Electric Dual Action Log Splitter 8 Ton

MODEL NO.: ED8T20

Owner’s Manual

ASSEMBLY & OPERATING INSTRUCTIONS

SECTION I: KNOW YOUR LOG SPLITTER

![]()

![]()

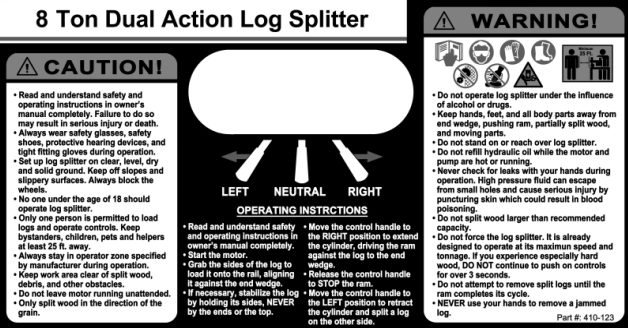

Make sure that all safety warning decals are in good condition and readable. Always replace missing or defaced decals. Contact Boss Industrial, Inc. at 1-800-780-2677 for replacement decals.

1. Safety Warning / Operating Label (Part #: 410-123)

2. Serial NO. / Spec. Label (Part #: 410-590)

3. Switch Label (Part #: 410-159)

4. Motor Label (Part #: 410-359)

5. Oil Tag (Part #: 410-602)

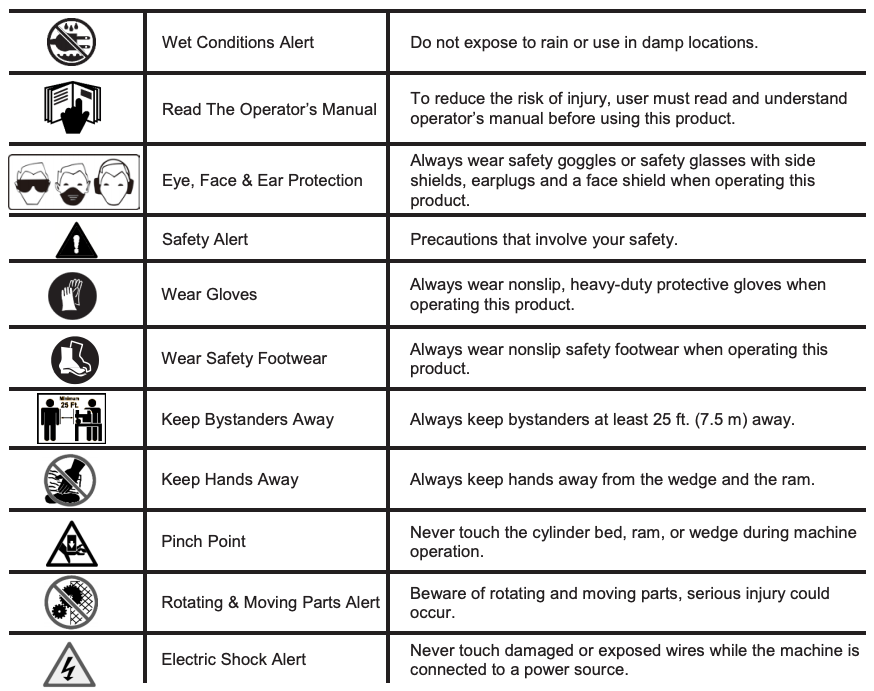

Study the following symbols used on this tool and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

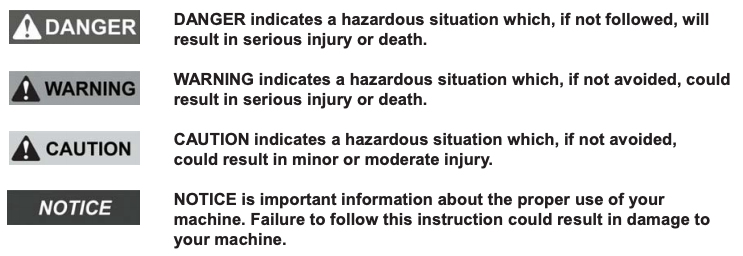

The following signal words and meanings are intended to explain the levels of risk associated with this product.

![]()

- DO NOT discard packing materials until you have carefully inspected and satisfactorily operated the tool.

