Aquascape ULTRA Water Pump Instruction Manual

Thank you for choosing the Aquascape Ultra™ Water Pump. At Aquascape, our goal is to supply our customers with the best valued products in water gardening. We hope you enjoy your purchase and thank you for choosing Aquascape.Your Paradise. Our Passion.®

Introduction

Aquascape Ultra™ Water Pumps are the complete solution for small ponds, fountains and water features. These alliin-one kits include a single or three-way flow control valve, multi-hose adapter(s) and a threaded 900 elbow connection, making it adaptable to almost any hose or application. Ultra™ Water Pumps are ideal for supplying water to run fountains, water features, external filters and spitting ornaments. The combination of energy-efficient mag-drive performance, flow and ease of maintenance makes this pump the ideal choice for discriminating water feature owners.

Contact UsFor more information about our company or products, please visit our website at aquascapeinc.com or call (US) 1-866-877-6637 (CAN) 1-866-766-3426.Find us on:

![]()

facebook.com/AquascapeIncyoutube.com/Aquascape4twitter.com/AquascapeInchttp://flip.it/xypDUd

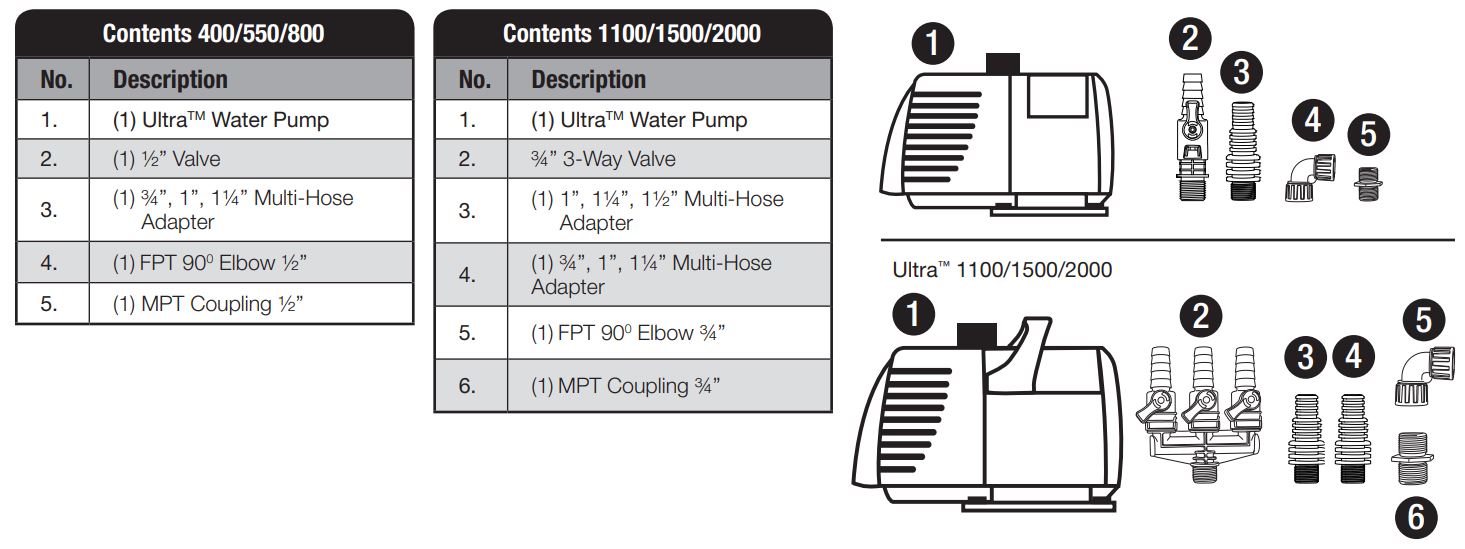

Contents

Helpful Symbols

![]() WARNING Symbol – Will alert you to the possibility of damage or injury if you do not comply with the warnings that accompany them. The hazard may come from something mechanical or from electrical shock.

WARNING Symbol – Will alert you to the possibility of damage or injury if you do not comply with the warnings that accompany them. The hazard may come from something mechanical or from electrical shock.

