PST 18 LI

Safety Instructions

General Power Tool Safety Warnings![]() WARNINGRead all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury.Save all warnings and instructions for future reference.The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.Work area safety

WARNINGRead all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury.Save all warnings and instructions for future reference.The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.Work area safety

- Keep work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks that may ignite dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.Electrical safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerate–ors. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. The use of an RCD reduces the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to a power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean, and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Battery tool use and care

- Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

- Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 130°C may cause an explosion.

- Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

- Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

Safety instructions for jigsaws

- Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the workpiece by hand or against your body leaves it unstable and may lead to loss of control.

- Keep hands away from the sawing area. Do not reach under the workpiece. Contact with the saw blade can lead to injuries.

- Only bring the power tool into contact with the workpiece when switched on. Otherwise, there is a danger of kickback if the cutting tool jams in the workpiece.

- Ensure that the footplate always rests securely while sewing. A jammed saw blade can break or lead to kickback. When the cut is completed, switch off the power tool and then pull the saw blade out of the cut only after it has come to a standstill. In this manner, you can avoid kickback and can place down the power tool securely.

- Always wait until the power tool has come to a complete stop before placing it down. The application tool can jam and cause you to lose control of the power tool.

- Use only undamaged saw blades that are in perfect condition. Bent or dull saw blades can break, negatively influence the cut, or lead to kickback.

- Do not brake the saw blade to a stop by applying side pressure after switching off. The saw blade can be damaged, break or cause kickback.

- Only use the power tool with the base plate. If you do not use the base plate, you are at risk of not being able to control the power tool.

- Use suitable detectors to determine if there are hidden supply lines or contact the local utility company for assistance. Contact with electric cables can cause fire and electric shock. Damaging gas lines can lead to explosions. Breaking water pipes causes property damage.

- In case of damage and improper use of the battery, vapors may be emitted. The battery can set alight or explode. Ensure the area is well ventilated and seek medical attention should you experience any adverse effects. The vapors may irritate the respiratory system.

- Do not open the battery. There is a risk of short-circuiting.

- The battery can be damaged by pointed objects such as nails or screwdrivers or by force applied externally. An internal short circuit may occur, causing the battery to burn, smoke, explode or overheat.

- Only use the battery with products from the manufacturer. This is the only way in which you can protect the battery against dangerous overload.

Protect the battery against heat, e.g. against continuous intense sunlight, fire, dirt, water, and moisture. There is a risk of explosion and short-circuiting.

Protect the battery against heat, e.g. against continuous intense sunlight, fire, dirt, water, and moisture. There is a risk of explosion and short-circuiting.

Product Description and Specifications

Read all the safety and general instructions.Failure to observe the safety and general instructions may result in electric shock, fire, and/or serious injury. Please observe the illustrations at the beginning of this operating manual.

Read all the safety and general instructions.Failure to observe the safety and general instructions may result in electric shock, fire, and/or serious injury. Please observe the illustrations at the beginning of this operating manual.

Intended Use

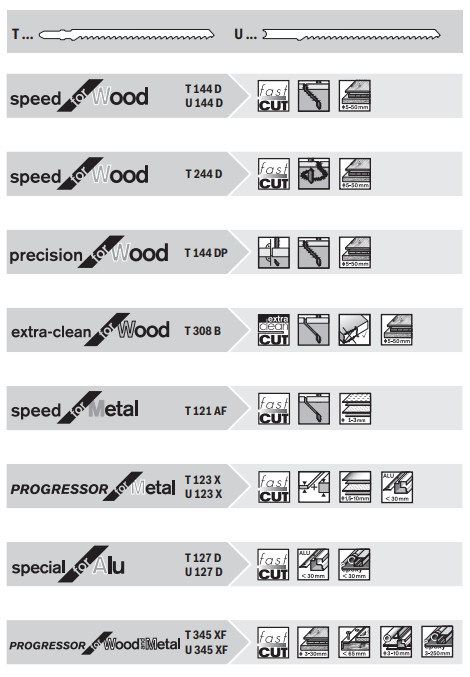

The power tool is intended for making separating cuts and cut-outs in wood, plastic, metal, ceramic plates, and rubber while resting firmly on the workpiece. It is suitable for straight and curved cuts with miter/bevel angles of up to 45°. Note the saw blade recommendations.

