Atlas Two-column Automotive Lift PRO-9D

9,000 POUND CAPACITYMODEL: PRO-9DTWO-COLUMN AUTOMOTIVE LIFT

READ THIS ENTIRE MANUAL BEFORE OPERATION BEGINSRECORD BELOW THE FOLLOWING INFORMATION WHICH IS LOCATED ON THE SERIAL NUMBER DATA PLATE

Serial No. ……….Model No. ……….Date of Install ……….

RECORD BELOW THE FOLLOWING CUSTOMER INFORMATIONCompany Name ……….Contact Person * ……….Street Address ……….City ……….State ……….Phone ……….Fax ……….Email ……….Optional FieldsNOTE: To validate warranty, this information must be copied and either faxed or mailed to:

WARRANTY

- The structural components on your new automotive lift are warranted for five years on equipment. Operating components are warranted one year to the original purchaser, to be free of defects in material and workmanship.

- The manufacturer shall repair or replace at their option for this period those parts returned to the factory freight prepaid which prove after inspection to be defective.

- This warranty only applies to the original purchaser of the equipment. This warranty does not extend to defects caused by ordinary wear, abuse, misuse, shipping damage, or damage as the result of improper maintenance.

- This warranty is exclusive and in lieu of all other warranties expressed or implied.

- In no event shall the manufacturer be liable for special, consequential or incidental damages for the breach or delay in performance of the warranty.

- The manufacturer reserves the right to make design changes or add improvements to its product line without incurring any obligation to make such changes on product sold previously.

- This warranty shall be governed under the laws of the state of Texas, and shall be subject to the exclusive jurisdiction of the Court in the state of Texas in the county of Tarrant.

PRO-9D Definition

This lift is a 9,000 lb. capacity, two-column lift. The safety system in this lift is attached to the back of the carriage to provide a single point release that saves time when operating.

PRO-9D Important NotesPlease read the Safety Procedures and operation instructions in this manual before operating the lift. Proper installation is very important. To minimize the chance of making an error in installation, please read this manual through carefully before beginning installation. Check with building owner and/or architect’s building plans when applicable. The lift should be located on a relatively level floor with 4” thick, 3000 psi sufficiently cured concrete.This is a vehicle lift installation / operation manual and no attempt is made or implied herein to instruct the user in lifting methods particular to an individual application. Rather, the contents of this manual are intended as a basis for operation and maintenance of the unit as it stands alone or as it is intended and anticipated to be used in conjunction with other equipment.Proper application of the equipment described herein is limited to the parameters detailed in the specifications and the uses set forth in the descriptive passages. Any other proposed application of this equipment should be documented and submitted in writing to the factory for examination. The user assumes full responsibility for any equipment damage or personal injury that occurs as the result of alteration of the equipment described in this manual or any subsequent damages.

