Arbors Kennedy, Freemont 12 x 12 Flat Top Pergola Kennedy

Introduc tion & O ver view

Getting Started

First off, allow us to say thank you for the investment you have made in one of our fine pergola kits. This kit is designed to be assembled and installed ideally by two people with basic carpentry knowledge and tools. Do not attempt alone, especially during the installation stage. Should you decide to moderately modify the dimensions of your pergola from the standard kit size, a circular saw with a sharp fine-tooth blade is all that is needed to cut, shorten or modify the vinyl components. When assembling components place on a non-abrasive surface (ie: shipping box) to avoid scratching. We recommend a 15’ x 15’area for unobstructed assembling. You should not need to use excessive force when assembling any components.

Planning & Preparing

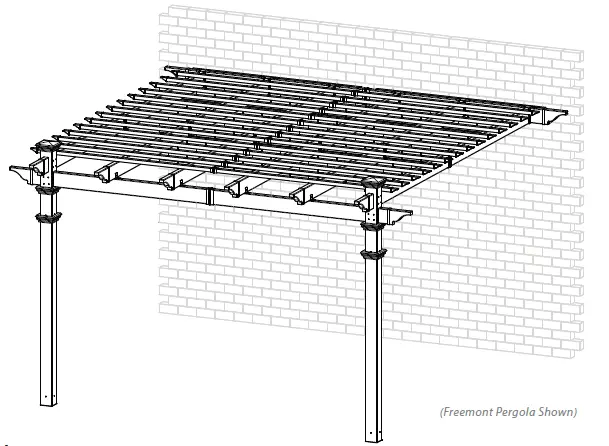

The Freeemont Pergola is designed to be attached to an existing structure such as your house. Please follow this instructions closely and plan ahead to avoid confusions and issues during installation.

What looks like the toughest part of this project is actually the easiest, the graceful, solid-looking columns. We’ve designed these columns to simply be slipped over treated 4×4 wood posts that are either embedded in concrete or directly mounted to a concrete or wood surface using our bolt down brackets. See pages 7, 8 and 9 for more details.

It is critical before you start that you consider the current slope of elevation where the pergola is planned – if there is any. Also utility or sprinkler line location is important to identify prior to excavating holes if necessary. You should also check to verify local building codes, ordinances, neighborhood covenants, or height restrictions regarding this type of structure

Restriction of Use

This product is not designed to carry additional weight loads such as swings, people or other objects.

Please take the time to read this instruction guide thoroughly prior to the construction of your pergola. If you have any questions, feel free to contact our technical dept by calling 1 800 282 9346 (Mon to Fri 8:00 A.M to 4:00 P.M. EST).