![]()

![]()

Safety Information

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

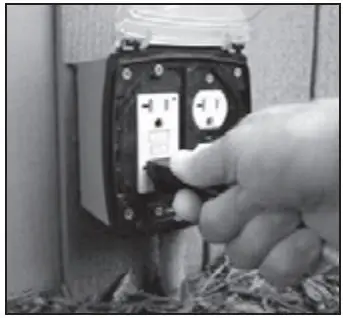

- (A) Have a qualified electrician install a properly grounded receptacle outlet, acceptable for outdoor use and protected from snow and rain.

- (B) Inspect cord before using.

- (C) Do not use extension cords.

- (D) Any wiring of pumps should be performed by a qualified electrician to ensure code compliance and user safety.

- (E) Unplug pump at receptacle outlet when not in use or before removal from pond.

- (F) To reduce risk of electrical shock, all wiring and junction connections should be made per local codes. Requirements may vary depending on usage and location.

- (G) The power cable should be protected at all times to avoid punctures, cuts, bruises and abrasions.

- (H) Never handle power cords with wet hands.

- (I) Do not remove cord and strain relief. Do not connect conduit to pump.

- (J) Do not use power cable to lift pump.

Optional Accessories

Ultra™ Pump Fountain Head Kits Incorporate a fountain into your pond by adding an Ultra™ Pump Fountain Head Kit to your Ultra™ Water Pump. Each kit comes complete with three fountain head options: Winterfell, Foaming Jet and Daisy. Each kit also includes four 3.5″ extensions for customizable fountain height and an integrated diverter valve that allows you to easily divert water to an external filter, ornamental spatter or waterfall.

Item #91045 is compatible with 400/550/800 Water Pumps. Item # 91046 is compatible with 1100/1500/2000 Water Pumps.

Item #91045Item #91046

Installation

- Always operate the pump fully submerged. Failure to do so will overheat the pump and cause it to fail, thus voiding the warranty. DO NOT OPERATE DRY!

- Use only in fully-assembled state, paying particular attention to be sure that both the filter screen and sponge are attached to the pump. Failure to operate the pump without the filter screen or pre-filter sponge will allow large debris to enter the pump, causing the pump to fail and voiding the warranty.

- Do not wear loose clothing that may become entangled in the impeller or other moving parts.

- Keep clear of suction and discharge openings. DO NOT insert fingers into pump with power connected.

- Do not pump hazardous materials or liquids other than water, such as oil or organic solvents.

- Do not block or restrict discharge.

- Products returned must be cleaned, sanitized or decontaminated, as necessary, prior to shipment to ensure that employees will not be exposed to health hazards in handling said material. All applicable laws and regulations shall apply.

![]()

![]()

![]()

![]()

![]()

