DELL SE2222H

Disassembly Procedures:

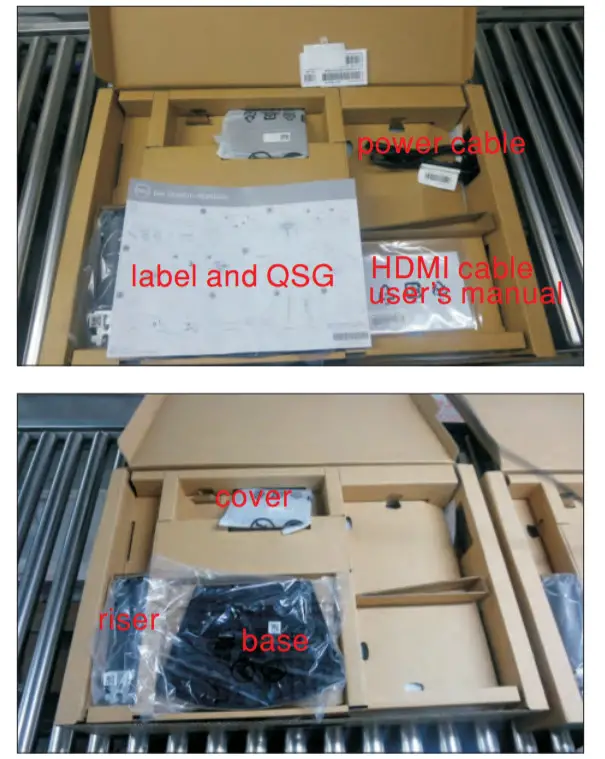

S1 Open the Pizza carton with a proper tool.

S2 Take out all of the accessories including QSG, HDMI cable, power cable, CD&user’s manual, stand base, stand riser and EEI label from the carton. (Note: It depends on whether users return the accessories)

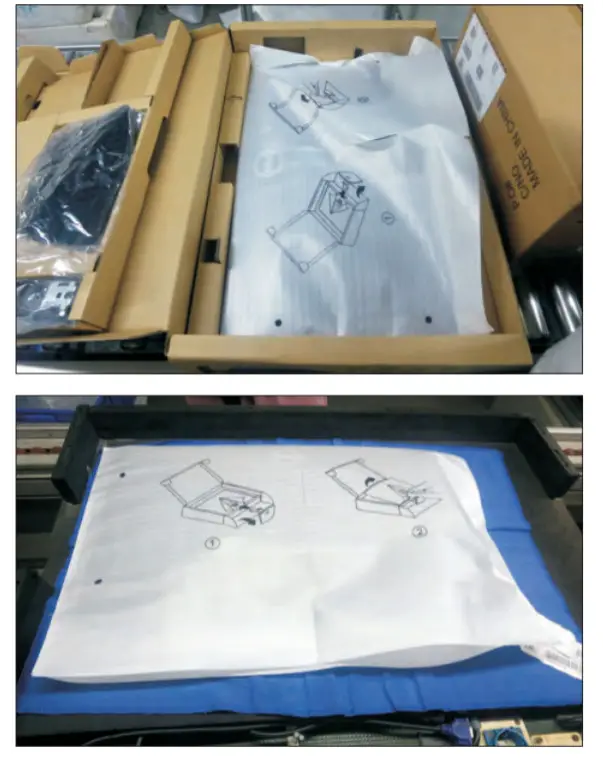

S3 Take out of the paper top with base, riser and cover from the carton, then take out the monitor from the EPE bag and put it on a protective cushion.