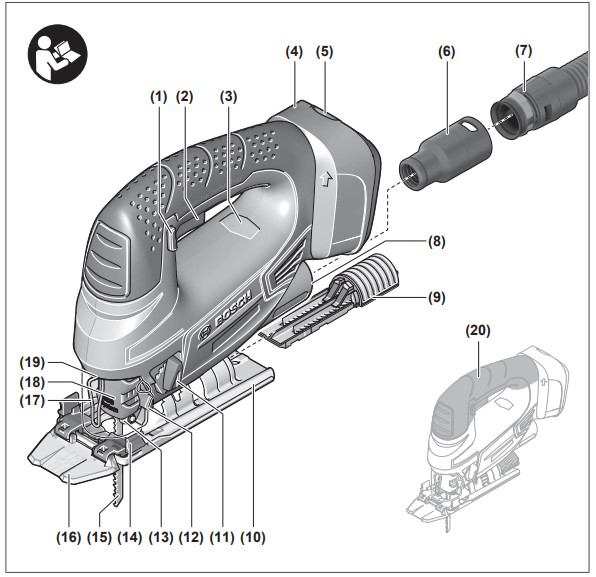

Product features

The numbering of the product features refers to the diagram of the power tool on the graphics page.

- Lock-off function for on/off switch

- On/off switch

- Battery charge indicator

- Rechargeable battery

- Battery release button

- Dust extraction adapter

- Extraction Hose

- Extraction outlet

- Saw blade storage compartment

- Baseplate

- Orbital action adjusting lever

- Hood for extraction attachment

- Guide roller

- The base for Cut Control

- Saw blade

- Viewing window for Cut Control

- Shock protection guard

- Saw blade receptacle

- Worklight

- Handle (insulated gripping surface)

- Anti-splinter guard

- Guide for the parallel guide

- Scale for miter/bevel angles

- Base plate screw

- 0° cut mark

- 45° cut mark

- Locking screw for the parallel guide

- Parallel guide with a circle cutter

- Circle cutter centering tipa) Accessories shown or described are not included with the product as standard. You can find the complete selection of accessories in our accessories range.

| Jigsaw | PST 18 LI | |

| Article number | 3 603 K11 0.. | |

| Stroke rate control | ● | |

| Pendulum action | ● | |

| Rated voltage | V= | 18 |

| No-load stroke rate n₀ | min−1 | 0−2400 |

| Stroke | mm | 20 |

| Max. cutting depth | ||

| – in wood | mm | 80 |

| – in aluminum | mm | 12 |

| – in steel (unalloyed) | mm | 5 |

| Max. cutting angle (left/right) | ° | 45 |

| Weight according to EPTA-Procedure 01:2014 A) | kg | 2.0 (1.5 Ah)–2.3 (6.0 Ah) |

| Recommended ambient temperature duringcharging | °C | 0 to +35 |

| Permitted ambient temperature during operation B) and during storage | °C | –20 to +50 |

| Recommended rechargeable batteries C) | PBA 18V…W-. | |

| Recommended battery chargers | AL 18… |

A) Depends on battery in useB) Limited performance at temperatures <0 °CC) The following chargers are not compatible with the PBA rechargeable battery: AL 1814 CV, AL 1820 CV, AL 1860 CV