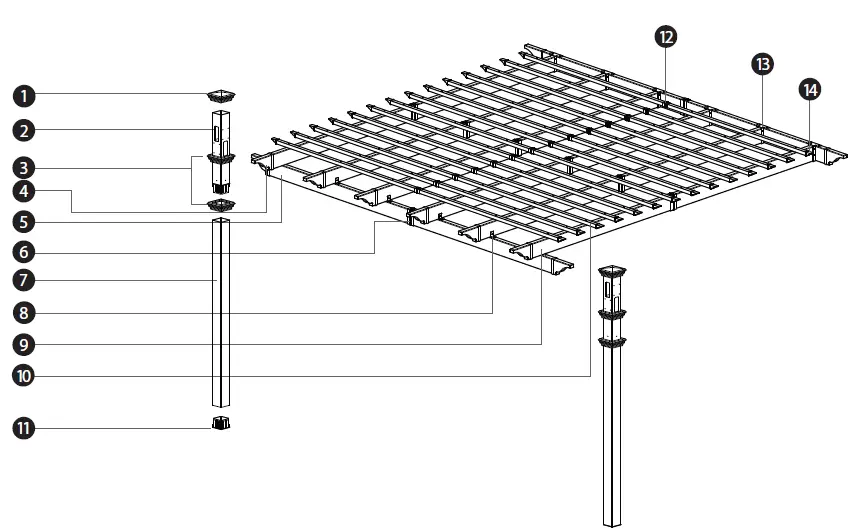

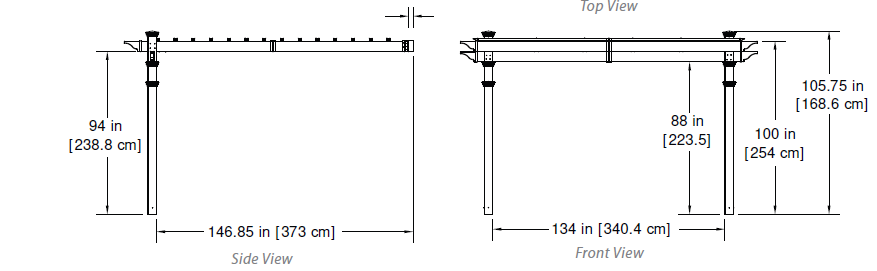

Freemont Pergola Materials Overview

- Post Caps (2) 10699-1 White / 14030 Composite

- Main Column Tops (2) 10826 White / 14025 Composite

- Post Trims (4) 10698-1 White / 14029 Composite

- Rafter & Beam Decorative End Caps (10) 10829 White / 14048 Composite

- Main Support Beams (4) 10817 White / 14033 Composite

- Beam & Rafter Joiners (8) 10820 White / 14026 Composite

- Main Column Bottoms (2) 10816 White / 14024 Composite

- Rafter Brackets (4) 10827 White / 14031 Composite

- Rafters (12) 10818 White / 14034 Composite

- Shade Slates (28) 10819 White / 14035 Composite

- One Way 4”x4” Internal Wood Post Guide (2) 10696-1 White / 14027 Composite

- Shade Slat Joiners (14)10600-1 White / 14028 Composite

- Rafter Hanger (6) 10828 White / 14082 Composite

- Shade Slat Decorative End Caps (28) 30030-1 White / 14032 Composite

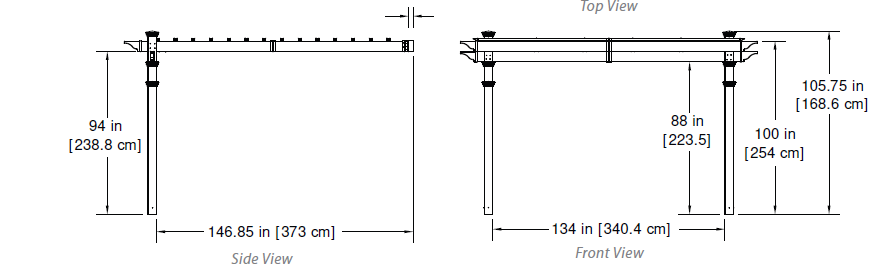

1.5 in [ 3.8 cm] Gap for 2×6 [ 50x150mm] Ledger board

1.5 in [ 3.8 cm] Gap for 2×6 [ 50x150mm] Ledger board

Freemont Pergola Materials Breakdown

Check Boxes (Total of 5) for These Contents

In the event of missing or defective parts please call our customer service dept. at 1 800 282 9346 (Mon. to Fri. 8:00 AM to 4:00 PM EST).(UK Tel: (44) 2038 687160 – Mon to Fri. 1:00 PM to 10:00 PM GMT).

- Post Caps (2) 10699-1 White / 14030 Composite

- Main Column Tops (2) 10826 White / 14025 Composite

- Post Trims (4) 10698-1 White / 14029 Composite

- Rafter & Beam Decorative End Caps (10) 10829 White / 14048 Composite

- Main Support Beams (4) 10817 White / 14033 Composite

- Beam & Rafter Joiners (8) 10820 White / 14026 Composite

- Main Column Bottoms (2) 10816 White / 14024 Composite

- Rafter Brackets (4) 10827 White / 14031 Composite

- Rafters (12) 10818 White / 14034 Composite

- Shade Slates (28) 10819 White / 14035 Composite

- One Way 4”x4” Internal Wood Post Guide (2) 10696-1 White / 14027 Composite

- Shade Slat Joiners (14)10600-1 White / 14028 Composite

- Rafter Hanger (6) 10828 White / 14082 Composite

- Shade Slat Decorative End Caps (28) 30030-1 White / 14032 Composite

Tools You Will Need

Tools You Will Need

- Level

- Hammer

- Tape Measure

- String Line

- Wood Stakes (4) (temporary support for string line)

- Step Ladders (2)