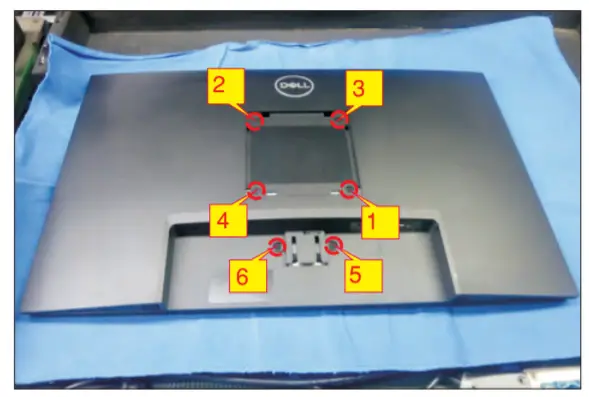

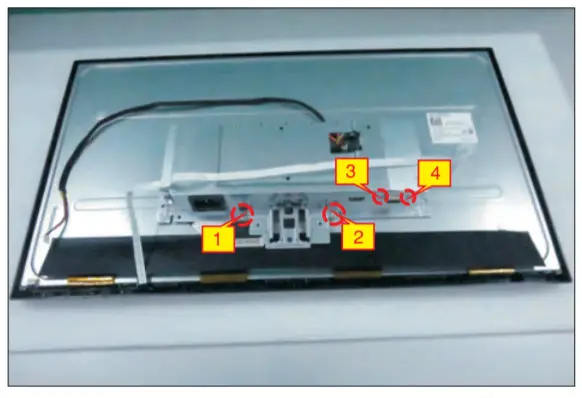

S4 Use a Philips-head screwdriver to remove 6pcs screws for unlocking mechanisms.(No.1~4 screw size=M4x11; Torque=11±1kgfxcm;No.5~6 screw size=M4x6; Torque=11±1kgfxcm)

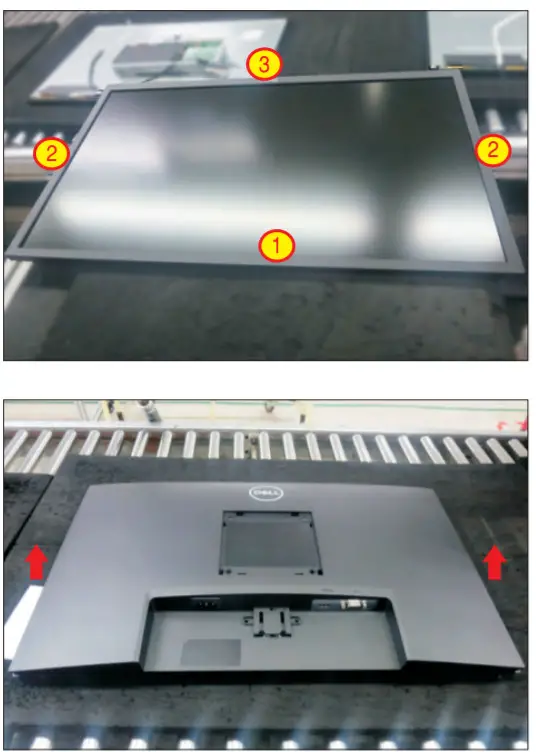

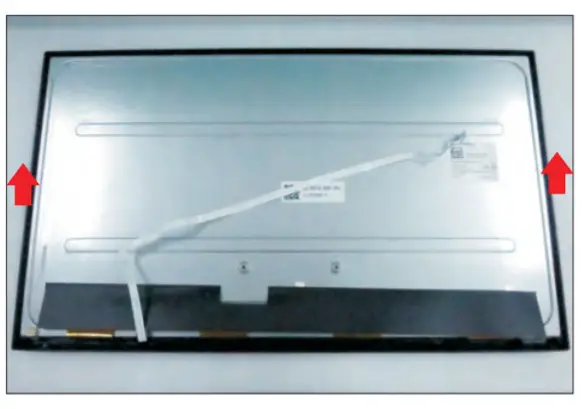

S5 Turn over the LCD monitor to let the screen face up, place a cloth on the panel where you are working on to protect the panel. Continually, wedge your fingers between the front bezel and the panel in order of arrow preference for unlocking mechanisms. Turn over the LCD monitor to let the screen faced down and then remove the rear cover.

