Black and Decker

Intended useYour BLACK+DECKER BDCCS18 Circular saw has been designed for sawing wood and wood products. This tool is intended for professional and private, non professional users.

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and all instructions. Failure to follow the warnings and instructions listed below may result in electric shock, fire and/or serious injury.

Warning! Read all safety warnings and all instructions. Failure to follow the warnings and instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.The term “power tool” in all of the warnings listed below refers to your mains operated (corded) power tool or battery operated (cordless) power tool.

- Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

- Electrical safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

3. Personal safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.b. Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.c. Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.d. Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

ENGLISH (Original instructions)

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.g. Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.5. Servicea. Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Additional power tool safety warnings

Cutting procedures

a.

b. Do not reach underneath the workpiece. The guard cannot protect you from the blade below the workpiece.

c. Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the blade teeth should be visible below the workpiece.d. Never hold piece being cut in your hands or across your leg. Secure the workpiece to a stable platform. It is important to support the work properly to minimize body exposure, blade binding, or loss of control.e. Hold the power tool by insulated gripping surfaces only, when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also make exposed metal parts of the power tool “live” and could give the operator an electric shock.f. When ripping, always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance of blade binding.

g. Always use blades with correct size and shape (diamond versus round) of arbour holes. Blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control.h. Never use damaged or incorrect blade washers or bolt. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

Further safety instructions for all saws

Kickback causes and related warnings

- kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator;

- when the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

a. Maintain a firm grip with both hands on the saw and position your arms to resist kickback forces. Position your body to either side of the blade, but not in line with the blade. Kickback could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if proper precautions are taken.b. When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion or kickback may occur. Investigate and take corrective actions to eliminate the cause of blade binding.c. When restarting a saw in the workpiece, center the saw blade in the kerf and check that saw teeth are not engaged into the material. If saw blade is binding, it may walk up or kickback from the workpiece as the saw is restarted.d. Support large panels to minimise the risk of blade pinching and kickback. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel.e. Do not use dull or damaged blades. Unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding and kickback.

f. Blade depth and bevel adjusting locking levers must be tight and secure before making cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

a. Use extra caution when sawing into existing walls or other blind areas. The protruding blade may cut objects that can cause kickback.

Lower guard function

a. Check lower guard for proper closing before each use. Do not operate the saw if lower guard does not move freely and close instantly. Never clamp or tie the lower guard into the open position. If saw is accidentally dropped, lower guard may be bent. Raise the lower guard with the retracting handle and make sure it moves freely and does not touch the blade or any other part, in all angles and depths of cut.b. Check the operation of the lower guard spring. If the guard and the spring are not operating properly, they must be serviced before use. Lower guard may operate sluggishly due to damaged parts, gummy deposits, or a build-up of debris.

c. Lower guard may be retracted manually only for special cuts such as “plunge cuts” and “compound cuts”. Raise lower guard by retracting handle and as soon as blade enters the material, the lower guard must be released. For all other sawing, the lower guard shouldoperate automatically.d. Always observe that the lower guard is covering the blade before placing saw down on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is released.

Residual risks.Additional residual risks may arise when using the tool which may not be included in the enclosed safety warnings. These risks can arise from misuse, prolonged use etc. Even with the application of the relevant safety regulations and the implementation of safety devices, certain residual risks can not be avoided. These include:

- Injuries caused by touching any rotating/moving parts.

- Injuries caused when changing any parts, blades or accessories.

- Injuries caused by prolonged use of a tool. When using any tool for prolonged periods ensure you take regular breaks.

- Impairment of hearing.

- Health hazards caused by breathing dust developed when using your tool (example:- working with wood, especially oak, beech and MDF.)

Saw blades

- Do not use blades of larger or smaller diameter than recommended. For the proper blade rating refer to the technical data. Use only the blades specified in this manual, complying with EN 847-1.

- Warning! Never use abrasive wheels

Safety of others

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.VibrationThe declared vibration emission values stated in the technical data and the declaration of conformity have been measured in accordance with a standard test method provided byEN 60745 and may be used for comparing one tool with another. The declared vibration emission value may also be used in a preliminary assessment of exposure.Warning! The vibration emission value during actual use of the power tool can differ from the declared value depending on the ways in which the tool is used. The vibration level mayincrease above the level stated.When assessing vibration exposure to determine safety measures required by 2002/44/EC to protect persons regularly using power tools in employment, an estimation of vibrationexposure should consider, the actual conditions of use and the way the tool is used, including taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time.

Labels on tool

The following symbols along with the date code are shown on the tool:

![]()

![]()

Electrical safety

![]()

![]()

- If the supply cord is damaged, it must be replaced by the manufacturer or an authorised BLACK+DECKER Service Centre in order to avoid a hazard.