- Cordless Drill

Tools You May Need

- Circular Saw with Fine Tooth Blade

- Framing Square

Pergola Additional Materials List

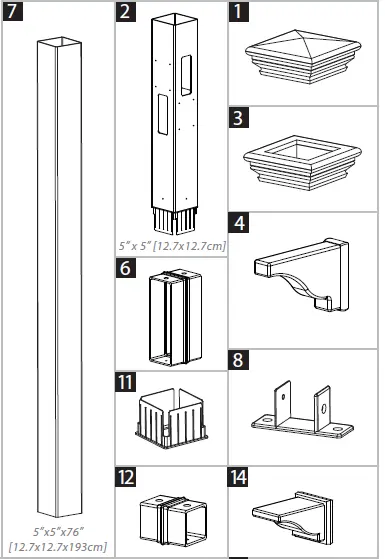

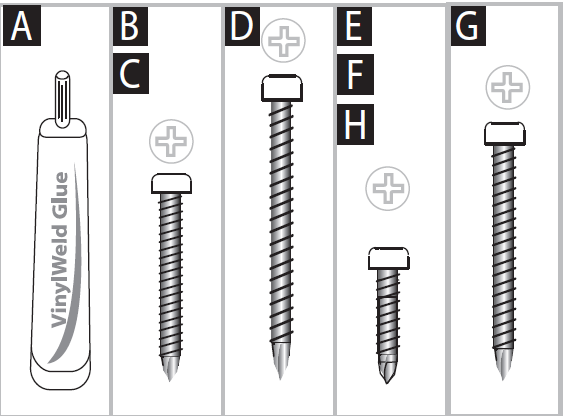

Hardware (in plastic bag)All Screws Included with this Kit are Self-Auguring.

- A/ Vinyl Weld Glue (3) – 20000 White / 20022 Composite

- B. 2 1/2” [64 mm] Self-Auguring Stainless Steel Screws (16) – 20009-1 White / 20032 Composite (to lock vinyl column and wood post together at bottom of each post) 2 1/2” [64 mm] Self-Auguring Stainless Steel Screws (16) – 20009-1 White / 20032 Composite (to lock vinyl column and wood post together at top of each post just above trim cap)

- C. 4” [102 mm] Self-Auguring Stainless Steel Screws (64) – 20006 White / 20034 Composite (to lock the intersection of beams and first rafters with vinyl columns)

- D. 1 1/2” [38 mm] Self-Auguring Stainless Steel Screws (40) – 20005 White / 20031 Composite (joiner screws)

- E. 1/2” [38 mm] Self-Auguring Stainless Steel Screws (32) – 20016 White / 20030 Composite (for rafter brackets and/or rafter hanger) 3” [76 mm] Self-Auguring Stainless Steel Screws (84) – 20007 White / 20033 Composite (for shade slats)

- F. 1 1/2“ [38 mm] Self-Auguring Stainless Steel Screws (24) – 20005 White / 20031 Composite (To mount the rafter joiners to the beam)

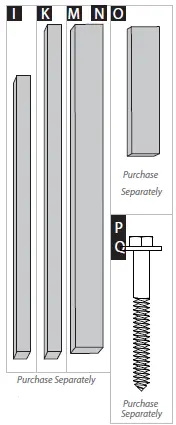

Extra Materials You will Need(Purchase separately from www.newenglandarbors.com or retailer of our products)

If Mounting Pergola on Concrete (not intended to be installed on concrete pavers, patio stones, or interlocking bricks) or Wood Deck

- I. 4x4x7 [10cmx10cmx200cm] Pressure-Treated Wood Posts (2) (purchase at local building center)

- J. 4×4 Bolt Down Bracket Kit (purchase from www.newenglandarbors.com or a retailer of our products)Refer to bolt down bracket instructions for hardware requirements, as they pertain to your application:

If mounting pergola onto an existing concrete surface:

- 1/2“ x 3 1/2” x 12“ (1.3×9.x30.5cm) Wood Shims (16) – Can Be Cut from 1/2” (1.3cm) Sheet of Plywood

- 1/4” x 2 3/4“ (6x70mm) Cement Screws – Countersunk Head (6)

- 3/16” (5mm) Concrete drill bit. Minimum 3“ long (1)

If mounting pergola onto a wooden/composite deck with AN ACCESSIBLE UNDERSIDE:

- 1/2“ x 3 1/2” x 12“ (1.3×9.x30.5cm) Wood Shims (16) – Can Be Cut from 1/2” (1.3cm) Sheet of Plywood

- 1/4” x ?“ (6x?mm) Bolts and Nuts – Countersunk Head (6) (Length depends on blocking material)

- 1/4” (6mm) Washers (6)

- 1/4” (6mm) Wood drill bit. Minimum 3“ (76 mm) long (1)

If Mounting Pergola in Ground

- K. 4x4x10 (10x10x300cm) Pressure-Treated Wood Posts (2) (purchase at local building center)

- L. Concrete Ready Mix (2) (purchase at local building center)

Rafter / Beam Support (Required)

Rafter / Beam Support (Required)

- M.2x6x12 (5x15x365cm) Pressure-Treated Boards (2) (purchase at local building center)

- N.2x6x14 (5x15x427cm) Pressure-Treated Boards (6) – To be cut down to 12’-6” (381cm) (purchase at local building center)

- O.2x6x6 (5x15x183cm) Pressure-Treated Boards (2) (purchase at local building center)

- P.3/8“ x 3 1/2” (10x90mm) Lag Screws with Washers (6) (purchase at local building center)

- Q.3/8“ x 3 1/2” (10x90mm) Lag Screws (for wood wall) or Anchor Screws (for brick or concrete wall) (6)(purchase at local building center, also purchase drill bit)*

*Please consult your local building center for mounting anchors. These second set of screws will be used to mount your wood beam / ledger onto your structure. Refer to page 12 for more information.

