DELL AW3821DWB 38 Inch Curved Gaming Monitor User Guide

Disassembly Procedures

- Turn off power

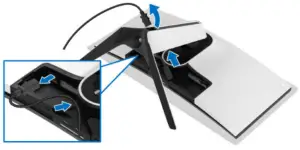

- Place monitor head on U3818DW curve sponge jigCarefully slide and remove the I/O cover from the monitor.

- Disconnect the cables from the monitor and slide them out through the cable management slot on the stand riser.

- Press and hold the stand release button

- Lift the stand up and away from the monitor.

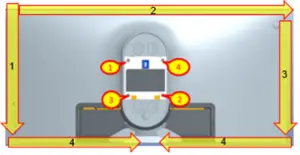

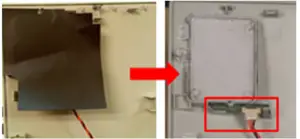

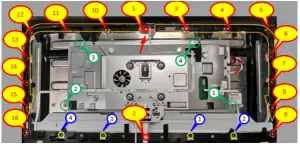

- Unlock 4 screws on rear coverUse hands or scraper bar to disassemble Rear Cover from the monitor.Notice the disassembly order:Left Side=> Top Side=>Right Side=>Bottom Side

(Screw Torque: 8-10 kgf)

(Screw Torque: 8-10 kgf) - Remove USB FFC and Audio FFC from USB BD

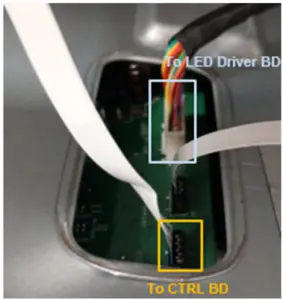

- Remove 1 tape on LED Driver BD wire from Main SHD and disconnect LED Driver BD wire from I/F BDDisconnect CTRL FFC cable from I/F BD and tear it from Main SHDTake off Rear Cover

- Remove all tapes from cables and Rear Cover

- Remove all cables from LED Driver BDUnlock 1 screw and disassemble LED Driver BD from Rear Cover

- Tear off “MYLAR HEAD LOGO” from cover LOGO LENSDisconnect LED wire from LED BDDisassemble LED BD from Rear Cover

- Tear off RC Mylar from USB BD and Jack BD

- Remove 2 tapes on Jack BD from Rear CoverDisassemble Jack BD from Rear CoverRemove 2 wires from Jack BDUnlock 2 screws to disassemble USB BD from Rear Cover

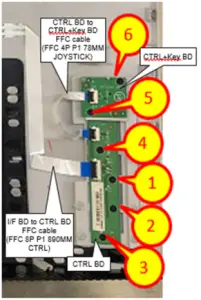

- Remove FFC cable from Rear Cover, CTRL BD and CTRL+KEY BDUnlock 6 screws to disassemble CTRL BD and CTRL+KEY BD from Rear Cover

- Take off 1 gasket from Middle Frame

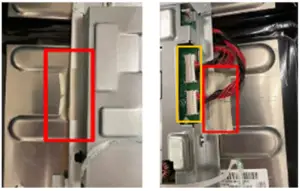

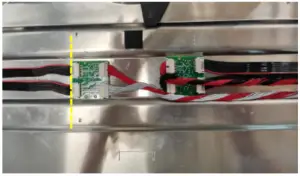

- Disconnect Backlight Wires from SPS+LED BDTear off conductive cloth from Main SHD

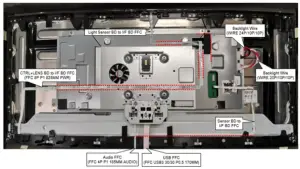

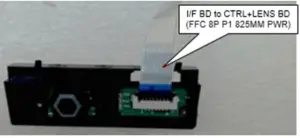

- Disconnect Light Sensor BD FFC cable from I/F BD and tear off it from Main SHDDisconnect Sensor BD FFC cable from I/F BD and tear off it from panelDisconnect “CTRL+LENS BD FFC” from I/F BD and tear off it from panel and Main SHD