Noise/Vibration InformationNoise emission values determined according to 62841‑2‑11.Typically, the A-weighted noise level of the power tool is:Sound pressure level 83 dB(A); sound power level 94 dB(A). Uncertainty K = 5 dB.Wear hearing protection!Vibration total values ah (triax vector sum) and uncertainty K determined according to 62841‑2‑11:Cutting boards with saw blade T 144 D:ah,B = 11 m/s 2 , K = 1.5 m/s 2 , cutting sheet metal with saw blade T 118 A: ah,M = 10 m/s 2 , K = 1.5 m/s 2 .The vibration level and noise emission value given in these instructions have been measured in accordance with a standardized measuring procedure and may be used to compare power tools. They may also be used for a preliminary estimation of vibration and noise emissions.The stated vibration level and noise emission value represent the main applications of the power tool. However, if the power tool is used for other applications, with different application tools or is poorly maintained, the vibration level and noise emission value may differ. This may significantly increase the vibration and noise emissions over the total working period.To estimate vibration and noise emissions accurately, the times when the tool is switched off or when it is running but not actually being used should also be taken into account.This may significantly reduce vibration and noise emissions over the total working period.Implement additional safety measures to protect the operator from the effects of vibration, such as servicing the power tool and application tools, keeping their hands warm, and organizing workflows correctly.

Rechargeable battery

Charging the battery

- Use only the chargers listed in the technical data. Only these chargers are matched to the lithium-ion battery of your power tool.Note: The battery is supplied partially charged. To ensure full battery capacity, fully charge the battery in the charger before using your power tool for the first time.The lithium-ion battery can be charged at any time without reducing its service life. Interrupting the charging process does not damage the battery.

The lithium-ion battery is protected against deep discharge by the “Electronic Cell Protection (ECP)”. When the battery is discharged, the power tool is switched off by means of a protective circuit: The application tool no longer rotates.

- Do not continue to press the On/Off switch after the power tool has automatically switched off. The battery can be damaged.

Inserting the BatteryPush the charged battery into the battery holder until it clicks into place.Removing the BatteryTo remove the rechargeable battery, press the battery release button and pull the battery out.Do not use force todo this.Battery charge indicatorThe battery charge indicator indicates the remaining battery capacity or an overload when the power tool is switched on.

| LED | Capacity |

| Continuous lighting 3 x green | ≥ 66% |

| Continuous lighting 2 x green | 33–66% |

| Continuous lighting 1 x green | 11–33% |

| Slowly flashing light 1 x green | ≤ 10% |

The three LEDs in the battery charge indicator flash quickly when the temperature of the rechargeable battery is outside the operating temperature range and/or the overload protection has been triggered.

Recommendations for Optimal Handling of the Battery Protect the battery against moisture and water.Only store the battery within a temperature range of −20 to 50 °C. Do not leave the battery in your car in the summer, for example.Occasionally clean the ventilation slots on the battery using a soft brush that is clean and dry.A significantly reduced operating time after charging indicates that the battery has deteriorated and must be replaced.Follow the instructions on correct disposal.

Assembly

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

Inserting/changing the saw blade

- When fitting or changing the saw blade, wear protective gloves. Blades are sharp and can become hot when used for prolonged periods of time.

Selecting the saw bladeYou will find an overview of recommended saw blades at the end of these operating instructions. Only use saw blades with a single lug shank (T shank) or with a 1/4″ universal shank (U shank). The saw blade should not be longer than required for the intended cut.Use a narrow saw blade when sawing tight curves.

Inserting the saw blade (see figure A)

- Clean the shaft on the saw blade before inserting it.A dirty shaft cannot be securely fixed in place.

If necessary, remove the hood (12).Push the saw blade receptacle (18) upwards in the direction of the arrow. Push the saw blade (15), with the teeth in the cutting direction, into the saw blade receptacle as far as it will go.Make sure when inserting the saw blade that the back of the saw blade is in the groove on the guide roller (13).

- Check that the saw blade is seated securely. A loose saw blade can fall out and lead to injuries.

