CHAMPION Automatic Transfer Switch with aXis Controller Module 102008 Installation Guide

INTRODUCTION

Congratulations on your purchase of a Champion Power Equipment (CPE) product. CPE designs, builds, and supports all of our products to strict specifications and guidelines. With proper product knowledge, safe use, and regular maintenance, this product should bring years of satisfying service.

Every effort has been made to ensure the accuracy and completeness of the information in this manual at the time of publication, and we reserve the right to change, alter and/or improve the product and this document at any time without prior notice.

CPE highly values how our products are designed, manufactured, operated, and serviced as well as providing safety to the operator and those around the generator. Therefore, it is IMPORTANT to review this product manual and other product materials thoroughly and be fully aware and knowledgeable of the assembly, operation, dangers and maintenance of the product before use. Fully familiarize yourself, and make sure others who plan on operating the product fully familiarize themselves too, with the proper safety and operation procedures before each use. Please always exercise common sense and always err on the side of caution when operating the product to ensure no accident, property damage, or injury occurs. We want you to continue to use and be satisfied with your CPE product for years to come

When contacting CPE about parts and/or service, you will need to supply the complete model and serial numbers of your product. Transcribe the information found on your product’s nameplate label to the table below.

- CPE TECHNICAL SUPPORT TEAM1-877-338-0999

- MODEL NUMBER102008

- SERIAL NUMBER

- DATE OF PURCHASE

- PURCHASE LOCATION

SAFETY DEFINITIONS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

DANGER indicates a hazardous situation which,if not avoided, will result in death or serious zinjury

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to property damage).

Safety Labels

These labels warn you of potential hazards that can cause serious injury. Read them carefully.If a label comes off or becomes hard to read, contact Technical Support Team for possible replacement.

| HANGTAG/LABEL | DESCRIPTION | |

| 1 | GENERATOR LOCATION: |

Alternate Power Source |

| 2 | Caution. Overcurrent device. | |

| 3 |  |

Danger. Electrocution shock hazard. Warning. More than one live circuit. |

Safety Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to more safely operate the product.

|

SYMBOL |

MEANING |

|

Read Installation Manual. To reduce the risk of injury, user must read and understand installation manual before using this product. |

|

|

Ground. Consult with local electrician to determine grounding requirements before operation. |

|

|

Electric Shock. Improper connections can create an electrocution hazard. |

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.govt

Instructions for Champion Automatic Transfer Switch with aXis ControllerTM Module

THE CHAMPION AUTOMATIC TRANSFER SWITCH WITH aXis CONTROLLERTM MODULE IS NOT FOR “DO-IT-YOURSELF” INSTALLATION. It must be installed by a qualified electrician thoroughly familiar with all applicable electrical and building codes.

This manual has been prepared for familiarizing servicing dealer/ installer with the design, application, installation and servicing of the equipment.

Read the manual carefully and comply with all instructions.

This manual or a copy of this manual should remain with the switch. Every effort has been taken to make sure that the contents of this manual are accurate and current.

The manufacturer reserves the right to change, alter or otherwise improve this literature and the product at any time without prior notice and without any obligation or liability whatsoever

The manufacturer cannot anticipate every possible circumstance that might involve a hazard.

The warnings in this manual, tags and decals affixed to the unit are, therefore, not all-inclusive. If using a procedure, work method or operating technique the manufacturer does not specificallyrecommend follow all codes to ensure safety for personnel.

Many accidents are caused by failing to follow simple and fundamental rules, codes and precautions. Before installing, operating or servicing this equipment, read the SAFETY RULES carefully.

The publications that cover the safe use of ATS and installation are the following NFPA 70, NFPA 70E, UL 1008 and UL 67. It is important to refer to the latest version of any standard/code toensure correct and current information. All installations must comply with local municipal, state and national codes.

Before Installation

WARNING: Per OSHA 3120 Publication; “lockout/tagout” refers to specific practices and procedures to safeguard individuals from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during installation, service or maintenance activities.

WARNING: Be certain that the power from the utility is turned off and all backup sources are locked out before starting this procedure. Failure to do so could result in serious injury or death. Be aware, automatic start generators will start upon loss of utility mains power unless locked in the “off” position.