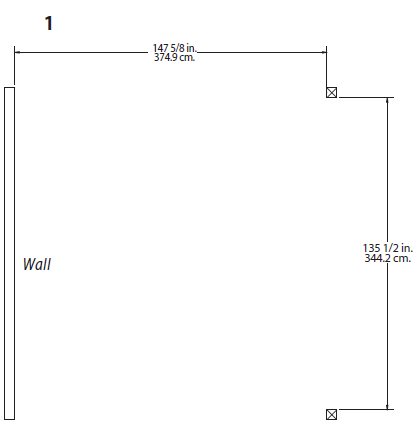

Wood Post Layout & Installation for attached Pergola

This pergola can also be installed on a pre-existing wood or concrete surface using our bolt down bracket system with a 4×4 wood post (sold separate). See page eight for more details.Post location and placement is the most critical step in the overall installation process. Please double check for the possibility of any underground utilities such as sprinkler, gas or telephone lines.

STEP ONE

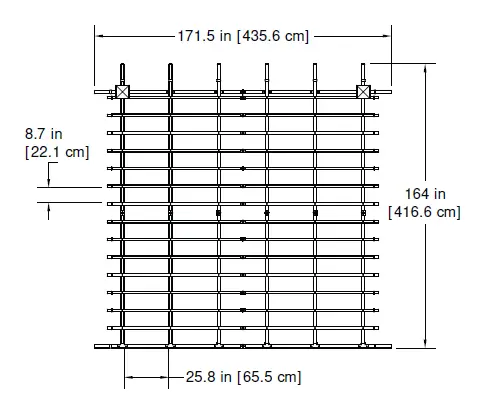

Measure and mark out the location of the pergola posts using string line and temporary wood stakes. Adjust string lines accordingly. The inside corner of the string lines will be the post location.

Please Note:Should you decide to moderately modify the dimensions of your pergola from the standard kit size, a circular saw with a sharp fine-tooth blade is all that you need to cut, shorten or modify the vinyl components. STEP TWO

STEP TWO

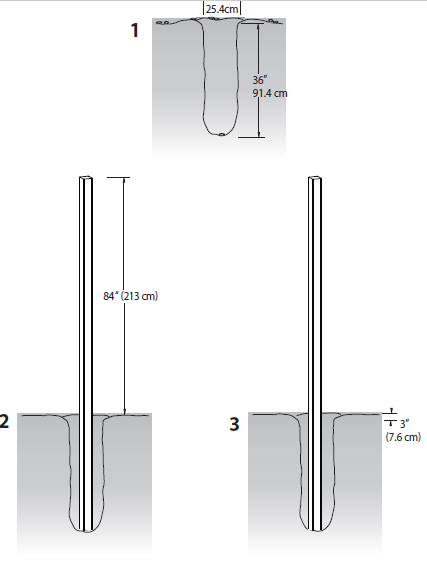

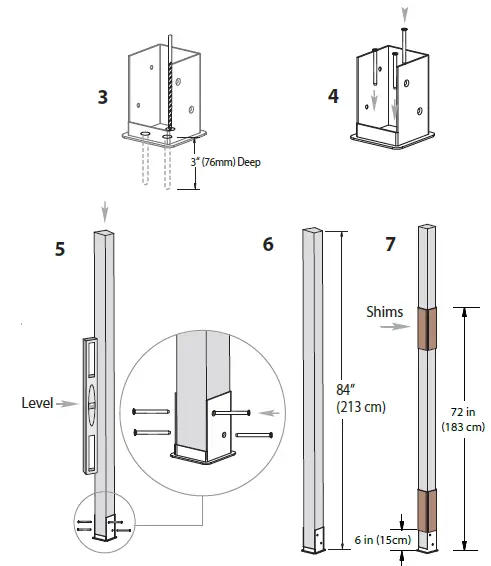

Install Wood Supporting Posts Directly into the Ground

After you have determined where the posts will be located, excavate 10” (25.4 cm) diameter x 36” (91.4 cm) deep post holes.

After holes are dug and cleaned, place the 4×4 (9x9cm) wood post into a hole ensuring it’s level and square to string lines. The final post height should be 84” (213 cm)out of the ground. If a post is higher because of obstructed excavation of footings, please cut down in height accordingly.