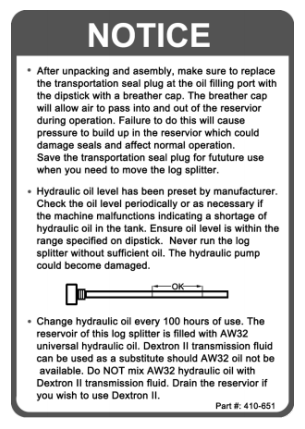

- Make sure to replace the transportation seal plug at the oil filling port with the breather cap mounted on dipstick. Failure to do so may cause the pressure to build up in the reservoir which could damage seals and void warranty.

- Lubricate the wedge and upper side of the machine body for splitting smoothly.

- Check the oil level before every operation.

- Sharpen the wedges periodically.

- USE only an electrical circuit having adequate capacity as recommended.

- DO NOT continue to push on the control handle more than 3 seconds if the wedge can’t cut through an oversized or extremely hard log. Force the tool will cause permanent damage and void warranty.

- Try to split from another end or cut a small piece from the border instead of the center when you fail to cut through a log.

- Release the handle lever as the cylinder is almost extended or retracted fully. Keep holding the control lever as the ram reaches to the farthest positions will cause the valve squeezed. You must turn off the motor to relieve the pressure and restart the tool to operate.

- DO NOT expose this machine to rain or use in a damp environment.

![]()

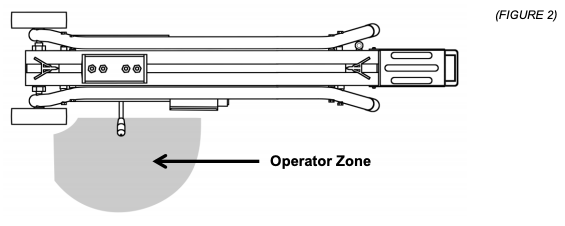

ONLY operate the log splitter from the operator zone as shown below. The operator has the safest and most efficient access to the control valve and the beam in this location. Failure to operate the log splitter in this position can result in serious injury or death.

![]()

1. This tool is powered by a precision built electric motor. Use only an electrical circuit having adequate capacity as recommended by the manufacturer — 115 volts, 60 Hz, AC only(normal household current). Do not operate this tool on direct current (DC). If you choose to connect the tool to a generator, make sure the generator carrying the current (Amperes) or power output (Watts) at least 50% more than motor rated power.

2. A substantial voltage drop will cause a loss of power and the motor will overheat. If the machine does not operate when plugged into an outlet, double check the power supply.

3. For voltage, the wiring is as important as the motor’s horsepower rating. A line intended only for lights cannot properly carry a power tool motor. Check the house wiring if you experience circuit breaker tripped or fuse blown even the motor is plugged into a wall outlet directly, or switch to a 20 A circuit if this happens on a 15 A circuit.

4. This tool is intended for use on a circuit that has an outlet like the one shown below (FIGURE 3). Ensure that the outlet has a grounding pin that is properly installed and grounded in accordance with all local codes and ordinances to reduce the risk of electric shock. Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

5. Check that the switch, cable and plug are not damaged before each use to avoid electric shock or short circuit.

6. Use only 3-wire extension cords with 3-prong grounding plugs, and 3-pole receptacles that accept the tool’s plug.

7. When using a power tool at a considerable distance from the power source, use an extension cord heavy enough to carry the current that the tool will draw. An undersized extension cord will cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat.

8. Use the chart provided below to determine the minimum wire size required in an extension cord. Only round jacketed cords listed by Underwriter’s Laboratories (UL) should be used.

9. When working with the tool outdoors, use an extension cord that is designed for outside use. This is indicated by the letters “WA” on the cord’s jacket.

10. Keep the extension cord clear of the working area. Position the cord so that it will not get caught on lumber, tools or other obstructions while you are working with a power tool. Failure to do so can result in serious injury.

11. “BLOWING” a fuse or tripping a circuit breaker is usually a warning that you are overloading the machine or have too many devices taking power from the circuit, or both. DO NOT install a higher capacity fuse!

12. DO NOT leave the motor running unattended.

13. DO NOT expose the motor to rain or use / store in damp locations.

![]()

- The hydraulic system of your log splitter requires careful inspection along with the mechanical parts. Be sure to replace frayed, kinked, cracked or otherwise damaged hydraulic hoses or hydraulic components.

- NEVER check for leaks of hydraulic fluid with your hand. Fluid escaping from a small hole can be almost invisible. Escaping fluid under pressure can have sufficient force to penetrate skin causing serious personal injury or even death. Leaks can be detected by passing a piece of cardboard over the suspected leak and looking for discoloration.

