Undercounter Crescent Ice Maker IB250SSIB250WH IB250BLIB250SSODOwner’s ManualFor more information on other great EdgeStar products on the web, go to http://www.edgestar.com To use the EdgeStar self-diagnostic tool, go to https://support.edgestar.comV3.1 – 09092020 i

IB250SSIB250WH IB250BLIB250SSODOwner’s ManualFor more information on other great EdgeStar products on the web, go to http://www.edgestar.com To use the EdgeStar self-diagnostic tool, go to https://support.edgestar.comV3.1 – 09092020 i

Important Safety Information

Improper handling can cause serious damage to the EdgeStar ice maker and/or injury to the user. This ice maker is designed for domestic use only. All units besides the IB250SSOD should only be used indoors. Do not use the unit for industrial or commercial use. Any other use or incorrect installation may invalidate the warranty. Please review the rating label located inside the unit for electrical and other technical data related to this unit. The unit must be used in a properly grounded wall outlet. Please read and follow the safety information listed below to reduce the risk of fire, electric shock, or injury. Installation should only be done by a licensed plumber.![]() Electrical Safety

Electrical Safety

- Do not exceed the power outlet ratings.

- Plug into a grounded 3-prong outlet. Do not remove the grounding prong, use an adapter, or use an extension cord.

- It is recommended that a separate circuit, serving only your ice maker, be provided. Use outlets that cannot be turned off by a switch or pull chain.

- Do not plug or unplug the unit when your hands are wet.

- Never unplug the ice maker by pulling on the power cord. Always grip the plug firmly and pull straight out from the outlet.

- Before proceeding with cleaning, maintenance, or service, make sure the unit’s power line is disconnected and the water line is shut off. Failure to do so can result in electrical shock or death.

- Unplug the unit if it is not going to be used for an extended period of time.

- Do not operate the unit with a power plug missing the ground plug, a damaged cord, or a loose socket.

- Do not bypass, cut, or remove the grounding plug. · All electrical and water connections for the unit must be installed in accordance with state and local codes. A standard electrical supply (115V, 60 Hz), properly grounded in accordance with the National Electrical Code and local codes and ordinances, is required.

- Do not kink or pinch the power supply cord between the ice maker and cabinet.

- The fuse (or circuit breaker) size should be 15 amps.

- Do not use extension cords or power strips with this unit. You may need to contact your electrician if it is necessary to use a longer cord or if you do not have a grounded outlet. Do not modify the power cord’s length or share the outlet with other appliances.

- Do not start or stop the unit by switching the circuit’s power on and off.

- If the power cord is damaged, it must be replaced by the manufacturer or a qualified technician.

- Immediately unplug the unit if it makes strange sounds, emits smells, or smoke comes out of it, and contact customer service.

- Do not remove any part of the casing unless instructed to do so by an authorized technician.

- You should never attempt to repair the unit yourself. Contact a customer service specialist for service options if the unit needs service.

![]() Important: Be sure the unit is standing upright for 24 hours before plugging it in.General Safety

Important: Be sure the unit is standing upright for 24 hours before plugging it in.General Safety

- Never clean ice maker parts with flammable fluids. Do not store or use this appliance near flammable gas or combustibles, such as gasoline, benzene, thinner, etc. The fumes can create a fire hazard or an explosion.

- This unit must be protected from any type of moisture or precipitation.

- Replace all of the unit’s panels before operation.

- Never allow children to operate, play with, or crawl inside the ice maker.

- Do not touch the ice maker mold while the machine is in use.

- This appliance should not be used by children eight (8) years of age and younger, or people withreduced physical, sensory, or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning the safe use of the appliance and understand the hazards involved. Children should not play with this appliance.

- Use two or more people to move and install the ice maker. Failure to do so can result in back or another injury.

- To ensure proper ventilation for your ice maker, the front of the unit must be completely unobstructed.

- The ice maker should not be located next to ovens, grills, or other sources of high heat.

- The ice maker must be leveled in order to work properly. Otherwise, water may not flow properly through the ice maker mold, and ice production will be below the normal capacity. You may need to make several adjustments to level the unit.

- All installations must be in accordance with local plumbing code requirements.

- Ensure that hoses are not pinched, kinked, or damaged during installation.

- Do not pinch or kink the water or power supply lines between the unit and cabinet.

- Check for leaks after the water line is connected.

- Although the unit has been tested and cleaned at the factory, the first batch of ice cubes must be discarded because of long-term transit and storage.

- Remove the packing materials and clean the ice maker before use.

- Turn on the water supply taps before turning the ice maker on. Never turn the water supply tap off when the ice maker is working.

- Only open the door to take ice from the unit. Keep the door closed as much as possible in order to reduce ice melting and to promote proper ice formation.

- If the ice maker has not been used for a long time, it must be thoroughly cleaned before its next use. Follow the cleaning instructions provided in this manual carefully. Do not leave any cleaning solutions inside the ice maker.