Fill the vacant hole with pre-mixed concrete all the way to within 3” (7.6 cm) of the top of the hole.Once concrete has set, backfill and compact 3” (7.6 cm) space with soil.

Repeat for second post.

Please Note:Some 4×4 pressure treated posts can be larger than 3 1/2 x 3 1/2 square due to twisting or cracking. We have allowed a tolerance for this in the internal one way and two way 4×4 wood post guides (see page 8). However in extreme cases you may need to shave down the top of the 4×4 wood post slightly to get the vinyl post started over the wood post. Before installing your wood posts in the ground, please check to confirm this and correct at this stage if necessary.

OPTIONAL STEP

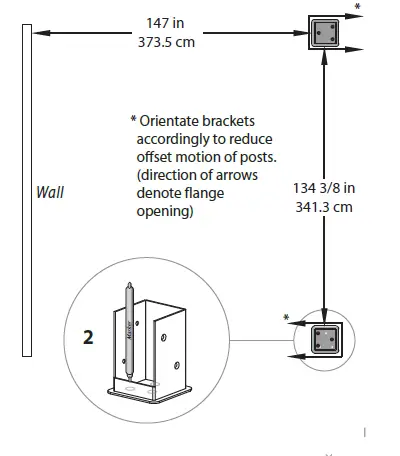

Wood Post Layout & Installation using Bolt Down Brackets for Concrete or Wood Surface for Attached Pergola

Note: for additional information on the bolt down bracket installation, refer to the bolt dow bracket instructions.

Measuring from the edges of the bottom base plates, measure and mark out the location of the bolt down brackets using string or chalk line. Adjust string lines accordingly. The inside corner of the string lines will be the corner of the bottom flange.

Measuring from the edges of the bottom base plates, measure and mark out the location of the bolt down brackets using string or chalk line. Adjust string lines accordingly. The inside corner of the string lines will be the corner of the bottom flange.

Mark out the location of bolt down brackets accordingly using the base of the bracket accordingly.

Using a 3/16” (5mm) masonry drill bit, drill 3“ (76mm) deep holes to allow installation of 2 3/4” (70mm) concrete screws (Not included)Proceed to install three 2 3/4” (70mm) concrete screws into the bottom base of the bolt down bracket.(Not included)

Please Note:Concrete patios generally have sloped surface for water run-off. If this is the case, when you secure the bolt down bracket to the concrete, the bracket may be at an angle. This can be corrected for level using galvanized steel washers (not provided), acting as shims underneath the base to level – VERY IMPORTANT ORPERGOLA BEAMS AND RAFTERS WILL NOT BE LEVEL.  With the two post brackets installed plumb, proceed to set the 4×4 x7’ wood post in place. Secure using the same concrete screws included in the kit. Repeat for both posts.

With the two post brackets installed plumb, proceed to set the 4×4 x7’ wood post in place. Secure using the same concrete screws included in the kit. Repeat for both posts.

Posts should be 84” (213 cm) in height.

In order to create a snug fit between the wood posts and the inner cavity of the vinyl posts, it will be necesary to “build out” the 4×4 posts near the bottom and the top using 1/2” x 3 1/2” x 12” (1.3×9.x30.5cm) shims. Follow instructions as illustrated.

Please Note:Some 4×4 pressure treated wood posts can be larger than 3 1/2 x 3 1/2 square due to twisting or cracking. We have allowed a tolerance for this in the post brackets and the internal one way and two way 4×4 wood post guides. However in extreme cases, you may need to shave down the end of your 4×4 wood post slightly to allow access.

STEP THREE

Vinyl Column Assembly & Installation Over Wood Posts

Using the vinyl weld glue, insert the One Way 4”x4” Internal Wood Post Guide in the one end of the main column posts. This step is only applicable if your wood 4×4 post are embedded into the ground. If your pergola is going to be installed on wood or concrete surface, please dispose of these four pieces.

Using a step ladder, guide the bottom vinyl columns over the wood 4×4 posts.

If you purchased base moldings or trims, slide the molding over the post.

Using a step ladder guide the top vinyl columns over the wood 4×4 posts.

Using a step ladder guide the top vinyl columns over the wood 4×4 posts.

Please Note:Ensure that holes at top of column are orientated correctly for future beam and rafter placement. See diagram at top of next page.

Connect the bottom and top vinyl column by using vinyl weld and sliding together. Please Note: Vinyl Weld Glue has about a sixty second cure time and about a 20 minute dry time.

Slide the bottom post trim into position to cover the joint on the column.  Slide the top post trim into approximate position just below the bottom routed hole on the bottom of the top vinyl column assembly.

Slide the top post trim into approximate position just below the bottom routed hole on the bottom of the top vinyl column assembly.

