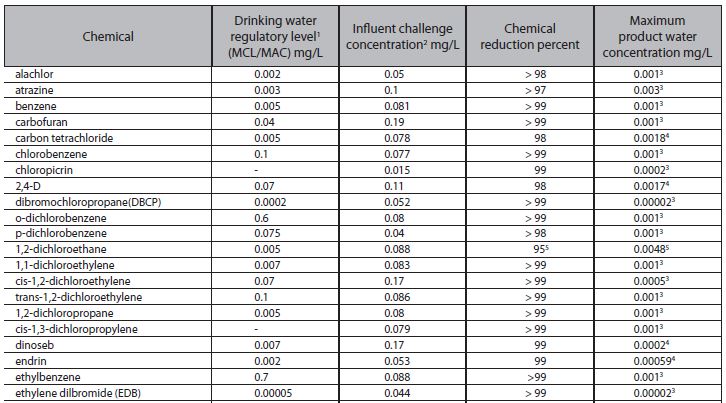

Circle Model RC100 System Performance Data Sheet

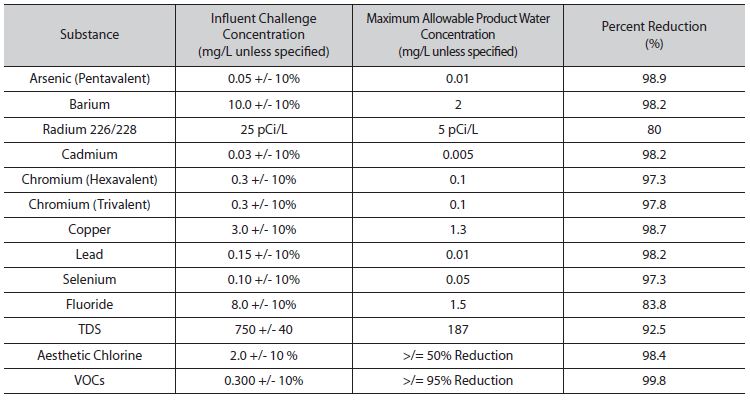

The RC100 is tested and certified to NSF/ANSI 42, 53 and 58 for the reduction of Aesthetic Chlorine, Taste and Odor, Cyst, VOCs, Fluoride, Pentavalent Arsenic, Barium, Radium 226/228, Cadmium, Hexavalent Chromium, Trivalent Chromium, Lead, Copper, Selenium and TDS as verified and substantiated by test data. The RC100 conforms to NSF/ANSI 372 for low lead compliance.

This system has been tested according to NSF/ANSI 42, 53 and 58 for the reduction of the substances listed below. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible for water leaving the system, as specified in NSF/ANSI 42, 53 and 58.

While testing was performed under laboratory conditions, actual performance may vary.

- Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

- Refer to the owners manual for specific installation instructions, manufacturer’s limited warranty, user responsibility, and parts and service availability.

- The influent water to the system shall include the following characteristics:

- No organic solvents

- Chlorine: < 2 mg/L

- pH: 7 – 8

- Temperature: 41 ~ 95 ºF (5 ~ 35 ºC)

- Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

For parts and service availability, please contact Brondell at 888-542-3355.

This system has been tested for the treatment of water containing pentavalent arsenic (also know as As(V), As(+5), or arsenate) at concentrations of 0.050 mg/L or less. This system reduces pentavalent arsenic, but may not remove other forms of arsenic. This system is to be used on water supplies containing a detectable free chlorine residual at the system inlet or on water supplies that have been demonstrated to contain only pentavalent arsenic. Treatment with chloramines (combined chlorine) is not sufficient to ensure complete conversion of trivalent arsenic to pentavalent arsenic. Please see the Arsenic Facts section of this Performance Data Sheet for further information.

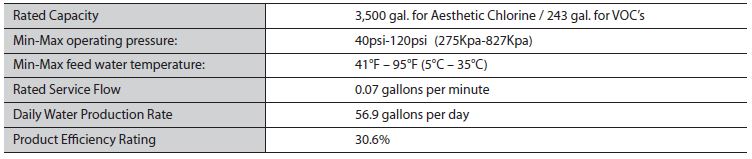

Efficiency rating means the percentage of the influent water to the system that is available to the user as reverse osmosis treated water under operating conditions that approximate typical daily usage.