- Do not touch the condenser fins. They are sharp and can be easily damaged.

- Do not use solvent-based or abrasive cleaning agents on the interior. These cleaners may transmit taste to the ice cubes, or damage or discolor the interior.

- Only connect a potable water supply.

- Do not use the appliance for anything other than its intended purpose.

- Cleaning and user maintenance should not be performed by children without supervision.

![]() Note: Installation should only be done by a licensed plumber.

Note: Installation should only be done by a licensed plumber.![]()

![]()

![]()

Introduction

Thank you for purchasing this EdgeStar built-in ice maker. We hope that this purchase will be the beginning of a lasting and rewarding relationship between you and EdgeStar. We will provide the customer support and exemplary products necessary to nurture that relationship.This manual contains important information regarding the proper installation, use, and maintenance of your ice maker. Following this manual will ensure that your product will work at its peak performance and efficiency.Please save the original product packaging in case you need to safely transport your ice maker.For Your Records:Please write down the model number and serial number below for future reference. Both numbers are located on the rating label inside the unit and are needed to obtain warranty service. You may also want to staple your receipt to this manual as it is the proof of your purchase, and is also needed for service under your warranty.Model Number:Serial Number:Date of Purchase:For a more efficient experience, please do the following before contacting customer service:

- If you received a damaged product, immediately contact the dealer that sold you the product.

- Read and follow this instruction manual carefully to help you install, use and maintain your ice maker.

- Read the troubleshooting section of this manual as it will help you diagnose and solve common issues.

- Visit us on the web at http://www.edgestar.com to register your product, download product guides, additional troubleshooting resources, and up-to-date information. You can also find an interactive self-diagnostic tool at https://support.edgestar.com.

- If you need warranty service, our friendly customer service representatives are available via email at [email protected].