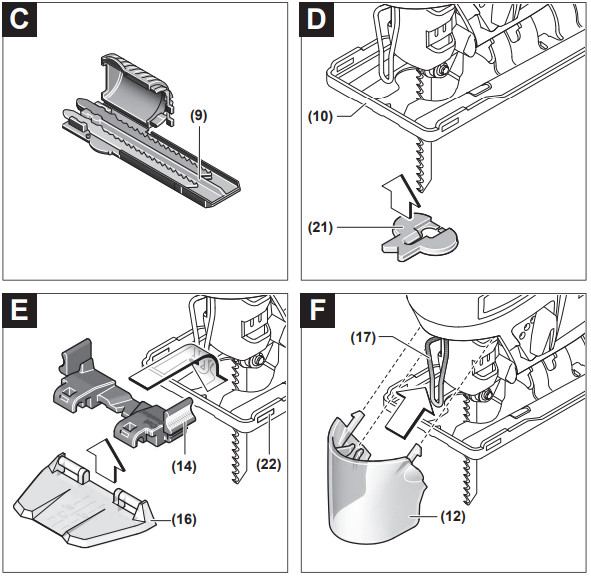

Removing the saw blade (see figure B)Push the saw blade receptacle (18) upwards in the direction of the arrow and remove the saw blade (15).Saw blade storage compartment (see figure C)You can keep up to six saw blades that are no longer than 110 mm in the saw blade storage compartment (9). Insert the saw blades with single lug shank (T shank) into the saw blade storage compartment in the recess intended for these. You can place up to three saw blades on top of each other. Close the saw blade storage compartment and push it as far as it will go into the recess in the base plate (10).

Anti-splinter guard (see figure D)The anti-splinter guard (21) (accessory) can prevent splintering of the surface while sawing wood. The anti-splinter guard can only be used with certain saw blade types and only at a cutting angle of 0°. When sawing with the anti-splinter guard, the base plate (10) must not be moved to the rear for sawing close to edges.Push the anti-splinter guard (21) into the base plate (10) from below (as shown in the figure with the groove facing upwards).

Cut ControlCut Control enables the power tool to be guided precisely along a cutting line marked on the workpiece. Cut Control includes the viewing window (16) with cut marks and the base (14) for securing to the power tool.

Securing Cut Control to the base plate (see figure E)Firmly insert the viewing window for Cut Control (16) into the brackets on the base (14). Then push the base together gently and allow it to click into place in the guide (22) on the base plate (10).

Dust/Chip ExtractionThe dust from materials such as lead paint, some types of wood, minerals and metal can be harmful to human health.Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as carcinogenic, especially in conjunction with wood treatment additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.– Use a dust extraction system that is suitable for the material wherever possible.– Provide good ventilation at the workplace.– It is advisable to wear a P2 filter class breathing mask.The regulations on the material being machined that apply in the country of use must be observed.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