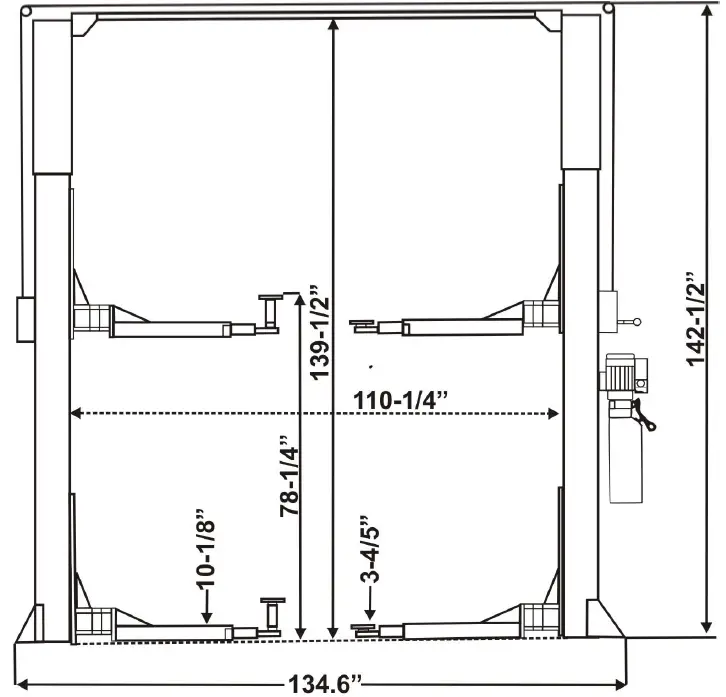

PRO-9D BASIC SPECIFICATION

| Capacity | 9,000 lbs |

| Lifting Time | 45 Seconds |

| Overall Height | 142-1/2″ |

| Overall Width | 140″ |

| Between Columns | 110-1/4″ |

| Drive Through | 92-1/4 |

| Height Shut-Off | 134-1/2″ |

PRO-9D NINE TWO POST LIFTSET-UP DIMENSIONS

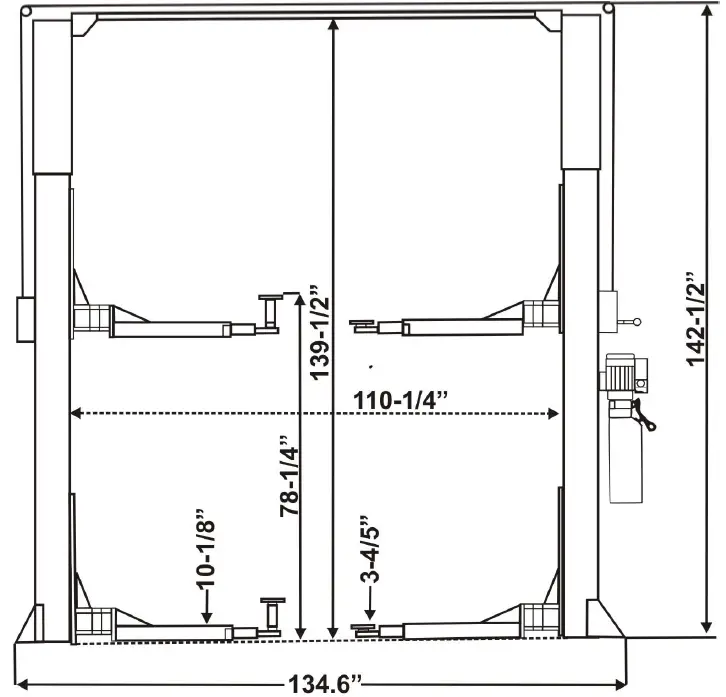

IMPORTANT FOUNDATION AND ANCHORING INFORMATION

- Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4” in order to achieve a minimum anchor embedment of 3 ¼”. When using the standard supplied ¾” x 5 ½” long anchors; if the top of the anchor exceeds 2 ¼” above the floor grade, you DO NOT have enough embedment.

- Use the existing holes in column base plate as a guide for drilling the ¾” diameter holes into the concrete. Maintain a 6” minimum distance from any slab edge or seam. Hole to hole spacing should be a minimum 6 ½” in any direction. Concrete thickness or hole depth should be a minimum of 4”.

- CAUTION: DO NOT install on asphalt or other similar unstable surface. Columns are supported only by anchoring in floor.

- Using the horseshoe shims provided, shim each column base as required until each column is plumb. If one column has to be elevated to match the plane of the other column, full size base shim plates should be used (Reference Shim Kit). Torque anchors to 150 ft-lbs. Shim thickness MUST NOT exceed ½” when using the 5 ½” long anchors provided with the lift. Adjust the column extensions plumb.

- If anchors do not tighten to 150 ft-lbs. Installation torque, replace the concrete under each column base with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under and flush with the top of existing floor. Allow concrete cure before installing lifts and anchors.

ANCHORING TIP SHEET

- Anchors must be at least 6″ from the edge of the slab or any seam.

- Use a concrete hammer drill with a carbide tip, solid drill bit the same diameter as the anchor, 3/4″. (.775 to .787 inches diameter). Do not use excessively worn bits or bits which have been incorrectly sharpened.

- Keep the drill in a perpendicular line while drilling.

- Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down occasionally to remove residue to reduce binding.

- Drill the hole to depth equal to the length of anchor.

- For better holding power blow dust from the hole.

- Place a flat washer and hex nut over threaded end of anchor, leaving approximately 1/2 inch of thread exposed carefully tap anchor. Do not damage threads. Tap anchor into the concrete until nut and flat washer are against base plate. Do not use an impact wrench to tighten. Tighten the nut, two or three turns on average concrete (28-day cure). If the concrete is very hard only one or two turns may be required. Check each anchor bolt with torque wrench set to 150 foot pounds.