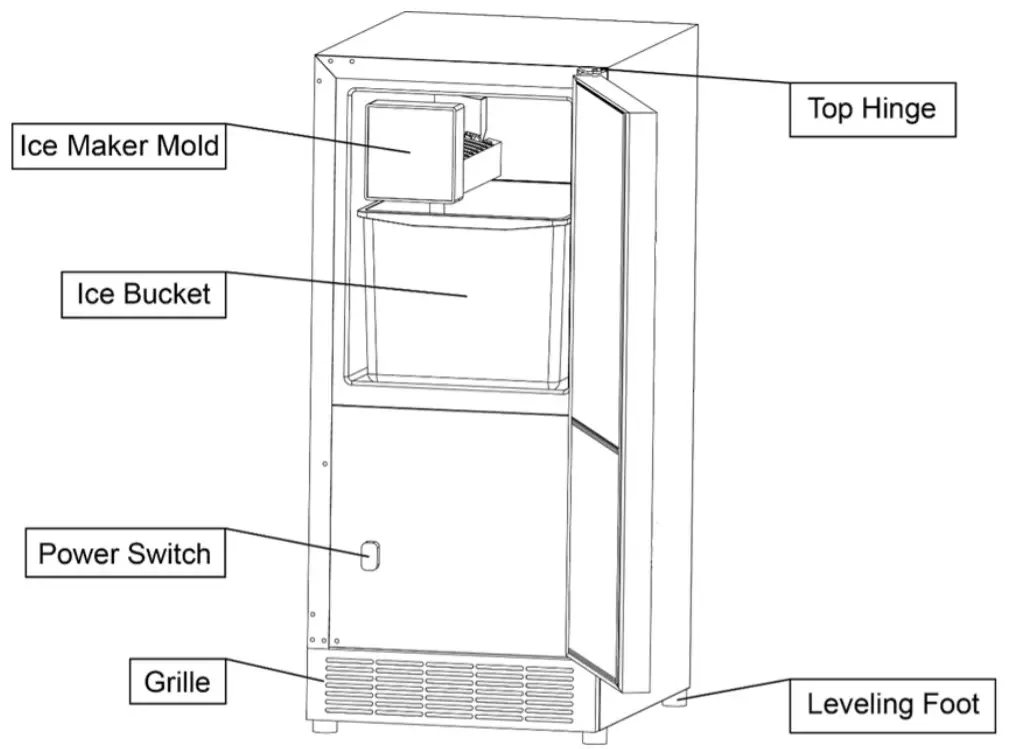

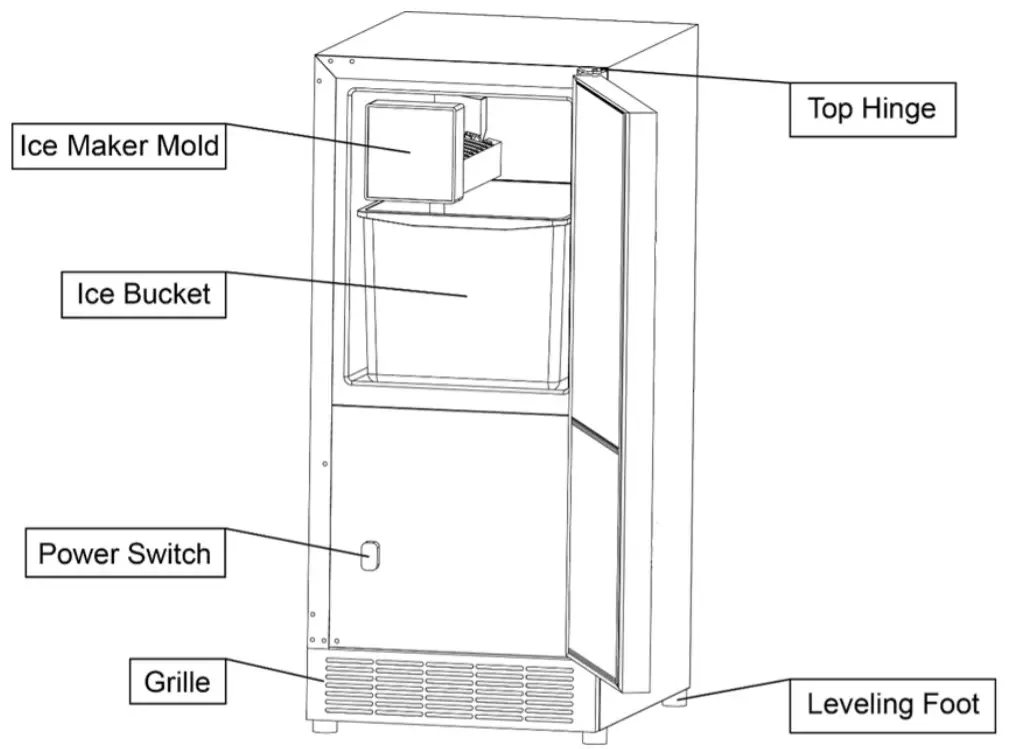

Parts Identification

Front View

Installing the Ice Maker

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Installation

![]()

![]()

![]()

![]()

![]()

- This device does not meet Federal requirements for ignition protection. Don’t install it inspaces containing gasoline engines, fuel tanks, or fuel line fittings. Failure to comply could result in accidental injury or death.

- If the rubber feet are removed from the bottom of the unit, the mounting screws must be reinstalled into the bottom of the cabinet to avoid damage to components mounted to the base pan.

- Choose a well-ventilated installation area. This unit MUST be installed in a location protected from the elements, such as rain and water spray or drips.

- This unit should not be located next to ovens, grills, or other high heat sources.

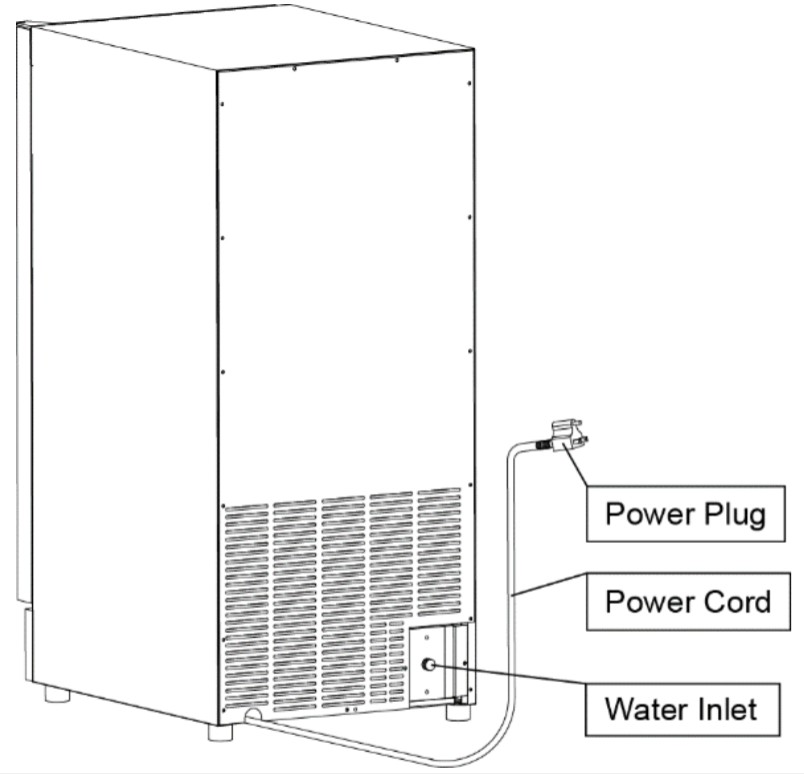

- Installation of the ice maker requires a cold water supply inlet of ¼” tubing with a shut-off valve within six (6) feet of the installation location.