- ALWAYS seek professional medical attention immediately if injured by escaping hydraulic fluid. Serious infection or reaction can develop if proper medical treatment is not administered immediately.

- ALWAYS be sure to relieve all pressure by shutting off the motor and moving the control handle back to stop position.

- NEVER remove the vent plug from the hydraulic tank or reservoir while the log splitter is running. The tank could contain hot oil under pressure which could result in serious injury.

- NEVER adjust the hydraulic valve. The pressure relief valve on your log splitter is preset at the factory. Only a qualified service technician should perform this adjustment.

- NEVER operate your log splitter near a flame or spark. Hydraulic oil is flammable and can explode.

- ALWAYS take a Class B fire extinguisher with you when operating this log splitter in dry areas as a precautionary measure against possible flying sparks.

SECTION II: PRE-OPERATION INSTRUCTIONS

This product has been shipped almost fully assembled.

- Carefully remove the log splitter and all accessories from the box. Make sure that all components listed in the packing List are included. See Page 16

- Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

- DO NOT discard packing materials until you have carefully inspected and satisfactorily operated the tool.

- If any parts are damaged or missing, please call 1-800-780-2677 for assistance.

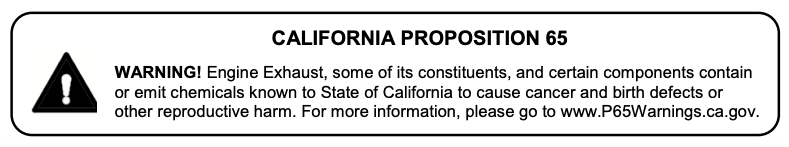

- Screw on the control handle lever onto the short lever on the valve. See FIGURE 4

- Attach the safety shield. See FIGURE 4

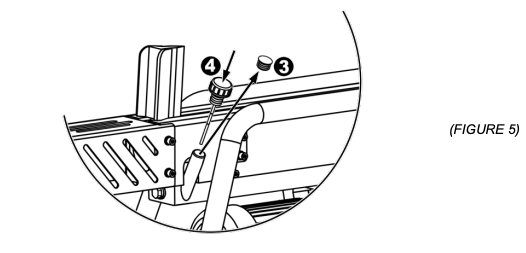

- Replace the transportation seal plug at the oil filling port with the breather cap mounted on the dipstick. See FIGURE 5

![]() NOTES:

NOTES:

- If any parts are damaged or missing, do not operate this tool until the missing parts are replaced. Failure to do so could result in possible serious personal injury.

- Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

![]()

![]()

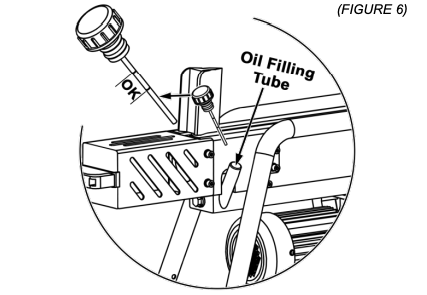

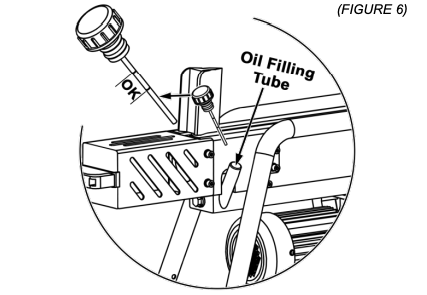

- Check the oil level. See FIGURE 6

1) Remove the breather cap mounted on dipstick.

2) Wipe the dipstick and insert it all the way back into the oil filling tube.

3) Take out the dipstick and see if the oil level is between the “OK” range.

4) Add oil (AW32) if the oil level is underneath the bottom line until the proper level is reached.

- Place the log splitter on flat, dry, solid ground.

- Block two wheels to prevent your log splitter from moving during operation.

- Lubricate the wedge and upper side of the machine body. This will allow the log to move smoothly on the surface. See FIGURE 7

- Wear non-slip safety shoes, safety goggles, safety gloves, protective hair covering and suitable work clothing. Never wear jewelry, necktie and other loose clothing.

- Logs should be cut with square ends. Never split logs larger than 10.5 in. diameter or 20-1/2 in. long. Uneven logs (e.g. knotted, curved, etc.) should not be used.