PREPARATION

The installation of this lift is relatively simple and can be accomplished by 2 men in a few hours. The following tools and equipment are needed:

Appropriate lifting equipmentAW 32, 46 or other good grade Non-Detergent Hydraulic Oil SAE-10 (12 quarts)Chalkline and 12′ Tape MeasureRotary Hammer Drill with 3/4″ Drill Bit. Core Drill ReBar Cutter recommendedTransit and a 4′ LevelSockets and Open Wrench set, 1/2″ thru 1-1/2″ (1-1/8″ for 3/4″ Anchors) Locking Pliers, 8mm Socket Head Wrench

GENERAL INFORMATION

- Any freight damage must be noted on the freight bill before signing and reported to the freight carrier with a freight claim established. Identify the components and check for shortages. If shortages are discovered, contact Hanmecson International, Inc. immediately.

- Consult building owner and / or architect’s plans when applicable to establish the best lift location. The lift should be located on a relatively level floor with 4” minimum thickness, 3000 psi concrete slab that has been properly cured. There can be no cracks in the slab within 36” of the base plate location, and no seams in the foundation within 6” of its location! Remember: any structure is only as strong as the foundation on which it is located!

Check for ceiling clearance first to see how high the lift can be set up in your bay.

STEP 1: After unloading the lift, place it near the intended installation location.STEP 2: Remove the shipping bands and packing materials from the lift. The power unit and cylinders will be unpacked from the top.STEP 3: Open the wrapping from the upper column and carefully remove the parts from inside. Unbolt the column from the shipping brackets.Unbolt the up-rights (Item # 20 in the parts list) from the columns and assemble it to the column (Item # 19 in the parts list). See Fig. # 4.STEP 4: Unpack the cylinders and open the oil port on each cylinder by unscrewing the black plastic cap. Move the carriage up about 20” to 25”. Next, carefully slide the cylinder inside from the bottom of the carriage. The oil port will face the backside of the column and the notch on the bottom of the cylinder will fit into the hole in the center of the base plate.STEP 5: Position the columns facing each other 105” inside base plates (see fig. 7). Square the columns by measuring diagonally from corner points on base plates (within1/4”).STEP 6: Using a 3/4″ diameter concrete drill, drill the anchor holes in the main side column, installing anchors as you go. Use a block of wood or rubber mallet to drive anchor bolts in. Drill to a minimum depth of 4″ to insure maximum holding power. Drilling thru concrete (recommended) will allow the anchor to be driven thru the bottom if the threads are damaged.STEP 7: Using a level, check column for side-to-side plumb and front-to-back plumb. If needed, use horseshoe shims provided by placing shims underneath the base plate and around the anchor bolt. This will prevent bending the column bottom plates (Shim thickness should not exceed ½”). Tighten ¾” anchor bolts to 150 ft-lbs. of torque.STEP 8: Using a tape measure, measure from back corner of the base to the opposite back corner to insure legs are square. After confirming dimensions, drill and install the anchors on the other side leg.STEP 9: Level the second column as described in step #7.STEP 10: Install the overhead cross beam. This cross beam has two pieces, to be connected by six (6) bolts in the center of the beam. Be sure to bolt them together by installing the bolts from inside the cross beam out. This is to avoid interference with the cable when operating the lift. Assemble cable pulleys and other parts as shown on Fig. 2 Next, install the cross beam between two columns as shown on Fig. 11.STEP 11: Install the safety latch on both side columns as shown on Fig. 6 and 7. Connect the safety release cable (parts #33) between two latches.Check that the tension of the cable is tight. Pull the single point release handle several times and check the tension again by making sure both latches release at the same time when the handle is pulled.STEP 12: Mount the power unit on the main side leg to the power unit bracket using the four 5/16” bolts and nuts. Connect the power unit to the fitting installed on the back of the main leg by using a short hose supplied. See Fig. 10STEP 13: Connect the equalizing cables (Item #32 on parts list) as shown in Fig. # 8. Do not tighten at this stage of assembly.NOTE:The cable stud that connects to the front right corner of the carriage should be connected first by pulling the stud through the carriage hole and up where it is easy to be held by locking pliers. Pull the stud back into place after threading at least ½” of the stud past the locknut. Connect the other ends to the rear right corners of the carriage with at least ½” of thread showing past the lock nut (cables run on the inside of the carriage). It may be necessary tomanually raise both carriages above the cylinder to provide enough space to use the locking pliers. Make sure the carriage is set in the LOCK position.STEP 14: Adjust the carriage cable tension. This is accomplished by tightening the carriage adjustment nut on top of each carriage. The rear carriage adjustment nut adjusts the opposite post carriage height. The left post carriage nut adjusts the right column carriage, and the right column carriage nut adjusts the left column carriage. Adjust each cable to approximately 1/2″ side-to-side play. Check the latch releases to insure the carriage is still engaged in the appropriate latch.STEP 15: Install all four swing arms, readjust the arm lock preinstalled to make sure that gear rack are engaging the moon gear on the arm properly.STEP 16: Remove the vent plug from the power unit and fill the reservoir. Use a Ten Weight (SAE-10) non-foaming, non-detergent hydraulic fluid (Texaco HD46 or equal). The unit will hold approximately twelve quarts of fluid.STEP 17: Make the Electrical hookup to the power unit; 220V Single Phase. It is recommended that a 220 Volt, 30 Amp twist lock plug be installed in the power line just ahead of the power unit. Use wire capable of supporting a 30-amp circuit.WARNING: The wiring must comply with local code. Have a certified electrician make the electrical hook-up to the power unit. Protect each circuit with time delay fuse or circuit breaker; 208v-230v single phase. 60 Hz 30 amp. Motor can not run on 50 Hz with out a physical change to motor.STEP 18: Do not place any vehicle on the lift at this time. Cycle the lift up and down several times to insure latches engage properly and all air is removed from the system. To lower the lift, first raised the lift to clear the latches and then pull down the safety release handle to lower the lift. If latches function out of sync, tighten the cable on the latch that engages first.

