AMPROBE Voltage Continuity Tester VolTect Non-contact Voltage Detection User Manual

VPC-12Voltage & Continuity Testerwith VolTect™ Non-contact Voltage Detection

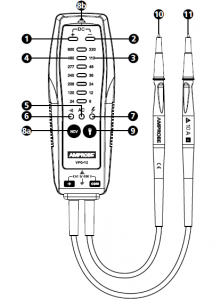

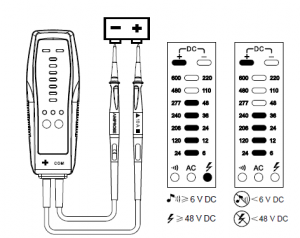

- Positive DC voltage LED indicator

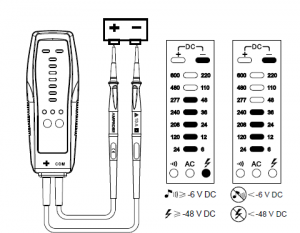

- Negative DC voltage LED indicator

- DC voltage range

- AC voltage range

- AC voltage LED indicator

- Continuity LED indicator

- Hazardous voltage LED indicator VPC-12 Voltage & Continuity Tester with VolTect™ Non-contact Voltage Detection

- a Non-Contact voltage detection button8b Voltect(TM) Non-Contact Voltage Sensor

- Flashlight button

- Measuring probe (COM)

- Measuring probe (+)

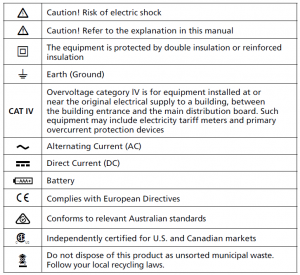

SYMBOLS

SAFETY INFORMATION

The meter complies with:IEC/EN 61010-1 3rd Edition, UL61010-1 3rd Ed., CAN/CSA C22.2 No. 61010-1- 12 + CAN/CSA C22.2 No. 61010-2-033 to CAT IV 600 V, pollution degree 2.IEC/EN 61010-2-033 IEC/EN 61010-2-31 for test leads EMC IEC/EN 61326-1

This product has been tested to the requirements of CAN/CSA-C22.2No. 61010-1-12 third edition, or a later version of the same standard incorporating the same level of testing requirements

CENELEC Directives

The instruments conform to CENELEC Low-voltage directive 2014/35/EU and Electromagnetic compatibility directive 2014/30/EU

Warning

Warning

- To prevent possible electrical shock, fire, or personal injury:

- Carefully read all instructions. Read safety information before using or servicing the tester.

- Comply with local and national safety codes. Use personal protective equipment (approved rubber gloves, face protection, and flame retardant clothing) to prevent shock and arc blast injury where hazardous live conductors are exposed.

- In CAT III or CAT IV environments, use the test probes with the probe cap on. This decreases the exposed probe tip to reduce the possibility of arc flash from short circuits. When the probe cap off, the probe tip is 18 mm and rated to 1000V CAT II.

- Use the product only as specified, or the protection supplied by the product can be compromised.

- Do not work alone.

- Do not use the tester or test leads if they appear damaged. Examine the instrument and test leads for damaged insulation or exposed metal. Check test lead continuity.

- Do not touch voltages >30 V AC rms, 42 V AC peak, or 60 V DC. These voltages pose electrical shock hazards. Keep fingers behind the finger guard on the probe.

- To avoid false readings, which could lead to possible electric shock or personal injury, check the battery and verify operation on a known source prior to measuring hazardous voltages (voltages above 30 V AC rms, 42 V AC peak and 60 V DC).

- indicates hazardous voltage present if the LED turns on.

- Do not exceed the measurement category (CAT) rating of the lowest rated individual component of a product, probe, or accessory.

- If the tester is used in a manner not specified in the user manual, the protection provided by the equipment may be impaired.

- Measurements can be adversely affected by impedances of additional operating circuits connected in parallel or by transient currents.

- Disconnect the test leads from energized circuits and from the tester before replacing the battery.

- Do not use the tester with battery door removed.

- Do not use the instrument around explosive gas, vapor, or in damp or wet environments.

- For indoor use only.

UNPACKING AND INSPECTION

Your shipping carton should include:1 VPC-12 Voltage & Continuity tester with VolTect™ non-contact voltage detection3 Batteries 1.5V IEC LR03 AAA1 User manual If any of the items are damaged or missing, return the complete package to the place of purchase for an exchange.

FEATURES

The Amprobe VPC-12 voltage and continuity tester is designed to be rugged and easy to use for testing voltage and continuity. It offers seven differentvoltage indicators clearly differentiating between key voltage levels and a buzzer alert indicating the presence of dangerous voltages and continuity.