Consult the generator operator manual section to locate theATS CONTROL and ENGINE CONTROL modules to make sure both switches are in the OFF position.

CAUTION: Consult with your Local municipal, State and Nationalelectrical codes for proper mandatory wiring methods.

CONTROLS AND FEATURES

Read this installation manual before installing your transfer switch. Familiarize yourself with the location and function of the controls and features. Save this manual for future reference.

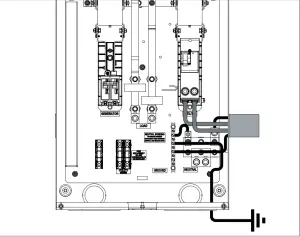

Champion Automatic Transfer Switch with aXis ControllerTM Module.

- aXis Controller

- Antenna

- Generator L1 and L2 Terminals

- Battery Charger Fuse Block

- Two Wire Sensing Fuse Block

- Ground Bar

- Neutral Ba

- Neutral to Ground Bonding Wire

- Load L1 and L2 Terminals

- Utility L1 and L2 Terminals

- Mounting Holes

- Front Cover

- Dead Front

PANEL BOARD SAFETY INFORMATION

As of January 1, 2017, enhanced UL 67 safety requirements took effect, applying to all panel boards and load centers with serviceequipment applications in accordance with the National Electrical Code, NFPA 70.

To comply, any single service disconnect panel board or load center must have provisions such that, when the service disconnect is opened, no person in the field servicing the equipment load side can make accidental contact to live circuit parts. Barriers to protect against unintended contact shall be constructed in such a way that they are easily installable and removable without contacting or damaging bare or insulated live parts. The barrier could be installed on the ARM, panel board or load center.

The battery(s) might be discharged to a level that is too low to re-charged with this charger (battery voltage below 6V). If this is the case, the batteries will need to be charged individually.Remove all battery cables from the batteries and follow the battery manufacturers’ instructions on properly servicing/charging the batteries.

Be careful to avoid corrosion on the battery post(s). Corrosion can have the effect of creating an insulation between the post(s) and the cable(s), this will severely affect the performance of thebattery. Follow battery manufacturers’ instructions on proper maintenance, service or replacement. The correct wire lands are read left to right, 6 land points;

|

1 |

Wire land #1 | Ground | G (GREEN) |

|

2 |

Wire land #2 |

L1 | P (PINK) |

| 3 | Wire land #3 | N |

W (WHITE) |

|

4 |

Wire land #4 | NOT CONNECTED EMPTY | |

| 5 | Wire land #5 | B- |

B (BLACK) |

| 6 | Wire land #6 | B+ |

R (RED) |

A 120VAC circuit must be installed for battery charging. From ATS fuse block or distribution panel install L1 and N to Wire land # 2 and #3 respectively.

Automatic Transfer Switch (ATS) Service Entrance models.

Refer to the Champion ATS instruction guide enclosed with eachunit for information related to installation, operation, service, trouble shooting and warranty.

The most reliable and convenient method to transfer power is with an automatic transfer switch (ATS). The ATS will automatically disconnect the home from the utility power prior to the HSBfunctioning (see NEC 700, 701 and 702). Failure to disconnect thehome from the utility with an approved UL listed ATS can result in damage to the HSB and can also cause injury or death to utility power workers who may receive electrical back-feed from theHSB.

ATS includes sensors to detect when a power failure (utility lost) occurs. These sensors trigger the ATS to disengage the home frozm the utility power. When the HSB reaches the proper voltage and frequency, the ATS will automatically transfer generator power to the home.

The ATS module continues to monitor the utility source for the return of utility power. When the utility power returns, the ATS disengages the home from generator power and re-transfers thehome to utility power. The HSB is now off line and will shut down- -returning to the standby mode.

NEMA 3R – This type of enclosed ATS is similar to the indoor box, except that it is a weatherproof enclosure and required for exterior installations by code. The enclosure has knockouts on the bottom and side, and requires water tight connections when installed outside per code. This enclosure can also be used inside.

The HSB Generator Exercise mode allows for automatic operation at specific times (set by the installer or owner).

UNPACKING

- Use care when unpacking to avoid damaging transfer switch components.

- Allow the ATS to acclimate to room temperature for a minimum of 24 hours before unpacking to prevent condensation on the electrical apparatus.