- Unlock 4 screws (Green mark) to disassemble Main SHD from panelUnlock 16 screws (Red mark) and 4 screws (Yellow mark) to disassemble Middle Frame from Panel

(Screw Torque-Main SHD: 7±1kgf)(Screw Torque-Middle Frame: 4.5±0.5 kgf)

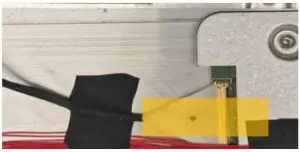

(Screw Torque-Main SHD: 7±1kgf)(Screw Torque-Middle Frame: 4.5±0.5 kgf) - Tear off a yellow tape and an acetate tape from EDP cable and panelDisconnect EDP cable from PanelTake off Main SHD from Panel

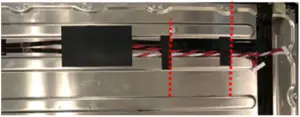

- Tear off a mylar and 2 tapes from Backlight wires

- Disconnect Backlight wires from transfer BD

- Disassemble transfer BD from Panel

- Disassemble Light Sensor BD from Middle Frame

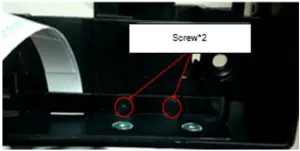

- Unlock 2 screws to disassemble Power Button module from Middle Frame(Screw Torque: 1.1±0.1 kgf)

- Disconnect FFC cable from “CTRL+LENS BD” (Power CTRL BD)

- Tear off “MYLAR-PWR-KE “ from “CTRL+LENS BD” (Power CTRL BD)

- Unlock 2 screws to disassemble “CTRL+LENS BD” (Power CTRL BD) from Power Button

(Screw Torque: 2±0.5 kgf)

(Screw Torque: 2±0.5 kgf) - Disassemble Sensor BD from Middle frame

- Unlock 1 screw to disassemble Docking BD from Main SHDDisassemble wire from Docking BD

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8.5±1.0 kgf) - Disassemble mylar from Main SHD

- Tear off an adhesive tape and a yellow tape from I/F BD and EDP cableDisconnect EDP cable from I/F BD

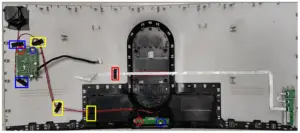

- Unlock 11 screws on PCBA to disassemble SPS+LED BD, SPS BD and I/F BD from Main SHD

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8.5±1.0 kgf) - Disconnect wires from I/F BD, SPS BD and SPS+LED BD

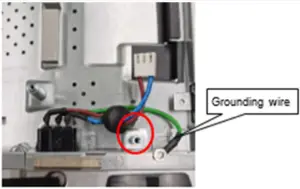

- Unlock 1 ground screw to disassemble AC Socket from Main SHD

(Screw Torque: 8-10 kgf)

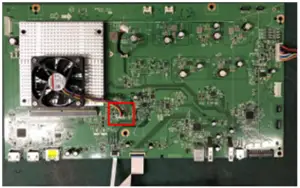

(Screw Torque: 8-10 kgf) - Disconnect Fan Cable from I/F BD

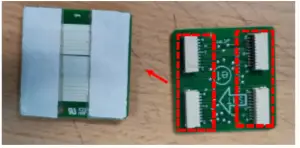

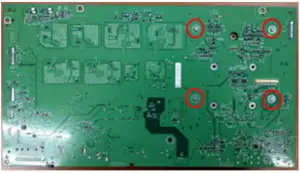

- Unlock 4 screws to disassemble GSYNC Module from I/F BD

(Screw Torque: 4-4.5 kgf)

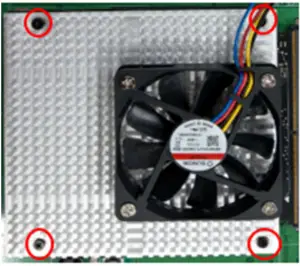

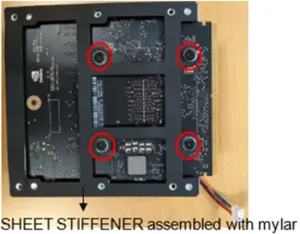

(Screw Torque: 4-4.5 kgf) - Unlock 4 Heat Sink screws and 4 captive screws to disassemble G-Sync module, Heat Sink Module and SHEET STIFFENERTear off MYLAR from SHEET STIFFENER