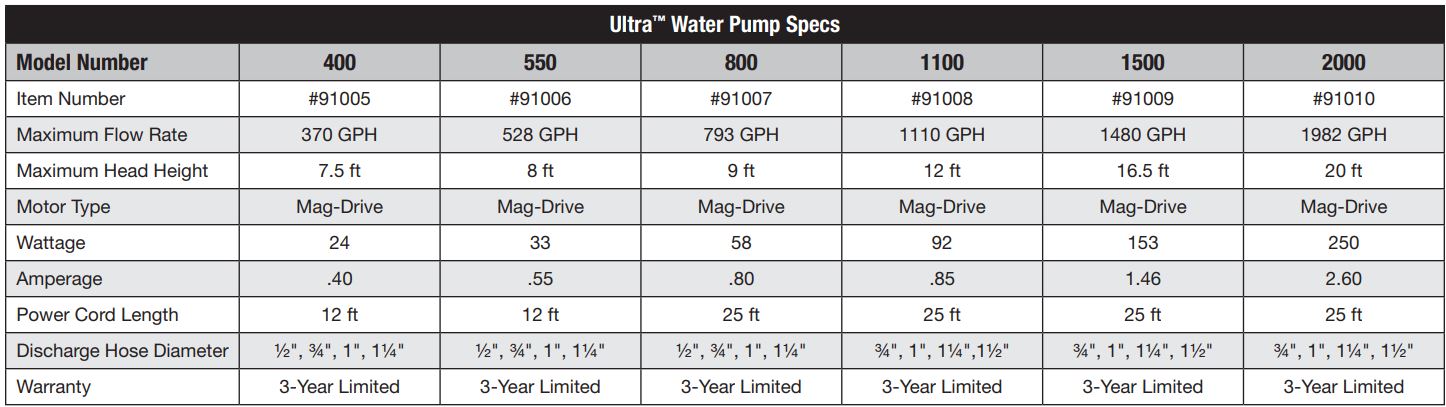

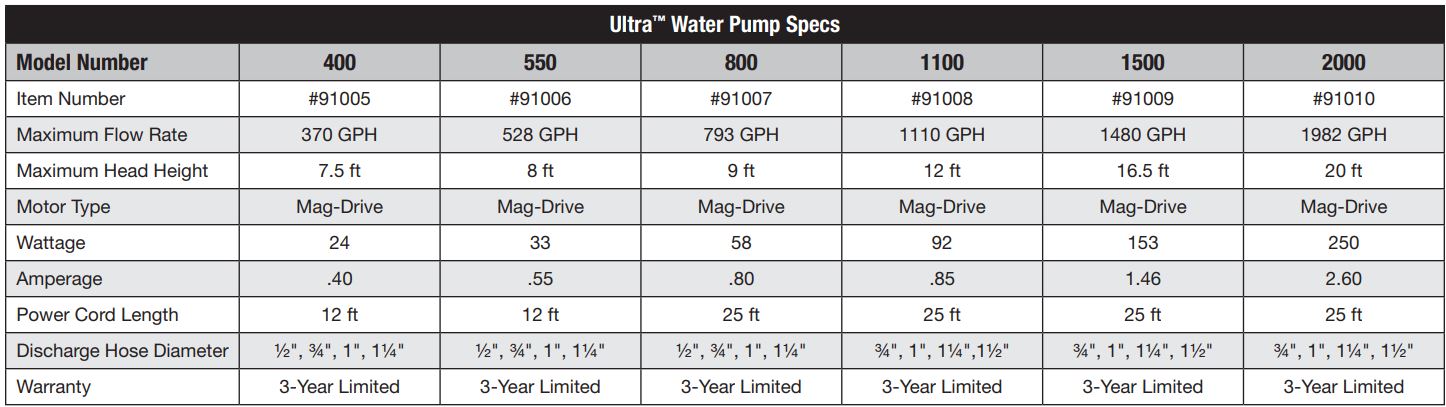

Ultra™ Water Pump Specifications

- Input Voltage: 120V AC

- Input Frequency: 60 Hz

- Submersible pump

- For outdoor or indoor use

- Thermally protected

- This pump has been evaluated for use with water only

- Input Amps & Wattage: See chart below

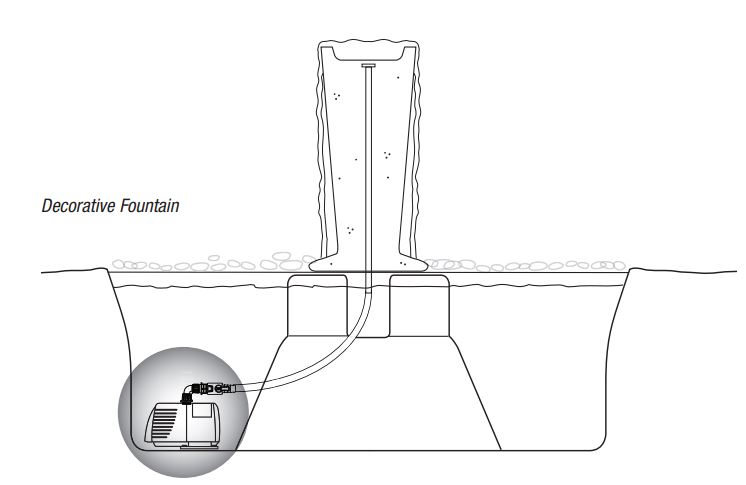

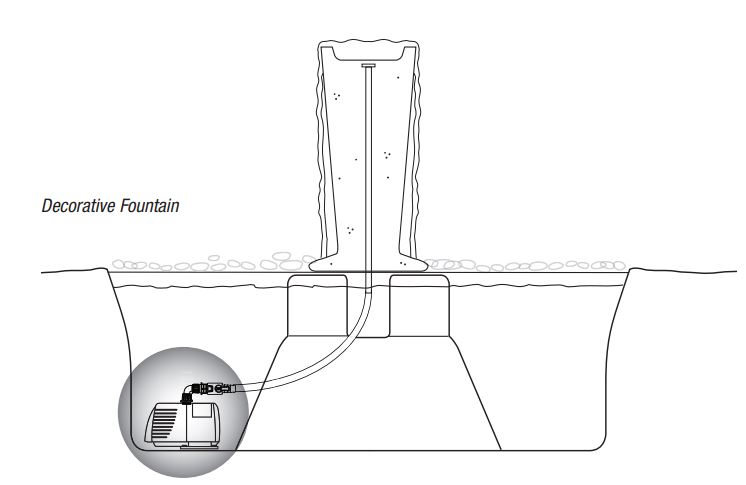

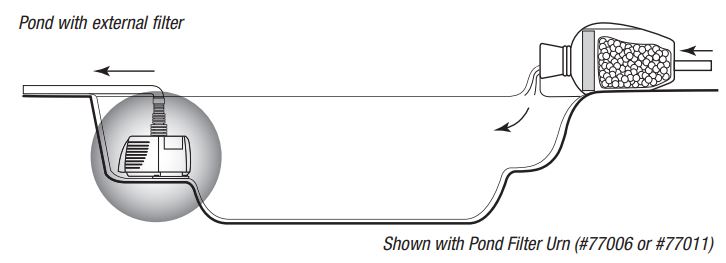

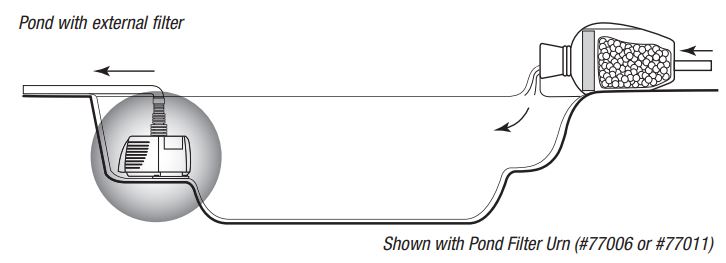

Typical Installation in a Decorative Fountain or Pond

- The Ultra™ Water Pump is designed to be submerged directly into a decorative fountain basin or pond. Several features and benefits of this pump make it the ideal choice for a wide variety of water feature applications.