![]()

![]()

![]()

![]()

![]()

![]()

- ALWAYS read the operator’s manual before operation.

- NEVER allow children to operate this log splitter. NEVER allow adults lacking proper instructions and understanding to operate this log splitter.

- NEVER operate the log splitter when tired or under the influence of alcohol, drugs or medication.

- Always use eye protection which is marked to comply with ANSI Z87.1.

- NEVER use this log splitter for any purpose other than splitting wood. It is designed for this use only. Any other use can cause serious injury or death.

- Check that the switch, power cable and plug are not damaged (no cracks, etc.) to prevent the risk of electric shock or a short circuit.

- Check that all nuts, bolts and hydraulic fittings are tight to be sure the equipment is in a safe working condition.

- Ensure that the horizontal distance between the splitter and outlet is more than 5 feet.

- Be familiar with all controls and proper operation. Know how to stop the machine quickly in the event of any malfunction or emergency.

SECTION III: OPERATION INSTRUCTIONS

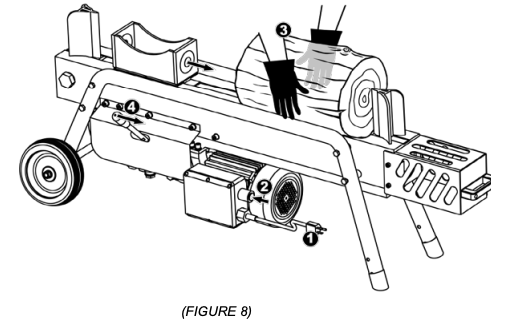

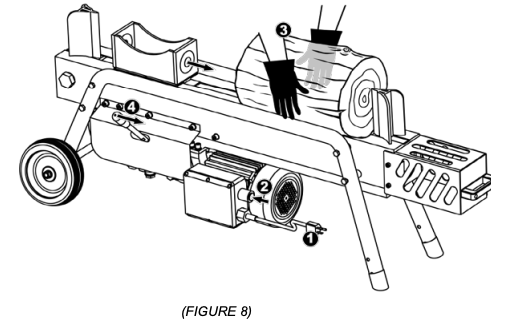

- Plug the machine into a 3 pole outlet and start the Motor.

- Grab the round side of the log and place it firmly against the wedge. See FIGURE 8

- Use your left hand to move the control handle left or right to split the log.

- Stabilize the log using your right hand when needed. Remove your hand immediately as the ram starts to contact the log.

- Release the control handle to stop splitting at any desired position and begin loading the next log. DO NOT keep holding the control handle when the ram reaches to the farthest positions.

- When you finish splitting, switch off and unplug the power cable.

![]()

![]()

![]()

![]()

![]()

![]()

- NEVER place hands or feet between the extending wedge and the end plates.

- NEVER straddle or step over the log splitter during operation.

- NEVER reach or bend over the log splitter to pick up a log.

- NEVER try to split two logs on top of each other.

- NEVER try to cross split a log.

- NEVER attempt to load your log splitter when the ram is in motion.

- ALWAYS use your hand to operate the control lever on the valve. NEVER use your foot, a rope or any extension device.

- ONLY operate your log splitter in daylight or under good artificial light.

- ALWAYS keep the work area clean. Remove split wood around your log splitter immediately so that you don’t stumble over it.

- Only a single operator is allowed to load and operate this log splitter. Keep bystanders, helpers, pets and children a sufficient distance at least 25 feet from the machine.

- DO NOT force the tool. It is designed to operate within its maximum speed and tonnage. No continuing to push on the control handle for more than 3 seconds. If you experience extremely hard wood, release the control handle at once to avoid permanent damage which will void warranty. If the motor stops, turn off the motor and then turn it back on again to continue splitting.

- If the log is clipped or jammed on the wedge, stop the machine and knock off the log with a hammer or mallet (not with your hands).

- DO NOT pull on the power supply cable to unplug the machine.

SECTION IV: MAINTENANCE

Store unit in a clean, dry area. Make sure it’s switched off and unplugged.

![]()

![]()

![]()

![]()

![]()

![]()

- Allow the machine to cool 5 minutes after use before storing.

- Protect power supply cable from heat, sunshine, aggressive liquids and sharp edges.

- Do not store unit in unprotected areas outdoors. Never place near corrosive materials or in a damp environment.

- Lean the machine against the wall if you store the machine upright. Make sure it won’t tip over.