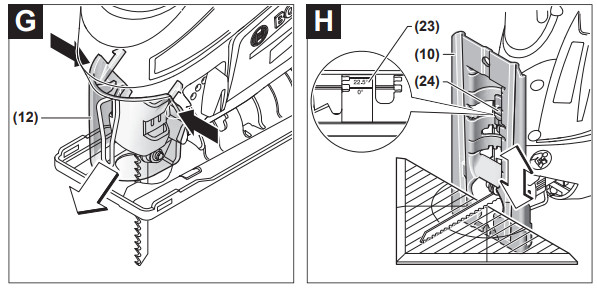

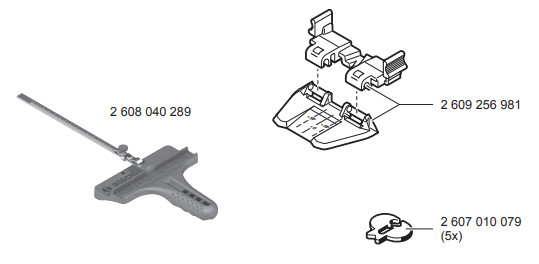

Hood (see figures F and G)Fit the hood (12) before you connect the power tool to the dust extraction system.Position the hood (12) on the power tool so that the two outer brackets engage in the recesses of the housing.Remove the hood (12) when working without a dust extraction system and for miter cuts. To do this, push the hood together at the level of the outer brackets and remove it by pulling it forwards.Connecting the dust extraction systemPush the dust extraction adapter (6) (accessory) onto an extraction hose (7) (accessory) until you hear it click into place. Connect the dust extraction adapter (6) to the extraction outlet (8) on the power tool and the extraction hose (7) to a dust extractor (accessory).You will find an overview of connecting to various dust extractors at the end of these operating instructions.For optimum dust extraction, where possible use the antisplinter guard (21).The dust extractor must be suitable for the material being worked.When extracting dry dust that is especially detrimental to health or carcinogenic, use a special dust extractor.

Operation

Operating modes

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

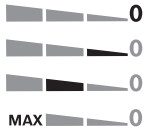

Pendulum action settingsThe pendulum action can be adjusted using four different settings, allowing the cutting speed, cutting capacity and the cut itself to be optimally adapted to the material that you want to cut.You can also adjust the pendulum action during operation using the adjusting lever (11).

|

No pendulum actionLow pendulum actionModerate pendulum actionHigh pendulum action |

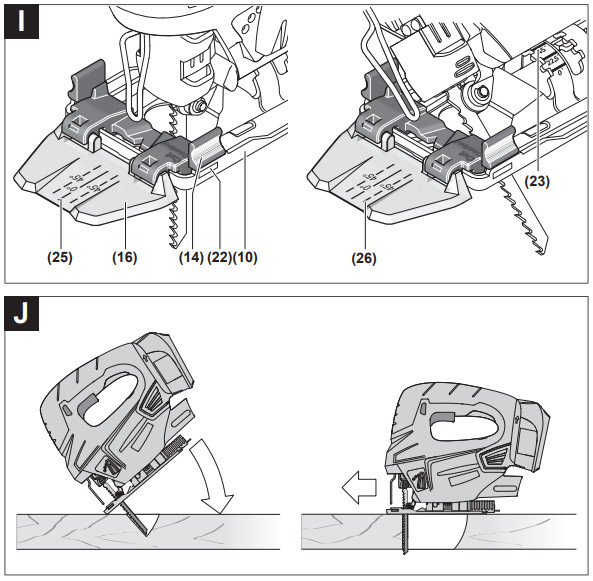

Adjusting the miter angle (see figure H)The base plate (10) can be swiveled to the right or left to make miter cuts up to 45°.The hood (12) and anti-splinter guard (21) cannot be used while miter cuts are being made.– Remove the hood (12) and the anti-splinter guard (21).– Pull the saw blade storage compartment (9) out of the base plate (10).– Loosen the screw (24) and push the base plate (10) slightly towards the extraction outlet (8).– The base plate has lock-in points at 0°, 22.5° and 45° on the left and right so that the precise miter angle can be adjusted. Swivel the base plate (10) to the desired position according to the scale (23). Other miter angles can be adjusted using a protractor.– Then push the base plate (10) towards the saw blade (15) as far as it will go.– Retighten the screw (24).Cut Control for miter cuts (see figure I)To enable you to track the cutting line (Cut Control), the viewing window for Cut Control (16) has a mark (25) for right-angled cuts at 0° and a mark (26) for rightward- and leftward-slanting miter cuts at 45° according to the scale (23).The cut mark for miter angles between 0° and 45° is proportional. It can also be marked on the viewing window for Cut Control (16) using a non-permanent marker and easily removed again.We recommend making a test cut for precise results.Moving the base plate (see figure H)You can move the base plate (10) back for sawing close to the edges.Pull the saw blade storage compartment (9) out of the base plate (10). Loosen the screw (24) and push the base plate (10) towards the extraction outlet (8) as far as it will go. Retighten the screw (24).Sawing with an offset base plate (10) is only possible with a miter angle of 0°. In addition, Cut Control must not be used with the base(14), the parallel guide with a circle cutter (28) (accessory) or the anti-splinter guard (21).

