E-flite EFL16575 Advance Electric Flight

NOTICEAll instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, LLC. For up-to-date product literature, visit www.horizonhobby.com or towerhobbies.com and click on the support or resources tab for this product.

MEANING OF SPECIAL LANGUAGE:The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, and serious injury OR create a high probability of superficial injury.CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND little or no possibility of injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating. Failure to operate the product correctly can result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage to the product or other property. This product is not intended for use by children without direct adult supervision. Do not use with incompatible components or alter this product in any way outside of the instructions provided by Horizon Hobby, LLC. This manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or serious injury.

Safety Precautions and Warnings

As the user of this product, you are solely responsible for operating in a manner that does not endanger yourself and others or result in damage to the product or the property of others.

- Always keep a safe distance in all directions around your model to avoid collisions or injury. This model is controlled by a radio signal subject to interference from many sources outside your control. Interference can cause momentary loss of control.

- Always operate your model in open spaces away from full-size vehicles, traffic and people.

- Always carefully follow the directions and warnings for this and any optional support equipment (chargers, rechargeable battery packs, etc.).

- Always keep all chemicals, small parts and anything electrical out of the reach of children.

- Always avoid water exposure to all equipment not specifically designed and protected for this purpose. Moisture causes damage to electronics.

- Never place any portion of the model in your mouth as it could cause serious injury or even death.

- Never operate your model with low transmitter batteries.

- Always keep aircraft in sight and under control.

- Always use fully charged batteries.

- Always keep transmitter powered on while aircraft is powered.

- Always remove batteries before disassembly.

- Always keep moving parts clean.

- Always keep parts dry.

- Always let parts cool after use before touching.

- Always remove batteries after use.

- Always ensure failsafe is properly set before flying.

- Never operate aircraft with damaged wiring.

- Never touch moving parts.

WARNING AGAINST COUNTERFEIT PRODUCTS: If you ever need to replace your Spektrum receiver found in a Horizon Hobby product, always purchase from Horizon Hobby, LLC or a Horizon Hobby authorized dealer to ensure authentic high-quality Spektrum product. Horizon Hobby, LLC disclaims all support and warranty with regards, but not limited to, compatibility and performance of counterfeit products or products claiming compatibility with DSM or Spektrum technology.

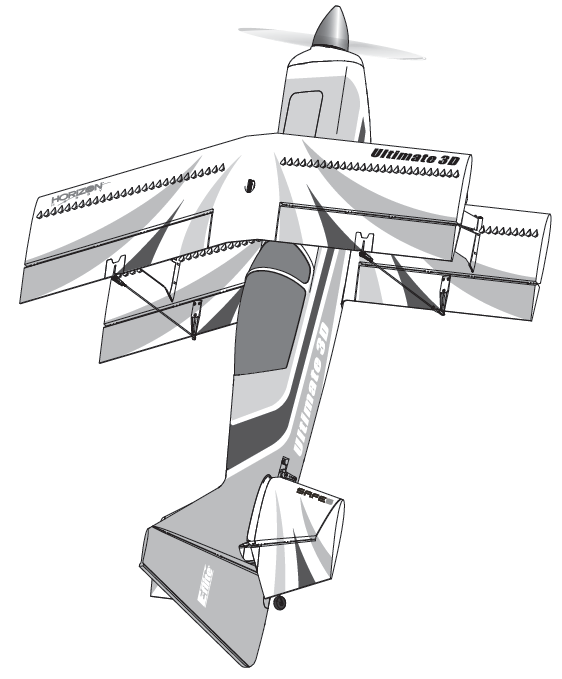

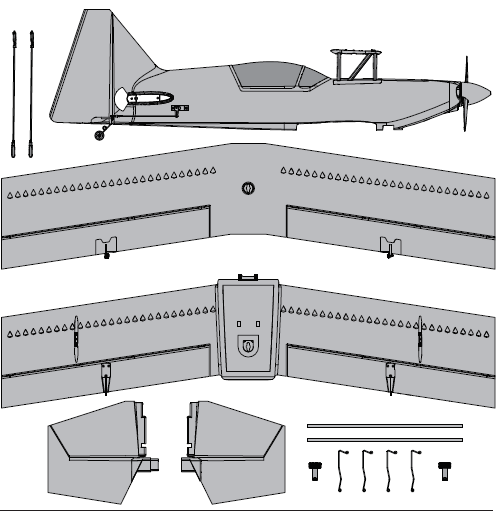

Box Contents

| Quick Start Information |

|

|

|

Transmitter Setup |

1. Blank (Acro) Model | |

| 2. Servo Reversing: Set all to normal | ||

| 3. Travel Adjust (All Surfaces): 100% | ||

|

Dual Rates* |

High Rate | Low Rate |

| Aileron | p = 24mm

q = 24mm |

p = 18mm

q = 18mm |

| Elevator | p = 45mm

q = 45mm |

p = 30mm

q = 30mm |

| Rudder | = 70mm

= 70mm |

= 50mm

= 50mm |

|

EXPO (Soft center) |

High Rate | Low Rate |

| Aileron | 10% | 5% |

| Elevator | 10% | 5% |

| Rudder | 10% | 5% |

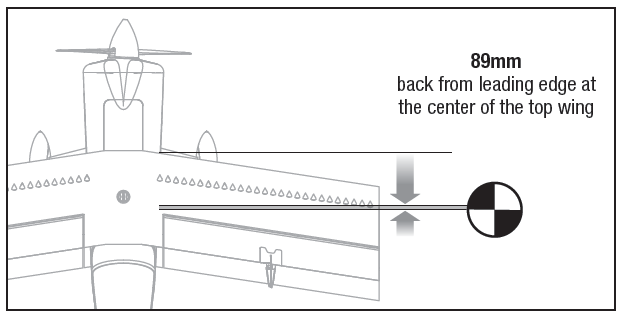

| Center of Gravity (CG) | 89mm back from the leading edge at the center of the top wing | |

| Flight Timer Setting | 3 minutes |

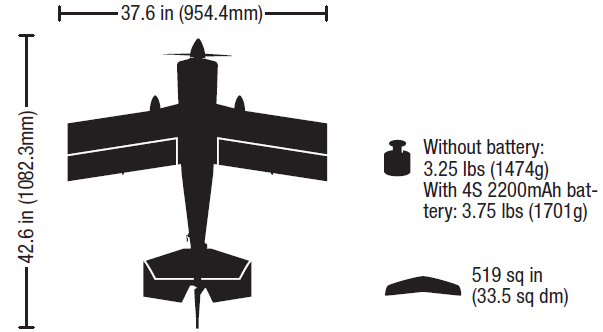

Specifications

| Motor: BL10 Brushless Outrunner, 800Kv Pole Count: 14 (EFLM17552) | Included | Included |

| ESC: AvianTM 60A Smart ESC, (SPMXAE1060) | Installed | Installed |

| Servos: (4) 9g Servos (SPMSA332) | Installed | Installed |

| Receiver: Spektrum™ AR637TA 6-Channel AS3X/SAFE Telemetry Receiver (SPMAR637T) | Installed | Required to Complete |

| Recommended Battery: 2200mAh 14.8v 4S 30C LiPo (SPMX22004S30) | Required to Complete | Required to Complete |

| Recommended Battery Charger:

3-4 cell Li-Po battery balancing charger |

Required to Complete | Required to Complete |

| Recommended Transmitter:

Full-Range 2.4GHz with Spektrum™ DSM2®/DSMX® technology with programmable mixing and adjustable dual rates |

Required to Complete |

Required to Complete |

| RECEIVER BIND INFORMATION | ||

| Channels | 6 | |

| Frequency | 2404 – 2476 MHz | |

| Compatibility | DSM2 and DSMX |

If you own this product, you may be required to register with the FAA.For up-to-date information on how to register with the FAA, please visit https://registermyuas.faa.gov/. For additional assistance on regulations and guidance on UAS usage, visit knowbeforeyoufly.org/

Preflight

| 1 | Remove and inspect contents. |

| 2 | Read this instruction manual thoroughly. |

| 3 | Charge the flight battery. |

| 4 | Setup Transmitter using transmitter setup chart. |

| 5 | Fully assemble the airplane. |

| 6 | Install the flight battery in the aircraft (once it has been fully charged). |

| 7 | Check the Center of Gravity (CG). |

| 8 | Bind the aircraft to your transmitter. |

| 9 | Make sure linkages move freely. |

| 10 | Perform the Control Direction Test with the transmitter. |

| 11 | Perform the AS3X Control Direction Test with the aircraft. |

| 12 | Adjust flight controls and transmitter. |

| 13 | Perform a radio system Range Test. |

| 14 | Find a safe open area to fly. |

| 15 | Plan flight for flying field conditions. |

Transmitter Setup

IMPORTANT: After you set up your model, always rebind the transmitter and receiver to set the desired failsafe positions.IMPORTANT: The included receiver has been programmed specifically for operation in this aircraft.If your transmitter allows it, enable the throttle cut feature. Always engage throttle cut before approaching the aircraft.

Dual Rates

Low rate is recommended for the initial flights.

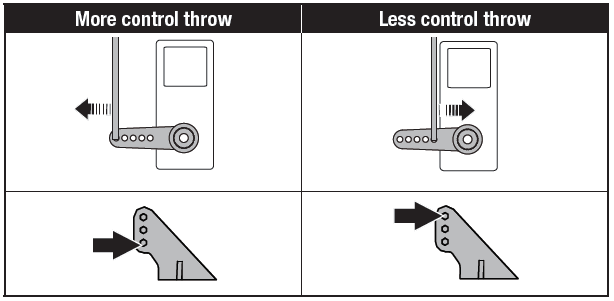

NOTICE: To ensure AS3X® technology functions properly, do not lower rate values below 50%. If lower rates are desired, manually adjust the position of the pushrods on the servo arm.NOTICE: If oscillation occurs at high speed, refer to the Troubleshooting Guide for more information.

