Commercial ZM-168 Ice Cream Machine

Parameter

| Model | Capacity | Yield | Voltage | Power | Refrigerant |

Dimensions |

| ZM-168 | 4.2L*2 | 16-18L/H | 220V50Hz110V60Hz220V60Hz | 1200W | R22 410a | 55*42*76CM |

Conditions

Our ice cream machine can work under below conditions:Ambient temperature:5-40℃ Mixture temperature:2-35℃Power: 200-230V/50±1HZ (standard model) customized model e.g. 110V/60Hz,or 220V/60Hz,please follow other instruction.

- The above conditions can directly affect performance and capacity.

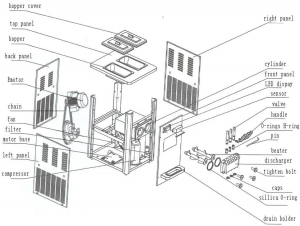

Structure

Installation & Cautions

Please strictly follow the instruction on the sticker.

- After received the machine, please lay it aside for more than 5 hours before using.

- There must be a free space more than 50cm left on both sides of the machine for heat releasing.

- Please make sure both cylinders to be filled with stuff before using, neither single nor both cylinders short of stuff will be forbidden. Do not use the water as stuff to test the machine.

- Put the machine still for 24 hour after transportation before using it.

- Power wire should not exceed 10m.

- Always use both cylinders at the same time.

- Ice cream mixture should be in accordance with appropriate formula.

- Always use the machine in stable voltage.

Placement

- Place the machine on an even plain ground, and lock the brakes.

- Make sure the machine is in good ventilation, avoid heat sources or sunlight, Air outlets of the machine should be at least 1m away from walls or any other barriers, other sides should be at least 0.5m away from any barrier.

- Avoid dust.

Wiring

- Make sure the socket is connected to the ground.

- Make sure the power supply has a circuit-breaker or any other device for protection against electric shock.

- The section area of power code copper core(a) MUST BE a≥2.5 ㎡.

- Under-size power code can result in low voltage and overload, which affect machine performance or causing damage.

Installation

- Open the carton box, you will find a parts bag in the hopper. In the parts bag you will find consumable parts, keep the spare parts for the future replacement.

- Please check the nameplate on the right panel, confirm this is the correct model (voltage, frequency and power)you order.

- Install the discharger properly ,tighten it to the machine with 4 bolts(2 long ones up,2 short ones down),screw the 2 bolts in diagonal at the same time, mate sure no gap between the discharger and the machine, otherwise, water or mixture can leak from it during washing or making ice cream.

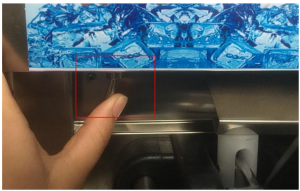

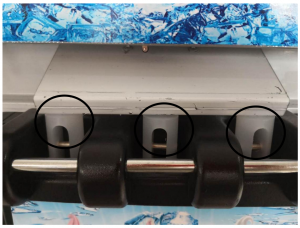

Notice: sensor plate MUST BE on top of all valve stems.(see right photo)

Notice: sensor plate MUST BE on top of all valve stems.(see right photo) - Install the handles to the valve stems one by one ,in the mean time, slowly push the steel pin through the discharger and the handles.(Refer to below photo for the correct direction of the handles)

- Install the drain holder to the 2 nuts on machine, to catch the possible falling ice cream.DO NOT put heavy object like buckets or basins on it, as it is too weak to support that.

How to Make ice cream

Wash

Connect it to 16A socket, switch on the power with the stick on the left down part of control panel. Pour water from the hoppers to fulfill the cylinders, press “CLEAN” mode. Repeat this 2-3 times, until the water comes out is all clean.

Make mixture

Currently in the market, there are ready-made mixture of ice cream, or the powder that needs to mix with water. Please follow the instructions and formula on powder package(generally speaking:1kg powder to 2.5-3kg water),stir them even, let them completely dissolve and mix together, avoid lumps forming, leave it still for 30 minutes. These are very important factors for the texture and amount of the ice cream later produced.