- The installation must allow the ice maker to be pulled forward so that the rear can be accessed for service.

- This unit is designed to be operated in ambient temperatures between 50° F and 90° F. High ambient temperatures (90° F or higher) may reduce the ice production rate. For the best performance, keep the unit out of direct sunlight and away from heat-generating equipment.

- The unit must sit on a secure and level surface. A mounting flange must NOT be used to support the unit’s weight. It is important for the ice maker to be leveled in order to work properly. If needed, you can adjust the height of the ice maker by revolving the rubber leveling feet.

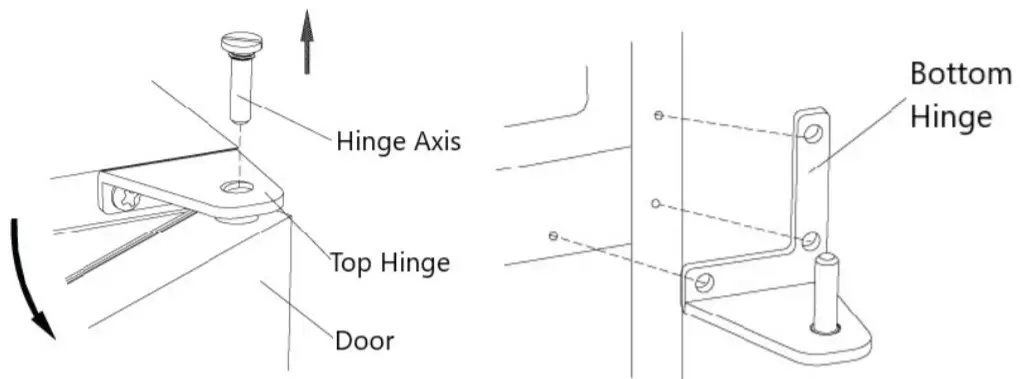

- If you are mounting the unit within cabinetry, make sure that the door has the desired range of motion. All doors come with the hinge on the right side, but can be reversed if desired.

- All electrical and water connections for the unit must be installed in accordance with all state and local codes.

- A standard electrical supply, properly grounded in accordance with the National Electric Code and local codes and ordinances is required.

![]()

![]()

![]()

![]()

![]()

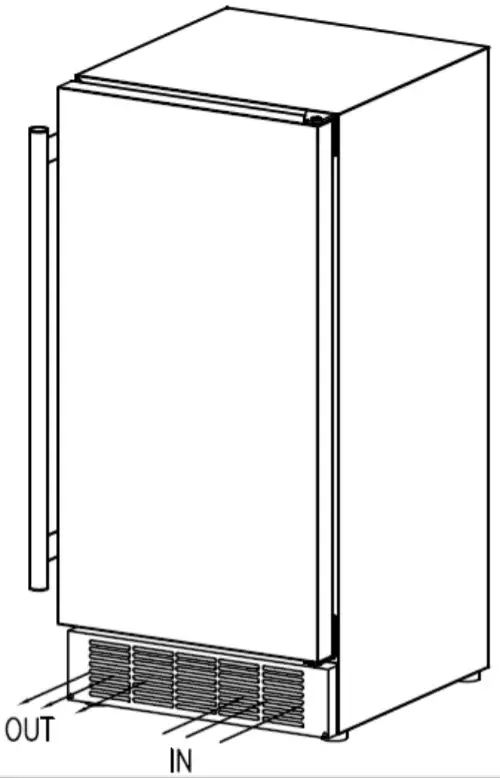

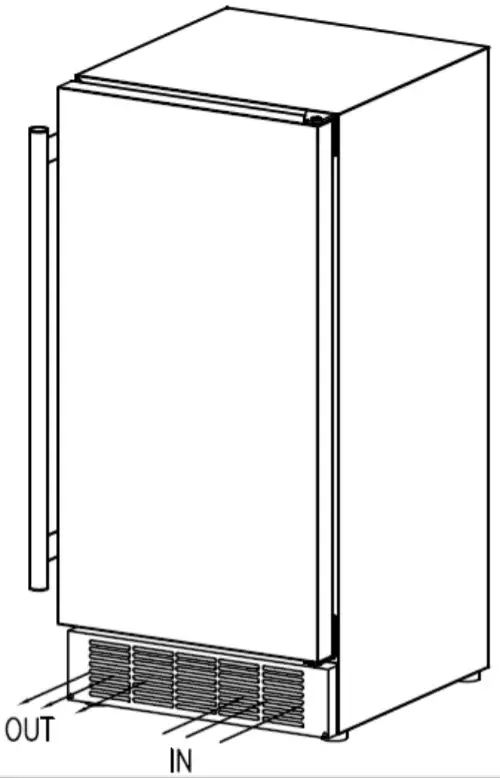

- There must be an unrestricted path for exhaust and fresh air intake. Recirculation between fresh air intake and exhaust air must be prevented.