Exponential

After first flights, you may adjust expo in your transmitter.Transmitter Telemetry SetupIf the transmitter that you intend to use with this aircraft is not displaying telemetry data, visit spektrumrc.com and update your firmware. With the latest firmware installed on your transmitter the telemetry option should now be functional on your transmitter.

- Some of the terminology and function locations used in the iX12 and iX20 programming may be slightly different than other Spektrum AirWare™ radios. The names given in parenthesis correspond to the iX12 and iX20 programming terminology. Consult your transmitter manual for specific information about programming your transmitter.

- The settings provided above for the DX6 and DX6e do not allow for the use of a SAFE Select switch. To use a SAFE Select switch on these systems see the section below for transmitter setup and operation information.

| Computerized Transmitter Setup | ||

| Start all transmitter programming with a blank ACRO model (perform a model reset), then name the model. | ||

|

Set Dual Rates to |

2 Position switch | 3 Position switch |

| HIGH 100% | HIGH 100% | |

| MID 70% | ||

| LOW 50% | LOW 50% | |

| Set Servo Travel to | 100% | |

| Set Throttle Cut to | -100% | |

| DXe | Refer to spektrumrc.com for the appropriate download setup. | |

|

DX7S DX8 |

1. Go to the SYSTEM SETUP | |

| 2. Set MODEL TYPE: AIRPLANE | ||

| 3. Go to CHANNEL ASSIGN:

CHANNEL INPUT CONFIG AUX2 Switch A SELECT GEAR: INH |

||

| DX6e

DX6 (Gen2) DX7 (Gen2) DX8e DX8 (Gen2) DX9 DX10t DX18 DX20 iX12 iX20 NX6 NX8 NX10 |

1. Go to the SYSTEM SETUP (Model Utilities)† |

|

|

2. Set MODEL TYPE: AIRPLANE |

||

|

3. Set AIRCRAFT TYPE (Model Setup, Aircraft Type)†: Wing: Normal |

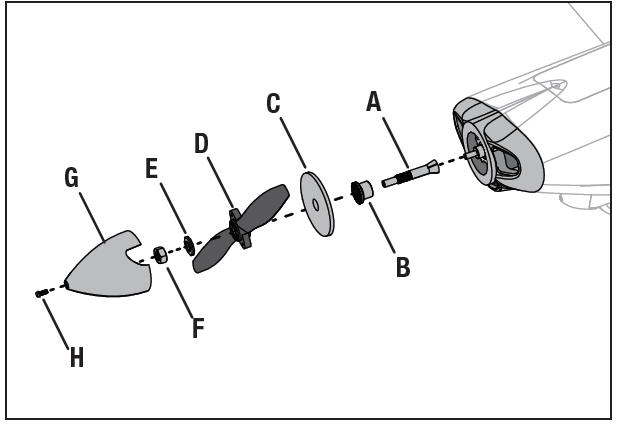

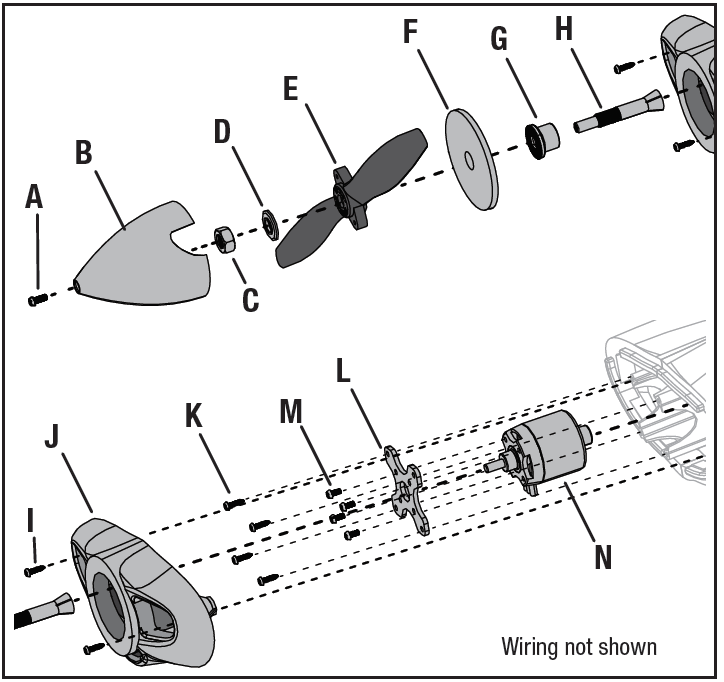

Factory Installed Propeller Removal

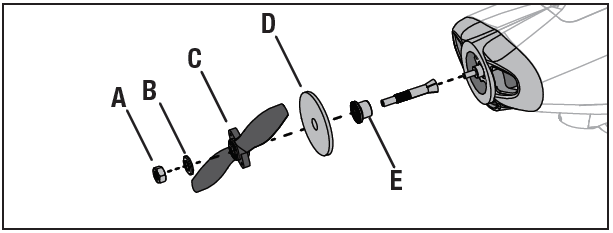

CAUTION: Before connecting a flight battery and binding to a transmitter, remove the factory installed propeller.

- Remove the spinner nut (A) using an adjustable wrench.

- Slide the washer (B), propeller (C), spinner backplate (D), backplate (E) off the propeller shaft.

Keep the removed parts in a safe place as they will need to be reinstalled at the end of the model assembly process.

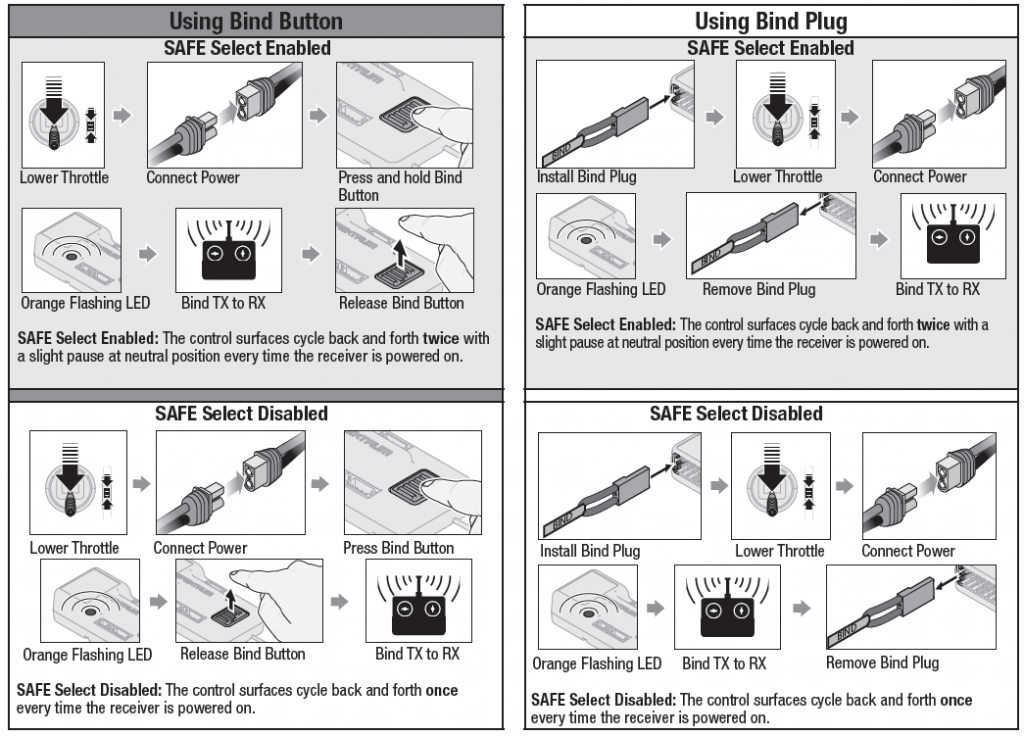

Transmitter and Receiver Binding / Switching ON and OFF SAFE Select

General Binding Tips

- The included receiver has been specifically programmed for operation of this aircraft. Refer to the receiver manual for correct setup if the receiver is replaced.

- Keep away from large metal objects while binding.

- Do not point the transmitter’s antenna directly at the receiver while binding.

- The orange LED on the receiver will flash rapidly when the receiver enters bind mode.

- Once bound, the receiver will retain its bind settings for that transmitter until you re-bind.

- If the receiver loses transmitter communication, the failsafe will activate. Failsafe moves the throttle channel to low throttle. Pitch and roll channels move to actively stabilize the aircraft in a descending turn.

- If problems occur, refer to the troubleshooting guide or if needed, contact the appropriate Horizon Product Support office.

SAFE Select Technology, Optional Flight Envelope ProtectionThe BNF Basic version of this airplane includes SAFE Select technology, enabling you to choose the level of flight protection. SAFE mode includes angle limits and automatic self leveling. AS3X mode provides the pilot with a direct response to the control sticks. SAFE Select is enabled or disabled during the bind process. With SAFE Select disabled the aircraft is always in AS3X mode. With SAFE Select enabled the aircraft will be in SAFE Select mode all the time, or you can assign a switch to toggle between SAFE Select and AS3X modes.Thanks to SAFE Select technology, this aircraft can be configured for full-time SAFE mode, full-time AS3X mode, or mode selection can be assigned to a switch.IMPORTANT: Before binding, read the transmitter setup section in this manual and complete the transmitter setup table to ensure your transmitter is properly programmed for this aircraft.IMPORTANT: Move the transmitter flight controls (rudder, elevators, and ailerons) and the throttle trim to neutral. Move the throttle to low before and during binding. This process defines the failsafe settings. You can use either the bind button on the receiver case OR a conventional bind plug to complete the binding and SAFE Select process.

