CHIPPER ASSEMBLY GUIDEMODEL: OPC5033 INCH CHIPPER SHREDDER

CHIPPER ASSEMBLY GUIDEMODEL: OPC5033 INCH CHIPPER SHREDDER

DK2 POWER USA

4301 S Valley View Blvd STE 10-11Las Vegas, NV 89103[email protected]702-331-5353 8-4 M-F

BRUSH TO 3 INCHESTOWABLEKOHLER ENGINE

CHIPPER SHREDDER TOP LOADING

OFF-ROAD TOWING ONLYREV 0 12/31/18

STEP 1:

Open and unpack all items. Leave lots of working space. Inspect all parts.The Chipper is shipped in a crate. Leave the sides folded down and use it as your workspace.

NOTE: UPON INSPECTION OF PARTS IF YOU FIND ANY DAMAGE OR MISSING PARTS PLEASE CALL DK2 POWER AT 702-331-3535 OR CONTACT US VIA OUR WEBSITE WWW.DK2POWER.COM WE WILL REPLACE ANY DAMAGED or MISSING PARTS TO YOU FREE

PLEASE DO NOT RETURN TO THE STORE

STEP 2:

- Remove all hardware from chute mounting holes, take care to NOT drop hardware down into the chute opening.

- Install the chute and the mounting hardware.

STEP 3:

- Mount the FEED CHUTE onto the Chipper using supplied bolts and hardware.

STEP

- INSTALL THE HANDLE USING 4 BOLTS PREINSTALLED ON THE CHUTE FOR THE HANDLE TO BE ASSEMBLED.

STEP 5:

- INSTALL TOW BAR, SECURE HITCH PIN SPRING LATCH.

STEP 6:

READ THE ENGINE MANUAL SUPPLIED WITH YOUR UNIT FOR FULL ENGINE OPERATION, SAFETY, AND MAINTENANCE.