![]()

![]()

This machine can fit in most pickup trucks or larger vehicles for transportation. Ensure that the splitter is properly secured before the vehicle is in motion.

![]()

![]()

![]()

![]()

![]()

![]()

- NEVER move this machine while the motor is running.

- Be extra cautious when moving this machine on rugged and rough terrain.

- Never allow anyone to ride on the machine while transporting.

- Make sure the transportation seal plug is inserted into the oil filling tube during transportation.

Regular maintenance is the way to ensure the best performance and long life of your machine.

- Replace hydraulic oil every 100 hours of use. AW32 universal hydraulic oil is highly recommended.

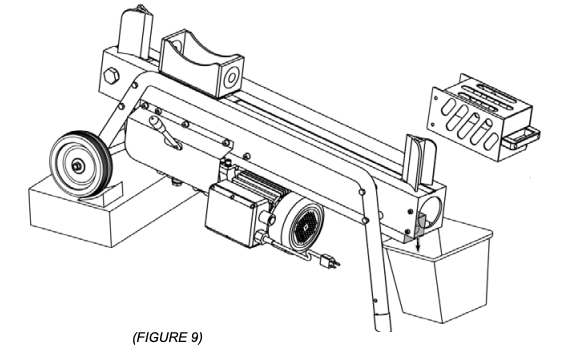

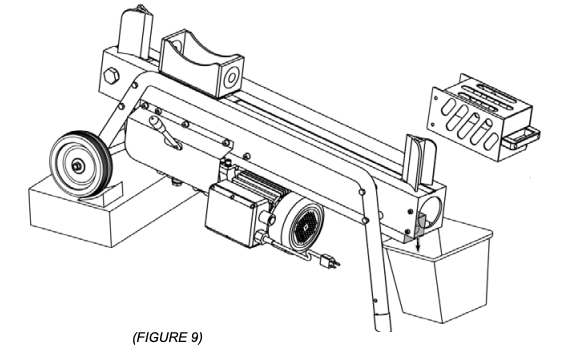

1) Raise the wheel end of the splitter 10 in. off the ground. See FIGURE 9

2) Place a container no less than 1.5 gallon of capacity under the oil drain port in the front of the reservoir.

3) Using a 19mm wrench or an adjustable wrench to remove the oil drain bolt. Also disconnect the dipstick with breather cap and safety shield to drain the oil easily.

4) Replace the oil drain bolt and tighten. after the oil is completely drained.

5) Level the machine and refill the reservoir tank with fresh oil via the oil filling tube until the oil level reaches the max. line on the dipstick. See FIGURE 6 on Page 7.

6) Push the dipstick all the way in and operate the unit unloaded. Move the control handle to engage the ram close to the farthest positions back and forth for 12 cycles to repel the air.

7) Dispose old oil at an oil recycling center.

- Sharpen the wedge when it gets dull or nicked. Using a fine-toothed file, smooth any burrs or crushed areas along the cutting edge.

- Periodically clean the machine using an oiled rag to prevent rust.

- Do not at any time let brake fluids, gasoline, petroleum based products, penetrating lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which may result in serious personal injury.

- ALWAYS unplug from the power source while repairing or adjusting the splitter.

- Replace all damaged or worn parts immediately that must meet manufacturer’s specifications.

![]()

![]()