SAFE® Select Switch Designation BNF

Once SAFE Select is enabled, you can choose to fly in SAFE mode full-time, or assign a switch. Any switch on any channel between 5 and 9 can be used on your transmitter.If the aircraft is bound with SAFE Select disabled, the aircraft will be in AS3X mode exclusively.

CAUTION: Keep all body parts well clear of the propeller and keep the aircraft securely restrained in case of accidental throttle activation.

- The aircraft was bound with SAFE Select enabled.

- Your choice for the SAFE Select switch is assigned to a channel between 5 and 9 (Gear, Aux1-4), and travel is set at 100% in each direction.

- The aileron, elevator, rudder and throttle direction are set to normal, not reverse.

- The aileron, elevator, rudder and throttle are set to 100% travel. If dual rates are in use, the switches need to be in the 100% position.

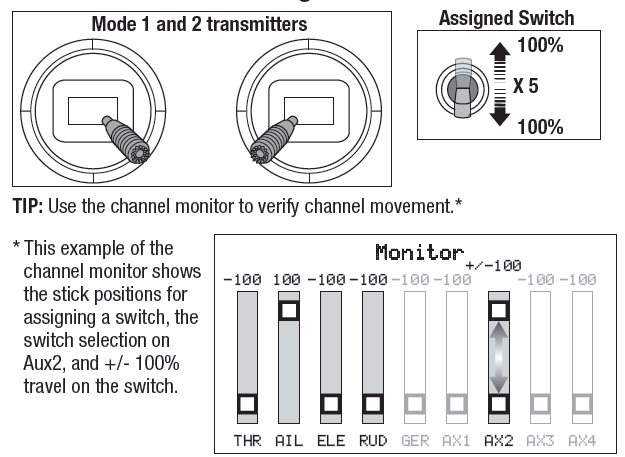

See your transmitter manual for more information about assigning a switch to a channel.Assigning a Switch

- Power on the transmitter.

- Power on the aircraft.

- Hold both transmitter sticks to the inside bottom corners, and toggle the desired switch 5 times quickly (1 toggle = full up and down).

- The control surfaces of the aircraft will move, indicating the switch has been selected.

Repeat the process to assign a different switch or to deactivate the current switch.

SAFE Select Switch Assignment Stick Positions

Forward ProgrammingAssign the SAFE Select channel through forward programming on your compatible Spektrum transmitter.

| Forward Programming SAFE Select Setup | |

|

DX series, NX series, iX series |

1. Begin with the transmitter bound to the receiver. |

| 2. Power ON the transmitter. | |

| 3. Assign a switch for SAFE Select that is not already in use for another function. Use any open channel between 5 and 9 (Gear, Aux1-4). | |

| 4. Set switch H (throttle cut) to prevent accidental motor operation. | |

| 5. Power ON the aircraft. A signal bar appears on your transmitter’s main screen when the telemetry information is being received. | |

| 6. Go to the FUNCTION LIST (Model Setup) | |

| 7. Select Forward Programming; Select Gyro Settings; Choose SAFE Select to enter the menu. | |

| 8. Set SAFE Select Ch: To the channel you have chosen for SAFE Select. | |

| 9. Set AS3X and SAFE On or Off as desired for each switch position. |

For more information about setting SAFE Select and using Forward Programming, please refer to the following link for a detailed video: https://www.youtube.com/watch?v=o-46P066cik

Integrated ESC Telemetry

BNF: This aircraft includes telemetry between the ESC and receiver, which can provide information including RPM, voltage, motor current, throttle setting (%), and FET (speed controller) temperature.PNP: The ESC in this aircraft is capable of delivering telemetry information over the throttle connection when paired with a Smart compatible Spektrum telemetry receiver. It will function with a normal PWM servo siganl for common radio control systems.For more information about compatible transmitters, firmware updates, and how to use the telemetry technology on your transmitter, visit www.SpektrumRC.com

| Telemetry Setup | |

|

DX series, NX series, iX series |

1. Begin with the transmitter bound to the receiver. |

| 2. Power ON the transmitter. | |

| 3. Set switch H (throttle cut) to prevent accidental motor operation. | |

| 4. Power ON the aircraft. A signal bar appears on your transmitter’s main screen when the telemetry information is being received. | |

| 5. Go to the FUNCTION LIST (Model Setup) | |

| 6. Select TELEMETRY; Smart ESC | |

| 7. Set Total Cells: 4 | |

| 8. Set LVC Alarm: 3.4V Set Alarm; Voice/Vibe | |

| 9. Set pole count; 14 pole |

Thrust Reversing

The Avian™ Smart ESC in this aircraft is equipped with thrust reversing, but it must be enabled before it will function. Reversing the motor can be helpful when taxiing or for shortening ground roll after a landing. Flipping the designated switch reverses motor rotation, throttle will still control motor speed.

WARNING: Never attempt to use thrust reversing in flight. Applying reverse thrust while in flight will result in loss of control and possibly a crash. Crash damage is not covered under warranty.

IMPORTANT: The motor will draw more current in reverse as the propeller becomes less efficient and creates more drag. This can reduce flight time.IMPORTANT: Thrust reversing requires a Spektrum receiver with Smart Throttle (including the AR637TA and AR631) and a Spektrum transmitter with a minimum of 7 channels. The Avian ESC is also backwards compatible with conventional receivers (PWM output signal) for normal operation, but reversing functions are only available with Smart Throttle technology.

Thrust Reversing Setup

TransmitterOn the transmitter, select an open channel (not already in use), and assign it to an open switch. Use a different channel for thrust reversing and SAFE Select. Motor reversing is assigned to Aux 2/Channel 7, by default, in the Smart ESC. If SAFE Select and the ESC are assigned to the same channel, the motor will reverse in flight.

WARNING: Do not assign thrust reversing and SAFE Select to the same channel. Doing so will reverse the motor when SAFE Select is enabled during flight, resulting in a crash.

ESCSet up the transmitter according to the setup chart, and bind your transmitter to the airplane. The airplane must be powered on and bound to the transmitter to access the Smart ESC programming.As an alternative, it is possible to program the ESC with the Smart ESC Programming Box (SPMXCA200, optional, not included).

| ESC Reversing Setup | |

|

DX series, NX series, iX series |

1. Begin with the transmitter bound to the receiver. |

| 2. Power ON the transmitter. | |

| 3. Set switch H (throttle cut) to prevent accidental motor operation. | |

| 4. Set elevator and aileron to high rate. | |

| 5. Set Flight Mode to AS3X (The menu will not open if the Flight Mode is set to SAFE). | |

| 6. Power ON the aircraft. A signal bar appears on the transmitter main screen when the telemetry information is being received. | |

| 7. From the main screen navigate to the last screen past the telemetry screens, the Avian Programming menu (Avian Prog). | |

| 8. Configuration in the Avian Programming menu is done by moving the elevator and aileron stick. Follow the on-screen prompts to access the menu. Move the stick up or down to move through the menu, left or right to change a setting. | |

| 9. Set BRAKE TYPE: Reverse | |

| 10. Set BRAKE FORCE: 7 | |

| 11. Set THRUST REV: Select the channel you designated for thrust reversing in your transmitter. CH7 is the selection by default, but do not use this default option if you are using Aux2/Ch7 for SAFE Select. | |

| 12. Select EXIT W/ SAVE to save your selections |

Model Assembly

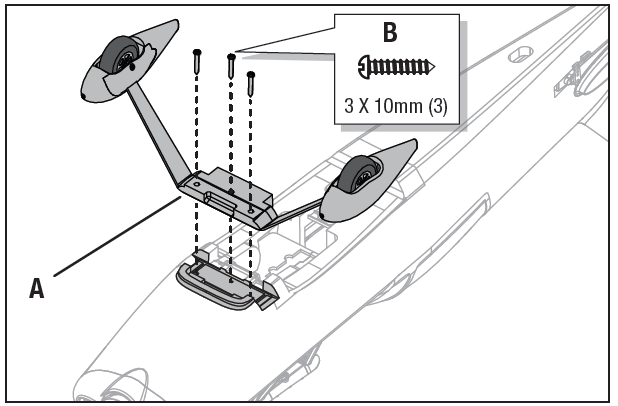

Landing Gear Installation

Install the landing gear assembly (A) on the fuselage and secure in place using 3 screws (B). Disassemble in reverse order.

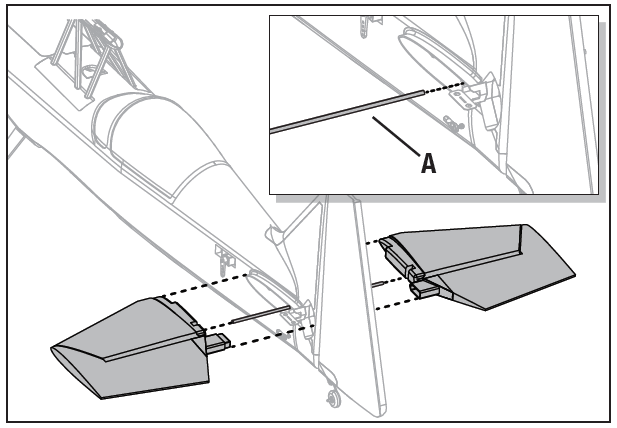

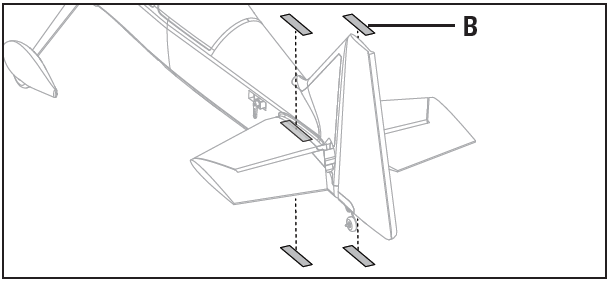

Horizontal Stabilizer Installation

IMPORTANT: The Ultimate 3D includes two tail tubes to accommodate the use of a 3s or 4s battery. The lightweight composite tube is recommended to achieve correct CG when using a 3S battery. The metal tube is recommended to achieve correct CG when using a 4S battery.