- Any restriction of airflow or ventilation will disrupt the normal operation of the unit, resulting in damage to components which voids the warranty.

- Only connect the unit to a potable water supply.Note: It is highly recommended that you install the ice maker with an inline water filter.

Installation Clearance Requirements

- If the unit is to be built in, 1″ or more must be allowed behind the unit for the waterline and plug clearance for proper operation.

- An additional ¼” must be left on both sides and the top of the unit.

- Fan-forced condenser cooling is used. This requires air circulation through the vents in the lower front section of the unit. The grille must be unobstructed.

Electrical Requirements![]()

![]()

- Plug into a grounded 3-prong outlet.

- Never remove the grounding prong from the plug.

- Never use an adapter.

- Never use an extension cord.

- Failure to follow these instructions can result in fire, electrical shock, or death.

Before you move your ice maker into its final location, it is important to make sure you have the proper electrical connection: a standard electrical supply (115 V, 60Hz.), properly grounded in accordance with the National Electrical Code and local codes and ordinances, is required. The ice maker should always be plugged into its own individual electrical outlet.It is recommended that a separate circuit, serving only your ice maker, be provided. This provides the best performance and prevents overloading boat wiring circuits which can lead to a fire hazard. Use an outlet that cannot be turned off by a switch or pull chain. Immediately repair or replace the power cord if it becomes frayed or otherwise damaged. Do not continue to use a cord that has cracks or abrasions along its length or at either end. Be careful not to damage the power cord when moving the ice maker.If the supply cord is damaged, it must be replaced by the manufacturer, service agent, or another qualified person.The fuse (or circuit breaker) size should be at least 15 amps.Recommended Grounding MethodFor your personal safety, this appliance must be properly grounded. It is equipped with a power supply cord having a 3-prong grounding plug. To minimize possible shock hazards, the cord must be plugged into a mating 3-pronged and grounding-type wall receptacle, grounded in accordance with the National Electrical Code and local codes and ordinances. Have the wall outlet and circuit checked by a qualified electrician to ensure the outlet is properly grounded? If a mating wall receptacle is not available, it is the personal responsibility of the customer to have a properly grounded, 3-prong wall receptacle installed by a qualified electrician.Leveling the Ice Maker![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Place a carpenter’s level on top of the product to check if the ice maker is level from front to back and side to side.

- Adjust the height of the feet as follows:

Turn the leveling feet to the right to lower that side of the ice maker. Turn the leveling feet to the left to raise that side of the ice maker.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Using a flathead screwdriver, separate the hinge axis from the top hinge.

- Remove the three screws securing the top hinge to the cabinet. Remove the plug buttons opposite the top hinge. Place hinge, screws, plug buttons, and hinge axis safely aside.

- Open the door about 20 degrees, then lift the door off the bottom hinge 2 and set the door aside.

- Remove the three screws securing the bottom hinge to the cabinet and the plugs opposite.

- Rotate the door 180 degrees from its original position. The handle should be opposite the door hinges.

- Replace the original top hinge on the opposite side at the bottom and the original bottom hinge on the opposite side at the top.

- Install the hinge axis back through the bottom hinge. Gently place the door on the bottom hinge and open it approximately 20 degrees.

- Install the top hinge axis and tighten firmly. Replace all plug buttons.