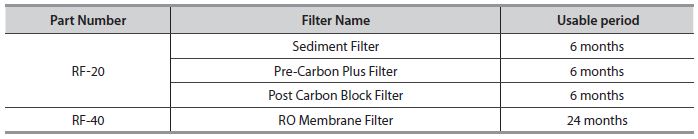

The product water should be tested every 6 months to ensure that the contaminants are being reduced effectively. For any questions, please contact Brondell toll free at 888-542-3355.This reverse osmosis system contains a replaceable treatment components, critical for the effective reduction of total dissolved solids and that product water shall be tested periodically to verify that the system is performing properly. Replacement of reverse osmosis component should be with one of identical specifications, as defined by the manufacturer, to assure the same efficiency and contaminant reduction performance.

The estimated replacement time of filter, which is a consumable part, is not an indication of quality guarantee period, but it means the ideal time of filter replacement. Accordingly, the estimated time of filter replacement may be shortened in case it is used in an area of poor water quality.

ARSENIC FACTS

Arsenic (abbreviated As) is found naturally in some well water. Arsenic in water has no color, taste or odor. It must be measured by a lab test. Public water utilities must have their water tested for arsenic. You can get the results from the water utility. If you have the own well, you can have the water tested. The local health department or the state environmental health agency can provide a list of certified labs. Information about arsenic in water can be found on the Internet at the US Environmental Protection Agency website: www.epa.gov/safewater/arsenic.html

There are two forms of arsenic: pentavalent arsenic (also called As(V), As(+5), and arsenate) and trivalent arsenic (also called As(III), As(+3), and arsenite). In well water, arsenic may be pentavalent, trivalent, or a combination of both. Special sampling procedures are needed for a lab to determine what type and how much of each type of arsenic is in the water. Check with the labs in the area to see if they can provide this type of service.

Reverse osmosis (RO) water treatment systems do not remove trivalent arsenic from water very well. RO systems are very effective at removing pentavalent arsenic. A free chlorine residual will rapidly convert trivalent arsenic to pentavalent arsenic. Other water treatment chemicals such as ozone and potassium permanganate will also change trivalent arsenic to pentavalent arsenic.

A combined chlorine residual (also called chloramine) may not convert all the trivalent arsenic. If you get the water from a public water utility, contact the utility to find out if free chlorine or combined chlorine is used in the water system. The RC100 system is designed to remove pentavalent arsenic. It will not convert trivalent arsenic to pentavalent arsenic. The system was tested in a lab. Under those conditions, the system reduced 0.050 mg/L pentavalent arsenic to 0.010 mg/L (ppm) (the USEPA standard for drinking water) or less. The performance of the system may be different at the installation. Have the treated water tested for arsenic to check if the system is working properly.

The RO component of the RC100 system must be replaced every 24 months to ensure the system will continue to remove pentavalent arsenic. The component identification and locations where you can purchase the component are listed in the installation/ operation manual.

Volatile Organic Chemicals (VOCs) included by surrogate testing*

Chloroform was used as the surrogate chemical for VOC reduction claims

- These harmonized values were agreed upon by representatives of USEPA and Health Canada for the purpose of evaluating products to the requirements of this Standard.

- Influent challenge levels are average influent concentrations determined in surrogate qualification testing.

- Maximum product water level was not observed but was set at the detection limit of the analysis.

- Maximum product water level is set at a value determined in surrogate qualification testing.

- Chemical reduction percent and maximum product water level calculated at chloroform 95% breakthrough point as determined in surrogate qualification testing.

- The surrogate test results for heptachlor epoxide demonstrated a 98% reduction. These data were used to calculate an upper occurrence concentration which would produce a maximum product water level at the MCL.

Circle RC100 System Performance Data Sheet – Circle RC100 System Performance Data Sheet –

[xyz-ips snippet=”download-snippet”]