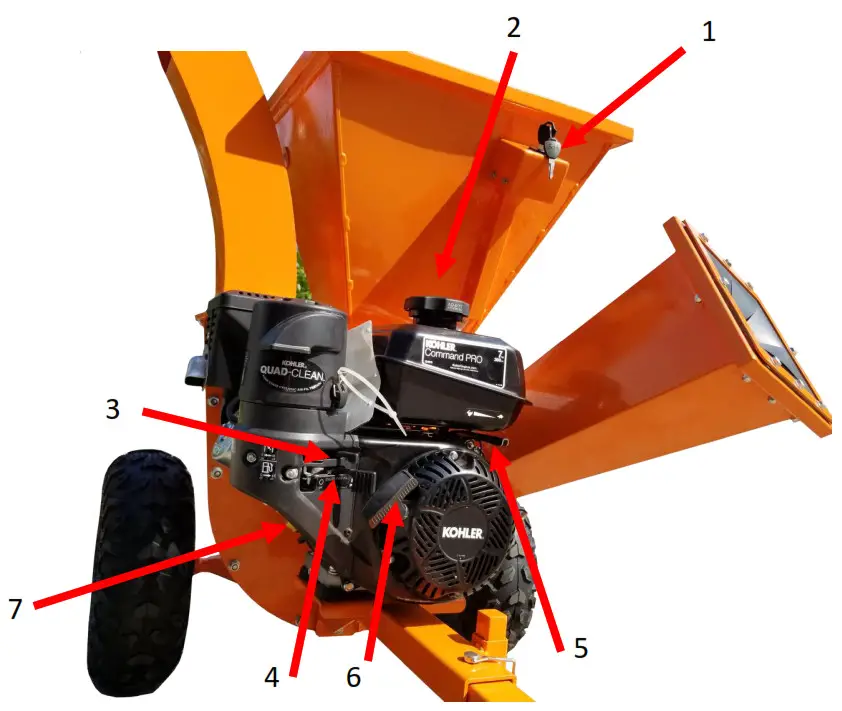

| 1 | ON/OFF KEY LOCK |

| 2 | GAS – USE MID-GRADE OR HIGHER |

| 3 | CHOKE – LEFT IS ON / RIGHT IS OFF (RUN POSITION) |

| 4 | GAS ON/OFF SWITCH – LEFT IS OFF / RIGHT IS ON |

| 5 | THROTTLE – RABBIT FAST / TURTLE SLOW |

| 6 | PULL STARTER – PULL TIGHT- THEN PULL START |

| 7 | OIL – FILL TO MARK 10W30, WILL NOT START IF OIL IS LOW, HAS LOW OIL SHUTOFF PROTECTION. 2 YELLOW CAPS ARE OIL FILL CAPS. USE EITHER ONE TO FILL OIL. |

Your Chipper is equipped with dual REVERSABLE cutting blades.

- Turn the engine key off, remove the key and unplug the spark plug on the engine.

- Remove the rear cover on the chipper housing

- Before removing the bolts that mount the blades, place paper towels in the area opening under the blade and the drum housing. This will help to catch bolts from dropping into the bottom of the drum housing.

- Remove the first bolt.

- Before removing the last bolt be sure to support the blade from sliding down into the drum.

- Remove the blade, reverse it to the new sharp edge and reinstall it. Use only DK2 POWER OEM blades.

- Use Loctite on the bolt threads when replacing bolts.

- Remove the feed chute to access additional blades.