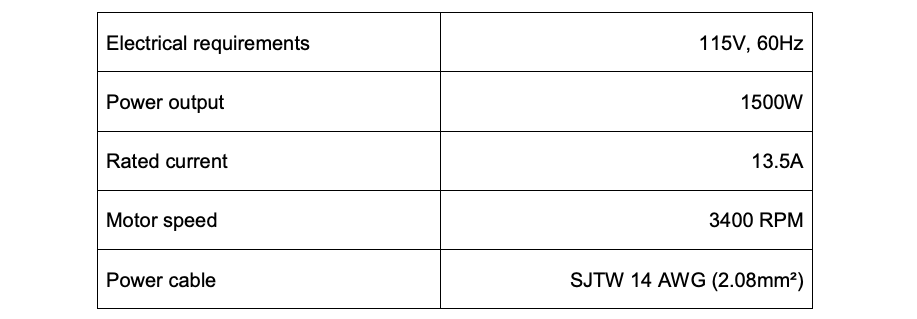

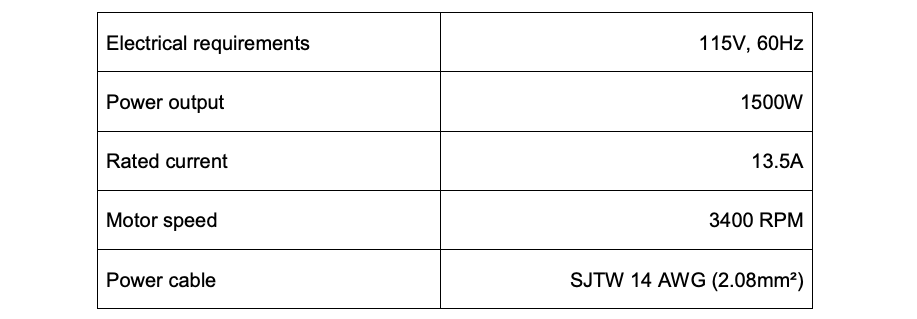

TECHNICAL SPECIFICATIONS

*Tonnage and cycle time may vary dependent upon electricity supply, mechanical and environmental conditions.