- Check for voltage presence in receptacles, light fixtures or extension cords

- Test continuity of fuses, light bulbs and electrical connections

- Automatically selects AC voltage, DC voltage or continuity

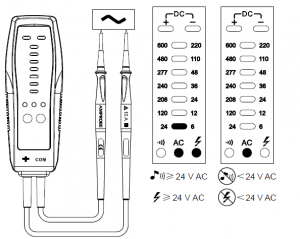

- LED lights indicate 7 levels of AC and DC voltages:– V AC: 24, 120, 208, 240, 277, 480, 600– V DC: 6, 12, 24, 36, 48,110, 220

- Full range polarity detection

- Continuity buzzer and visual continuity indication

- Built-in VolTect™ non-contact voltage detection and flashlight

OPERATING THE TESTER

Warning

Warning

- Do not use on a voltage source higher than AC 600 V and/or DC 600V between any terminal and earth ground.

- Connecting test lead.• Connect the common (COM) test lead to the circuit before connecting the live lead.• After measuring, remove live lead before removing the common (COM) test lead from the circuit.

- Test on a known live source within the rated AC/DC voltage range of the instrument, both before and after use to ensure the instrument is in good working condition.

- Indicates hazardous voltage levels if the LED turns on.

- Do not touch voltages >30 V AC rms, 42 V AC peak, or 60 V DC. These voltages pose electrical shock hazards. Keep fingers behind the finger guard on the probe.

Automatic Operation

The tester automatically turns on when you place the probes across a complete circuit. The tester selects AC or DC voltage or continuity mode based on the resistance or voltage between the probes. The tester automatically turns off when you remove the probes from the circuit being measured.

Voltage Measurement

Connect test leads across the source or load to be measured. The LEDs turn on at between 70% and 100% of their rated voltages.Note: The maximum testing voltage of this product is 600Vac/220Vdc. It will indicate 600Vac/220Vdc LED even if the testing voltage is greater than this limit. In this case, users should beware of electric shock, and operate with care or stop testing.

AC Voltage: 600V rms maximum, 50 to 60Hz

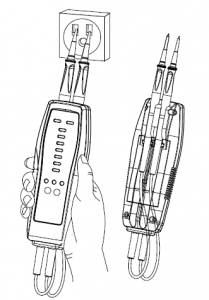

Figure 1: AC Voltage measurement

Figure 2: Check for voltage presence in electrical outlets

DC Voltage: 600V maximum

Figure 3: +DC voltage measurement

Figure 4: -DC voltage measurement

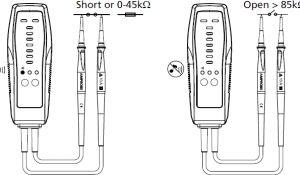

Continuity Testing

Disconnect circuit power and discharge all high-voltage capacitors before testing continuity. Short circuit=0-45kΩ

Figure 5: Continuity testing

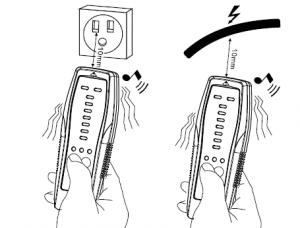

VolTect™ Non-contact Voltage Detection

Press and hold down “NCV” button while placing the tester near AC voltages within the specified voltage range. The tester will continually beepand vibrate while AC voltage is detected.

Figure 6: Checking for the presence of AC voltage

Flashlight

Press to turn on the flashlight. Press again to switch it off.

DETAILED SPECIFICATIONS

| LED voltage range | 24…600 VAC

6…220 VDC |

| LED indicator | AC volts: 24 V, 120 V, 208 V, 240 V, 277 V, 480 V, 600 V

DC volts: 6 V, 12 V, 24 V, 36 V, 48 V, 110 V, 220 V |

| Frequency range | 50 to 60 Hz |

| Acoustic and vibration indication | ³ 24 VAC, ³ 6 VDC |

| Tolerances LEDs | -30% to 0% of reading |

| Voltage detection | Automatic |

| Range detection | Automatic |

| Hazardous voltage indication | ³ 24 V AC, ³ 48 V DC |

| Polarity detection | Full range |

| Continuity range | 0 – 45 kW |

| Continuity tolerances | 0% to +50% |

| Continuity buzzer | 3 kHz |

| Continuity indication | LED, buzzer and vibration 0 – 45 kW ON; >85 kW OFF |

| VolTect™ non-contact voltage detection | 90 – 600 VAC

Sensitivity: beeps and vibrates £ 10 mm (0.39 in) distance from a wire carrying 100 VAC. |

| Flashlight | Yes |

| Input impedance | 1 MW |

| Operating time | 30 seconds ON maximum and wait for 5 minutes before making another measurement |

| Operating altitude | Up to 2000 m / 6561 feet |

| Operating temperature | 41OF to 122OF / 5OC to 50OC |

| Storage conditions | -22OF to 140OF / -30OC to 60OC |

| Humidity

(without condensation) |

£ 80% RH at 41OF to 104OF / 5OC to 40OC;