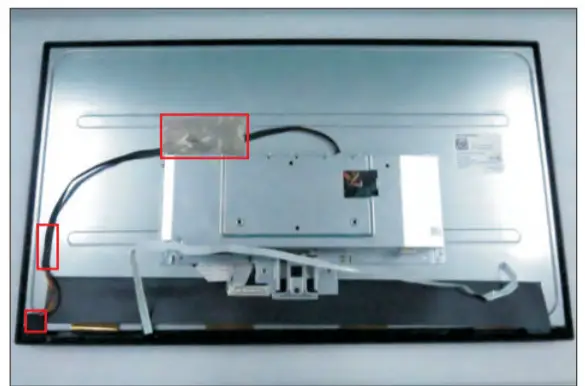

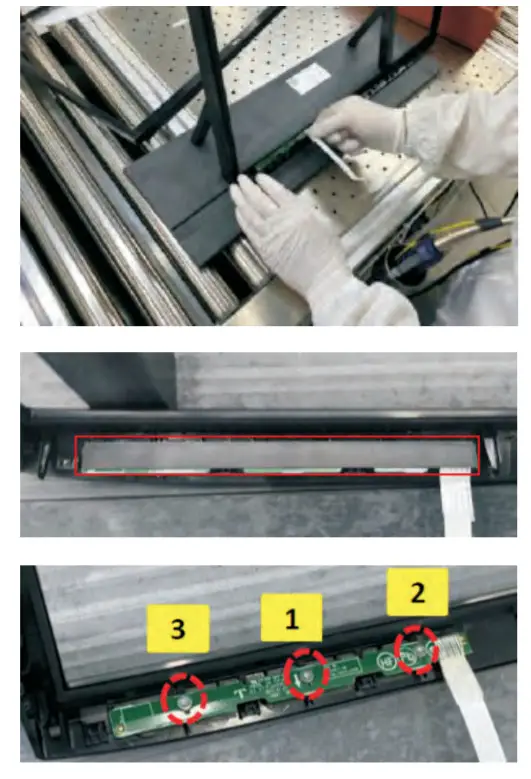

S6 Disconnect the function key cable away from the connector of the board, then tear off 3pcs adhesive tape for releasing the function keyboard.

S7 Tear off 2pcs acetate tapes and tape on the back of the panel lamp cable for unlocking the panel lamp cable, and then disconnect the panel lamp cable away from the connector of the panel module.

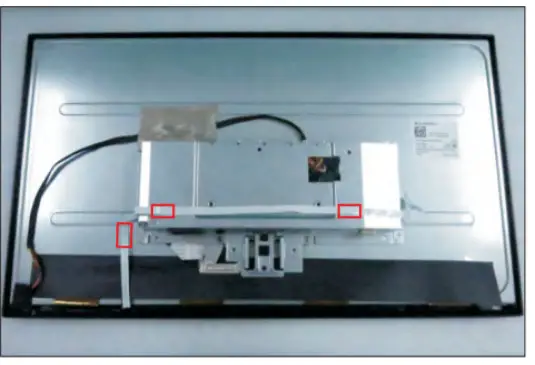

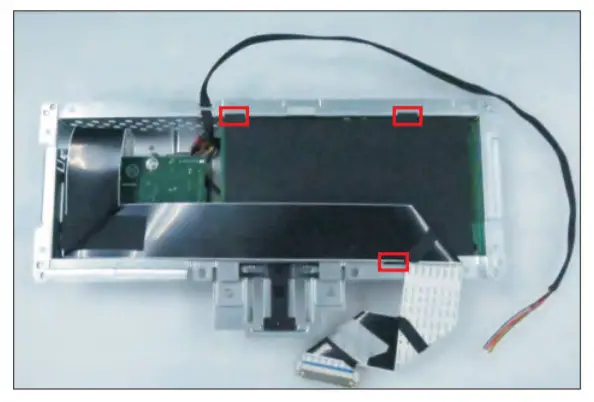

S8 Use a Philips-head screwdriver to remove 2pcs screws for unlocking the bracket with the panel module.Use a Hex-head screwdriver to remove 2pcs screws or unlock the VGA connector.(No.1~2 screw size=M3x2.6, Torque=4 ±0.5kgfxcm;No.3~4 screw size=M3x8, Torque=6±0.5kgfxcm)