- To maximize pond circulation, locate the pump as far away as possible from the location of the water entering back into the water feature.

- It is recommended that the pump NOT be positioned in the deepest area of the pond. This will protect the fish by preventing the pond from completely draining in the case of a leak in the plumbing or filter. If needed, bricks or stones can be used to raise the pump off the bottom of the pond.

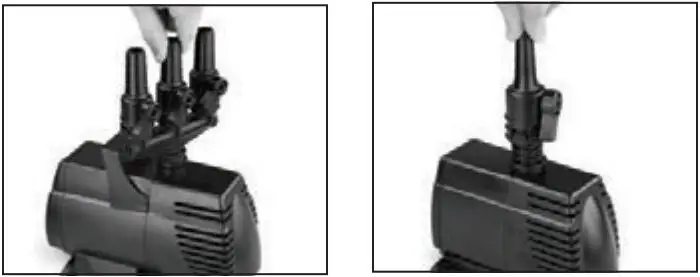

- The Ultra™ Water Pump includes an assortment of fittings for a wide variety of plumbing options. Select and install the appropriate fitting(s) for your application.

- The included Multi-Hose Adapter(s) is (are) designed to accommodate different diameters of tubing and ideal for applications using a single plumbing line.

- The Multi-Hose Adapter can be threaded directly into the discharge of the pump.