£ 50% RH at 104OF to 122OF / 40OC to 50OC |

| Pollution degree | 2 |

| Power supply | Three 1.5 V batteries, AAA, LR03, UM4 |

| Battery life | 40 hours (alkaline) (typical) |

| Dimensions (H x W x D) | 5.90 x 2.13 x 1.34 in

150 x 54 x 34 mm |

| Weight | Approximately 0.45 lb (205 g) with batteries installed |

|

Electrical safety |

CAN/CSA-C22.2 No. 61010-1-12, UL Std. No. 61010-

1 (3rd Edition), CAN/CSA-C22.2 No. 61010-031-07,UL 61010-031 (1st Edition – 2007), CAN/CSA-C22.2 No. 61010-2-030-12, UL 61010-2- 030(1st Edition -2012) |

| Overvoltage category | CAT IV 600 V |

| EMC | Conforms to IEC 61326-1 |

| Agency approvals | ) P |

MAINTENANCE

Caution – To prevent damage to the VPC-12:

- Do not attempt to repair or service the VPC-12 unless qualified to do so.

- Make sure that the relevant calibration, performance tests, and service information is being utilized.

- Do not use abrasives or solvents.

Cleaning

The only maintenance the VPC-12 requires is inspection and cleaning. Periodically wipe the case with a mild solution of detergent and water. Apply sparingly with a soft cloth and allow time to dry completely before using. Do not use aromatic hydrocarbons, gasoline or chlorinated solvents for cleaning.

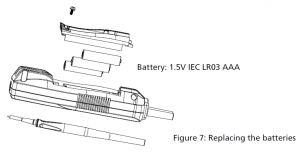

Replacing the Battery

Replace the batteries immediately if the continuity LED doesn’t turn on when touching both probes together.

Warning

Warning

- To avoid electric shock, disconnect the test leads from the source before opening the VPC-12 for battery replacement.

- To avoid false readings, which could lead to possible electric shock or personal injury, replace the battery as soon as the battery is low or dead.

The VPC-12 uses three 1.5V batteries. To replace the batteries, follow thesesteps and refer to Figure 7:

- Disconnect test leads from any power source.

- Place the VPC-12 face down on a non-abrasive surface and loosen the battery-door screw with a Phillips screwdriver.

- Lift the battery cover away from the VPC-12.

- Replace the battery as shown in Figure 7. Observe the battery polarity shown in the battery compartment.

- Secure the battery cover back in position with the screw.

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for one year from the date of purchase unless local laws require otherwise. This warranty does not cover fuses,disposable batteries or damage from accident, neglect, misuse, alteration, contamination, or abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on the behalf of Amprobe. To obtain service during the warranty period, return the product with proof of purchase to an authorized Amprobe Service Center or to an Amprobedealer or distributor. See Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY. ALL OTHER WARRANTIES – WHETHER EXPRESS, IMPLIED OR STATUTORY – INCLUDING IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you.

Repair

All Amprobe tools returned for warranty or non-warranty repair or for calibration should be accompanied by the following: your name, company’s name, address, telephone number, andproof of purchase. Additionally, please include a brief description of the problem or the service requested and include the test leads with the meter. Non-warranty repair or replacementcharges should be remitted in the form of a check, a money order, credit card with expiration date, or a purchase order made payable to Amprobe.

In-warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During the warranty period, any defective test tool can be returned to your Amprobe distributor for anexchange for the same or like product. Please check the “Where to Buy” section on amprobe.com for a list of distributors near you. Additionally, in the United States and Canada,in-warranty repair and replacement units can also be sent to an Amprobe Service Center (see address below).

Non-warranty Repairs and Replacement – United States and Canada

Non-warranty repairs in the United States and Canada should be sent to an Amprobe ServiceCenter. Call Amprobe or inquire at your point of purchase for current repair and replacement rates.USA: Canada:Amprobe AmprobeEverett, WA 98203 Mississauga, ON L4Z 1X9Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe distributor for a nominalcharge. Please check the “Where to Buy” section on beha-amprobe.com for a list ofdistributors near you.

Beha-Amprobe*In den Engematten 1479286 Glottertal, GermanyTel.: +49 (0) 7684 8009 – 0beha-amprobe.com*(Correspondence only – no repair or replacement available from this address. European customers pleasecontact your distributor.)

Read More About This Manual & Download PDF:

References

[xyz-ips snippet=”download-snippet”]

Warning

Warning