- Slide the horizontal tail tube (A) into the hole in the rear of the fuselage.

- Install the 2 piece (left and right) horizontal tail as shown. Ensure the control horn faces down.

- Secure the 2 piece horizontal tail in place with 4 pieces tape (B) included.

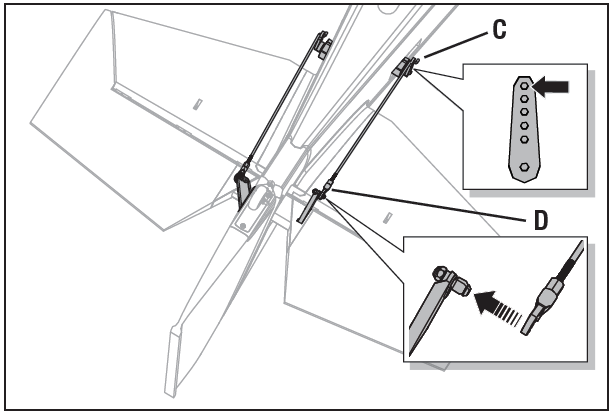

- Attach the z-bend end of the elevator pushrod (C) to the outermost hole of the servo arm.

- Connect the ball-link end of the elevator pushrod (D) to the ball on the elevator control horn using ball-link pliers or similar tool.

- Ensure the elevator and rudder servo arms are in the correct position, then adjust the linkage to center them.

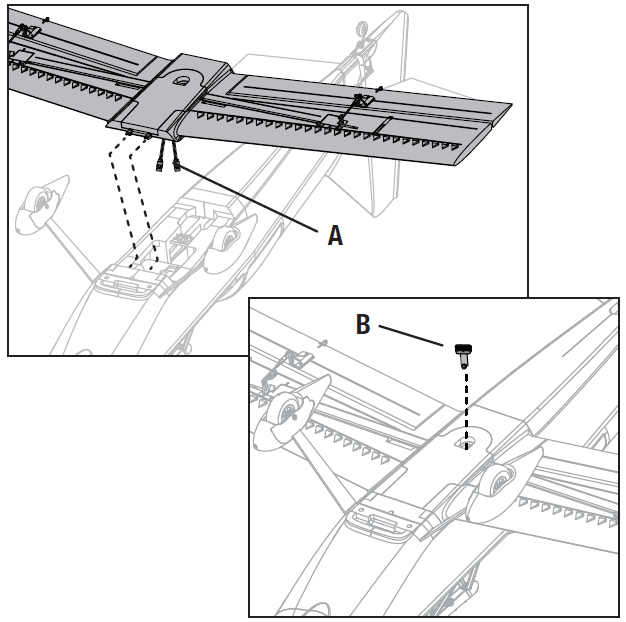

Wing Installation

Bottom Wing Installation

- Connect the aileron servo connectors (A) to the aileron y-harness connectors in the fuselage.

- Align the bottom wing mounting pins with the fuselage mounting plate to attach the bottom wing to the fuselage.

- Secure the wing in place with the locking pin (B). Insert pin and turn 90 degrees to lock in place.

Disassemble in reverse order.

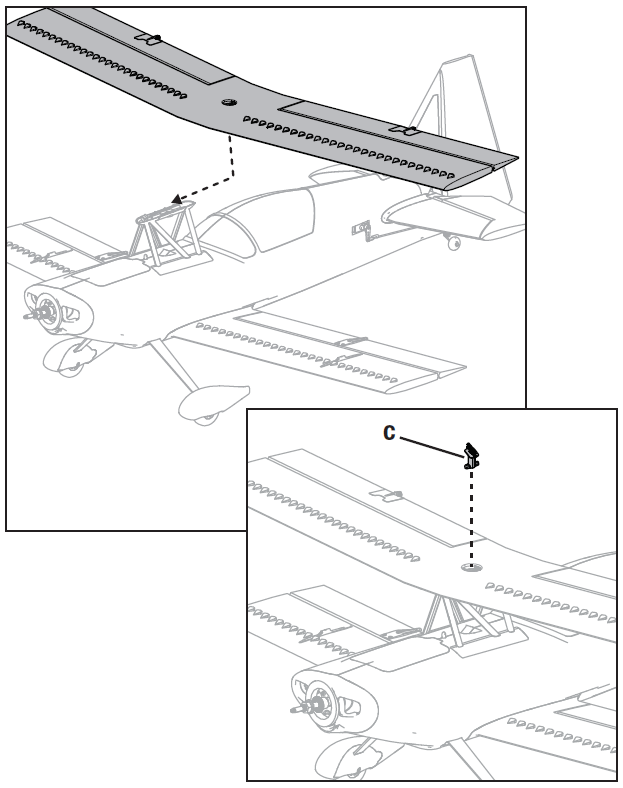

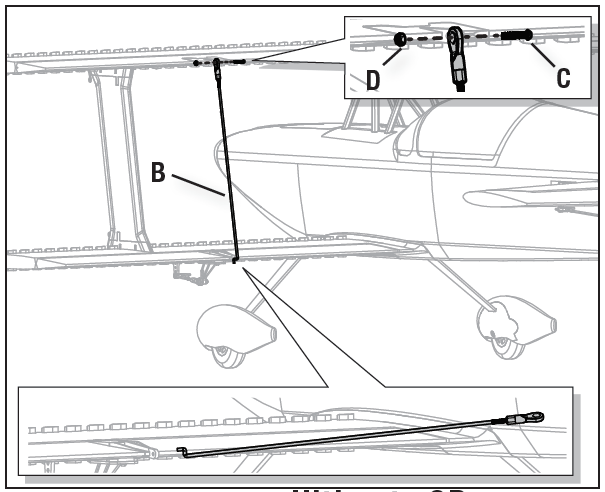

Top Wing Installation

- Align the top wing with the center mounting post. Slide it into the latch as shown.

- Secure the wing in place with the locking pin (C). Insert pin and turn 90 degrees to lock in place.

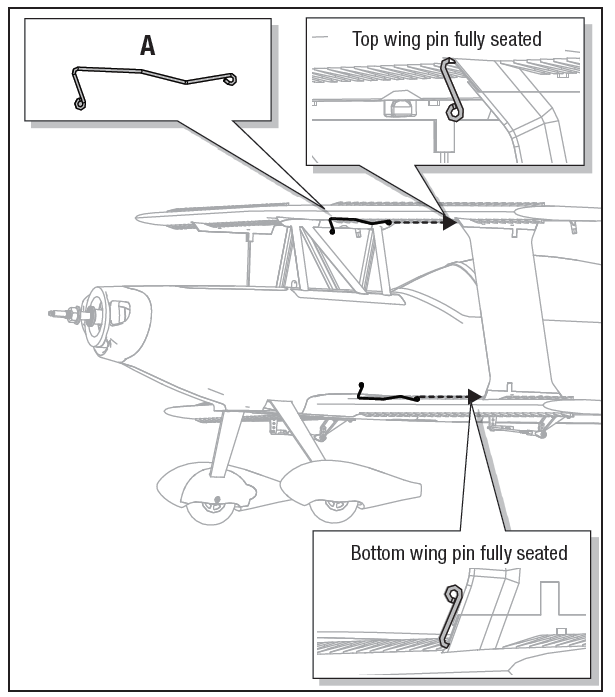

- Slide the left and right wing strut in place, between the upper and lower wings as shown. Ensure that the arrow indicator on top of the strut is pointing forward and that the smooth side of the strut faces out.

- Secure the wing struts to the top and bottom wing with the 4 included pins (A). Ensure that the wing pins are fully seated.

- Link the upper and lower ailerons by installing the Z-bend end (B) to the lower wing’s aileron control horn.

- Center the lower aileron and adjust the ball link as needed so the top aileron is centered.

- Secure the ball link end of the pushrod to the top wing control horn with the included screw (C) and nut (D).

Propeller and Spinner installation

- Slide the collet (A), backplate (B), spinner backplate (C) and the propeller (D) on the motor shaft. Ensure the propeller size (11 X 6.6) faces forward.

- Slide the washer (E) on the propeller shaft and tighten the spinner nut (F) with an adjustable wrench to secure the propeller into place.

- Slide the spinner (G) on the propeller shaft in front of the propeller.

- Secure the spinner with the spinner screw 3 x 8mm (H).