RAISE LIFTPress button on power unitThe safety latch mechanism will ‘trip over’ when the lift raises and drop into each latch stop. To lock the lift you must press the Lower lever to relieve the hydraulic pressure and let the latch set tight in a lock position.Note: It is normal for an empty lift to lower slowly – it may be necessary to add weight.

LOWER LIFT

- Raise the lift until the latches clear the safety racks in both sides.

- Pull down and hold the safety release handle.WARNING: Always make sure latches on both sides clear the rack at same time when pulling down the release handle by adjusting the cable.

- Press the lowering lever at the power unit to lower the lift.

ATTENTION!!!ALWAYS LOCK THE LIFT BEFORE GOING UNDER THE VEHICLE. NEVER ALLOW ANYONE TO GO UNDER THE LIFT WHEN RAISING OR LOWERING.

SAFETY PROCEDURES

- Never allow unauthorized persons to operate lift. Thoroughly train new employees in the use and care of lift.

- Caution – the power unit operates at high pressure.

- Remove passengers before raising vehicle.

- Prohibit unauthorized persons from being in shop area while lift is in use.

- Total lift capacity is 9,000-lbs. with 2,250-lbs. per swivel pad. Do not exceed this capacity.

- Prior to lifting vehicle, walk around the lift and check for any objects that might interfere with the operation of lift and safety latches; tools, air hoses, shop equipment.

- When approaching the lift with a vehicle, center the vehicle between the columns so that the tires will clear the swing arms easily. Slowly drive the vehicle up between the posts. Have some one outside the vehicle guide the driver.

- Always lift vehicle using all four pads.

- Never use lift to raise one end or one side of vehicle.

- Raise vehicles about 3” and check stability by rocking.

- Prior to lowering vehicle, walk around the lift and check for any objects that might interfere with the operation of lift and safety latches; tools, air hoses, shop equipment. Swing the arms out and slowly drive the vehicle out. Have some one outside the vehicle guide the driver.