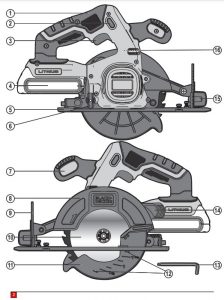

FeaturesThis tool includes some or all of the following features.1. Main handle2. Lock-off button3. On/Off trigger4. Battery (may not be included)5. Shoe6. Depth adjustment knob7. Secondary handle8. Upper Guard9. Bevel adjustment scale10. Blade11. Lower blade guard12. Depth adjustment scale13. Locking tool14. Dust extraction port15. Bevel adjustment knob16. Spindle lock

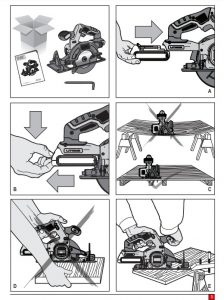

AssemblyWarning! Before attempting any of the following operations, make sure that the tool is switched off and unplugged and that the saw blade has stopped.To install the battery pack (fig. A)

- Insert battery pack into tool as shown in figure A. Ensure battery pack is fully seated and fully latched into position.

To Remove the battery pack (fig. B)

- Depress the battery release button as shown in figure B. and pull battery pack out of tool.

Supporting large panels/Securing workpiece (fig. C)

- Support large panels to minimize the risk of blade pinching and kickback. Large panels tend to sag under their own weight as shown in figure C.

- Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel figure C.

- Never hold piece being cut in your hands or across your leg figure D.

- Secure the workpiece to a stable platform as shown in figure E. It is important to support the work properly to minimize body exposure, blade binding, or loss of control.Cutting Depth Adjustment – (fig. F – G)

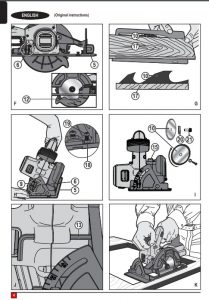

- The depth of cut should be set according to the thickness of the workpiece.

- Loosen the depth adjustment knob (6) to unlock the saw shoe (5) as shown in figure F.Move the saw shoe into the desired position. The corresponding depth of cut can be read from the scale (12).

- Set depth adjustment of saw such that one tooth (10) of the blade projects below the workpiece (16) as shown in figure G.

- Tighten the knob to lock the saw shoe in place.

Bevel Angle Adjustment – (fig. K)

This tool can be set to bevel angles between 0° and 50°.

- Loosen the bevel adjustment knob (14) to unlock the saw shoe (5).

- Move the saw shoe (5) into the desired position. The corresponding bevel angle can be read from the scale (9).

- Tighten the bevel adjustment knob (15) to lock the saw shoe in place.

- Confirm the accuracy of the setting by checking the bevel angle of an actual cut on a scrap piece of material.

Shoe Adjustment For 90° Cuts

The shoe (5) has been set by the factory to assure that the blade is perpendicular to the shoe at 0° bevel setting.IF REALIGNMENT IS NEEDED:

- Adjust the saw to 0° bevel.

- Retract blade guard (11).

- Loosen bevel adjustment knob (15). Place a square against the blade (10) and shoe (5) to adjust the 90° setting.

- Loosen jam nut (16) and move the adjustment screw (19) (inset figure H) so that the shoe will stop at the proper angle. Retighten jam nut against the shoe while holding adjustment screw in position.

- Confirm the accuracy of the setting by checking the squareness of an actual cut on a scrap piece of material.

Attaching and Removing the Blade (fig. I – J)

- Retract lower guard and assemble blade (10) and clamp washer (20) as shown in figure I.

- Depress the spindle lock (16) while turning the blade bolt (21) with the locking tool (13) until the blade lock engages and the blade stops rotating.

NOTE: Locking tool is stored on the saw as shown in figure J

- Tighten the blade bolt securely with the locking tool.NOTE: Bolt has a left-handed thread. To loosen, turn clockwise. To tighten, turn counterclockwise.NOTE: Never engage the blade lock while the saw is running, or engage in an effort to stop the tool.

Never turn the tool on while the blade lock is engaged. Serious damage to your saw will result.

Lower Blade Guard

WARNING: Laceration Hazard. The lower blade guard is a safety feature which reduces the risk of serious personal injury. Never use the saw if the lower guard is missing, damaged, misassembled or not working properly. Do not rely on the lower blade guard to protect you under all circumstances. Your safety depends on following all warnings and precautionsas well as proper operation of the saw. Check lower guard for proper closing before each use as outlined in Additional Safety Rules for Circular Saws. If the lower blade guard is missingor not working properly, have the saw serviced before using. To assure product safety and reliability, repair, maintenance and adjustment should be performed by an authorized servicecenter or other qualified service organization, always using identical replacement parts.WARNING: To minimize the risk of eye injury, always use eye protection. Foreign objects in the work place such as wire or nails can cause tips to crack or break. Only operate saw whenproper saw blade guard is in place. Mount blade securely in proper rotation before using, and always use a clean, sharp blade.WARNING: To reduce the risk of injury, It is important to support the work properly and to hold the saw firmly to prevent loss of control which could cause personal injury. Figure Eillustrates typical hand support.