Starting OperationSwitching on/offTo switch on the power tool, press the lock-off switch (1) first. Then press the on/off switch (2) and keep it pressed.The work light lights up when the on/off switch (2) is lightly or fully pressed allowing the work area to be illuminated in poor lighting conditions.To switch off the power tool, release the on/off switch (2).Note: For safety reasons, the on/off switch (2) cannot be locked; it must remain pressed during the entire operation.

Controlling the stroke rateYou can variably adjust the stroke rate of the power tool when it is on by pressing in the on/off switch (2) to varying extents.Applying light pressure to the on/off switch (2) results in a low stroke rate. Applying increasing pressure to the switch increases the stroke rate.The required stroke rate is dependent on the material and the work conditions and can be determined using practice tests.It is recommended that you reduce the stroke rate when placing the saw blade on the workpiece and when sawing plastic and aluminum.During prolonged periods of use at a low stroke rate, the power tool may heat up significantly. Remove the saw blade and let the power tool run at the maximum stroke rate for around three minutes to cool down.

Temperature-dependent overload protectionIn normal conditions of use, the power tool cannot be overloaded. If the power tool is overloaded or not kept within the permitted battery temperature range, the speed is reduced or the power tool switches off. At reduced speed, the power tool will run again at full speed once the permitted battery temperature is reached or the load is reduced. If it automatically shuts down, switches the power tool off, allows the battery to cool down, then switch the power tool back on.The three LEDs in the battery charge indicator (3) flash quickly when the temperature of the battery is outside the operating temperature range of −20 to +50 °C and/or the overload protection has been triggered.

Working Advice

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is a risk of injury from unintentionally pressing the on/off switch.

- Switch the power tool off immediately if the saw blade becomes blocked.

- When machining small or thin workpieces, always use a stable base or saw table (accessory).

Under certain conditions, strong electromagnetic fields can negatively affect or stop the power tool. After switching the power tool off, press the on/off switch (2) again to restart the power tool.

Plunge cutting (see figure J)

- Plunge cuts may only be applied to soft materials, such as wood, gypsum board, etc.

For plunge cutting, use only short saw blades. Plunge cutting is possible only with a miter angle of 0°.Place the power tool so that the front edge of the base plate (10) rests on the workpiece, without the saw blade (15) touching the workpiece, and switch it on. On power tools with stroke rate control, select the maximum stroke rate.Press the power tool firmly against the workpiece and allow the saw blade to plunge slowly into the workpiece.As soon as the base plate (10) rests fully on the workpiece, continue sawing along the required cutting line.