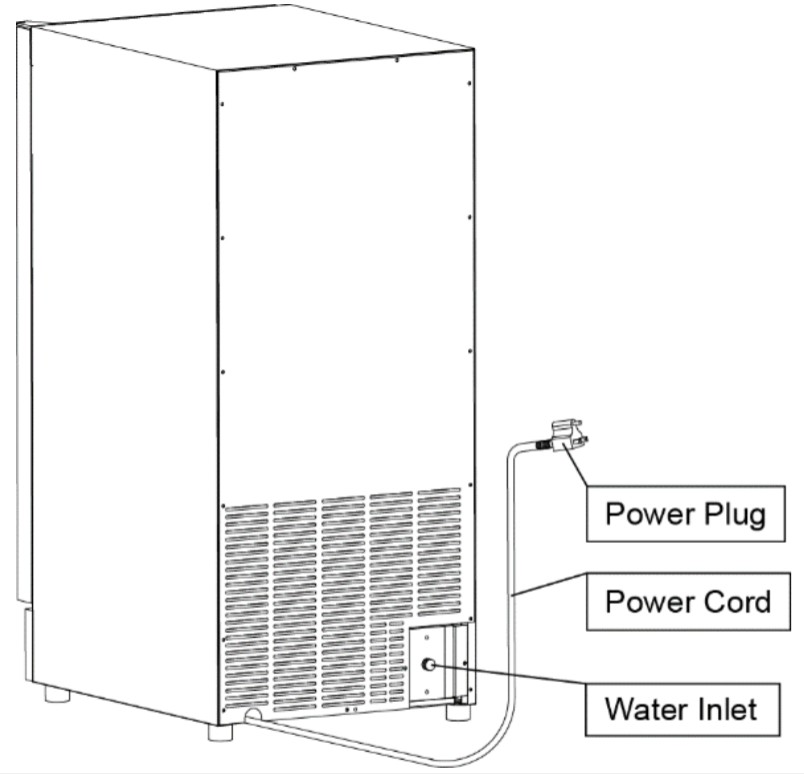

Water Supply ConnectionsThe water supply should be ready at the point of installation. The water supply pressure should be a minimum of 20 PSIG with a static pressure of not more than 120 psi. (A wall outlet directly behind the ice maker will make installation easier.) The temperature of the water feeding into the ice maker should be between 41° F and 90° F for proper operation.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- All installations must be in accordance with local plumbing code requirements.

- Make certain that the pipes are not pinched or kinked or damaged during installation.

- Check for leaks after connection.

Connecting the Water Line:

Tools required: ½” Open-end Wrench, Phillips Screwdriver

- Turn off the main water supply. Turn on the nearest faucet long enough to clear the line of water.

- Find a 1/4″ vertical cold water inlet of soft copper tubing with a shut-off valve near the installation location. The distance should be less than six (6) feet. The water supply hose provided with the ice maker is about six (6) feet long. Drains are not required for this unit.

- Connect the nuts of the water supply hose to the tap and water inlet valve. Tighten the nuts firmly by the hand, then one-half turn with the wrench.

- Turn on the main water supply and tap. Check for water supply connection leaks. Tighten every connection (including connections at the water inlet).

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Operation

Final Check List Before Operation

- Have all packing materials and tape been removed from the interior and exterior of the ice maker?

- Did you clean the ice storage bin?

- Have the installation instructions been followed, including connecting the machine to water and electricity?

- Has the machine been leveled?

- Is the ice maker in a site where the ambient temperature is between 50º F and 90º F and the water temperature is between 41º F and 90º F all year round?

- Has the water supply pressure been checked to ensure a minimum of 20 PSIG with a static pressure not to exceed 120 PSIG?

- Is there a clearance of at least 1″ at the rear of the ice maker?

- Has the power supply voltage been checked or tested against the nameplate rating? And has proper grounding been installed for the ice maker?

- Is the ice maker plugged in?

- Have you turned on the main water supply and the tap?

- Have you checked for leaks at all water supply connections?

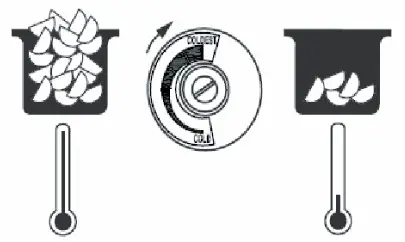

Operating MethodThe power on-off switch is located inside the door towards the bottom of the ice maker. Press the power switch to turn the unit on or off. The ice maker will begin to produce ice within 60 minutes after startup. Ice production will stop automatically when the bucket is full enough to trigger the wire shut-off arm. The unit should not be turned off if the door is closed or there is ice or water inside the ice maker.Ice Harvest ControlThe ice harvest control adjusts the temperature at which the ice is harvested from the ice maker mold. A colder setting results in harder ice, which is slower to melt, but also increases ice production time. A warmer setting speeds up ice production time. The ice harvest control is preset at the factory and adjustments are not normally needed.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Unscrew the two screws on the front grille and remove the grille.

- Use a flathead screwdriver to turn the adjusting screw in small increments. Turn the adjusting screw clockwise for a colder setting, resulting in harder ice and slower ice production. Turn the adjusting screw counterclockwise for a warmer setting and faster ice production.

- Replace the front grille and tighten the two screws to secure it in place.

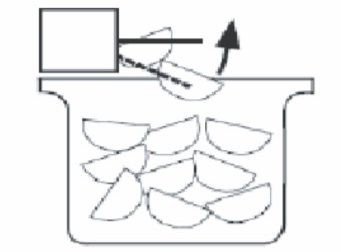

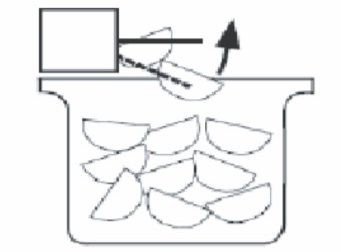

Ice ProductionWhen the ice bucket is full, the ice maker mold will shut off. However, the refrigeration system will continue to cool and maintain the ice cube supply.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Due to fast freezing, ice cubes may appear “cloudy.” This is trapped air in the water and does not affect the taste or quality of the ice.

- “Hollow” ice cubes may result from fast freezing under certain climatic conditions such as high humidity. This is not an indication of a problem with the ice maker.