NOTICE: Ensure the propeller is secure using an adjustable wrench before securing the spinner

Motor Shaft Diameter: 5mmCollet thread size: 6mm

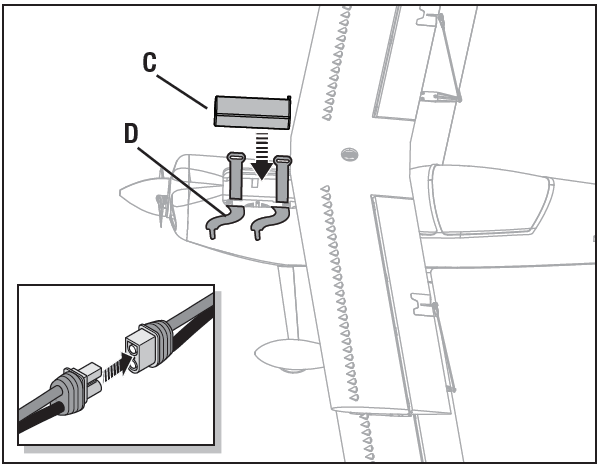

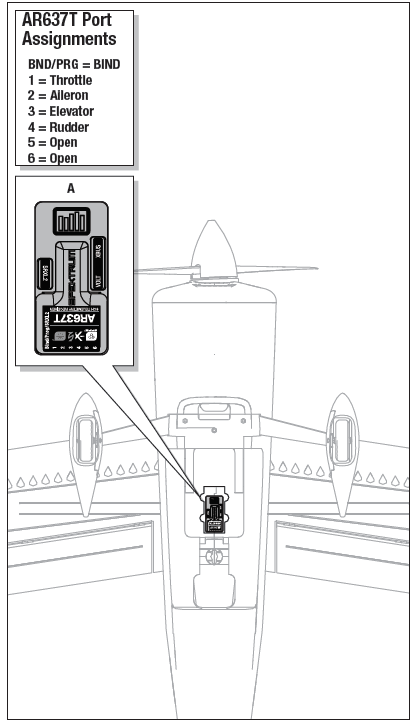

PNP Receiver Selection and Installation

The recommended receiver for this aircraft is the Spektrum AR637T. If you choose to install a different receiver, ensure that it is at least a 6-channel full range receiver. Refer to the manual of your chosen receiver for correct installation and operation instructions.

AR637T Installation

- Before installing the bottom wing, position the aircraft so the bottom of the fuselage faces up. If the bottom wing has already been installed, remove the bottom wing to expose the receiver compartment.

- Connect the appropriate control surfaces to the their respective ports on the receiver using the table at the right.

- Using double-sided servo tape,(not included) mount the receiver to the flat area behind the battery compartment, as shown. The receiver (A) should be mounted in the orientation shown, parallel to the length of the fuselage, with the label visible and the servo ports facing the rear of the aircraft. The orientation of the receiver is critical for all AS3X® and SAFE® technology setups.

CAUTION: Incorrect installation of the receiver could cause a crash.

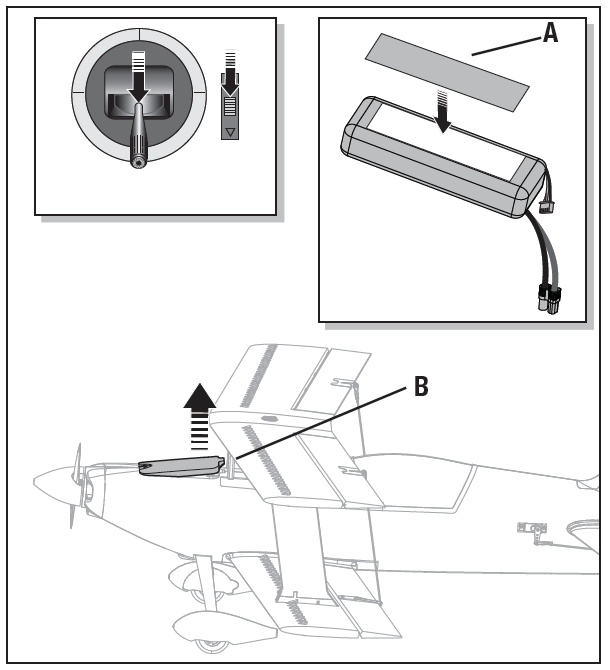

Battery Installation and ESC Arming

Battery Selection

We recommend the 2200mAh 14.8V 4S 30C Li-Po battery (SPMX22004S30). Refer to the Optional Parts List for other recommended batteries. If using a battery other than those listed, the battery should be within the range of capacity, dimensions and weight of the Spektrum Smart Li-Po battery packs to fit in the fuselage. Be sure the model balances at the recommended CG.

- Lower the throttle to the lowest settings. Power on the transmitter, then wait 5 seconds.

- For added security apply the loop side (soft side) of the optional hook and loop tape (A) to the bottom of your battery and the hook side to the battery tray.

- Press the battery latch button (B) to remove the battery hatch.

- Install the fully charged battery (C) in the battery compartment as shown. See the Adjusting the Center of Gravity instructions for more information.

- Make sure the flight battery is secured using the hook and loop straps (D).

- Connect the battery to the ESC (the ESC is now armed).

- Keep the aircraft immobile on its landing gear and away from wind or the system will not initialize.

- The ESC will sound a series of tones.

- An LED will light on the receiver.

- . Reinstall the canopy hatch.

If the ESC sounds a continuous beep after the flight battery is connected, recharge or replace the battery.

WARNING: Always keep hands away from the propeller. When armed, the motor will turn the propeller in response to any throttle movement.WARNING: If your transmitter supports it, always engage throttle cut before approaching the aircraft any time a battery is connected.

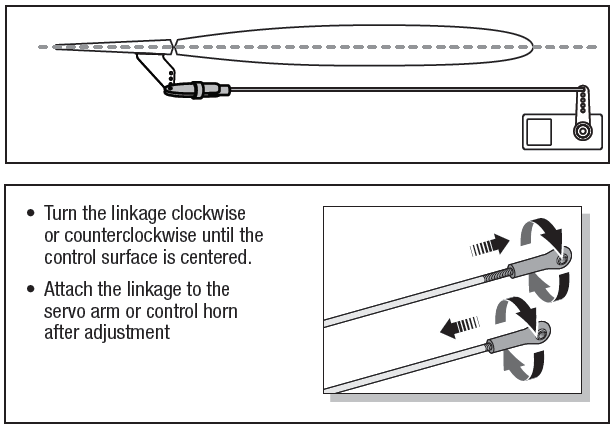

Control Surface Centering and Adjusting a Ball Link

IMPORTANT: Perform the Control Direction Test before performing control surface centering.While SAFE is inactive, mechanically center the control surfaces.IMPORTANT: Correct operation of the SAFE system requires sub-trim and trim at 0.After binding a transmitter to the airplanes receiver, set the trims and sub-trims to 0, ensure the servo arms are in the correct positions, then adjust the linkages to center the control surfaces.

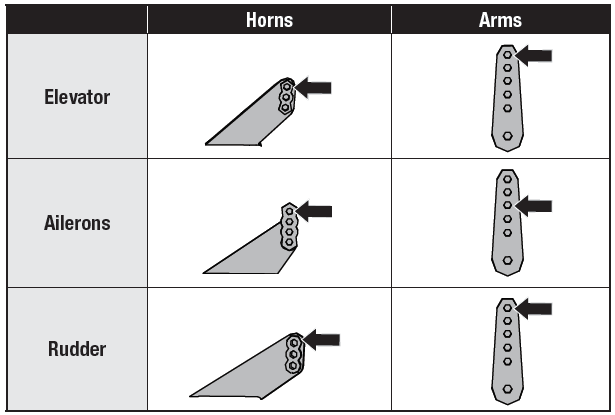

Control Horn and Servo Arm Settings

The table to the right shows the factory settings for the control horns and servo arms. Fly the aircraft at factory settings before making changes.After flying, you may choose to adjust the linkage positions for the desired control response. See the table to the right.

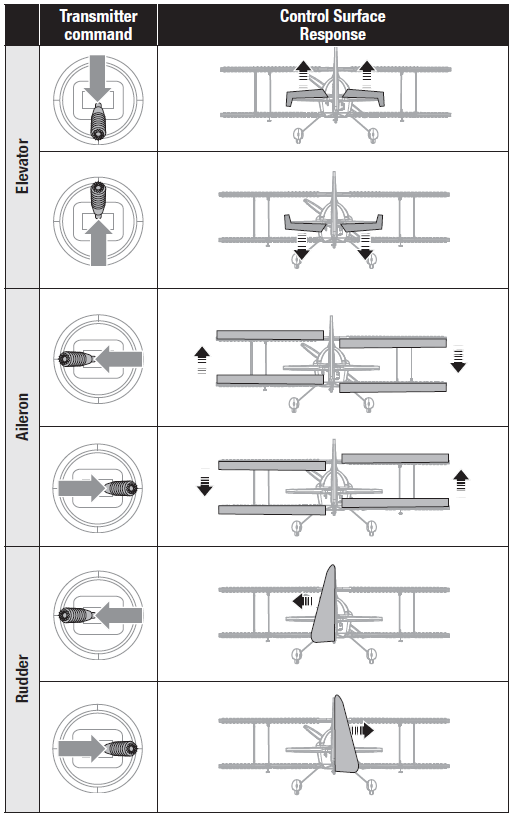

Control Direction Test

Switch on the transmitter and connect the battery. Use the transmitter to operate the aileron, elevator and rudder controls. View the aircraft from the rear when checking the control directions.

Elevator

- Pull the elevator stick back. The elevators should move up, which will cause the aircraft to pitch up.

- Push the elevator stick forward. The elevators should move down, which will cause the aircraft to pitch down.

Ailerons

- Move the aileron stick to the left. The left ailerons should move up and the right ailerons down, which will cause the aircraft to bank left.

- Move the aileron stick to the right. The right ailerons should move up and the left ailerons down, which will cause the aircraft to bank right.

Rudder

- Move the rudder stick to the left. The rudder should move to the left, which will cause the aircraft to yaw left.

- Move the rudder stick to the right. The rudder should move to the right, which will cause the aircraft to yaw right.