Make ice cream

- Make sure water is completely drained, them pour the mixture into thehopper.

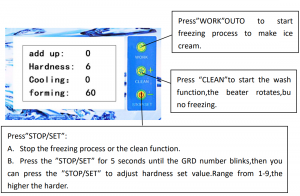

- Press“ CLEAN”(beater will start to rotate, to beat it even),after 2 minutes, press“ STOP” ,then press “WORK” to start freezing(Notice: Make sure the mixture level in neither cylinder should be lower than the inlet of discharger, or else can result in loud noise or damage.)

- In“ forming ”mode, displayer shows the progress of ice cream making, generally speaking, when it reach 60 ,the ice cream is ready for dispensing. When it reach 100%,the machine will stop automatically and back to “OK” mode.

- Serve: Put a cone or a cup under the nozzle, press the handle down, slowly rotate the cone in hand, press the handle back to stop.

How to Operate

How to Operate

Wash cylinder

Please wash the cylinder once a day to improve the serve life of the machine and also to ensure food safety for customers.

- Press “ CLEAN ” ,to beat out all the mixture from the cylinder, then press” STOP/SET”.

- Dissolve proper amount of disinfectant in warm water, pour it inside the hopper.

- Press” CLEAN” to beat for 5minutes,then drain it.

- Pour in clear, to wash 3-5 minutes, then stop the machine.

- Turn off the machine, and disassemble all other components(detail see the above picture for washing)Please disassemble and wash the components according the following steps if the machine has stopped serving for a long time

A. Unscrew all 4 bolts from the discharger, unload the discharger, then disassemble all components from the discharger,B. Take off the pin, handles, valve stems and silicone O-ring.C. Take our the beater, disassemble the silicone seal from the beater end.D. Wash the components thoroughly and replace the broken ones,E. Assemble back all the components.(apply some lubricant to the valve stem for easier assembling the O-rings and the valve stem back to discharger). Notice: the O-ring on the middle stem is H shape, while the side stems are all O shape

Wash the case

Please use a wet cloth to wipe the case only, avoid pouring water directly on control board or the inside, or else can result in malfunction

Clean the condenser

After serving for a certain period of time, dust will cover the condenser and affect refrigeration (symptom: Ice cream hardness decreases in the same running time), please wash it at least once in 3 months.(or once a month in a worse condition).Make sure the machine is disconnected to electricity before washing, and avoid damaging the fins inside the condenser. Hiring a professional cleaner is recommended.

Lubricate the chain

After serving for a long time, it is recommended to open the back cover and maintain the chain with oil every month.

Error & Solution

|

Problem |

Cause |

Solution |

| Voltage too low | Voltage too low | Install a voltage stabilizer. |

| Voltage too high | Voltage too high | Install a voltage stabilizer. |

| No display while machine turned on |

|

|

| Display not clearly | Display and motherboard not well connected.Motherboard malfunction | Reconnect display to the motherboard well.Check motherboard. |

| Ice cream won’t come out |

|

|

| Ice cream is too soft |

|

|

| Leakage |

|

|

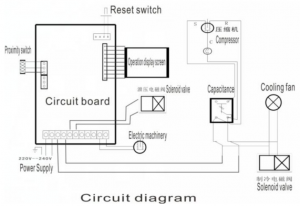

Repair

- Please disconnect power before installing or wiring, always follow the circuit diagram, and make sure the power supply is in accordance with that on the nameplate.

- Please hire a professional electrical technician for wiring.

- Make sure all terminals are firmly connected to connectors.

- Keep hands, fluid or any foreign objects off the PCB, and at least 6mm away from the panels, or else may result in short-circuit and fire.

References

[xyz-ips snippet=”download-snippet”]

Notice: sensor plate MUST BE on top of all valve stems.(see right photo)

Notice: sensor plate MUST BE on top of all valve stems.(see right photo)