- Ice production can be interrupted by raising the wire shut-off arm into an upright and locked position. The unit will maintain its temperature for ice storage.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- If you are not intending to use the ice maker and turn the supply valve off, it is imperativeto raise the bin arm of the ice maker. Failure to raise the bin arm may result in damage to the water valve.

- Although the unit has been tested and cleaned at the factory, due to long-term transit and storage, the first batch of cubes must be discarded.

- Never turn the water supply tap off when the ice maker is running.

- Never touch the ice maker mold when the unit is running!

- Except to take ice from the unit, keep the door closed to reduce melting and ensure proper ice formation.

Cleaning and Maintenance

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Periodically vacuum dust and dirt from the condenser, which is located behind the grille atthe bottom front of the unit.

- Regularly inspect the plumbing connections to ensure that no leaks are present.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Do not touch the power plug when your hands are wet.

- Never unplug the unit by pulling on the cord. Grasp the plug and pull it out firmly.

Exterior CleaningThe door and cabinet may be cleaned with a mild detergent and warm water solution such as one (1) ounce of dishwashing liquid mixed with two (2) gallons of warm water. Do not use solvent-based or abrasive cleaners. Use a soft sponge and rinse with clean water. Wipe with a soft clean towel to prevent water spots. If the door panel is stainless steel, it can discolor when exposed to chlorine gas and moisture. Clean stainless steel with a cloth dampened with a mild detergent and warm water solution and a damp cloth. Never use an abrasive cleaning agent.Interior CleaningWhen necessary, defrost the unit and thoroughly clean the inside with mild soap and water. Do not use electrical heating devices or sharp or pointed tools when defrosting the ice maker. When defrosting the unit or leaving it turned off, prop the door open. This allows the inside of the cabinet to air dry, reducing the chance for mildew or mold to form and damage the ice maker’s components.WinterizingWarning: Disconnect power at the source before working on the unit. Do not winterize this unit with ANY type of anti-freeze; damage to the ice maker mold coating will occur, invalidating the product’s Limited Warranty and creating a potential health hazard.

- Shut off the water supply to the unit.

- Disconnect the water supply connector behind the front grille at the solenoid valve. Remove the white plastic tubing and nut from the bottom of the solenoid valve.

- Turn the power on. Allow the unit to run for an hour. Remove any cubes that may have been ejected during this period. Turn off the power and open the door to allow the inside to defrost. After it has defrosted, wipe it dry and leave the door open.

RecommissioningReconnect the water supply connector, white plastic tubing, and nut discussed above in Winterizing, turn on the water, check for leaks, and then reconnect the unit to power. After an initial cooldown of 45-60 minutes, the unit will cycle approximately every 40 minutes.Start-Up Turn on the water, check for leaks and then turn on the power. Press the power switch (located just below the door). The fan and compressor will normally turn on immediately, resulting in air circulation through the grille and a faint hum from the compressor. If the machine was shut off while in the ice harvesting cycle, it will take approximately five (5) minutes to complete the cycle before the compressor and fan turn on. The interior temperature will drop below freezing. The first harvest of ice will occur within 60 minutes of startup. After the connection lines are purged of air, normal harvesting and refilling will occur every 40 minutes or less under normal conditions.Condenser CleaningA dirty or clogged condenser prevents proper airflow, reduces ice-making capacity, and causes higher than recommended operating temperatures that may lead to component failure. Has the condenser been cleaned at least once every six (6) months?

- Unplug the ice maker.

- Remove the two (2) screws on the front cover and gentlyremove the cover.

- Use the brush attachment of a vacuum cleaner to remove dirt and lint from the condenser and the surrounding compartment.

- Replace the front cover and screws.

- Plugin the ice maker.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Troubleshooting

Before Calling for ServiceIf the unit appears to be malfunctioning, read through the “Operation” section of this manual first. If the issue persists, check the Troubleshooting Guide below. Some of the problems mentioned in the Troubleshooting Guide can be solved easily without a service call.

| Problem | Possible Cause |

Probable Correction |

| The ice maker doesn’t operate. | The ice maker is unplugged. | Plugin the ice maker. |

| The breaker is tripped. | Check the breaker. If the problem occurs again, call for service to check for a short circuit in the unit. | |

| The ice maker’s power button is set to OFF. | Switch the ice maker’s power button to ON. | |

| The ice storage bin is full of ice or the wire shut-off arm is locked in the up position. | Remove some of the ice. Be sure the wire shut-off arm is lowered. | |

| The water doesn’t feed in after the ice maker starts. | The water supply tap is turned off. | Turn on the water supply tap. |

| The water supply pipe is not properly connected. | Reconnect the water supply pipe. | |

| The machine makes ice but at a very slow rate. | The condenser is dirty. | Clean the condenser. |

| The airflow to the ice maker is obstructed. | Check the installation to ensure the airflow to the ice maker is not blocked. | |

| The ambient temperature is high, or the unit is near a heat source. | Check the installation to ensure the ambient temperature is in the proper range. | |