- The convenient included 1/2″ Valve (400/550/800) or 3/4″ 3-Way Valve (1100/1500/2000) provide the ability to customize flow rates.

- If using a diameter of pipe that is larger than the smallest section of the Multi-Hose Adapter, trim off the smaller sections to prevent flow restriction.

- The included threaded FPT 90° elbow allows the water flow to be directed horizontally, perfect for fountain basin applications where vertical space is limited.

- To install the elbow, attach the included MPT Coupling to the discharge of the pump. Then thread the collared elbow fitting to the MPT Coupling to attach it to the pump.

- The collared connections allow the pump to be quickly and easily disconnected from the tubing for pump removal or maintenance.

- The included flow control valve can be installed directly into the pump discharge or installed horizontally using the threaded FPT 90° elbow.

- Once installed, simply adjust the valve(s) to dial in the desired water flow.

- When using the 3-Way Valve, close off any unused valves to maximize water flow to the valves in use.

- Attach the tubing to the selected fitting(s) using a twisting motion. If the tubing fits loosely, a hose clamp (not included) can be used to secure the attachment.

- In some instances the tubing may be difficult to attach to the selected fitting. If this is the case, we recommend heating the hose with a hair dryer or simply dipping the hose in very hot water for a few seconds prior to attachment. Lubrication can also be used; we recommend silicone grease or olive oil.

- Connect the other end of the pump tubing to the decorative fountain or pond filter.

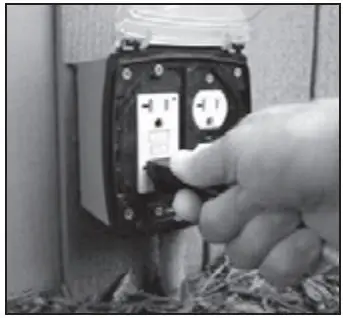

- Connect the pump to an outlet that is protected by a ground fault circuit interrupter (GFCI). Once the pump is running and water is circulating, check for leaks where the external connections are made.

Operation and Maintenance

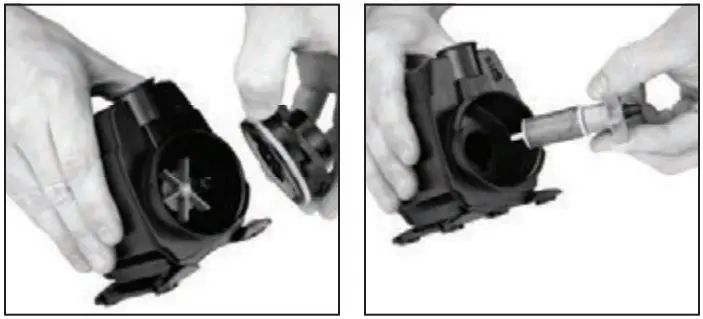

- Filter Screens – The outer screen is designed to pop off when it is gently pulled from either side. Do not remove while operating the pump. Operating the pump without the front cover or pre-filter sponge can allow large debris to enter the pump, causing the pump to fail, thus voiding the warranty.

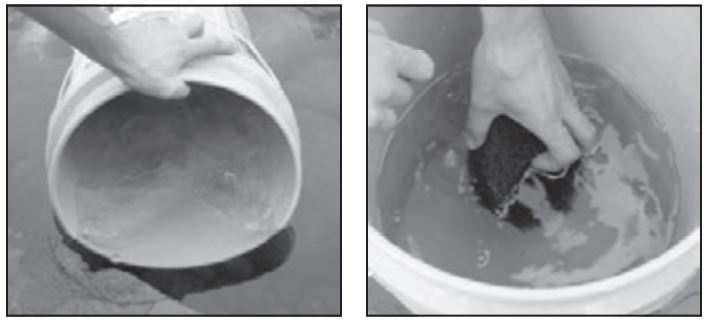

- Filter Screen Cleaning – We recommend inspecting your pump on a regular basis to make sure it is functioning properly. Always disconnect the power before performing maintenance on the pump. If you notice the water flow rate is diminished, it may be due to the filter screen or sponge becoming clogged with debris. In many cases the filter screen can be cleaned by reaching into the water and manually removing any debris from the filter screen by hand. If there is a lot of debris and/or the debris is difficult to clean, you may need to remove the pump from the pond or basin for a more thorough cleaning. A garden hose can be used to spray off any debris stuck on the filter screen. Be sure to re-attach the filter screen and pre-filter sponge, before lowering the pump back into the water.