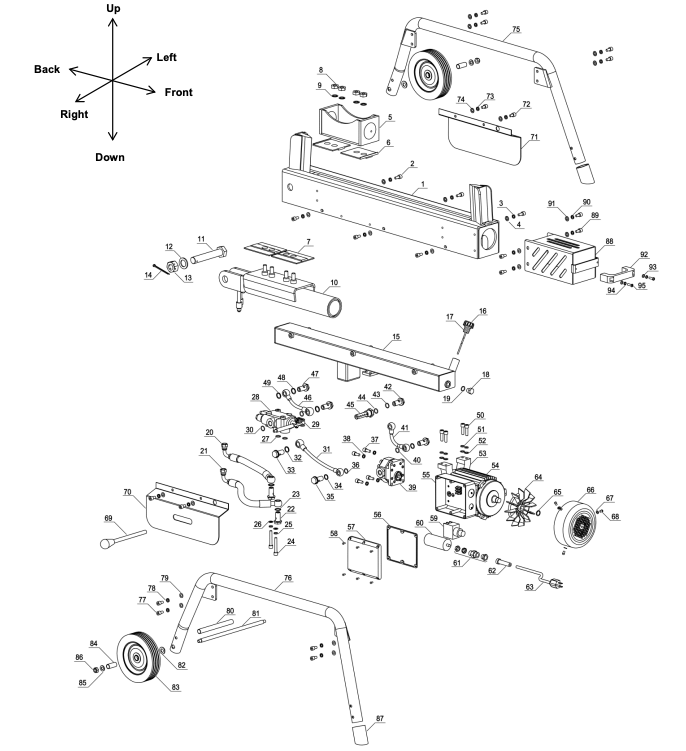

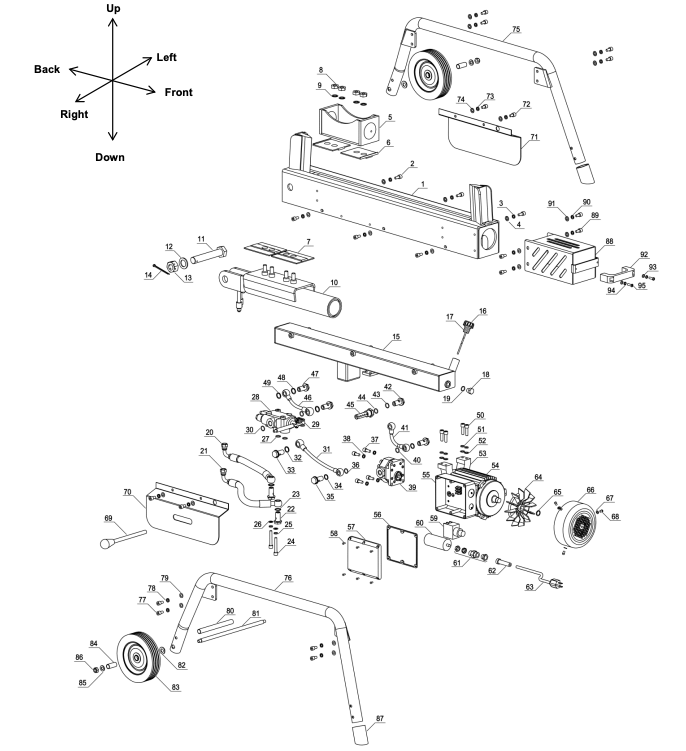

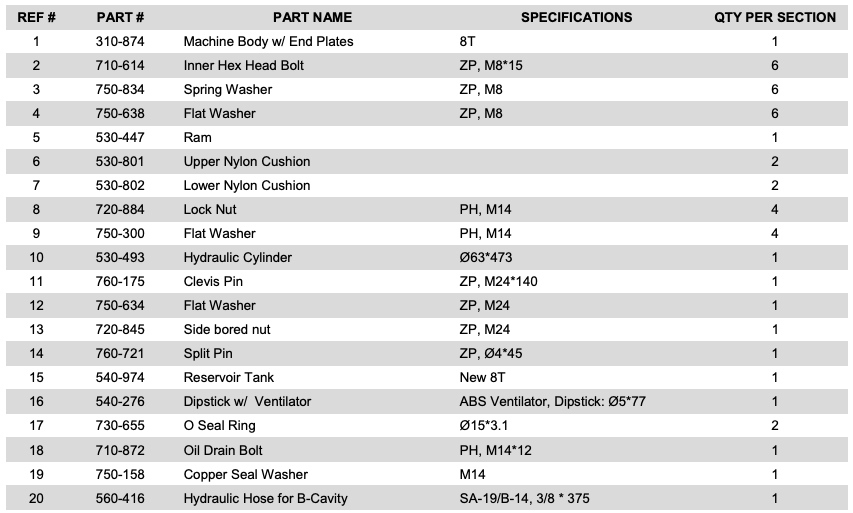

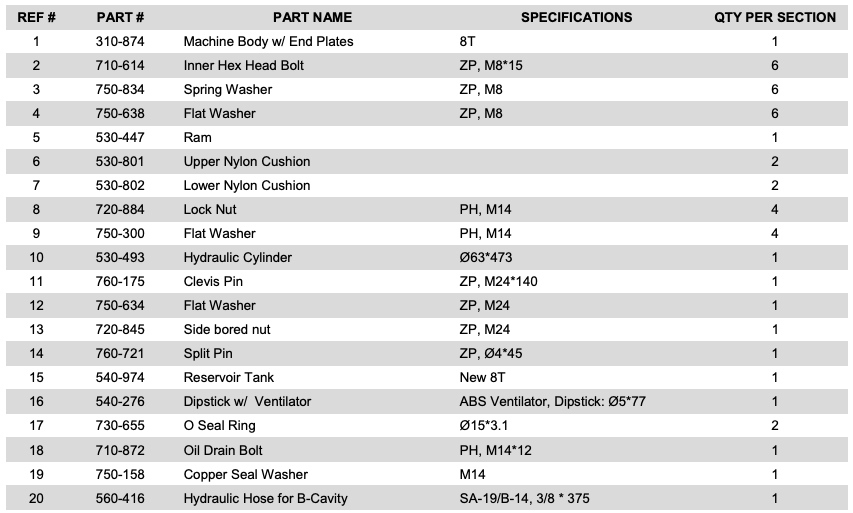

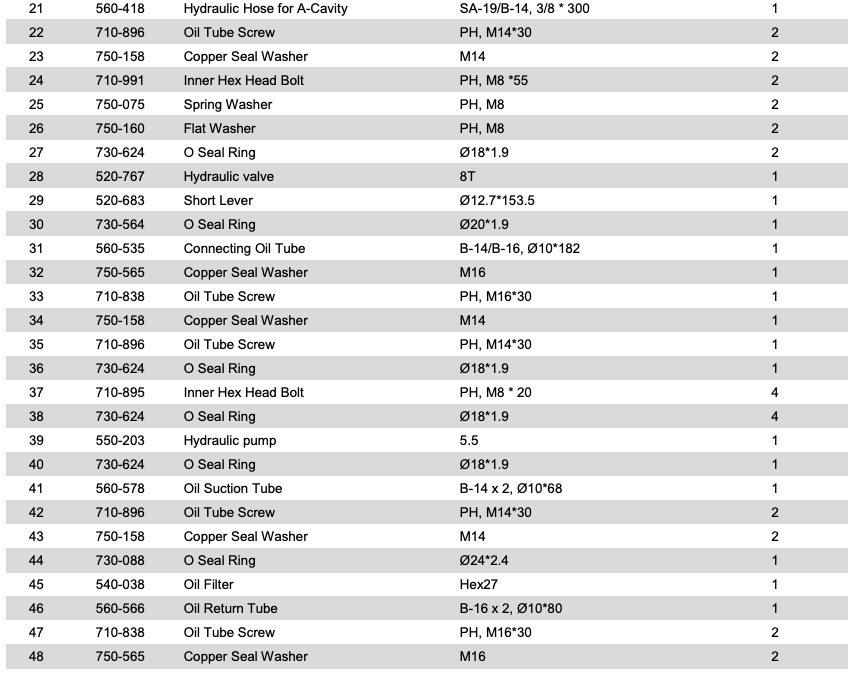

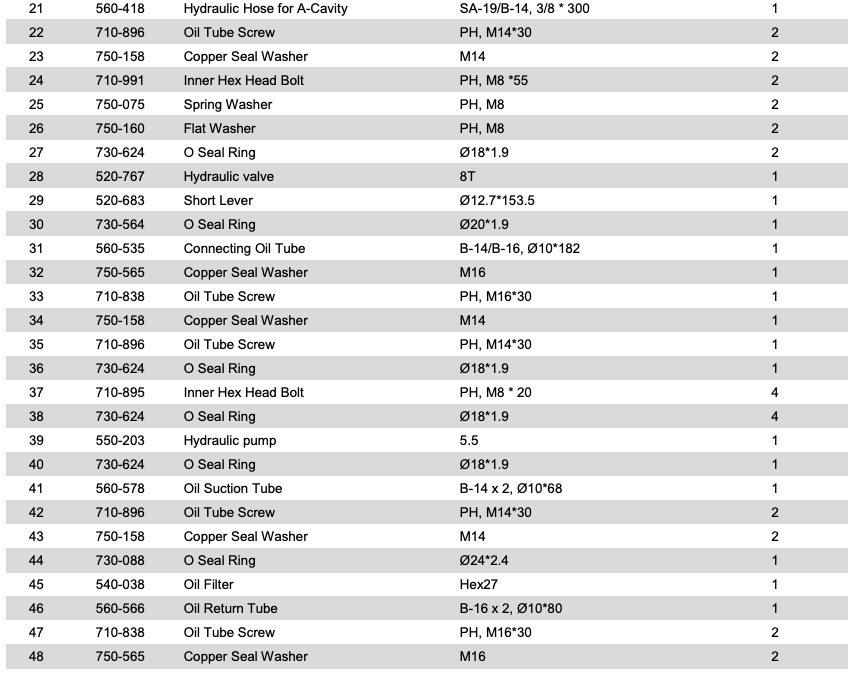

