AQUAPANEL Cement Board Floor Tile Underlay

The ideal substrate for tiles on a wooden subfloor

Benefits

- Thickness of only 6mm allowing for increased room height

- Can be installed over existing wooden subfl oors

- Will not deteriorate in water

- Resistant to mould and mildew

- Easy to score and snap

- No pre-drilling required

- Only 9 screws per board necessary

Your big helper in fl oor renovation projectsClassy kitchen fl oors with large-size natural stone tiles or comprehensive bathroom refurbishments can also be done on old wooden subfloors. Knauf AQUAPANEL® Cement Board Floor Tile Underlay is a light, highly stable dry floor panel, perfectly suited for ceramic, mosaic or natural stone. As part of the Knauf AQUAPANEL® Cement Board range, it is resistant to water or mildew and thus an ideal solution for wet and humid areas. With a thickness of only 6mm, it makes low floor heights possible as well.

Solid substrate for your new fl oor

Set-up for floor tiling in a system overview

Application table – timber or steel joists

| Application table – timber or steel joists | |||

| Minimum subfloor thickness | |||

| Joist centres | 400 mm | 600 mm | 800 mm |

| OSB 3 subfloor thickness acc. to EN 300 | 18 mm | 18 mm | 22 mm |

| Chipboard cat. P5 subfloor thickness acc. to EN 312 | 19 mm | 22 mm | − |

Deflection limits: L/300 bearing wooden/steel framework L/400 wooden subfloor (OSB or chipboard)Minimum subfloor thickness dependent on centre distance of wooden joists.

Specifications of Knauf AQUAPANEL® Cement Board Floor Tile Underlay

| Length (mm) | 1200 |

| Width (mm) | 900 |

| Thickness (mm) | 6.0 |

| Weight per unit area (kg/m²) | approx. 8.5 |

| Dry density (kg/m³) | approx. 1250 |

| Building material class according to EN 13501 | A1 non-combustible |

System components

One system that works perfectly From board to fitting accessories

With Knauf AQUAPANEL® Cement Board Floor Tile Underlay you have a complete system solution for your tiling project. You benefit from one-stop shopping and an ensured compatibility of all components and accessories. When working with wooden subfl oors we recommend our system screws for fixing boards on timber, as well as our KnaufAQUAPANEL® Tape (100mm) to effectively reinforce all floor joints.

Knauf AQUAPANEL® Cement Board Floor Tile Underlay

- Aggregated Portland cement board

- Coated glass fibre mesh embedded in back and front surfaces

- Square cut ends with reinforced and smoothly finished edges (EasyEdge™).

Knauf AQUAPANEL® Maxi Screw SN 25

- Specially suited for fixing boards onto wooden subfloors.

- Special corrosion-proof coating.

Knauf AQUAPANEL® Tape (100mm)

- Glass fabric joint tape with alkaline-resistant coating

- Used to reinforce joints in fl oors and walls in interior areas

- Coverage of approx. 2.1m/m²

- Width: 100 mm, Length: 20m

Floor installation

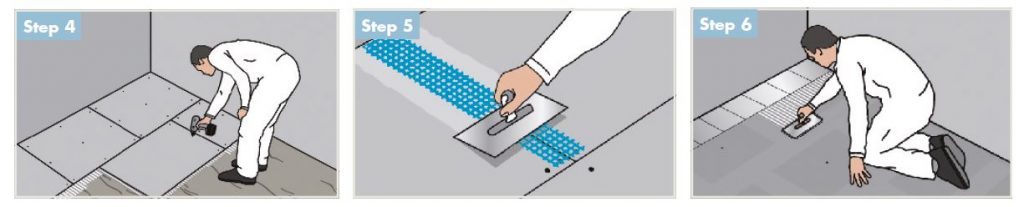

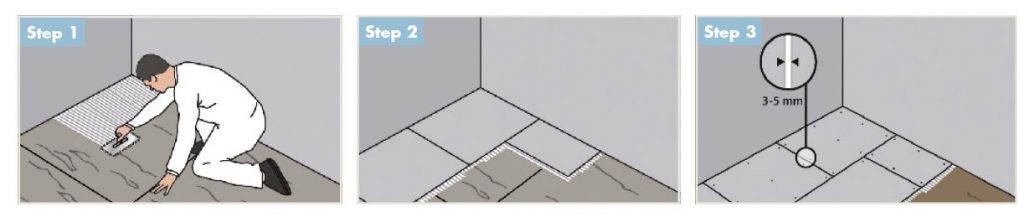

Six easy steps to installation

- Apply a complete bed of flexible tile adhesive (class C2/S1 acc. EN 12004 /12002) to the subfloor, in accordance with manufacturer’s guidelines. Wooden subfloor must be primed before applying Knauf AQUAPANEL® Cement Board Floor Tile Underlay.

- Lay Knauf AQUAPANEL® Cement Board Floor Tile Underlay, starting in the corner farthest from the door. Joints between boards and the subfloor should be staggered (minimum 200mm). No two joints should coincide.

- Leave a gap of 3–5mm between each board and screw Knauf AQUAPANEL® Cement Board Floor Tile Underlay to the subfloor using Knauf AQUAPANEL® Maxi Screws SN 25.

- Nine screws per board evenly distributed with a minimum distance from the board edge of 15mm.

- Fill all the joints with flexible tile adhesive (class C2/S1 acc. EN 12004/12002), then embed Knauf AQUAPANEL® Tape (10cm). Allow for the adhesive in the joints to dry.

- Ready to lay tiles: apply a complete bed of flexible tile adhesive (class C2/S1 acc. EN 12004/12002), in accordance with manufacturer’s guidelines.

[xyz-ips snippet=”download-snippet”]