If necessary, adjust post heights accordingly to ensure future level installation of beams and rafters as necessary. If slope is severe causing a height difference between the posts, you may need to trim down the bottom of two or more of your vinyl columns as necessary.

Secure the vinyl columns to the wood posts using 4 – 2 1/2“ (64mm) self-auguring stainless steel screws at 8” (20.3cm) up from the base of the posts, and 4 – 2 1/2” (64mm) selfauguring stainless steel screws just above the trim cap as illustrated. This will prevent possible uplift during high winds, etc.

If base moldings are installed, place screws above the base moldings.

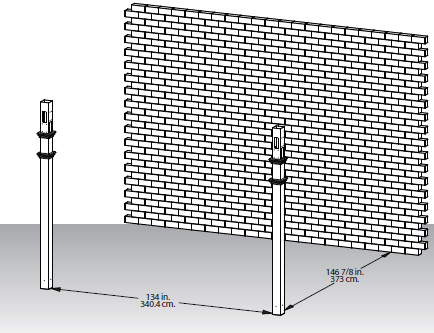

At this stage, the columns should be properly installed as per the following illustration, with the columns 134” in. (340.4 cm) apart.

Critical: Note the opening direction of the holes on the top of the posts.

STEP FOUR

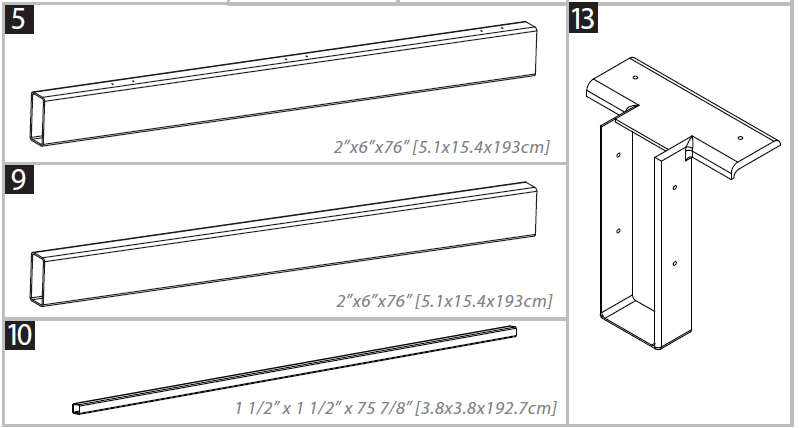

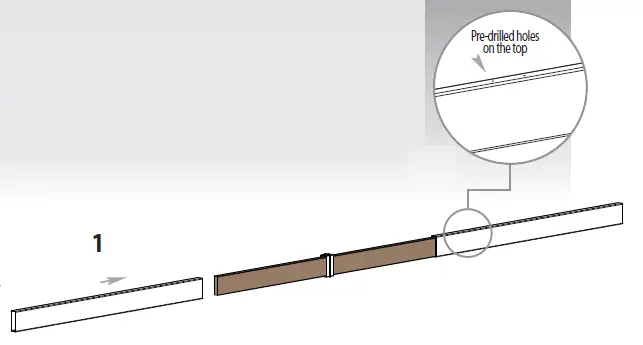

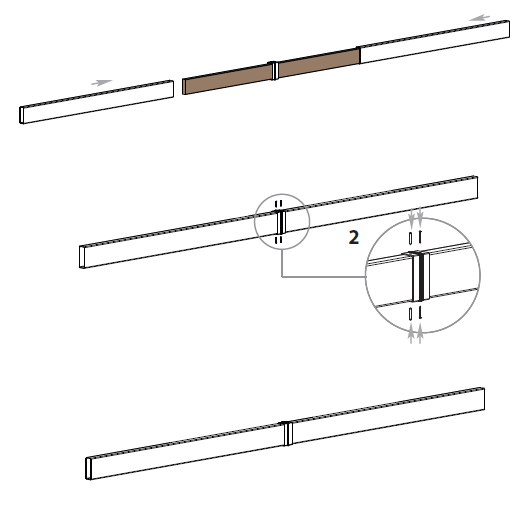

Main Support Beam Assembly  Insert one 2x6x12 (5x15x365cm) pressure treated wood into a beam followed by the joiner and another beam section.Center the 2x6x12 (5x15x365cm) within the main support beam.

Insert one 2x6x12 (5x15x365cm) pressure treated wood into a beam followed by the joiner and another beam section.Center the 2x6x12 (5x15x365cm) within the main support beam.

Critical Note:Note the location of the pre-drilled holes on the top edge of the main support beams. As pictured aside, the further distanced holes need to mate together inside the beam joiner.

This is critical to ensure equal spacing of your rafters.