MAINTENANCE SCHEDULE

The following periodic maintenance is the suggested minimum requirements and minimum intervals; accumulated hours or monthly period, which ever comes sooner. If you hear a noise not associated with normal lift operation, or, if there is any indication of impending lift failure – CEASE OPERATION IMMEDIATELY! -inspect, correct and/or replace parts as required.WARNING: OSHA AND ANSI REQUIRE USERS TO INSPECT LIFTING EQUIPMENT AT THE START OF EVERY SHIFT. THESE AND OTHER PERIODIC INSPECTIONS ARE THE RESPONSIBILITY OF THE USER.

DAILY PRE-OPERATION CHECK (8 HOURS)The user should perform daily check.ATTENTION! Daily check of safety latch system is very important – the discovery of a potential device failure could prevent expensive property damage, lost production time, serious personal injury, and even death.

- Check safety lock audibly and visually while in operation

- Check safety latches for free movement and full engagement with rack.

- Check hydraulic connections, and hoses for leakage.

- Check chain connections – bends, cracks-and loose links.

- Check cables connections- bends, cracks-and looseness.

- Check for frayed cables in both raised and lowered position.

- Check snap rings at all rollers and sheaves.

- Check bolts, nuts, and screws and tighten if needed.

- Check wiring & switches for damage.

- Keep base plate free of dirt, grease or any other corrosive substances.

- Check floor for stress cracks near anchor bolts.

- Check swing arm restraints.

WEEKLY MAINTENANCE (40 HOURS)

- Check anchor bolts torque to 150 ft-lbs for the ¾” anchor bolts.Do not use impact wrench.

- Check floor for stress cracks near anchor bolts

- Check hydraulic oil level.

- Check and tighten bolts, nuts, and screws.

- Check cylinder pulley assembly for free movement or excessive wear on cylinder yoke or pulley pin.

- Check cable pulley for free movement and excessive wear.

YEARLY MAINTENANCE

- Lubricate chain

- Grease rub blocks and column surface contacting rub blocks

- Change the hydraulic fluid – good maintenance procedure makes it mandatory to keep hydraulic fluid clean. No hard fast rules can be established; – operating temperature, type of service, contamination levels, filtration, andchemical composition of fluid should be considered. If operating in dusty environment shorter interval may be required.

The following items should only be performed by a trained maintenance expert.

- Replace hydraulic hoses.

- Replace chains and rollers.

- Replace cables and sheaves.

- Replace or rebuild air and hydraulic cylinders as required.

- Replace or rebuild pumps / motors as required.

- Check hydraulic cylinder rod and rod end (threads) for deformation or damage.

Relocating or changing components may cause problems. Each component in the system must be compatible; an undersized or restricted line will cause a drop in pressure. All valve, pump, and hose connections should be sealed and/or capped until just prior to use. Air hoses can be used to clean fittings and other components. However, the air supply must be filtered and dry to prevent ontamination. Most important – cleanliness – contamination is the most frequent cause of malfunction or failure of hydraulic equipment.

TROUBLESHOOTING

- Motor does not operateA. Breaker or fuse blown.B. Motor thermal overload tripped. Wait for overload to cool.C. Faulty wiring connections; call electrician.D. Defective up button call electrician for checking.

- Motor functions but lift will not riseA. A piece of trash is under check valve. Push handle down and push the up button at the same time. Hold for 10-15 seconds. This should flush the system.B. Check the clearance between the plunger valve of the lowering handle. There should be 1/16″.C. Remove the check valve cover and clean ball and seat.D. Oil level to low. Oil level should be just under the vent cap port when the lift is down!!!

- Oil blows out breather of power unitA. Oil reservoir overfilled.B. Lift lowered too quickly while under a heavy load.

- Motor hums and will not runA. Impeller fan cover is dented. Remove cover and straighten.B. Faulty wiring.……. call electricianC. Bad capacitor..….. call electricianD. Low voltage……….. call electricianE. Lift overloaded .…. remove excessive weight from lift

- Lift jerks going up and down Air in hydraulic system. Raise lift all the way to top and return to floor. Repeat 4-6 times. Do not let this overheat power unit.

- Oil leaksA. Power unit: if the power unit leaks hydraulic oil around the tank-mounting flange check the oil level in the tank. The level should be two inches below the flange of the tank. A screwdriver can be used as a “dipstick”.B. Rod end of the cylinder: the rod seal of the cylinder is out. Rebuild or replace the cylinder.C. Breather end of the cylinder: the piston seal of the cylinder is out. Rebuild or replace the cylinder.