- Use a wet/dry vacuum cleaner or a dry cloth to remove dirt and packing material that may have accumulated in the transfer switch or any of its components during storage.

- Do not use compressed air to clean the switch, cleaning with compressed air can cause debris to lodge in the components and damage the switch per the ATS manufacturers specifications.

- Retain the ATS manual with or near the ATS for future reference

|

TOOLS REQUIRED |

NOT INCLUDED |

|

5/16 in. Hex Wrench |

Mounting Hardware |

|

Line Voltage Wire |

|

|

1/4 in. Flat Screwdriver |

Conduit |

|

Fittings |

Location and Mounting

Install the ATS as close as possible to utility meter socket. Wires will run between the ATS and main distribution panel, proper installation and conduit are required by code. Mount the ATS vertically to a rigid supporting structure. To prevent the ATS or enclosure box from distortion, level all mounting points; use washers behind the mounting holes (outside the enclosure, between enclosure and supporting structure), see following image. The recommended fasteners are 1/4” lag screws. Always follow local code.

Electrical Grommet(s)

Grommets can be used in any enclosure knockout for NEMA 1 installations. Grommets can only be used in the bottom enclosure knockouts for NEMA 3R installations, when installed outside.

Installation Wiring for ATS Utility Socket

WARNING: The manufacturer recommends that a licensed electrician or an individual with complete knowledge of electricity perform these procedures

Always be certain that the power from the main panel is turned “OFF” and all backup sources are locked out prior to removal of the cover or removal of any wiring of the utility main electrical distribution panel.

Be aware, automatic start generators will start upon loss of utility main power unless locked in the “OFF” position.

Failure to do so could result in serious injury or death.

CAUTION: Consult with your Local municipal, State and National electrical codes for proper mandatory wiring methods.

Conductor sizes must be adequate to handle the maximum current to which they will be subjected. The installation must comply fully with all applicable codes, standards and regulations. Conductors must be properly supported, of approved insulation materials, protected by approved conduit and with the correct wire gauge size in accordance with all applicable codes. Before connecting wire cables to terminals, remove any surface oxides from the cable ends with a wire brush. All power cables must enter the enclosure through the enclosure knockouts.

- Determine where the flexible, liquid tight conduit will pass through the building from the inside to outside. When you are certain that there is adequate clearance on each side ofthe wall, drill a small pilot hole through the wall to mark the location. Drill an appropriate sized hole through the sheathing and siding.

- In compliance with all local electrical codes, route the conduit along ceiling/floor joists and wall studs to the location where the conduit will pass through the wall to the exterior of the house. Once the conduit is pulled through the wall and in proper position to attach to the HSB generator, place silicone caulk around the conduit on both side of the hole, inside and outside.

- Mount the ATS near the Utility meter socket.

Wiring the ATS

NOTICE: US ATS model shown for reference. For Canadian installation, refer to ATS Installation Manual.

- Have authorized utility personnel pull the utility meter from the meter socket.

- Remove door and deadfront of ATS.

- Connect Utility (L1-L2) to ATS Utility side breaker. Torque to 275 in-lbs.

- Connect Utility N to Neutral lug. Torque to 275 in-lbs.

- Connect earth GROUND to GROUND bar. NOTE: GROUND and NEUTRAL bonded in this panel.

- Connect Generator L1-L2 to Generator side breaker. Torque to 45-50 in-lbs.

- Connect Generator Neutral to neutral bar. Torque to 275 in-lbs.

- Connect Generator Ground to ground bar. Torque to 35-45 in-lbs.

- Connect Load bars L1 and L2 to distribution panel. Torque to 275 in-lbs.

- Pull NEUTRAL from ATS to distribution panel. Pull GROUND from ATS to distribution panel.

CAUTION: Remove bond from distribution panel if installed.

INSTALLATION

Low Voltage Control Relays

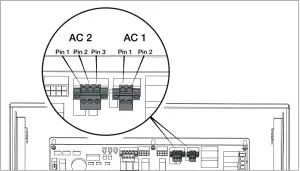

The aXis ControllerTM ATS has two low voltage relays that can be used to manage the load of air conditioners or other devices that utilize low voltage controls. The ATS’s two low voltage relays are called AC1 and AC2 and are found on the aXis control board as shown in the picture below.