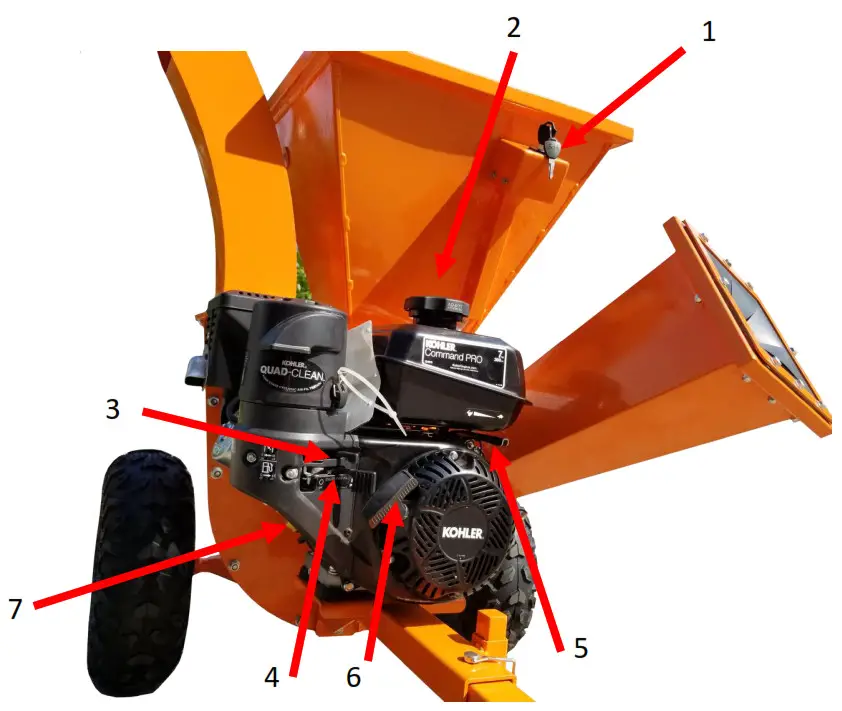

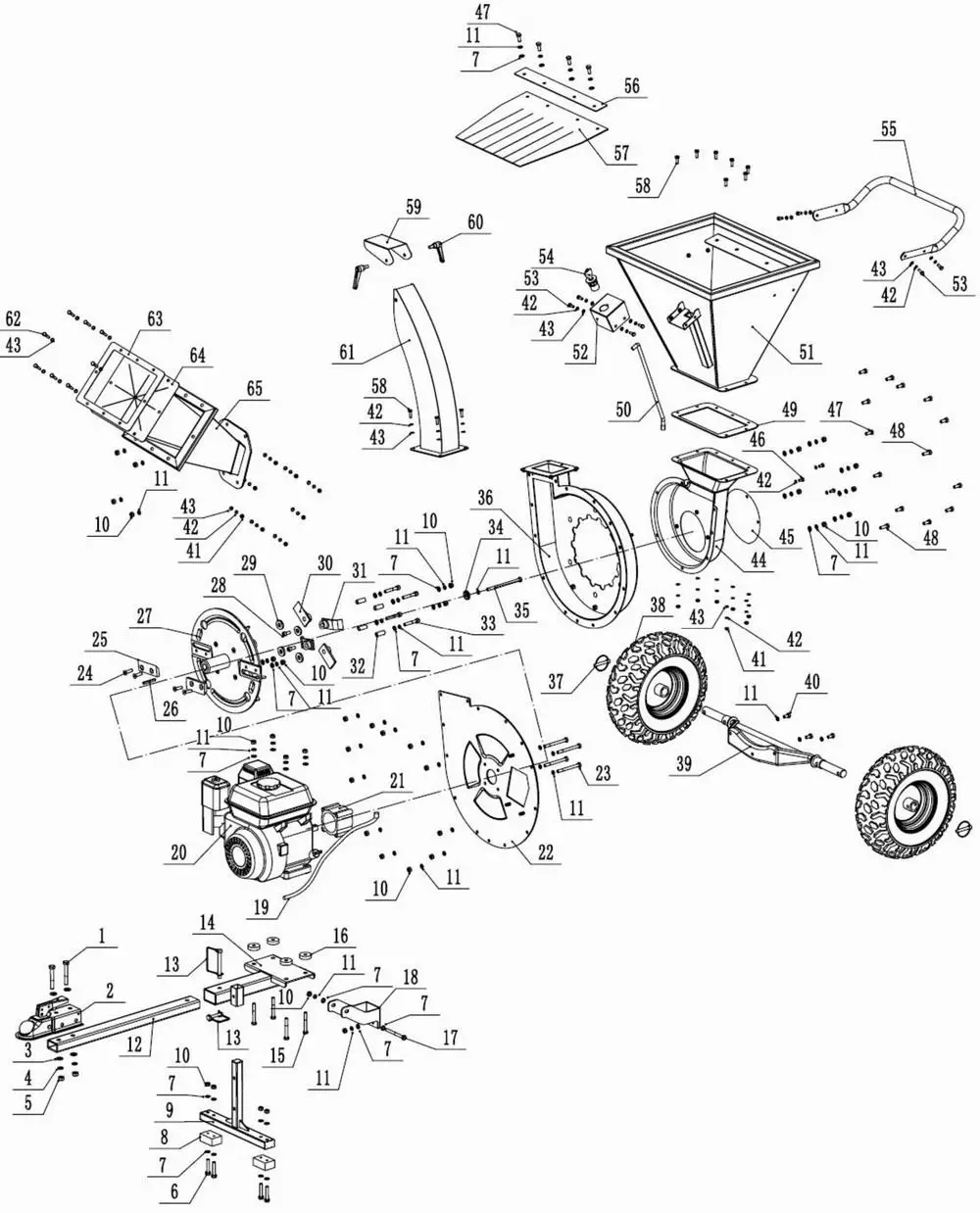

| Part Number | Description | Part Number | Description. |

| 1 | M10*70 bolt | 34 | gland |

| 2 | hitch trailer | 35 | 5/16-24UNF*135 bolt |

| 3 | washer⌀10.5*⌀22*2 | 36 | main chipper room |

| 4 | spring washer⌀10 | 37 | O-latch⌀8 |

| 5 | M10locknut | 38 | tire |

| 6 | M8*45 bolt | 39 | axle |

| 7 | washer⌀8.4*⌀20*1.6 | 40 | M8*16 bolt |

| 8 | Rubber pad | 41 | M6locknut |

| 9 | support feet | 42 | spring washer⌀6 |

| 10 | M8locknut | 43 | washer⌀6.4*⌀12*1.6 |

| 11 | spring washer⌀8 | 44 | side chipper room |

| 12 | tow bar | 45 | side chipper room cover |

| 13 | latch⌀8 | 46 | M6*12 bolt |

| 14 | engine plate | 47 | M8*20 bolt |

| 15 | M8*60 bolt | 48 | M8*25 bolt |

| 16 | Rubber pad⌀10 | 49 | rubber pad |

| 17 | M8*85 bolt | 50 | swtich key wire |

| 18 | U-protection plate | 51 | top feed hopper |

| 19 | engine wire | 52 | swtich stop cover |

| 20 | engine | 53 | M6*16 bolt |

| 21 | protection pipe | 54 | switch key |

| 22 | main chipper room cover | 55 | handle |

| 23 | 5/16-24UNF*85 bolt | 56 | plate for protection sheet |

| 24 | M8*25bolt | 57 | protection sheet |

| 25 | blade | 58 | M6*20 bolt |

| 26 | key | 59 | outlet hopper adjusting plate |

| 27 | blade roller | 60 | knob |

| 28 | M8*20 bolt | 61 | outlet hopper |

| 29 | washer⌀30*⌀13*4 | 62 | M6*35 bolt |

| 30 | straight hammer | 63 | side plate for protection sheet |

| 31 | L-hammer | 64 | side protection sheet |

| 32 | Straight sleeve | 65 | side feed hopper |

| 33 | M8*50bolt |

OPERATION – BEFORE TURNING THE KEY AND PULL STARTING ENGINE