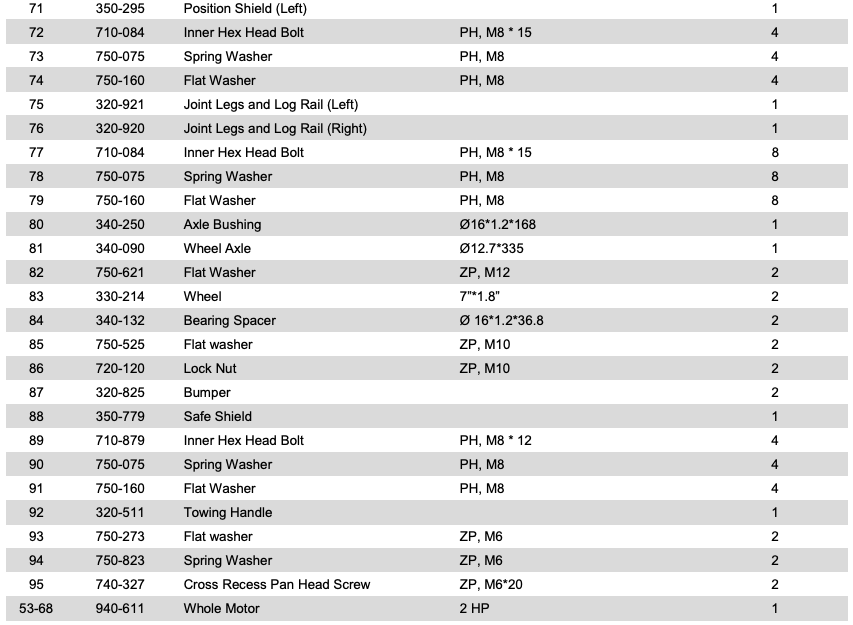

EXPLODED DIAGRAM & PARTS LIST

PACKING LIST

Electric Dual Action Log Splitter 8 Ton ED8T20 User Manual – Electric Dual Action Log Splitter 8 Ton ED8T20 User Manual –

[xyz-ips snippet=”download-snippet”]