- Lift makes excessive noiseA. Leg of the lift is dry and requires grease.B. Cylinder pulley assembly or cable pulley assembly is not moving freely.C. May have excessive wear on pins or cylinder yoke.

OWNER / EMPLOYER RESPONSIBILTIESThe Owner / Employer:

- Shall established procedures to periodically maintain, inspect and care for the lift in accordance with the manufactures recommended procedures to ensure its’ continued safe operations.

- Shall provide necessary lockout / tagouts of energy sources per ANSI Z244.1 – 1982 before beginning any lift repairs.

- Shall not modify the lift in any manner without prior written consent of the manufacturer.

- Shall display the operating instructions, “Lifting It Right” and “Safety Tips” supplied with the lift in a conspicuous location in the lift area convenient to the operator.

- Shall insure that lift operators are instructed in the proper and safe use and operation of the lift using the manufacturer’s instructions and “Lift It Right” and “Safety Tips” supplied with the lift.

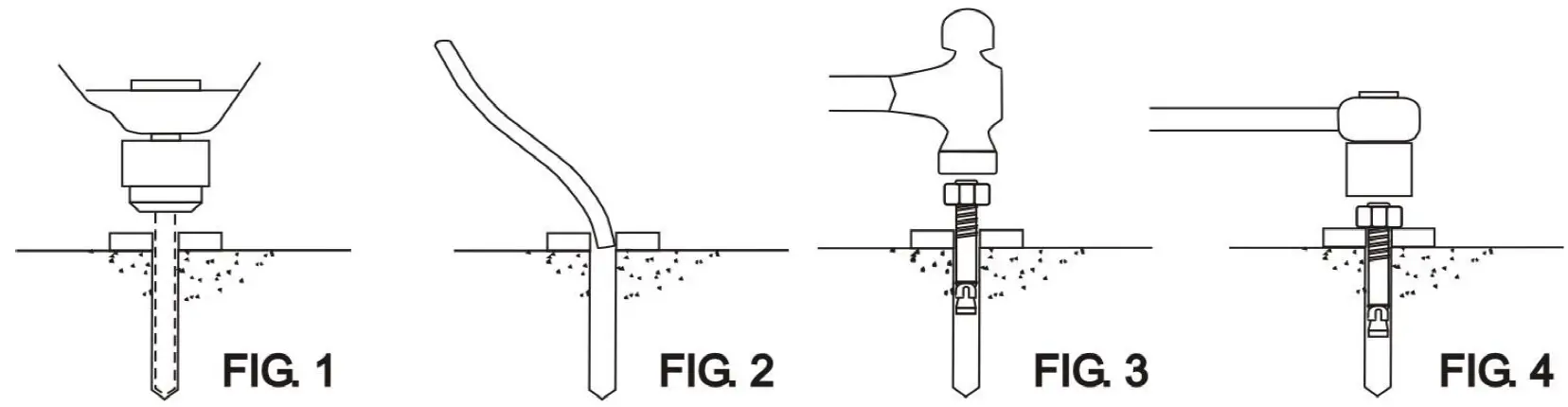

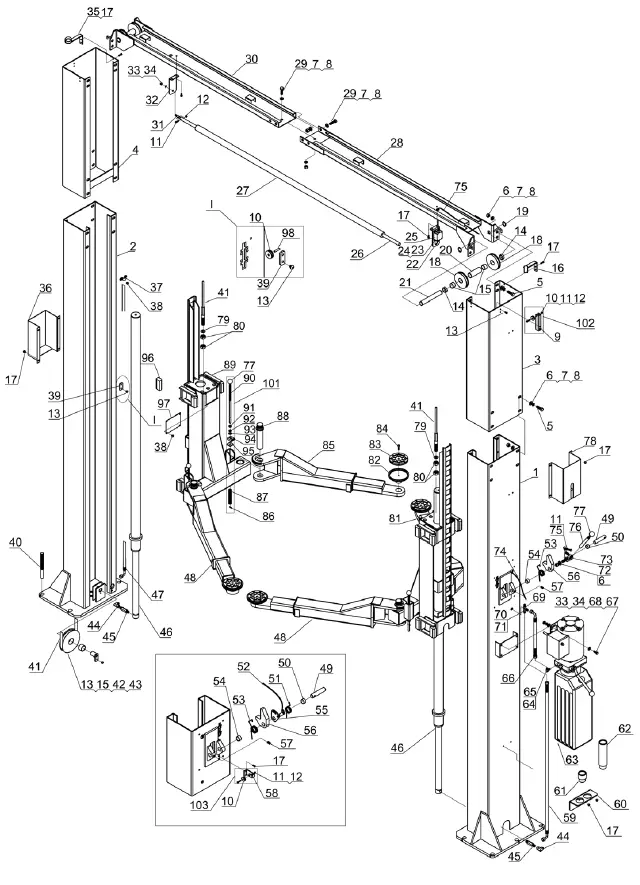

TWO POST LIFTS EXPLODED DIAGRAM

PART LIST OF PRO-9D

| 1 | QLSM-2R1-00 | RIGHT COLUMN WELOMENT GROUP | 1 |

| 2 | QLSM-2L1-00 | LEFT COLUMN WELOMENT GROUP | 1 |

| 3 | QLSM·R0-00 | RIGHT EXTEND COLUMN GROUP | 1 |

| 4 | QLSM-lL0-00 | LEFT EXTENDCOLUMN GROUP | 1 |

| 5 | GB5782-86 | HEXAGONAL HEAD BOLT M12*40 | 24 |

| 6 | GB93-87 | LOCK WASHER 12 | 24 |

| 7 | GB97.1-85 | FLAT WASHER 12 | 60 |

| 8 | GB6170-86 | HEXAGON NUTS M12 | 29 |

| 9 | QL4L-000-08 | TOP PULLEY STANO | 2 |

| 10 | QL4L-000-10 | PULLEY | 6 |

| 11 | GB5782-86 | HEXAGONAL BOLT M6*35 | 5 |

| 12 | GB889-86 | NYLON NUTS M6 | 4 |

| 13 | GB819-85 | BOLT M6 10 | 14 |