Use.WARNING: To reduce the risk of serious personal injury, read, understand and follow all important safety warnings and instructions prior to using tool.Blade SelectionYour circular saw is designed for use with 140 x 2 mm diameter blades that have a 12.7 mm diameter bore. Blades must be rated for 7000 RPM operation (or higher). DO NOT use anyabrasive wheels.General CutsWARNING: To reduce the risk of injury, remove the battery, and follow all assembly, adjustment and set up instructions. Make sure lower guard operates. Select the proper blade forthe material to be cut.

- Measure and mark work for cutting.

- Support and secure work properly (See Safety Rules and Instructions).

- Use appropriate and required safety equipment (See Safety Rules).

- Secure and maintain work area (See Safety Rules).

- With battery inserted, make sure switch turns saw on and off.

SwitchSaw is equipped with a switch lock-off feature to prevent unintentional operation.

- To operate the tool, press in on the lock-off button (2) from either side of the saw and hold it in as you depress the trigger switch (3).

- After you have depressed the trigger and the tool is running, release the lock-off button.

- The tool will continue to run as long as the trigger is depressed.

- To turn the tool off, release the trigger switch.NOTE: This tool has no provision for locking the tool on, and the switch should never be locked on by any other means.Automatic Electric BrakeYour saw is equipped with an electric blade brake which stops the saw blade within 1-2 seconds of trigger release. This is automatic and requires no adjustment.SawingWARNING: To reduce the risk of serious personal injury, always hold the tool with both hands.

- Let the blade run freely for a few seconds before starting the cut.

- Apply only a gentle pressure to the tool while performing the cut.

- Work with the shoe pressed against the workpiece. Hints for optimum use

- As some splintering along the line of cut on the top side of the workpiece cannot be avoided, cut on the side where splintering is acceptable.

- Where splintering is to be minimized, e.g. when cutting laminates, clamp a piece of plywood onto the top of the workpiece.

Pocket cutting (fig. K)WARNING: Never tie the blade guard in a raised position. Never move the saw backwards when pocket cutting. This may cause the unit to raise up off the work surface whichcould cause injury.A pocket cut is one that is made when the edge of the material does not push the lower guard open, but the bottom edge of the rotating blade cuts into the middle of the material.

- Adjust the shoe (5) so the blade cuts at desired depth.

- Tilt the saw forward and rest front of the shoe on material to be cut.

- Using the retracting lever, retract lower blade guard to an upward position. Lower rear of shoe until blade teeth almost touch cutting line.

- Release the blade guard (its contact with the work will keep it in position to open freely as you start the cut).

- Remove hand from guard lever and firmly grip secondary handle (7), as shown in figure N. Position your body and arm to allow you to resist kickback if it occurs.

- Make sure blade is not in contact with cutting surface before starting saw.

- Start the motor, allow saw to come to full speed, and then gradually lower the saw until its shoe rests flat on the material to be cut. Advance saw along the cutting line until cut is completed as shown in figure K.

- Release trigger and allow blade to stop completely before withdrawing the blade from the material.

- When starting each new cut, repeat as above.

Troubleshooting

| Problem | Possible Cause | Possible Solution |

| Unit will not start. | Battery pack not installed properly.

Battery pack not charged. |

Check battery pack installation.

Check battery pack charging requirements. |

| Battery pack will not charge. | Battery pack not inserted into charger.

Charger not plugged in. Surrounding air temperature too hot or too cold. |

Insert battery pack into charger until LED appears.

Plug charger into a wodeng outlet. Refer to ‘Important Charging Notes for more details. Move charger and battery to a surrounding air teperature of above 40 degrees F (4.5°C) or below 105 degrees F (+40.5°C). |

| Unit shuts oft abruptly. | Battery pack has

reached its. maximum thermal limit. Out of charge. ( To maximize the life of the battery pack it is designed to shutoff abruptly when the charge is depleted.) |

Allow battery pack to cool down.

Place on charger and Mow to charge. |

AccessoriesThe performance of your tool depends on the accessory used. BLACK+DECKER accessories are engineered to high quality standards and designed to enhance the performance of yourtool. By using these accessories you will get the very best from your tool.MaintenanceYour tool has been designed to operate over a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon proper tool care and regular cleaning.Warning! Before performing any maintenance, switch off andunplug the tool.

- Regularly clean the ventilation slots in your tool and charger using a soft brush or dry cloth.

- Regularly clean the motor housing using a damp cloth. Do not use any abrasive or solvent-based cleaner.

