› Modular Wagner Taper Strength

The strength of the taper junction is critical to the success of a modular revision stem.

A robust taper junction will increase the longevity of the stem and ultimately reduce the risk of stem fracture. Factors affecting the strength of the junction include:

- Size of the taper

- Surface treatment of the material

The size of the taper is often limited to the smallest diameter stem and proximal body. A larger, more robust taper will withstand more fatigue stress (See FIGURE 1). In a competitive comparison, the Exprt® Revision Hip distal taper is:

- 1mm larger in diameter compared to Stryker’s Restoration Modular* stem

- 0.75mm larger than Zimmer Biomet’s Arcos® Modular Femoral Revision System

Exprt® Revision Hip tapers are shot peened, larger than competitors’ tapers, and can withstand loading of 1,000lbf for the worst case construct.

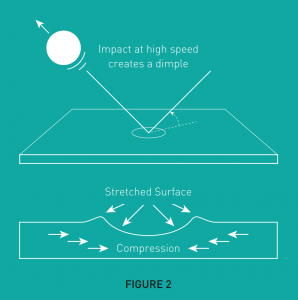

- Shot peening is a method of blasting a surface with small, round pellets of metal, glass or ceramic creating small indentations on the surface. (See FIGURE 2)

- Each indentation induces beneficial compressive stresses while removing potentially harmful tensile stresses to the material.

- Compressive stresses provide increased resistance to fatigue failures. A 20% improvement in both strength and wear is typical for shot-peened parts.¹

An Emphasis on Strength

The Exprt® Revision Hip meets the guidelines established by ISO 7206-4:2010 (2,300 N or 517 lbf). In an effort to replicate unsupported proximal fixation, the potting depth was increased from the required 80mm below the center of the femoral head to 90mm.

This left the modular junction unsupported during testing. This was done to further challenge the worst case configuration in which the Exprt Revision Hip stem (14mm stem with lateral offset proximal body and +12mm femoral head) endured 5 million cycles of fatigue loading without failure.4

In order to further test the taper, the worst case construct (lateral offset proximal body and +12mm femoral head) was tested up to 1,000 lbf or 4,450 N.

The potting depth of the test was increased up to the proximal fins of the distal stem, ensuring all of the loading force would occur at the taper junction. The Exprt Revision Hip stem endured 5 million cycles of fatigue loading at the increased load of 1,000 lbf without failure.

References:

- Mechanical Engineering Reference Manual, 12th Edition, 2006

- https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfmaude/search.cfm

- ZMR® Revision Hip System Zimmer. (n.d.) Accessed 27June2017, from

- DJO Surgical Exprt Revision Hip Fatigue Test Report Document No. PR16-062-01 Rev. F Dec 2016.

- DJO Surgical Exprt Revision Hip Fatigue Test at 1000lbf Report Document No. PR17-035-01 Rev. A May 2017.

Copyright © 2017 by DJO, LLC All rights reserved.

Individual results may vary. DJO Surgical is a manufacturer of orthopedic implants and does not practice medicine. Only an orthopedic surgeon can determine what treatment is appropriate. Individual results of total joint replacement may vary. The life of any implant will depend on the patient’s weight, age, activity level, and other factors. For more information on risks, warnings, and possible adverse effects please speak with your doctor directly; you should always ask your doctor if you have any questions regarding your particular condition or treatment options.

Stryker Corporation or its divisions or other corporate affiliated entities own, use or have applied for the following trademark(s) or service mark(s): Restoration Modular. All other trademarks are trademarks of their respective owners or holders.

Arcos® is a registered trademark of Zimmer Biomet

MKT0020231-003 Rev A 12/17

References

[xyz-ips snippet=”download-snippet”]