CLEAR AREA OF ALL PEOPLE AND PROPERTY THAT COULD BE DAMAGED. THINK SAFETY. CHIPS ARE FLYING PROJECTILES AND CAN CAUSE INJURY. WEAR SAFETY GLASSES, HEARING PROTECTION, AND GLOVES DO NOT WEAR LOOSE-FITTING CLOTHES THAT COULD GET STUCK IN THE MACHINE MOVING PARTS, ONLY CHIP WOOD, CHILDREN SHOULD NOT RUN THIS EQUIPMENT, STAY ALERT OF YOUR SURROUNDINGS AND PERSONS THAT COULD APPEAR IN THE CHIP PATH WHILE YOU ARE WORKING.

UNIT IS DIRECT DRIVE. NO CLUTCH TO SLIP OR BURN UP.Before starting make sure all chutes are clear of branches as the cutting wheel will turn as you pull the recoil starter. The cutter wheel must be free to turn when starting.

PERFORMANCE OPERATIONFeed larger trees up to 3 inches in diameter slowly into the tubular feed chute allowing the cutter wheel to regain speed. Shoving a tree into the cutter wheel will stall the machine and damage the cutters or drive shaft.

Feed twigs, leaves, and branches up to 1-inch dia into the top hopper.Wear gloves, as the cutter will grab the branches and pull them into the machine and from your hands. NEVER PLACE HANDS INTO THE TOP FEEDER.To clear the top feeder turn the key off, remove it, unplug the spark plug. Be safe, the cutter on this machine are high speed and very sharp.

SET BOTH OF YOUR WHEEL BRAKE PINS to STABILIZE MACHINE DURING OPERATION.READ AND OBEY ALL WARNING LABELS ON THIS MACHINE.

QUICKSTART AND TROUBLESHOOTING GUIDE

QUICK START SETUP

- ADD 10W30 OIL TO THE ENGINE

- ADD GAS

- PIN BOTH WHEELS INTO PIVOT BRAKE HOLES.

- TURN KEY ON

- HALF THROTTLE (CHOKE OPTIONAL FOR COLD STARTS)

- PULL START THE ENGINE

TREE CHIPPING

- ENGINE ON HIGHEST SPEED

- FEED SMALLER TREES INTO CHUTE AND LET GO, TREE WILL AUTO-FEED.