CONNECTING TO AC1 AND AC2

For air conditioner or other low voltage controls, route your low voltage wiring into the ATS using code appropriate conduit and fittings. Connect the wiring to pin 1 and pin 2 of either AC1 or AC2 as shown in the diagram above. Please note that AC2 has three pins available. Pin 3 of AC2 is only used when this ATS is being wired to a non-aXis ControllerTM HSB. In that scenario, Pin 1 and Pin 3 of AC2 become the two-wire start signal for the non-axis HSB and AC2 cannot be used to manage a load.

Settings on the aXis ControllerTM Module

- On the aXis control board, set the two circular pots that are located to the right of the DIP switches to match the maximum power output of the generator for your fuel type.1st pot (left pot) is 10’s value, 2nd pot (right pot) is 1’s value, donot go over generator rating. If wattage rating of generator falls between settings choose the next lower value; i.e. generator rating is 12,500W, set pots to 1 and 2 for 12,000W.

NOTICE: All DIP switches are set to ON by default from the factory.

- Verify the DIP switches are set for your installation. Adjust as needed.DIP Switch SettingsSwitch 1. Load Module 1 Lockout

- On= Load Module 1 is being managed. Load Module 1 is the lowest priority of the 4 load modules. This load will be turned off first as the ATS manages the home’s load.

- Off= Load module 1 will stay off during HSB power. Switch 2. Load Module 2 Lockout

- On= Load Module 2 is being managed.

- Off= Load module 2 will stay off during HSB power. Switch 3. Load Module 3 Lockout.

- On= Load Module 3 is being managed.

- Off= Load module 3 will stay off during HSB power Switch 4. Load Module 4 Lockout

- On= Load Module 4 is being managed. Load Module 4 is the highest priority of the 4 load modules. This load will be turned off last as the ATS manages the homes load.

- Off= Load module 4 will stay off during HSB power Switch 5. Frequency Protection.

- On= All managed loads will be turned off when if the HSB frequency drops below 58 Hz.

- Off= All managed loads will be turned off when if the HSB frequency drops below 57 Hz. Switch 6. Spare. Not used at this time. Switch position does not matter.Switch 7. Power Management

- On= ATS is managing the homes load.

- Off= ATS has disabled power management. Switch 8. PLC vs. Two Wire Communication

- On= ATS will control HSB startup and shutdown through PLC. This is the preferred method of communication however it requires the HSB to be an aXis controlled HSB.

- Off= ATS will control the start of the HSB using the AC2 Relay. In this setting the AC2 can not be used to manage a load. Pins 1 and 3 of the AC2 connector will be used for the HSB startup signal.Switch 9. Test HSB with Load

- On= Test occurs with load.

- Off= Test occurs without load.Switch 10. Master/Slave

- On= This ATS is the primary or only ATS. <- most common.

- Off= This ATS is being controlled by a different aXis ControllerTM ATS. Used for installations that require two ATS boxes (i.e. 400A installations).Switch 11. Exercise Test

- On= Exercise tests will occur per the schedule that is programmed into the aXis controller.

- Off= Exercise tests are disabled.Switch 12. Time delay for HSB to accept load.

- On= 45 seconds

- Off= 7 seconds.

- Have authorized utility personnel reconnect the utility meter to the meter socket.

- Verify voltage at utility circuit breaker

- Turn on utility circuit breaker.

- ATS aXis ControllerTM module will begin boot up process.Allow ATS aXis ControllerTM module to fully boot up (approximately 6 minutes).

- Home should be fully powered at this point.

WIFI Setup Method

- Use a WiFi enabled device (laptop, smart phone, tablet, etc.) in near proximity to the ATS.

- Search and Connect to network name (SSID) “Champion HSB”. The password for the network is located on a decal on the deadfront of the ATS.

- After connecting, open your device’s web browser. Many times the Champion aXis ControllerTM Home Standby Generator Settings Page will autoload however if that is not the case, refresh the browser or change the web address to anything.com. As your device attempts to reach the internet the WiFi module in the ATS will redirect your browser to the Champion aXis ControllerTM Home Standby Generator Settings Page.