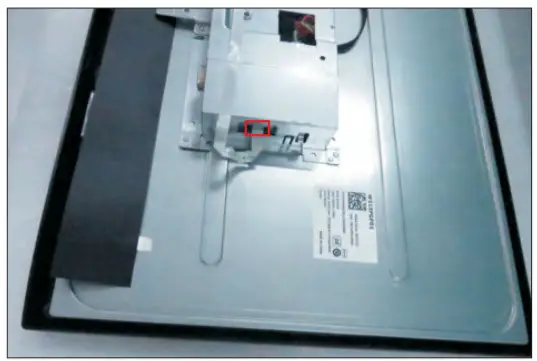

S9 Unplug the LVDS cable from the connector of the panel module by pushing the earing locks.

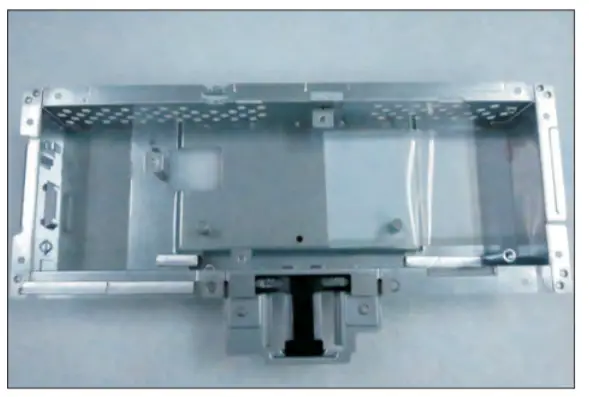

S10 Lift up the bracket chassis and put it on a protective cushion.

S11 Release the panel module away from the hooks of the front bezel, then lift up the panel module and take away the front bezel with a keyboard.

S12 Tear off the mylar tape, then ut the front bezel into a fixture, then up sea Philips-head screwdriver to remove 3pcs screws for unlocking the function keyboard with the front bezel.(No.1~3 screw size=M2x2.4, Torque=0.8±0.2kgfxcm

S13 Remove the Mylar from the hooks of the bracket chassis module.