| 14 | QL4L-400-04 | SHORT BUSHING | 4 |

| 15 | QL40-700-02 | THICK SLEEVE | 6 |

| 16 | QL4L-700-RO | HOSE STAND | 1 |

| 17 | GB818-85 | BOLT M6*10 | 22 |

| 18 | QL4L-400-02 | 4″ THICK CABLE WHEEL | 4 |

| 19 | GB894.1-86 | AXIAL ELASTIC RINGS 25 | 8 |

| 20 | QL4L-400-03 | LONG BUSHING | 2 |

| 21 | QL4L-400-01 | SHAFT | 2 |

| 22 | QL4L-000·11 | TOP SWITCH BRACKET | 1 |

| 23 | GB818-85 | BOTL M3··16 | 4 |

| 24 | GB6170-86 | NUT M3 | 4 |

| 25 | QL4L-000-16 | TOP SWITCH | 1 |

| 26 | QL4L-000-13 | TOP LIMITED BAR | 1 |

| 27 | QL4L-000-15 | RUBBER HOSE FOR TOP BAR | 1 |

| 28 | QL4L-4RO·OO | RIGHT BEAM WELDING GROUP | 1 |

| 29 | GB5782-86 | BOTL M12’25 | s |

| 30 | QL4L-4LO-OO | LEFT BEAM WELDING GROUP | 1 |

| 31 | QL4L-000-14 | BOLT OF TOP ROD | 1 |

| 32 | QL4L-000-12 | TOP ROD STAND | 1 |

| 33 | GB93-87 | LOCK WASHER 8 | 7 |

| 34 | GB6170-86 | NUT M8 | 5 |

| 35 | QL4L-700-LO | LEFT HOSE BRACKET | 1 |

| 36 | QL4L-510-00 | COVER WELDMENT | 1 |

| 37 | QL4L-000-0S | TUBING CLAMP | 10 |

| 38 | GB818-85 | BOLT M6 6 | 20 |

| 39 | QL41-000-01 | PRESSING PLATE | 4 |

| 40 | QL40-000-15 | ANCHOR BOLT | 10 |

| 41 | QL4L-600-00 | CABLE | 2 |

| 42 | QL40-700-01 | THICK PULLEY | 2 |

| 43 | QL4M-220-00 | SHAFT | 2 |

| 44 | QL40-000·09 | F TIING | 2 |

| 45 | QL4L-000-06 | FITIING | 2 |

| 46 | QL4M-100-00 | CYLINOER | 2 |

| 47 | QL4L-000-04 | HYDRAULIC HOSE | 1 |

| 48 | QLSM-410-00 | STRANGE ARM | 2 |

| 49 | QL4L-200-01 | LOCK SHAFT | 2 |

| 50 | QL4L-200-03 | SHORT SPACER | 2 |

| 51 | QL4L-200-02 | SPRING | 2 |

| 52 | QL4L-000-20 | CABLE | 1 |

| 53 | QL4L-200-04 | SPRING | 2 |

| 54 | QL4L-200-0S | LONG SPACER | 2 |

| 55 | QL4L-220-00 | LOCK HOOK BOARD | 1 |

| 56 | QL4L-230-00 | LOCK HOOK | 2 |

| 57 | GB78-85 | SOLT MJO•J6 | 2 |