- The pre-filter sponge is designed to protect the pump from fi ne particles, such as sand or other pond debris that could clog or damage the interior of the pump. Clean the filter sponge using a bucket of pond water or rinse clean using a garden hose.

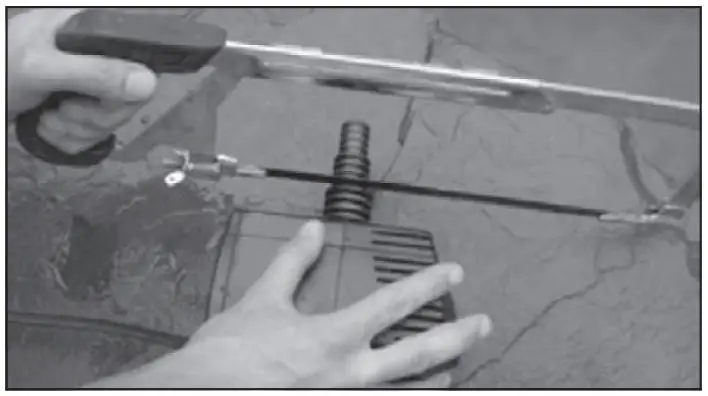

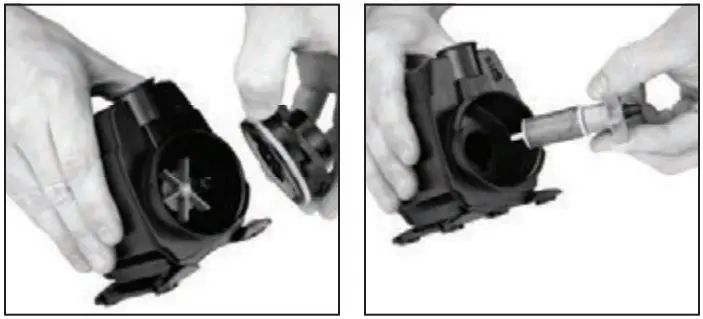

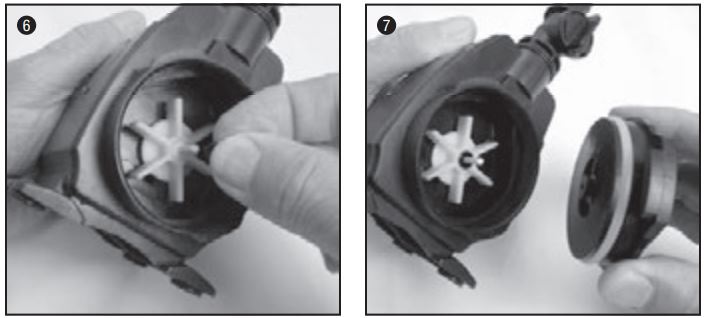

- Internal Pump Cleaning – If you have thoroughly cleaned the filter screen and still have diminished flow rates, you may need to clean the interior of the pump. Remove the water chamber cover by rotating it counterclockwise a 1/4 turn and pulling outward. This will expose the impeller assembly for closer inspection. Carefully remove the impeller from the pump, pulling outward until the impeller releases from the body of the pump. Be careful not to lose the two plastic bearing washers on either end of the impeller or the centering bushings that center the ceramic impeller shaft on both ends.

- If your rotor assembly impeller and internal pump body have excessive scale build-up, clean with a mild acid, such as white vinegar or non-abrasive calcium, lime and rust remover product. Use a sponge or soft-bristled brush that won’t scratch or damage the impeller or pump body. Removing scale build-up will allow your pump to run like new again.