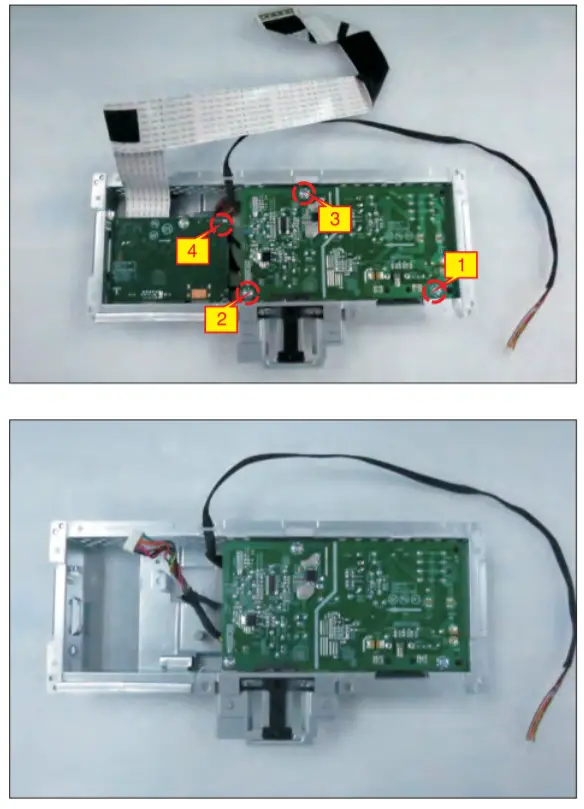

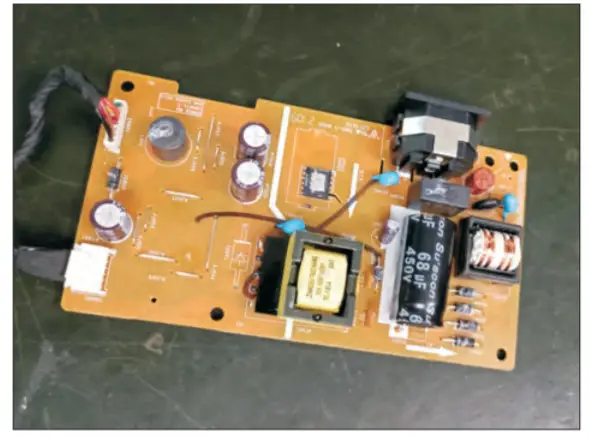

S14 Use a Philips-head screwdriver to remove 4pcs screws for unlocking the circuit board, release all the cables from the hooks.(No.1 screw size=M4x8, Torque=6±0.5kgfxcm;No. 2~4 screw size=M3x7.5, Torque=6±0.5kgfxcm)

S15 Remove the interface board and power board from the bracket chassis module carefully, and disconnect all the cables.

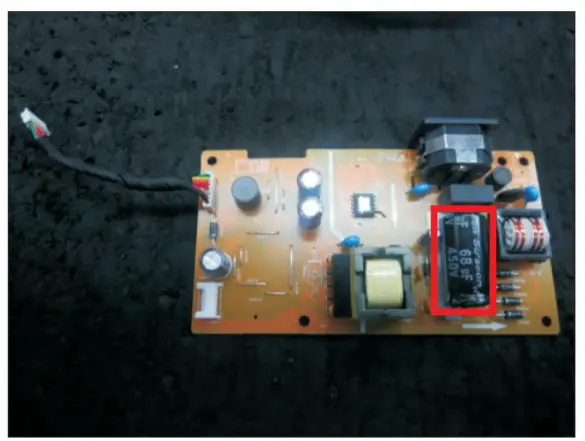

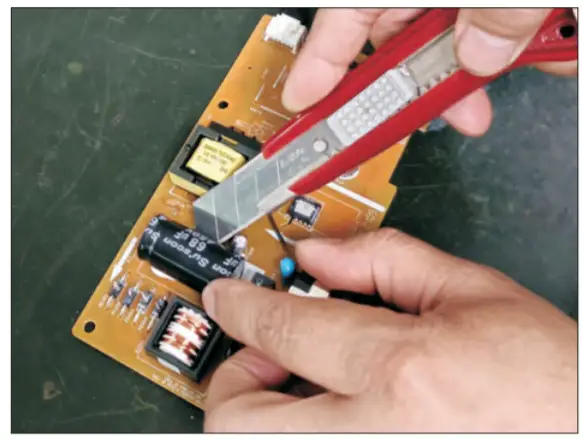

S16 Remove electrolyte capacitors (red mark) from printed circuit boards. S16-1 Cut the glue between bulk cap. and PCB with a knife.

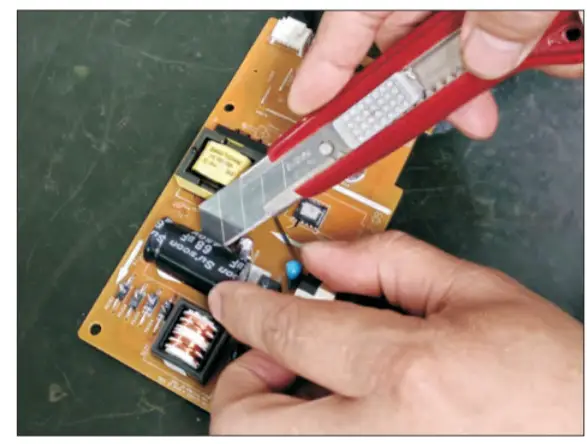

S16-1 Cut the glue between bulk cap. and PCB with a knife.

