 |

315F-039 |

Rubber Protector |

1 |

48 |

00-2001 |

Lock Nut |

1 |

|

13 |

2826Q-001 |

Motor Housing |

1 |

32 |

00-3207 |

Snap Ring |

2 |

49 |

2824-026 |

D-Type Handle |

1 |

|

14 |

00-2301 |

Ball Bearing |

1 |

33 |

315S-034 |

Pin |

2 |

50 |

2824-024 |

Handle Clamper |

1 |

|

15 |

00-3330 |

Spring Pin |

2 |

34 |

315S-026 |

Valve Bushing |

1 |

51 |

00-0167 |

Cap Screw |

1 |

|

16 |

2826Q-005 |

Front End Plate |

1 |

35 |

315S-027 |

Valve Stem (Inner) |

1 |

52 |

00-3909 |

6 mm Hex. Wrench |

1 |

|

17 |

00-3823 |

Steel Ball |

2 |

36 |

568-026 |

Bushing |

1 |

53 |

531-031 |

Spanner |

1 |

|

18 |

2824-007 |

Rotor |

1 |

37 |

00-3809 |

Steel Ball |

1 |

AIRCAT WARRANTY

AIRCAT VIBROTHERM DRIVETM impact wrenches are warranted to be free from defects in material and workmanship for 3 years from date of purchase. We will repair or replace; at our option any defective part or unit which proves to be defective in material or workmanship during this 3 year period. The foregoing obligation is AIRCAT and Florida Pneumatic’s sole liability under this or any implied warranty, under no circumstances shall it be liable for any incidental or consequential damages.

This warranty applies to the tool only. The warranty does not apply to any attached accessories/consumable products; such as drill chucks, sander backing pads, air hammer retainers and chisels or “kit” accessories or any other accessory included with the tool.

Any repair required due to normal wear and tear, abuse, misuse, modification of the tool or repair attempts (by other than an AIRCAT or Florida Pneumatic Authorized Service Center) are not covered by this warranty.

Return your tool to an AIRCAT or Florida Pneumatic Authorized Service Center freight prepaid. Be sure to include your name, address, copy of purchase with date and description of the suspected defect.

AIRCAT whose policy is continued product improvement reserves the right to make changes in design or construction at any time without incurring any obligation on tools previously sold.

Tune-Up and Head Kits for all AIRCAT PNEUMATIC impact wrenches and ratchets are available.For Authorized Service Centers, please visit www.aircat.com/warranty-service

SERVICE CENTER LISTINGS ENCLOSED

References

[xyz-ips snippet=”download-snippet”]