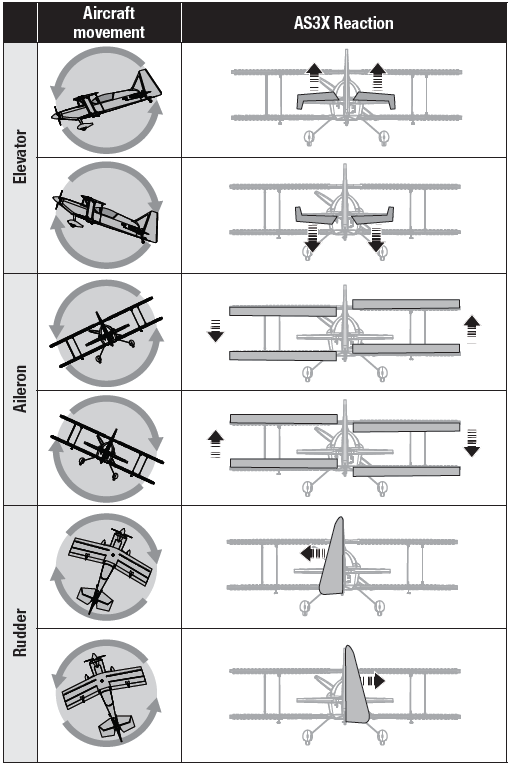

AS3X Control Response Test

This test ensures that the AS3X® control system is functioning properly. Assemble the aircraft and bind your transmitter to the receiver before performing this test.

- Raise the throttle just above 25%, then lower the throttle to activate AS3X.CAUTION: Keep all body parts, hair and loose clothing away from a moving propeller, as these items could become entangled.

- Move the entire aircraft as shown and ensure the control surfaces move in the direction indicated in the graphic. If the control surfaces do not respond as shown, do not fly the aircraft. Refer to the receiver manual for more information.Once the AS3X system is active, control surfaces may move rapidly. This is normal. AS3X remains active until the battery is disconnected.

Center of Gravity

The CG location is measured from the leading edge of the wing at the root.This CG location has been determined with the recommended Li-Po battery (SPMX22004S30) installed in the center of the battery tray.

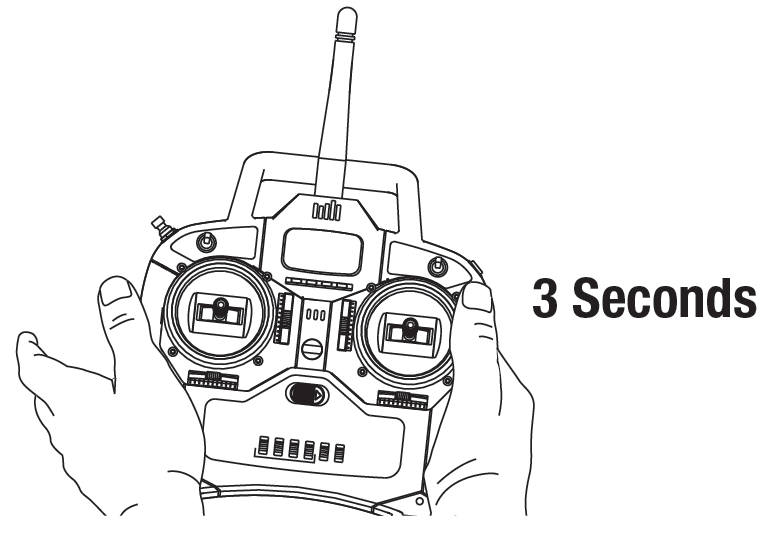

In-Flight Trimming

During your first flight, trim the aircraft for level flight at 3/4 throttle. Make small trim adjustments with your transmitter’s trim switches to achieve straight and level flight.After adjusting trim do not touch the control sticks for 3 seconds. This allows the receiver to learn the correct settings to optimize AS3X performance.Failure to do so could affect flight performance.

Flying Tips and Repairs

Consult local laws and ordinances before choosing a flying location.

Range Check your Radio SystemBefore you fly, range check the radio system. Refer to your specific transmitter instruction manual for range test information.OscillationOnce the AS3X system is active (after advancing the throttle for the first time), you will normally see the control surfaces react to aircraft movement. In some flight conditions you may see oscillation (the aircraft rocks back and forth on one axis due to overcontrol). If oscillation occurs, refer to the Troubleshooting Guide for more information.TakeoffPlace the aircraft in position for takeoff (facing into the wind). Select low rates for first takeoff and gradually increase the throttle to 3/4 to full and steer with the rudder. Pull back gently on the elevator and climb to a comfortable altitude.FlyingFor your first flights with the recommended battery pack (SPMX22004S30), set your transmitter timer or a stopwatch to 3 minutes. After four minutes, land the aircraft. Adjust your timer for longer or shorter flights once you have flown the model.Fly the aircraft and trim it for level flight in Precision Mode at 3/4 throttle. After landing, adjust the linkages mechanically to account for trim changes and then reset the trims to neutral. Ensure the aircraft will fly straight and level with no trim or sub-trim.

NOTICE: Due to the high-performance nature of the Ultimate 3D’s power system, we recommend allowing the motor to cool to ambient temperature between flights when using 4S batteries and flying aggressively in temperatures of 90+°F (approximately 32+°C).

Landing

To land the aircraft, fly the aircraft down to the ground using 1/4 –1/3 throttle to allow for enough energy for a proper flare. The aircraft is easiest to land doing a wheel landing (two point), where the aircraft touches down on the main landing gear first while the tailwheel is still off the ground. The aircraft can also be landed in a three-point attitude, where all three wheels touch down at the same time. When the aircraft touches down, reduce back pressure on the elevator stick to prevent the plane from becoming airborne again.

If landing on grass, it is best to hold full up elevator after touchdown and when taxiing to prevent nosing over.Once on the ground, avoid sharp turns until the plane has slowed enough to prevent scraping the wingtips.

WARNING:

- Always decrease throttle at propeller strike.

- If a crash is imminent, reduce the throttle and trim fully. Failure to do so could result in extra damage to the airframe, as well as damage to the ESC and motor.

- After any impact, always ensure the receiver is secure in the fuselage. If you replace the receiver, install the new receiver in the same orientation as the original receiver or damage may result.

- Crash damage is not covered under warranty.

- When you are finished flying, never leave the aircraft in direct sunlight or in a hot, enclosed area such as a car. Doing so can damage the aircraft.

Low Voltage Cutoff (LVC)

When a Li-Po battery is discharged below 3V per cell, it will not hold a charge. The ESC protects the flight battery from over-discharge using Low Voltage Cutoff (LVC). Before the battery charge decreases too much, LVC removes power supplied to the motor. Disconnect and remove the Li-Po battery from the aircraft after use to prevent trickle discharge. Charge your Li-Po battery to about half capacity before storage. During storage, make sure the battery charge does not fall below 3V per cell. LVC does not prevent the battery from over-discharge during storage.NOTICE: Repeated flying to LVC will damage the battery.Tip: Monitor your aircraft battery’s voltage before and after flying by using a Li-Po Cell Voltage Checker (SPMXBC100, sold separately).

Repairs

Thanks to the EPO foam material in this aircraft, repairs to the foam can be made using virtually any adhesive (hot glue, regular CA, epoxy, etc). When parts are not repairable, see the Replacement Parts List for ordering by item number. For a listing of all replacement and optional parts, refer to the list at the end of this manual.

NOTICE: Use of CA accelerant on your aircraft can damage paint. DO NOT handle the aircraft until accelerant fully dries.

SAFE® Select Flying Tips

When flying in SAFE Select mode the aircraft will return to level flight any time the aileron and elevator controls are at neutral. Applying aileron or elevator control will cause the airplane to bank, climb or dive. The amount the stick is moved will determine the attitude the airplane flies. Holding full control will push the aircraft to the pre-determined bank and roll limits, but it will not go past those angles.When flying with SAFE Select, it is normal to hold the control stick deflected with moderate aileron input when flying through a turn. To fly smoothly with SAFE Select, avoid making frequent control changes and don’t attempt to correct for minor deviations. Holding deliberate control inputs will command the aircraft to fly at a specific angle, and the model will make all corrections to maintain that flight attitude.When flying with SAFE Select, throttle will make the aircraft climb or descend. Full throttle will cause the aircraft to pitch up and climb slightly. Mid throttle will keep the airplane flying level. Low throttle will cause the airplane to descend slightly nose-down.Return the elevator and aileron controls to neutral before switching from SAFE Select mode to AS3X mode. If you do not neutralize controls when switching into AS3X mode, the control inputs used for SAFE Select mode will be excessive for AS3X mode and the aircraft will react immediately.

Differences between SAFE Select and AS3X modesThis section is generally accurate but does not take into account flight speed, battery charge status, and other limiting factors.

| SAFE Select | AS3X | ||

| Control Input | Control stick is neutralized |

Aircraft will self level |

Aircraft will continue to fly at its present attitude |

| Holding a small amount of control | Aircraft will bank or pitch to a moderate angle and maintain the attitude | Aircraft will continue to pitch or roll slowly | |

| Holding full control | Aircraft will bank or pitch to the predetermined limits and maintain the attitude | Aircraft will continue to roll or pitch rapidly | |

|

Throttle |

Full throttle: Climb Neutral: Level flight

Low throttle: Descend nose-down |

Throttle will not affect flight response. |

Post Flight

| 1 | Disconnect the flight battery from the ESC (Required for Safety and battery life). |

| 2 | Power OFF the transmitter. |

| 3 | Remove the flight battery from the aircraft. |

| 4 | Recharge the flight battery. |

| 5 | Repair or replace all damaged parts. |

| 6 | Store the flight battery apart from the aircraft and monitor the battery charge. |

| 7 | Make note of the flight conditions and flight plan results, planning for future flights. |

Motor Service

CAUTION: Always disconnect the flight battery before performing motor service.

Disassembly

- Remove the screw (A), Spinner (B), Propeller nut (C) and washer (D).

- Remove the propeller (E), spinner backplate (F) backplate (G), and collet (H) from the motor shaft.

- Pull to remove 2 screws (I) from the cowling (J), and remove the cowling.

- Remove the 4 screws (K) from the motor mount (L), and remove the motor and motor mount from the fuselage.

- Disconnect the motor wires from the ESC wires.