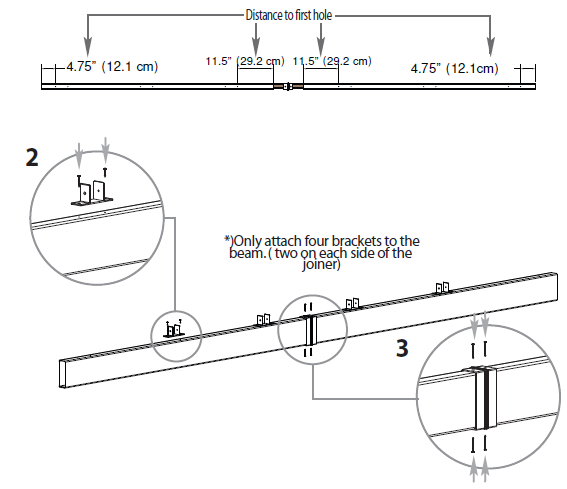

Install the rafter brackets to the main beams using 1 1/2” (64mm) screws. Only attach four brackets to the beam as shown. Follow the pre-drilled holes to identify locations.

Screw the joiner to vinyl beams and wood insert using 1 1/2” (64mm) screws.

STEP FIVEMain Support Beam Assembly

STEP FIVEMain Support Beam Assembly

Repeat step 1 from the previous step.

Install the rafter hanger to the main beams using four 1 1/2” (38mm) screws. Follow the pre-drilled holes to identify locations.

Screw the joiner to vinyl beams and wood insert using 1 1/2” (38mm) screws.  STEP SIXRafter Assembly

STEP SIXRafter Assembly

Cut one 2x6x14 (5x15x427cm) down to 12’-6” (381cm) and Insert into a rafter section followed by the joiner and another rafter section.

Make sure the 2x6x12’-6“ (381cm) wood is inserted about 1/8” (3mm) from the one end (the end that will be installed against the wall), to accommodate the screw heads on the rafter hangers

Screw the joiner to vinyl rafters and wood insert using 1 1/2” (38mm) screws.

Repeat steps 1 and 2 for the remainder of the rafters.

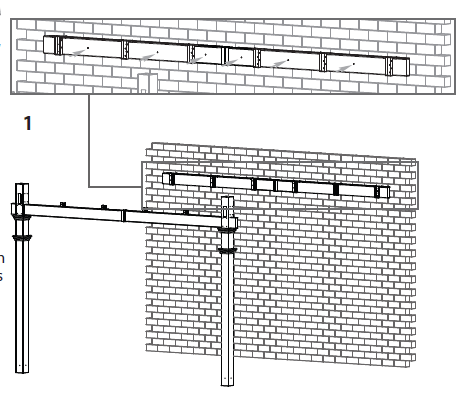

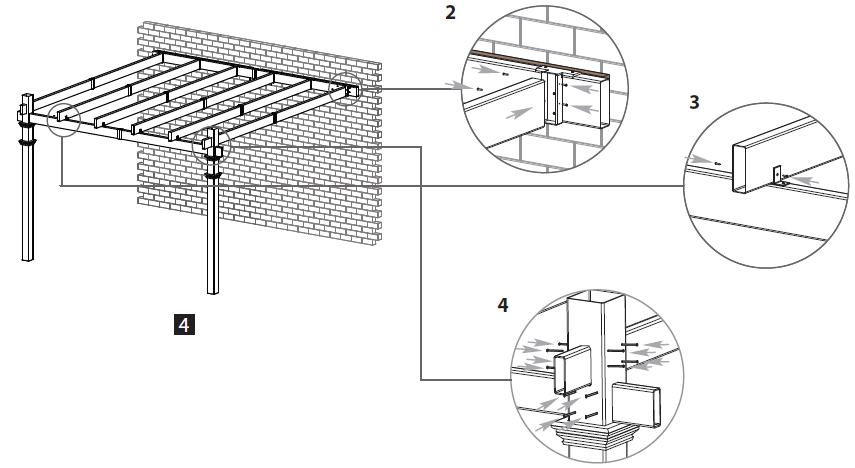

STEP SEVENMain Support Beams & Rafter PlacementUsing a helper and two ladders proceed to complete the following steps:

Slide the main support beam with rafter brackets pre-installed through both holes of the vinyl column (overshooting), and then back through both holes of the opposite column.

Please Note:The top of the vinyl columns may need to be tensioned in opposite directions to each other to allow the beams and rafters to be installed on a slight angle. The vinyl columns naturally allow some measure of flex.

Mount the two 2x6x6’ (5x15x183cm) pressure treated wood pieces(sold separate) on your wall surface. Please consult your local hardware store regarding methods of mounting. We recommend 6 lag screws if mounting to a wood siding or concrete/brick anchor if you are mounting to a brick wall. Screws heads should berecessed flush with the wood beam.