Replacing the Impeller

- The impeller assembly is the only moving part on theUltra™ Water Pump and will experience wear and tear. If you’ve cleaned the pump, as described above, and still experience poor pump performance, it is most likely time to replace the impeller. Replacing the impeller is extremely easy. Replacement impeller kits are available through your local Aquascape dealer.

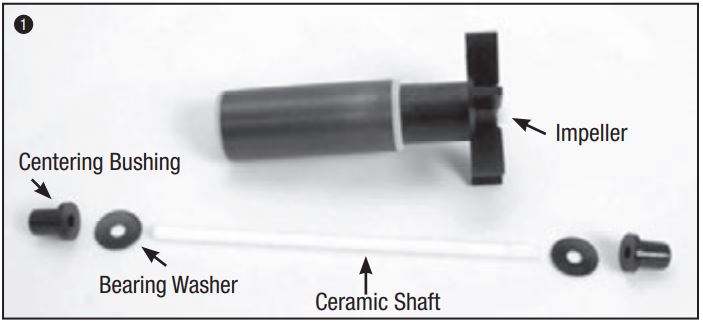

- Note the orientation of parts in the photo below. The replacement impeller kits include all parts shown. Make sure to remove all of the original parts from the inside of the pump before installing the replacement impeller kit.

- A centering bushing is required on both ends of the impeller shaft; one bushing is located inside the pump and an outer bushing sits in the water chamber cover.

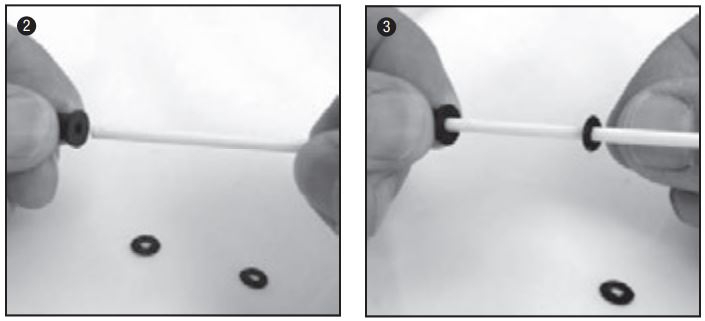

- Slide the first interior bearing washer onto the ceramic shaft.

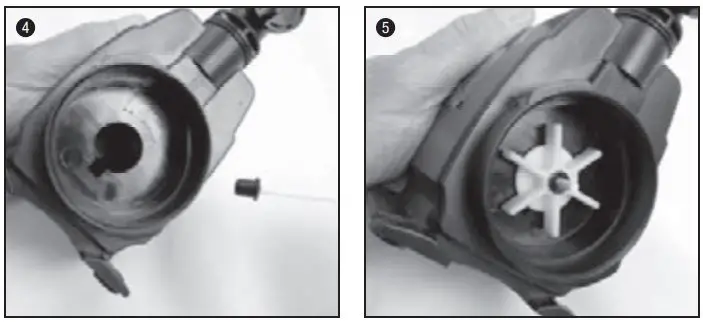

- Place the ceramic impeller shaft into the pump, checking to be sure the centering bushing seats inside the pump.

- Carefully slide the impeller back onto the shaft. Use caution: the impeller assembly is magnetic and will be pulled forcefully back into the pump.

- Install second outer bearing washer over the impeller shaft.

- Replace water chamber cover containing the impeller shaft centering bushing by sliding it over the impeller shaft and then rotating it clockwise to lock it into place over the tabs on the pump housing.

- Replace the pre-filter sponge and filter screen by snapping them back onto the pump housing.

- Winter Storage – If concerned about possible freeze damage, disconnect the pump and remove the pump from the water. Clean the pump with fresh water and store the pump in a frost-free location. The pump can be run during cold weather, if desired, but should be removed in the event of a power failure to prevent any freeze damage to either the pump or the tubing.

Troubleshooting

- Reduced Water Flow – It may be necessary to clean the filter screen, sponge and impeller.

- Pump Hums and Doesn’t Push Water– It may be necessary to clean the filter screen, sponge and impeller.– Remove the water chamber cover and inspect and clean the impeller rotor assembly and internal pump body. – Make sure nothing is blocking or wrapped around the impeller.– Make sure the pump is receiving the correct voltage.