S16-2 Ensure cutting path within the glue, don’t touch bulk cap. or PCB.

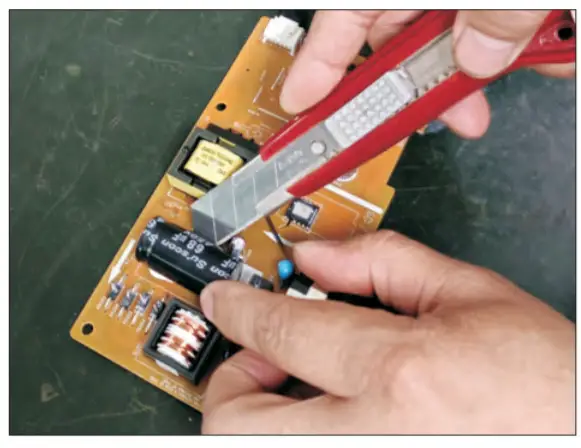

S16-2 Ensure cutting path within the glue, don’t touch bulk cap. or PCB. S16-3 Cut into the bottom of the bulk cap. and pull it up carefully.

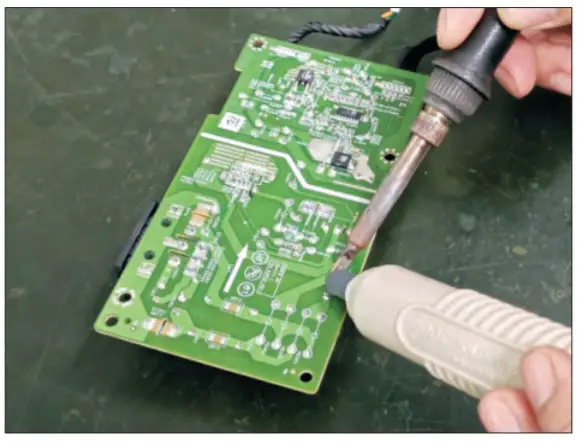

S16-3 Cut into the bottom of the bulk cap. and pull it up carefully. S16-4 Take out the bulk cap. pin solder with soldering iron and absorber.

S16-4 Take out the bulk cap. pin solder with soldering iron and absorber. S16-5 Lift the bulk cap. up and away from the PCB.

S16-5 Lift the bulk cap. up and away from the PCB.

Product material information

The following substances, preparations, or components should be disposed of or recovered separately from other WEEE in compliance with Article 4 of EU Council Directive 75/442/EEC.

| Capacitors / condensers (containing PCB/PCT) | No used |

| Mercury-containing components | No used |

| Batteries | No used |

| Printed circuit boards (with a surface greater than 10 square cm) | The product has printed circuit boards (with a surface greater than 10 square cm) |

| The component contains toner, ink, and liquids | No used |

| Plastic containing BFR | No used |

| Component and waste contain asbestos | No used |

| CRT | No used |

| Component contain CFC, HCFC, HFC and HC | No used |

| Gas discharge lamps | No used |

| LCD display > 100 cm2 | The product has an LCD greater than 100 cm2 |

| External electric cable | The product has external cables |

| The component contains refractory ceramic fibers | No used |

| The component contains radioactive substances | No used |

| Electrolyte capacitors (height > 25mm, diameter > 25mm) | Product has electrolyte capacitors (height > 25mm, diameter > 25mm) |

Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point where components and materials requiring selective treatment can be removed.Tool Description:– Screwdriver (Phillip’s head) #1– Screwdriver (Phillip’s head) #2– Penknife– Soldering iron and absorber

[xyz-ips snippet=”download-snippet”]