- On the Champion aXis ControllerTM Home Standby GeneratorSettings Page, set the date and time. Use either the dropdown boxes or the “USE THIS DEVICE’S DATE & TIME” button to set the time and date. Confirm and Save the settings before continuing.

- Set the HSB exercise frequency and schedule. Confirm and Save the settings before continuing.

- Wireless network settings are not used at this time. The default values (shown below) should not be adjusted.

- The time, date, and exercise information have now been setup for the aXis ATS and HSB. You can close your browser and disconnect from the WIFI, or skip to step 2 in the next section “ATS & HSB STATUS USING WIFI”.

ATS and HSB Status Using WIFI

- Using a WIFI enabled device, connect to the “Champion HSB”WIFI network following steps 1, 2, and 3 from WIFI Setup Method.

- After loading the Home Standby Generator Settings page, locate and click the icon at the bottom right corner of the page.

- You are now viewing the ATS and HSB status page. Items such as voltage, frequency, current, etc. can all be viewed for both utility and HSB power. All of the information is live. There are three tabs located at the top of the page. ATS, GEN, and LMM. Each tab will display the status for the Transfer Switch, Home Standby Generator,or Load Management Module(s) respectively.

- When finished viewing the status of the ATS, Generator, and LMM, close your browser and disconnect from the WIFI.

Connecting the Load Management Systems

The following instructions pertain only to aXis ControllerTM Load Management Modules (LMM) that use Power Line Carrier (PLC) communication. If one or more LMM’s are being installed on the home, install them per the installation instructions included with the LMM before continuing.

Teaching System

After installation and wiring are complete teach the ATS which loads are attached by the following procedure. Teaching the system is only required if 1 or more LMM’s were installed OR if AC1 OR if AC2 is being used to manage loads.

- Turn Champion aXis ControllerTM ATS UTILITY circuit breaker to the OFF position. Generator will start and run automatically.

- Confirm managed loads are all operating.

- Press and hold the button marked “LEARN” for 8 seconds. ATS will shutoff managed loads one at a time until all are OFF. ATS will flash LED’s indicating function in process.

- After ATS has learned all loads the LMM units will be returned to normal operation.

- Installation configuration is now held in memory and will not be affected by power outage.

- Return UTILITY circuit breaker to the ON position. ATS will transfer load back to utility and generator will cool down and shut off7. Repeat this process if LMM units are added or removed from the system.

Full System Check

- Open Utility breaker for full system test, close breaker after confirming all systems working.

- After Utility breaker opens engine will start automatically.

- aXis ATS control panel will reboot on Generator power and control switching of latching relays.

- Home is now powered by Generator. If Load Management modules (LMM) have been installed, they will become active after 5 minutes.

- Close Utility breaker.

- System is now fully functional.

- Replace the deadfront by sliding it from the bottom up into the cabinet; panel should index into the door latch protrusions. Secure it to the deadfront bracket with included nut and stud.

- Replace the door and secure with included hardware. It is recommended to secure the door with a lock.

- Return to HSB and verify the controller is in “AUTO” mode. Confirm icons indicate Utility power is active, Utility side relay is closed, and home is receiving power.

- Close and lock HSB hoods return keys to customer.

NEMA 1 – This type of enclosed ATS is for indoor installations only

NEMA 3R – This type of enclosed ATS is similar to the indoor box, except that it is a weatherproof enclosure and required for exterior installations by code. The enclosure only has knockouts on the bottom side for the enclosure, requires water tight fasteners/ grommets when installed outside per code. This enclosure can also be used inside.

SPECIFICATIONS

aXis ControllerTM Module Automatic Transfer Switch

Model Number: 102008Enclosure Style: NEMA 3R outdoorMaximum Amps: 150Nominal Volts: 120/240Load Management Circuits: 4Weight: 43 lbs (19.6 kg)Height : 28 in. (710mm)Width: 20 in. (507mm)Depth:.8.3 in. (210mm)

Technical Specifications

- 22kAIC, no short-time current rating.

- Suitable for use in accordance with the National Electrical Code, NFPA 70.

- Suitable for control of motors, electrical discharge lamps, tungsten filament lamps, and electrical heating equipment, where the sum of the motor full load ampere ratings and the ampere ratings of the other loads does not exceed the ampere rating of the switch, and the tungsten load does not exceed 30% of the switch rating.