Mains plug replacement (U.K. & Ireland only)If a new mains plug needs to be fitted:

- Safely dispose of the old plug.

- Connect the brown lead to the live terminal in the new plug.

- Connect the blue lead to the neutral terminal. Warning! No connection is to be made to the earth terminal. Follow the fitting instructions supplied with good quality plugs.Recommended fuse: 13 A.

Protecting the environment

Should you find one day that your BLACK+DECKER product needs replacement, or if it is of no further use to you, do not dispose of it with household waste. Make this product available for separate collection.

Local regulations may provide for separate collection of electrical products from the household, at municipal waste sites or by the retailer when you purchase a new product.BLACK+DECKER provides a facility for the collection and recycling of BLACK+DECKER products once they have reached the end of their working life. To take advantage of this serviceplease return your product to any authorised repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair agent by contacting your local BLACK+DECKER office at the address indicated in this manual. Alternatively, a list of authorised BLACK+DECKER repair agents and full details of our after-sales service and contacts are available on the Internet at: www.2helpU.com

Technical data

| BDCCS18 | ||

| Input voltage | V. | 18 |

| No-load speed | mit’ | 3700 RPM |

| Max depth of cut | mm | 43 |

| Max depth of cut at 45° bevel | mm | 35 |

| Blade diameter | mm | 140 |

| Blade bore | mm | 12.7 |

| Blade tip width | mm | 2.0 |

| Weight | kg | 2.5 |

| Charger | 90590**TYP2 | |

| Input voltage | Vx | 220.240 |

| Output voltage | V« | 20 (max) |

| Current | A | 0.4 |

| Approx. charge time | min | 225 |

| Battery | BL1518 | |

| Voltage | V“ | 18 |

| Capacity | Ah | 1.5 |

| Type | Lion |

| LpA (sound pressure) 76.0 dB(A), Uncertainty (K) 3 dB(A) |

| L (sound power) 87.0 dB(A), Uncertainty (K) 3 dB(A)

wA |

| Vibration total values (triax vector sum) according to EN 60745: |

| Cutting wood (ah vv) 1.5 m/s2. uncertainty (K) 1.5 m/s2 |

EC declaration of conformity

MACHINERY DIRECTIVE

BDCCS18 Circular saw

Black & Decker declares that these products described under“technical data” are in compliance with:2006/42/EC, EN 60745-1, EN 60745-2-5

These products also comply with Directive2004/108/EC and 2011/65/EU. For more information, pleasecontact Black & Decker at the following address or refer to theback of the manual.

The undersigned is responsible for compilation of the technical file and makes this declaration on behalf of Stanley Europe.

R. LaverickEngineering ManagerBlack & Decker Europe, 210 Bath Road, Slough,Berkshire, SL1 3YDUnited Kingdom22/04/2015

GuaranteeBlack & Decker is confident of the quality of its products and offers an outstanding guarantee. This guarantee statement is in addition to and in no way prejudices your statutory rights.The guarantee is valid within the territories of the Member States of the European Union and the European Free Trade Area.

If a Black & Decker product becomes defective due to faulty materials, workmanship or lack of conformity, within 24 months from the date of purchase, Black & Decker guarantees toreplace defective parts, repair products subjected to fair wear and tear or replace such products to ensure minimum inconvenience to the customer unless:

- The product has been used for trade, professional or hire purposes;

- The product has been subjected to misuse or neglect;

- The product has sustained damage through foreign objects, substances or accidents;

- Repairs have been attempted by persons other than authorised repair agents or Black & Decker service staff.

To claim on the guarantee, you will need to submit proof of purchase to the seller or an authorised repair agent. You can check the location of your nearest authorised repair agentby contacting your local Black & Decker office at the address indicated in this manual. Alternatively, a list of authorised Black & Decker repair agents and full details of our aftersales service and contacts are available on the Internet at: www.2helpU.com

Please visit our website www.blackanddecker.co.uk to register your new BLACK+DECKER product and to be kept up to date on new products and special offers. Further information on the BLACK+DECKER brand and our range of products is available at www.blackanddecker.co.uk

| Australia | Black & Decker (Australia) Pty. Ltd.

20 Fletcher Road, Mooroolbark, Victoria, 3138 |

Tel.

Fax |

03-8720 5100

03-9727 5940 |

| New Zealand | Black & Decker | Tel. | +64 9 259 1133 |

| 5 Te Apunga Place | Fax | +64 9 259 1122 | |

| Mt Wellington | |||

| Aukland 1060 | |||

| United Kingdom & | Black & Decker | Tel. | 01753 511234 |

| Republic Of Ireland | 210 Bath Road

Slough, Berkshire SL1 3YD |

Fax | 01753 512365 |

References

[xyz-ips snippet=”download-snippet”]