- Pump Not Working – The ground-fault circuit-interrupter (GFCI) may have tripped.– The pump is not receiving the correct voltage.

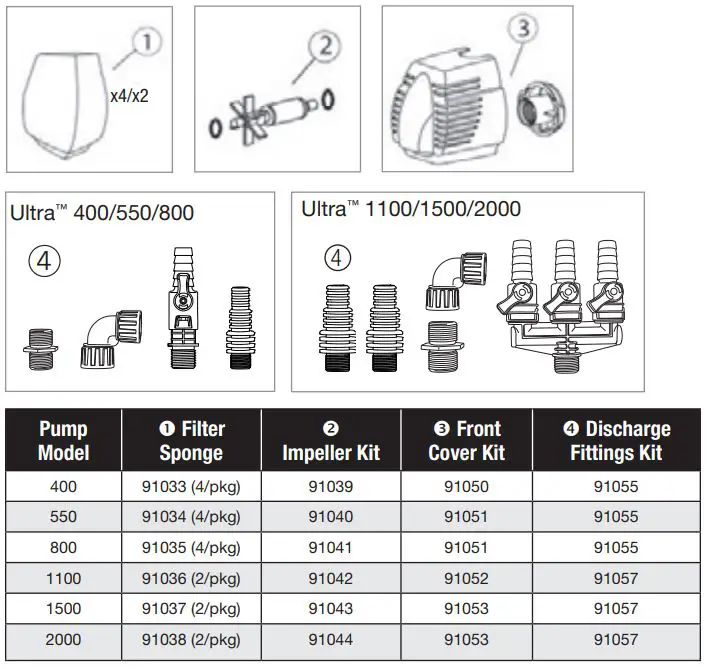

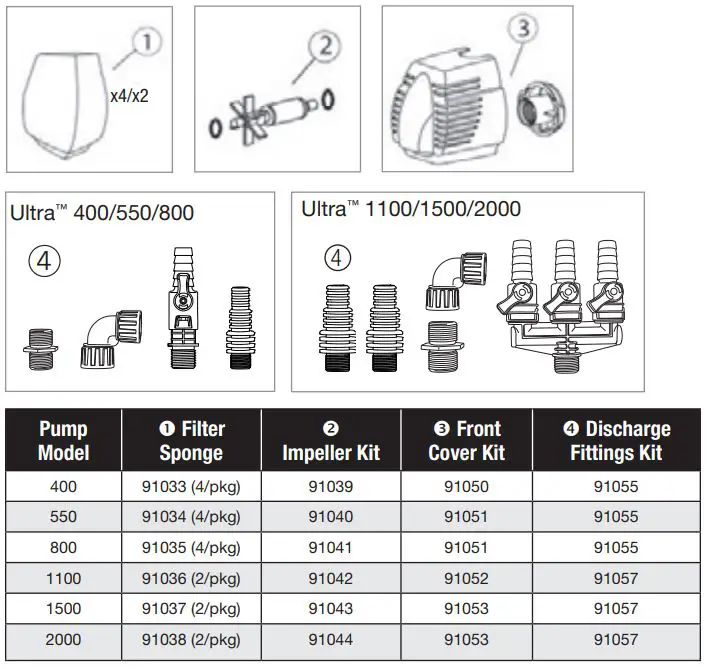

Replacement Parts

Warranty

3-YEAR WARRANTYThe Ultra™ Water Pump is guaranteed for three years from date of purchase. Proof of purchase required. Warranty does not cover damage resulting from negligent handling, misuse or lack of reasonable maintenance or care. Warranty is valid against defects due to material and the company’s workmanship only.The sole obligation shall be to replace the defective unit with a suitable replacement unit. Units should be checked for proper operation prior to returning as defective. No liability for loss or damage of any nature or kind, whether arising out of or from the use of the product, whether defective or not defective, is assumedby Aquascape, Inc. or its affiliates.

US 1-866-877-6637 | CAN 1-866-766-3426 | aquascapeinc.com

References

[xyz-ips snippet=”download-snippet”]