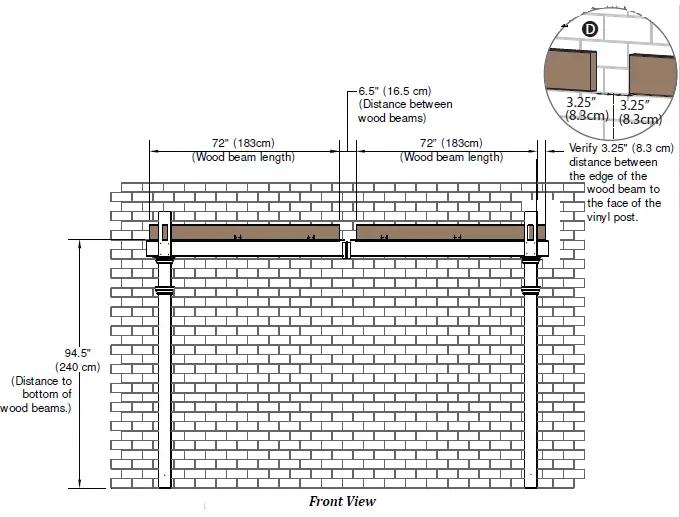

To locate the position of your wood beams;

To locate the position of your wood beams;

- A. Measure half way between the two vinyl posts = 67” (170cm)

- B. Mark and draw a string line square to the wall.

- C. Measure up 94.5” (240cm) and mark with pencil

- D. Measure 3.25” (8.3cm) on either side of the mark. This would be the bottom corner of the two wood beams as shown.

Mount the main support beam which has the rafter hangers onto the wood beam as shown. The top of the wood beam should be flush with the top of the pergola beam.

Mount the main support beam which has the rafter hangers onto the wood beam as shown. The top of the wood beam should be flush with the top of the pergola beam.

Align the two main support beams such that they are centered to each other.

To fasten, use a minimum of six 3½” (90mm) lag screws through the main support beam and wood beam. Space the lag screws between the rafter hangers.

Place the six rafters into the rafter hangers & rafter brackets.

Ensure that the ends with the wood inserted 1/4“ (6mm) from thr edge are pushed all the way in the rafter hangers.

Fasten into the rafter hanger using four – 1 1/2” (38mm) screws as shown.

Fasten the rafters onto the rafter brackets using 1 1/2” (38mm) screws as shown.  Finally, adjust the main support beam and rafters ensuring the overhang past the column is equal. Using 4“ (102mm) screws, lock the main support beams and rafters into position inside the posts by driving in 8 screws from the outside and 8 screws from the inside of each column.

Finally, adjust the main support beam and rafters ensuring the overhang past the column is equal. Using 4“ (102mm) screws, lock the main support beams and rafters into position inside the posts by driving in 8 screws from the outside and 8 screws from the inside of each column.

STEP EIGHTFastening Pergola ends and Caps

Install decorative pergola end caps using vinyl weld.

Install the post caps using vinyl weld.

Final position your post trims.

To glue decorative end caps place:

- Apply a generous amount of vinyl glue to the decorative end caps as shown.

- Slide the decorative end caps into the beam/rafter and allow a few minutes for glue to cure.

To position post trim in place:

- Slide the post trim down.

- Apply a generous amount of vinyl glue around the post

- Slide the post trim back up to the desired location and allow a few minutes for glue to cure.

STEP NINEShade Slat Assembly

Assemble shade slats by first gluing the decorative end caps as shown, and then inserting the two slats into one joiner.

Push firmly until extrusion bottoms out inside joiner. No screws are necessary

Shade Slats Installation

Shade Slats Installation

The 1 1/2 x 1 1/2 shade slats are designed to be installed with 8 3/4” (22.2cm) spacing between each slat.

Shade slats are designed to extend approximately 8 1/4” (21cm) past the last rafter. Measurement includes the pre-installed pergola ends. Your goal is to ensure that all the shade slats overhang equally to the eye.

Install first shade slat adjacent to the top of the vinyl columns.

Install the rest of the shade slats at he 8 3/4” (22.2cm) spacing.

Install one 3” (76mm) screw at each intersection of rafter and shade slat.

Suggestions for Additional Shade as Necessary

Suggestions for Additional Shade as Necessary

- White resin lattice in variety of shapes and sizes are available at your local lumberyard. Cut to size and fasten directly to the top of shade slats using stainless steel screws.

- In areas of extreme snow or wind load, do not use tight diamond privacy lattice.

References

[xyz-ips snippet=”download-snippet”]