(Screw Torque-Heat Sink: 2-2.5 kgf)

(Screw Torque-Heat Sink: 2-2.5 kgf) (Screw Torque-Captive screw:4-4.5 kgf)

(Screw Torque-Captive screw:4-4.5 kgf) -

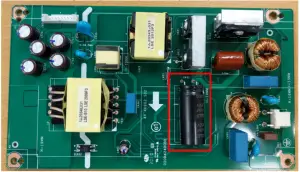

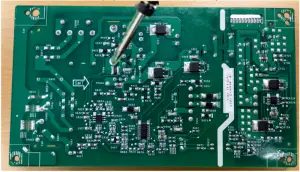

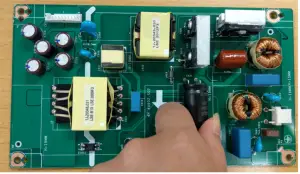

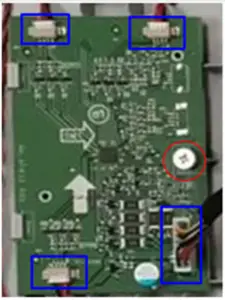

- Remove electrolyte capacitors (red mark) from printed circuit boards

- S38-1 Cut the glue between bulk cap. and PCB with a knife

- S38-2 Ensure cutting path within the glue, don’t touch bulk cap. or PCB

- S38-3 Take out bulk cap. pin solder with soldering iron and absorber

- S38-4 Lift the bulk cap. up and away from the PCB

- Remove electrolyte capacitors (red mark) from printed circuit boards

Product material information

The following substances, preparations, or components should be disposed of or recovered separately from other WEEE in compliance with Article 4 of EU Council Directive 75/442/EEC.

| Capacitors / condensers (containing PCB/PCT) | No used |

| Mercury containing components | No used |

| Batteries | No used |

| Printed circuit boards (with a surface greater than 10 square cm) | Product has printed circuit boards (with a surface greater than 10 square

cm) |

| Component contain toner, ink and liquids | No used |

| Plastic containing BFR | No used |

| Component and waste contain asbestos | No used |

| CRT | No used |

| Component contain CFC, HCFC, HFC and HC | No used |

| Gas discharge lamps | No used |

| LCD display > 100 cm2 | Product has an LCD greater than 100 cm2 |

| External electric cable | Product has external cables |

| Component contain refractory ceramic fibers | No used |

| Component contain radio-active substances | No used |

| Electrolyte capacitors (height

> 25mm, diameter > 25mm) |

Product has electrolyte capacitors (height >25mm, diameter > 25mm) |

Tools Required

List the type and size of the tools that would typically can be used to disassemble the product to a point where components and materials requiring selective treatment can be removed.

Tool Description:

- Screwdriver

- Scraper Bar

- Penknife

- Soldering iron and absorber

- Curve Sponge Jig

[xyz-ips snippet=”download-snippet”]

(Screw Torque: 8-10 kgf)

(Screw Torque: 8-10 kgf)

(Screw Torque-Main SHD: 7±1kgf)(Screw Torque-Middle Frame: 4.5±0.5 kgf)

(Screw Torque-Main SHD: 7±1kgf)(Screw Torque-Middle Frame: 4.5±0.5 kgf)

(Screw Torque: 2±0.5 kgf)

(Screw Torque: 2±0.5 kgf)

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8.5±1.0 kgf)

(Screw Torque: 8-10 kgf)

(Screw Torque: 8-10 kgf)

(Screw Torque: 4-4.5 kgf)

(Screw Torque: 4-4.5 kgf) (Screw Torque-Heat Sink: 2-2.5 kgf)

(Screw Torque-Heat Sink: 2-2.5 kgf) (Screw Torque-Captive screw:4-4.5 kgf)

(Screw Torque-Captive screw:4-4.5 kgf)