- Remove the 4 screws (M) and motor (N) from the motor mount.

Assembly

Assemble in reverse order.

- Correctly align and connect the motor wire colors with the ESC wires.

- Tighten the prop nut by using a wrench

Servo Service

Wing Servo Removal

- Remove the propeller.

- Remove the wing.

- Unplug the wing servo wires from the marked fuselage servo extensions.

- Flip the wing over, and set it on a smooth, soft surface.

- Remove the servo tape from the wing bottom of the damaged servo.

- Remove the pushrod clevis from the aileron control horn.

- Remove the foam servo wire-retaining strip.

- Firmly pull on the servo to remove it from the wing.

- Remove the servo screw and the servo arm.

Fuselage Servo ReplacementUse the wing servo replacement instructions (1–9) to replace the rudder and/or elevator servos. Then plug the fuselage wire directly into the receiver.

Wing Servo Installation

- Plug the servo into the correctly marked aileron extension in the fuselage.

- With the propeller removed, power ON the plane. Wait for the plane to initialize and for the servos to center.

- Center the transmitter trims.

- Align the servo arm by pressing the arm onto the servo. Install the servo arm screw, disconnect the servo from the aileron extension, and begin the servo installation.

- Using Deluxe Materials Foam 2 Foam (DLMAD34), secure the servo into the servo pocket.

- Press the servo wire into the servo wire channel in the bottom of the wing.

- Using Deluxe Materials Foam 2 Foam (DLMAD34), reinstall the foam servo wire retainer.

- Reinstall the pushrod clevis into the aileron control horn.TIP: Make sure the glue is dry!

- Connect the aileron servo wires to the proper aileron extension wires in the fuselage.

- Install the wing.

| Control Surface | Replacement Servo | Description | Adhesive |

| Aileron | SPMSA332 | 9g Sub-Micro Servo | Deluxe Materials Foam 2 Foam (DLMAD34) |

| Elevator | SPMSA332 | 9g Sub-Micro Servo | Deluxe Materials Foam 2 Foam (DLMAD34) |

| Rudder | SPMSA332 | 9g Sub-Micro Servo | Deluxe Materials Foam 2 Foam (DLMAD34) |

Troubleshooting Guide AS3X

| Problem | Possible Cause | Solution |

|

Oscillation |

Damaged propeller or spinner | Replace propeller or spinner |

| Imbalanced propeller | Balance the propeller. For more information, view John Redman’s propeller balancing video at www.horizonhobby.com | |

| Motor vibration | Replace parts or correctly align all parts and tighten fasteners as needed | |

| Loose receiver | Align and secure receiver in fuselage | |

| Loose aircraft controls | Tighten or otherwise secure parts (servo, arm, linkage, horn and control surface) | |

| Worn parts | Replace worn parts (especially propeller, spinner or servo) | |

| Irregular servo movement | Replace servo | |

|

Inconsistent flight performance |

Trim is not at neutral | If you adjust trim more than 8 clicks, adjust the clevis to remove trim |

| Sub-Trim is not at neutral | No Sub-Trim is allowed. Adjust the servo linkage | |

| Aircraft was not kept immobile for 5 seconds after battery connection | With the throttle stick in lowest position. Disconnect battery, then reconnect battery and keep the aircraft still for 5 seconds | |

| Incorrect response to the AS3X Control Direction Test | Incorrect direction settings in the receiver, which can cause a crash |

DO NOT fly. Correct the direction settings (refer to the receiver manual), then fly |

Troubleshooting Guide

| Problem | Possible Cause | Solution |

| Aircraft will not respond to throttle but responds to other controls | Throttle not at idle and/or throttle trim too high | Reset controls with throttle stick and throttle trim at lowest setting |

| Throttle servo travel is lower than 100% | Make sure throttle servo travel is 100% or greater | |

| Throttle channel is reversed | Reverse throttle channel on transmitter | |

| Motor disconnected from ESC | Make sure motor is connected to the ESC | |

|

Extra propeller noise or extra vibration |

Damaged propeller and spinner, collet or motor | Replace damaged parts |

| Propeller is out of balance | Balance or replace propeller | |

| Prop nut is too loose | Tighten the prop nut | |

|

Reduced flight time or aircraft underpowered |

Flight battery charge is low | Completely recharge flight battery |

| Propeller installed backwards | Install propeller with numbers facing forward | |

| Flight battery damaged | Replace flight battery and follow flight battery instructions | |

| Flight conditions may be too cold | Make sure battery is warm before use | |

| Battery capacity too low for flight conditions | Replace battery or use a larger capacity battery | |

|

Aircraft will not Bind (during binding) to transmitter |

Transmitter too near aircraft during binding process | Move powered transmitter a few feet from aircraft, disconnect and reconnect flight battery to aircraft |

| Aircraft or transmitter is too close to large metal object, wireless source or another transmitter | Move aircraft and transmitter to another location and attempt binding again | |

| The bind plug is not installed correctly in the bind port | Install bind plug in bind port and bind the aircraft to the transmitter | |

| Flight battery/transmitter battery charge is too low | Replace/recharge batteries | |

| Bind switch or button not held long enough during bind process | Power off transmitter and repeat bind process. Hold transmitter bind button or switch until receiver is bound | |

|

Aircraft will not connect (after binding) to transmitter |

Transmitter too near aircraft during connecting process | Move powered transmitter a few feet from aircraft, disconnect and reconnect flight battery to aircraft |

| Aircraft or transmitter is too close to large metal object, wireless source or another transmitter | Move aircraft and transmitter to another location and attempt connecting again | |

| Bind plug left installed in bind port | Rebind transmitter to the aircraft and remove the bind plug before cycling power | |

| Aircraft bound to different model memory (ModelMatchTM radios only) | Select correct model memory on transmitter | |

| Flight battery/Transmitter battery charge is too low | Replace/recharge batteries | |

| Transmitter may have been bound to a different aircraft using different DSM protocol | Bind aircraft to transmitter | |

|

Control surface does not move |

Control surface, control horn, linkage or servo damage | Replace or repair damaged parts and adjust controls |

| Wire damaged or connections loose | Do a check of wires and connections, connect or replace as needed | |

| Transmitter is not bound correctly or the incorrect airplane was selected | Re-bind or select correct airplane in transmitter | |

| Flight battery charge is low | Fully recharge flight battery | |

| BEC (Battery Elimination Circuit) of the ESC is damaged | Replace ESC |

| Problem | Possible Cause | Solution |

| Controls reversed | Transmitter settings are reversed | Perform the Control Direction Test and adjust the controls on transmitter appropriately |

|

Motor power pulses then motor loses power |

ESC uses default soft Low Voltage Cutoff (LVC) | Recharge flight battery or replace battery that is no longer performing |

| Weather conditions might be too cold | Postpone flight until weather is warmer | |

| Battery is old, worn out, or damaged | Replace battery | |

| Battery C rating might be too small | Use recommended battery |

Replacement Parts

| Part # | Description |

| EFL108006 | Cowl: Ultimate 2 |

| EFL108009 | Strut Set: Ultimate 2 |

| EFL108010 | Strut Wire Clips (4): Ultimate |

| EFL108011 | Pushrod Set: Ultimate 2 |

| EFL108013 | Wing Thumb Screws: Ultimate 2 |

| EFL108016 | Motor Mount: Ultimate 2 |

| EFL108017 | Prop Adapter: Ultimate 2 |

| EFL165501 | Painted Fuselage: Ultimate 3D |

| EFL165502 | Top Wing Set: Ultimate 3D |

| EFL165503 | Bottom Wing Set: Ultimate 3D |

| EFL165504 | Horiz Stab Set: Ultimate 3D |

| EFL165505 | Rudder: Ultimate 3D |

| EFL165507 | Landing Gear Set: Ultimate 3D |

| EFL165512 | Control Horn Set: Ultimate 3D |

| EFL165514 | Decal Sheet: Ultimate 3D |

| EFL165515 | Spinner w/ Screw: Ultimate 3D |

| EFL165516 | Stab Joiner Set: Ultimate 3D |

| EFL165517 | Battery Hatch: Ultimate 3D |

| EFLM108019 | Motor Shaft: Ultimate 2 |

| EFLM17552 | BL10 Motor 800KV: Turbo Timber |

| EFLP11606E | 11.6 X 6 Propeller : Ultimate 3 |

| SPMAR637T | AR637T 6CH SAFE and AS3X TelemRX |

| SPMSA332 | 9g servo MG |

| SPMXAE1060 | Avian 60Amp Brushless Smart ESC 6S |

Recommended Parts

| Part # | Description |

| SPMR6775 | NX6 Transmitter Only MD2 |

| SPMX22004S30 | 2200mAh 4S 14.8V Smart 30C; IC3 |

| SPMXC2040 | Smart S1400 G2 AC Smart Charger, 1X400W |

Optional Parts

| Part # | Description |

| SPMXBC100 | LiPo Cell Voltage Checker |

| SPM6722 | Spektrum Single Aircraft TX Case |

| SPMA9574 | Aircraft Telemetry Airspeed Indicator |

| SPMA9589 | Aircraft Telemetry Altitude and Variometer Sensor |

| SPMAR9350 | AR9350 9 Channel AS3X RX |

| SPMR12000 | iX12 12 Channel Transmitter Only |

| SPMR8200 | NX8 Transmitter Only MD2 |

| SPMR10100 | NX10 Transmitter Only MD2 |

| SPMXC2010 | Smart S2200 G2 AC Smart Charger, 2X200W |

| SPMX22003S100 | 2200mAh 3S 11.1V Smart 100C; IC3 |

| SPMX22003S30 | 2200mAh 3S 11.1V Smart 30C; IC3 |

| SPMX22003S50 | 2200mAh 3S 11.1V Smart 50C; IC3 |

| SPMX22004S100 | 2200mAh 4S 14.8V Smart 100C; IC3 |

| SPMX22004S50 | 2200mAh 4S 14.8V Smart 50C; IC3 |

| SPMXC10201 | 30A 540W Power Supply |

AMA National Model Aircraft Safety Code

Academy of Model AeronauticsNational Model Aircraft Safety Code

A model aircraft is a non-human-carrying device capable of sustained flight within visual line of sight of the pilot or spotter(s). It may not exceed limitations of this code and is intended exclusively for sport, recreation, education and/or competition. All model flights must be conducted in accordance with this safety code and related AMA guidelines, any additional rules specific to the flying site, as well as all applicable laws and regulations.As an AMA member I agree:

- I will not fly a model aircraft in a careless or reckless manner.