| 58 | QL4L-000-09 | DOWN PULLEY BRACKET | 1 |

| 59 | QL4L-000-03 | HYDRAULIC HOSE | 1 |

| 60 | QL4B-000-01 | TROUGH PLATE | 2 |

| 61 | QL40-000-04 | SHORT ADAPTER | 4 |

| 62 | QL40-000-05 | LONG ADAPTER | 4 |

| 63 | QL4L-000-21 | POWER UNIT | 1 |

| 64 | QL40-000-07 | 90 DEGREE FITIING | 1 |

| 65 | “O” RING | 1 | |

| 66 | QL4L-000-02 | HYDRAULIC HOSE | 1 |

| 67 | GB5782-86 | BOLT M8*25 | 4 |

| 68 | GB97.1-85 | FLAT WASHER 8 | 10 |

| 69 | QL4L-000-01 | T FITIING | 1 |

| 70 | GB97.1-85 | FLAT WASHER 14 | 1 |

| 71 | GB6170-86 | NUT 9/16 | 1 |

| 72 | GB6172-86 | NUT M12 | 2 |

| 73 | QL4L-210-00 | HANDLE BRACKET | 1 |

| 74 | QL4L-000-17 | SHEATHED LINES | 1 |

| 75 | GB6170-86 | NUT M6 | 1 |

| 76 | QL4L-000-07 | HANDLE | 1 |

| 77 | QL40-000-15 | HANDLE BALL M O | 5 |

| 78 | QL4L-520-00 | COVER | 1 |

| 79 | GB97.1-85 | FLAT WASHER 20 | 4 |

| 80 | GB6170-86 | NUT M20 | 8 |

| 81 | QL40-400-RO | RIGHT FRONG ARM | 1 |

| 82 | QL40-000-02 | PALLET | 4 |

| 83 | QL40-000-03 | RUBBER PAD | 4 |

| 84 | GB70-85 | BOLT M6•20 | 4 |

| 85 | QL40-400-LO | LEFT FORM ARM | 1 |

| 86 | GB879-86 | SLOTTED SPRING PlNS | 4 |

| 87 | QL40-530-02 | PRESSING SPRING | 4 |

| 88 | QL40.800-00 | PINWELDMENT | 4 |

| 89 | QL40-510-00 | SLIPWAY WELDING GROUP | 2 |

| 90 | QL40-530-01 | DRAFT BAR | 4 |

| 91 | GB6170-86 | HEXAGON NUTS MlO | 4 |

| 92 | GB93-87 | LOCK WASHER 10 | 4 |

| 93 | GB97.1-85 | FLAT WASHER 10 | 8 |

| 94 | QL40-530-04 | RACK | 4 |

| 95 | QL40-530-03 | GEAR GASKET | 4 |

| 96 | QL40-500-01 | SLIDE BLOCK | 16 |

| 97 | QL4M-300 01 | COVER PLATE | 2 |

| 98 | QL4L-2L1-01 | PINOF NYLON WHEEL | 3 |

| 101 | QL40-530-00 | ARM LOCK SYSTEM | 4 |

| 102 | TOP PULLEY STAND SYSTEM | 1 | |

| 103 | DOWN PULLEY STAND SYSTEM | 1 | |

[xyz-ips snippet=”download-snippet”]