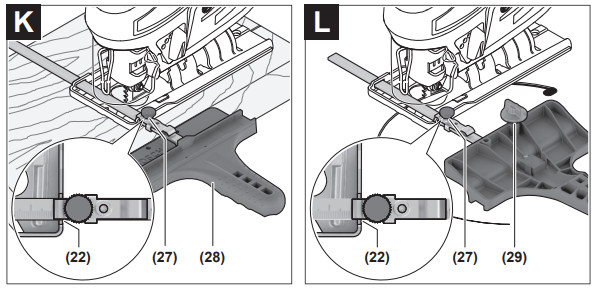

Parallel guide with a circle cutter (accessory)When working with the parallel guide with a circle cutter (28) (accessory), the workpiece must be no more than 30 mm thick.Remove the base for Cut Control (14) from the base plate (10). To do this, push the base together gently and remove it from the guide (22).Parallel cuts (see figure K): Loosen the locking screw (27) and slide the scale on the parallel guide through the guide (22) in the base plate. Adjust the desired cutting width as a scale value on the inside edge of the base plate. Retighten the locking screw (27).Circular cuts (see figure L): Drill a hole large enough to push the saw blade through on the cutting line within the circle to be cut. Machine the drill hole with a router or file so that the saw blade can lie flush with the cutting line.Position the locking screw (27) on the other side of the parallel guide. Slide the scale on the parallel guide through the guide (22) into the base plate. Drill a hole in the workpiece in the middle of the section to be cut out. Insert the centring tip (29) through the inner opening of the parallel guide and into the drilled hole. Adjust the radius as a scale value on the inside edge of the base plate. Retighten the lockingscrew (27).Coolant/lubricant As the material heats up along the cutting line when cutting metal, you should apply coolant or lubricant.

EU Declaration of Conformity

Jigsaw

Article number

We declare under our sole responsibility that the stated products comply with all applicable provisions of the directives and regulations listed below and are in conformity with the following standards.Technical file at: *

| PST 18 LI | 3 603 K11 0.. | 2006/42/EC2014/30/EU2011/65/EU | 62841-1:201562841-2-11:2016+A1:202055014-1:2017+A11:202055014-2:2015IEC 63000:2018 |

Henk BeckerChairman ofExecutive Management |

Helmut HeinzelmannHead of Product Certification |

||

| Robert Bosch Power Tools GmbH, 70538 Stuttgart, GERMANYStuttgart, 22.03.2021 |

Declaration of Conformity

| JigsawPST 18 LI | Article number3 603 K11 001 |

We declare under our sole responsibility that the stated products comply with all applicable provisions of the regulations listed below and are in conformity with the following standards.Technical file at: Robert Bosch Ltd. (PT/SOP-GB), Broadwater Park, North Orbital Road, Uxbridge UB9 5HJ, United Kingdom

| Supply of Machinery (Safety) Regulations 2008Electromagnetic Compatibility Regulations 2016The Restriction of the Use of Certain Hazardous Substances inElectrical and Electronic Equipment Regulations 201262841-1:201562841-2-11:2016+A1:202055014-1:2017+A11:202055014-2:2015IEC 63000:2018 | |

Vonjy RajakobaManaging Director – Bosch UK |

Robert Bosch Power Tools GmbH, 70538 Stuttgart, Germany represented (in terms of the above regulations) byRobert Bosch Limited, Broadwater Park, North Orbital Road,Uxbridge UB9 5HJ, United KingdomMartin SibleyHead of Sales Operations and Aftersales |

| Robert Bosch Ltd. Broadwater Park, North Orbital Road, Uxbridge UB9 5HJ, United Kingdom, as authorized representative acting on behalf of Robert Bosch Power Tools GmbH, 70538 Stuttgart, GermanyUxbridge, 11/05/2021 |

Robert Bosch Power Tools GmbH70538 StuttgartGERMANYwww.bosch-pt.com1 609 92A 6DA (2021.05) T / 119

Bosch Power Tools

1 609 92A 6DA | (11.05.2021)

References

Invented for life | Bosch Global

Bosch el-værktøj | Bosch el-værktøj

Invented for life | Bosch Global

Service worldwide

Bosch-sähkötyökalut | Bosch-sähkötyökalut

Ηλεκτρικά εργαλεία Bosch | Ηλεκτρικά εργαλεία Bosch

Outillage électroportatif Bosch | Outillage électroportatif Bosch

Select your country | Bosch Power Tools

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

Skånevik Ølen Kraftlag AS

📧[email protected]

📧[email protected]

Loading…

📧[email protected]

Ana Sayfa | Bosch Türkiye

Bosch Power Tools | Bosch Power Tools

📧[email protected]

📧[email protected]

Bosch Elektrowerkzeuge und Zubehör | Bosch Elektrowerkzeuge

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

📧[email protected]

[xyz-ips snippet=”download-snippet”]