- I will not interfere with and will yield the right of way to all human-carrying air craftusing AMA’s See and Avoid Guidance and a spotter when appropriate.

- I will not operate any model aircraft while I am under the influence of alcohol or any drug that could adversely affect my ability to safely control the model.

- I will avoid flying directly over unprotected people, moving vehicles, and occupied structures.

- I will fly Free Flight (FF) and Control Line (CL) models in compliance with AMA’s safety programming.

- I will maintain visual contact of an RC model aircraft without enhancement other than corrective lenses prescribed to me. When using an advanced flight system, such as an autopilot, or flying First-Person View (FPV), I will comply with AMA’s Advanced Flight System programming.

- I will only fly models weighing more than 55 pounds, including fuel, if certified through AMA’s Large Model Airplane Program.

- I will only fly a turbine-powered model aircraft in compliance with AMA’s Gas Turbine Program.

- I will not fly a powered model outdoors closer than 25 feet to any individual, except for myself or my helper(s) located at the flight line, unless I am taking off and landing, or as otherwise provided in AMA’s Competition Regulation.

- I will use an established safety line to separate all model aircraft operations from spectators and bystanders.

Limited Warranty

What this Warranty Covers – Horizon Hobby, LLC, (Horizon) warrants to the original purchaser that the product purchased (the “Product”) will be free from defects in materials and workmanship at the date of purchase.What is Not Covered – This warranty is not transferable and does not cover (i) cosmetic damage, (ii) damage due to acts of God, accident, misuse, abuse, negligence, commercial use, or due to improper use, installation, operation or maintenance, (iii) modification of or to any part of the Product, (iv) attempted service by anyone other than a Horizon Hobby authorized service center, (v) Product not purchased from an authorized Horizon dealer, or (vi) Product not compliant with applicable technical regulations, or (vii) use that violates any applicable laws, rules, or regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE, HORIZON MAKES NO OTHER WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

Purchaser’s Remedy – Horizon’s sole obligation and purchaser’s sole and exclusive remedy shall be that Horizon will, at its option, either (i) service, or (ii) replace, any Product determined by Horizon to be defective. Horizon reserves the right to inspect any and all Product(s) involved in a warranty claim. Service or replacement decisions are at the sole discretion of Horizon. Proof of purchase is required for all warranty claims. SERVICE OR REPLACEMENT AS PROVIDED UNDER THIS

WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY.

Limitation of Liability – HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Further, in no event shall the liability of Horizon exceed the individual price of the Product on which liability is asserted. As Horizon has no control over use, setup, final assembly, modification or misuse, no liability shall be assumed nor accepted for any resulting damage or injury. By the act of use, setup or assembly, the user accepts all resulting liability. If you as the purchaser or user are not prepared to accept the liability associated with the use of the Product, purchaser is advised to return the Product immediately in new and unused condition to the place of purchase.Law – These terms are governed by Illinois law (without regard to conflict of law principals). This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Horizon reserves the right to change or modify this warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services – Your local hobby store and/or place of purchase cannot provide warranty support or service. Once assembly, setup or use of the Product has been started, you must contact your local distributor or Horizon directly. This will enable Horizon to better answer your questions and service you in the event that you may need any assistance. For questions or assistance, please visit our website at www.horizonhobby.com, submit a Product Support Inquiry, or call the toll free telephone number referenced in the Warranty and Service Contact Information section to speak with a Product Support representative.

Inspection or Services – If this Product needs to be inspected or serviced and is compliant in the country you live and use the Product in, please use the Horizon Online Service Request submission process found on our website or call Horizon to obtain a Return Merchandise Authorization (RMA) number. Pack the Product securely using a shipping carton. Please note that original boxes may be included, but are not designed to withstand the rigors of shipping without additional protection. Ship via a carrier that provides tracking and insurance for lost or damaged parcels, as Horizon is not responsible for merchandise until it arrives and is accepted at our facility. An Online Service Request is available at http://www.horizonhobby.com/content/service-center_render-service-center. If you do not have internet access, please contact Horizon Product Support to obtain a RMA number along with instructions for submitting your product for service. When calling Horizon, you will be asked to provide your complete name, street address, email address and phone number where you can be reached during business hours. When sending product into Horizon, please include your RMA number, a list of the included items, and a brief summary of the problem. A copy of your original sales receipt must be included for warranty consideration. Be sure your name, address, and RMA number are clearly written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If you have any issue with a LiPo battery, please contact the appropriate Horizon Product Support office.

Warranty Requirements – For Warranty consideration, you must include your original sales receipt verifying the proof-of-purchase date. Provided warranty conditions have been met, your Product will be serviced or replaced free of charge. Service or replacement decisions are at the sole discretion of Horizon.

Non-Warranty Service – Should your service not be covered by warranty, service will be completed and payment will be required without notification or estimate of the expense unless the expense exceeds 50% of the retail purchase cost. By submitting the item for service you are agreeing to payment of the service without notification. Service estimates are available upon request. You must include this request with your item submitted for service. Non-warranty service estimates will be billed a minimum of ½ hour of labor. In addition you will be billed for return freight. Horizon accepts money orders and cashier’s checks, as well as Visa, MasterCard, American Express, and Discover cards. By submitting any item to Horizon for service, you are agreeing to Horizon’s Terms and Conditions found on our website http://www.horizonhobby.com/content/service-center_render-service-center

ATTENTION: Horizon service is limited to Product compliant in the country of use and ownership. If received, a non-compliant Product will not be serviced. Further, the sender will be responsible for arranging return shipment of the un-serviced Product, through a carrier of the sender’s choice and at the sender’s expense. Horizon will hold non-compliant Product for a period of 60 days from notification, after which it will be discarded.

Contact Information

| Country of Purchase | Horizon Hobby | Phone Number/Email Address | Address |

|

United States of America |

Horizon Service Center (Repairs and Repair Requests) | servicecenter.horizonhobby.com/ RequestForm/ |

2904 Research Rd Champaign, Illinois, 61822 USA |

| Horizon Product Support (Product Technical Assistance) | [email protected] | ||

| 877-504-0233 | |||

| Sales | [email protected] | ||

| 800-338-4639 | |||

| European Union | Horizon Technischer Service | [email protected] | Hanskampring 9

D 22885 Barsbüttel, Germany |

| Sales: Horizon Hobby GmbH | +49 (0) 4121 2655 100 |

FCC Information

FCC ID: BRWTIARLGTNG1This equipment complies with FCC and IC radiation exposure limits set forth for an uncontrolled environment. This equipment should be installed and operated with minimum distance 20cm between the radiator and/or antenna and your body (excluding fingers, hands, wrists, ankles and feet). This transmitter must not be colocated or operating in conjunction with any other antenna or transmitter.

Supplier’s Declaration of ConformityEFL Ultimate 3D BNF Basic and PNP (EFL16550 and EFL16575)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.CAUTION: Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interferencein a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Horizon Hobby, LLC2904 Research Rd.,Champaign, IL 61822Email: [email protected] Web: HorizonHobby.com

IC Information

CAN ICES-3 (B)/NMB-3(B)IC: 6157A-TIARLGTNG1This device contains license-exempt transmitter(s)/receivers(s) that comply with Innovation, Science, and Economic Development Canada’s license-exempt RSS(s). Operation is subject to the following 2 conditions:

- This device may not cause interference.

- This device must accept any interference, including interference that may cause undesired operation of the device.

©2021 Horizon Hobby, LLC.E-flite, Avian, Plug-N-Play, Bind-N-Fly, BNF, the BNF logo, DSM, DSM2, DSMX, Spektrum AirWare, EC5, IC5, AS3X, SAFE, the SAFE logo, ModelMatch,and the Horizon Hobby logo are trademarks or registered trademarks of Horizon Hobby, LLC.The Spektrum trademark is used with permission of Bachmann Industries, Inc.Futaba is a registered trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan.All other trademarks, service marks and logos are property of their respective owners. US 8,672,726. US 9,056,667. US 9,753,457. US 10,078,329. US 9,930,567. US 10,419,970 . US 10,849,013. Other patents pending.http://www.horizonhobby.com/

References

RC Airplanes and Helicopters, RC Cars and Trucks, RC Boats, RC Radios | Horizon Hobby

RC Airplanes and Helicopters, RC Cars and Trucks, RC Boats, RC Radios | Horizon Hobby

Spektrum RC Transmitters and RC Electronics | Spektrum

RC Airplanes & Helicopters, RC Cars & Trucks, RC Boats, RC Radios | Horizon Hobby

Product Serivce Center

registermyuas.faa.gov/

RC Airplanes and Helicopters, RC Cars and Trucks, RC Boats, RC Radios | Horizon Hobby

Home – Know Before You Fly

RC Cars, RC Trucks, RC Airplanes, Model Trains, and Slot Cars at Tower Hobbies

RC Airplanes and Helicopters, RC Cars and Trucks, RC Boats, RC Radios | Horizon Hobby

[xyz-ips snippet=”download-snippet”]