- FEED LARGER TREES SLOWLY ALLOW CUTTER WHEEL TO REGAIN RPM SPEED

BETWEEN CUTS.

- FEED LEAVES, TWIGS, AND UP TO 1 INCH DIA TREES INTO THE TOP HOPPER.

TROUBLESHOOTING

- THE ENGINE WON’T START

- TURN KEY ON – CHECK ENGINE OIL LEVEL – CHECK GAS LEVEL

- UNPLUG KEY SWITCH – IF THE ENGINE STARTS REPLACE THE KEY SWITCH.

- FOLLOW YOUR ENGINE MANUAL FOR FURTHER TROUBLESHOOTING.

- UNIT VIBRATES

- CHECK YOUR CHIPPER FOR MISSING OR LOOSE BLADES.

- CHECK YOUR CHIPPER WHEEL IS NOT OBSTRUCTED AND FREELY TURNS.

PLEASE DO NOT RETURN TO THE STOREYOU HAVE A 1 YEAR WARRANTY AND DK2 WILL REPLACE A DEFECTIVE PART FOR FREECALL US AT 702-331-5353 FOR FAST WARRANTY PARTS AND QUESTIONS

WHAT IS COVEREDDK2 Inc. warrants to the original purchaser of any DK2 product that it will be free and clear of manufacturing defects in workmanship and materials under normal use and service for a period of one (1) year from the date of the original purchase.If within one (1) year from the original date of purchase this product fails due to a defect in material or workmanship, Detail K2 will repair, replace, or supply any defective part at our option for DK2 trailer products. DK2 POWER outdoor power equipment is 1-year parts only warranty no labor.Upon expiry of one (1) year, Detail K2 will have no further liability related to the product. Detail K2 does not authorize any party, including its authorized distributors or dealers, to offer any other warranty on behalf of Detail K2 Inc.

KOHLER ENGINES – KOHLER CH-SERIES ENGINES COMMERCIAL 3 YR PARTS AND LABOR WARRANTYKOHLER ENGINES – KOHLER SH SERIES ENGINES RESIDENTIAL 2 YR PARTS AND LABOR WARRANTY see your Kohler manual for a specific warranty.DIESEL TRACTORS – Chassis component parts only, no labor, ENGINES – 1 YR KOHLER WARRANTY3PT EQUIPMENT – 1-YEAR parts only, Gearbox drive unit 3-year warranty parts only.DK2 POWER OUTDOOR EQUIPMENT – 1-Year parts only, no labor. 3-year commercial Kohler warranty.

THIS WARRANTY DOES NOT COVER OR APPLY TO:Damage to the product due to misuse, mishandling, and abuse(b) Improper installation, maintenance, and storage(c) Expendable parts such as nuts and bolts, pins and springs, wiring and switch components, hydraulic hoses and fittings, cutting teeth, cutting chains, cutting blades, throttles, belts, and tires.(d) Normal wear and tear(e) Consequential damage & incidental damages such as damage to persons or property

PROCEDURE FOR OBTAINING AN RETURN AUTHORIZATIONWithin the one (1) year warranty period, the purchaser of the product must notify DK2 of the claimed defect and provide proof of original purchase. At this time the validity of the claim will be determined, and if approved replacement parts will be issued.A Return Goods Authorization Number (RGA) will be issued if approved for DK2 Automotive products. No returned product will be accepted under warranty unless accompanied by an RGA# issued by Detail K2 Inc.

RESOLUTION FOR A DEFECTIVE PRODUCTDK2 POWER – Tractors, Chippers, Stump Grinders, Log Splitters, 3pt, and Outdoor Power Equipment.Call DK2 at 702-331-5353 in Las Vegas between 8 am-4 pm M-F Pacific Time.DK2 Snow, Trailer, Rack, and Winch Products.Call DK2 at 888-277-6960 in Burlington Canada between 8 am-4 pm M-F Eastern Time.

References

[xyz-ips snippet=”download-snippet”]