- Continuous load not to exceed 80% of switch rating.

- Line voltage wiring: Cu or AL, min 60°C, min AWG 1 – max AWG 000, torque to 250 in-lb.

- Signal or Com Wiring: Cu only, min AWG 22 – max AWG 12, torque to 28-32 in-oz.

WARRANTY

Each Champion transfer switch or accessory is guaranteed against mechanical or electrical failure due to manufacturing defects for a period of 24 months following shipment from the factory. The manufacturer’s responsibility during this warranty period is limited to repair or replacement, free of charge, of products proving defective under normal use or service when returned to the factory, transportation charges prepaid. Guarantee is void on products that have been subjected to improper installation, misuse, alteration, abuse or unauthorized repair. The manufacturer makes no warranty with respect to the fitness of any goods for a user’s particular application and assumes no responsibility forproper selection and installation of its products. This warranty is in lieu of all other warranties, expressed or implied, and limits the manufacturer’s liability for damages to the cost of the product. This warranty gives you specific legal rights, and you may have other rights, which vary from state to state.

CHAMPION POWER EQUIPMENT2 YEAR LIMITED WARRANTY

Warranty Qualifications

To register your product for warranty and FREE lifetime call centertechnical support please visithttps://www.championpowerequipment.com/register

To complete registration you will need to include a copy of the purchase receipt as proof of original purchase. Proof of purchase is required for warranty service. Please register within ten (10) days from date of purchase.

Repair/ReplacementWarranty

CPE warrants to the original purchaser that the mechanical and electrical components will be free of defects in material and workmanship for a period of two years (parts and labor) from the original date of purchase and 180 days (parts and labor) for commercial and industrial use. Transportation charges on product submitted for repair or replacement under this warranty are the sole responsibility of the purchaser. This warranty only applies to the original purchaser and is not transferable.

Do Not Return The Unit To The Place Of Purchase

Contact CPE’s Technical Service and CPE will troubleshoot any issue via phone or e-mail. If the problem is not corrected by this method, CPE will, at its option, authorize evaluation, repair or replacement of the defective part or component at a CPE Service Center. CPE will provide you with a case number for warranty service. Please keep it for future reference. Repairs or replacements without prior authorization, or at an unauthorized repair facility, will not be covered by this warranty.

Warranty Exclusions

This warranty does not cover the following repairs and equipment:

Normal Wear

Products with mechanical and electrical components need periodic parts and service to perform well. This warranty does not cover repair when normal use has exhausted the life of a part or the equipment as a whole.

Installation, Use and Maintenance

This warranty will not apply to parts and/or labor if the product is deemed to have been misused, neglected, involved in an accident, abused, loaded beyond the product’s limits, modified, installed improperly or connected incorrectly to any electrical component. Normal maintenance is not covered by this warranty and is not required to be performed at a facility or by a person authorized by CPE.

Other Exclusions

This warranty excludes:

- Cosmetic defects such as paint, decals, etc.

- Wear items such as filter elements, o-rings, etc.

- Accessory parts such as storage covers.

- Failures due to acts of God and other force majeure events beyond the manufacturer’s control.

- Problems caused by parts that are not original Champion Power Equipment parts.

Limits of Implied Warranty and Consequential Damage

Champion Power Equipment disclaims any obligation to cover any loss of time, use of this product, freight, or any incidental or consequential claim by anyone from using this product. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, NCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

A unit provided as an exchange will be subject to the warranty of the original unit. The length of the warranty governing the exchanged unit will remain calculated by reference to the purchase date of the original unit.

This warranty gives you certain legal rights which may change from state to state or province to province. Your state or province may also have other rights you may be entitled to that are not listed within this warranty

Contact Information

Address

Champion Power Equipment, Inc.12039 Smith Ave.Santa Fe Springs, CA 90670 USAwww.championpowerequipment.com

Customer Service

Toll Free: 1-877-338-0999[email protected]Fax no.: 1-562-236-9429

Technical Service

Toll Free: 1-877-338-0999[email protected]24/7 Tech Support: 1-562-204-1188

References

[xyz-ips snippet=”download-snippet”]