| Ice harvest control is set too low. | Adjust ice harvest control to a higher setting (pg. 8). | |

| Water is leaking out of the unit | The water supply connection is leaking. | Tighten the fitting. |

| The unit accumulates frost and has to be defrosted often. | The door is left open or opened too often. | Defrost the ice maker as needed. Keep the door closed as much as possible. |

| The ice cubes are partially formed. | There is not enough water in the water trough. | Check if the water supply pressure is below 20 PSIG. The water supply or filter may be restricted. |

| There is noise during the operation. | The unit may not be leveled and secure. | Level and secure the unit. |

| No ice is produced. | The wire shut-off arm is locked in the upright position. | Lower the wire shut-off arm. |

| No water is being supplied to the unit | Turn on the water or contact a plumber. |

Specifications

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

| Description of Product | Undercounter Crescent Ice Maker |

| Model | IB250BL, IB250VVH, IB250SS, IB250SSOD |

| Voltage/Frequency | AC 115V-60Hz |

| Ice-Making / Ice-Harvest rated current | 1.8 A / 1.5 A |

| Color | Stainless Steel, White, or Black |

| Ice Storage Capacity | 25 lbs. maximum |

| Ice-making Capability | 25 lbs. / day* |

| Ice Shape | Crescent |

| Ice Cube Dimensions (Approximate) | ‘A” x %” x 2 1/2″ |

| Refrigerant | R134a, 2.4 oz. |

| High / Low Side Pressure | 380 psig / 130 PSIG |

| Unit Dimensions (Width x Depth x Height) | 14 7/8″ x 20 Vie x 33 vie’ |

| Net Weight | 68 lbs. IB250BL / IB250WH / IB250SS 71 lbs. IB250SSOD |

* The actual quantity of ice produced per day will vary with ambient room and water conditions.**The height includes ½” leveling feet.

EdgeStar Limited Warranty

Full One-Year Parts and LaborThis product is warranted by EdgeStar and is subject to any conditions set forth as follows:WHAT IS COVERED:For a period of ONE (1) YEAR from the date of original retail purchase, EdgeStar will repair or replace any part free of charge including labor that fails due to a defect in materials or workmanship. Labor will be performed free of charge at an authorized EdgeStar repair facility and EdgeStar will supply new, rebuilt, or refurbished parts free of charge. EdgeStar may request a defective part be returned in exchange for the replacement part. All replacement parts or products will be new, remanufactured, or refurbished. All products and parts replaced by EdgeStar under warranty service become the property of EdgeStar. After the 12 month period, EdgeStar will no longer be responsible for labor charges incurred or replacement parts. All defective products and parts covered by this warranty will be repaired or replaced on a mail-in basis to an EdgeStar authorized repair facility.This warranty applies to the original purchaser only, and only covers defects in workmanship experienced during operation of the product under normal service, maintenance, and usage conditions. This warranty applies to the purchase and use of this product in residential settings within the contiguousThe United States of America.Exceptions: Commercial or Rental Use Warranty90 days labor and parts from the date of original purchase. No other warranty applies.WHAT IS NOT COVERED- The following limitations apply to the coverage of this warranty. This warranty does not cover:-Labor charges for installation, setup, or training to use the product.-Shipping damage, and any damage caused by improper packaging for shipment to an authorized service center, and any damage caused by improper voltage or any other misuse, including abnormal service, handling, or usage.-Cosmetic damage such as scratches and dents.-Normal wear and tear on parts or replacement of parts designed to be replaced, e.g. filters, cartridges, batteries.-Service trips to deliver, pick-up, or repair, install the product or instruct in proper usage of the product.-Damages or operating problems resulting from misuse, abuse, operation outside environmental specifications, uses contrary to instructions provided in the owner’s manual, accidents, acts of God, vermin, fire, flood, improper installation, unauthorized service, maintenance negligence, unauthorized installation or modification, or commercial use.-Labor, service transportation, and shipping charges for the removal and replacement of defective parts, beyond the initial 12 month period.-Products that have been modified to perform outside of specifications without the prior written permission of EdgeStar.-Products lost in shipment or theft. -Products sold AS IS or from an unauthorized reseller.-Products that have had their serial numbers removed, defaced, or with serial numbers that have been invalidated.-Damage from other than normal household use.-Replacement or repair of household fuses, circuit breakers, wiring, or plumbing.-Damage to personal property from use of the product.-Damage from service other than from an authorized EdgeStar repair facility.-Hoses, knobs, lint trays, and all attachments, accessories, and disposable parts.-Any service charges not specifically identified as normal such as normal service area or hours.-Any special or consequential damages arising out of the use of the product.OBTAINING WARRANTY SERVICE: If you believe your product is defective, contact EdgeStar Customer Support for troubleshooting assistance and warranty service at www.edgestar.com or call 1-866-319-5473. Before contacting Customer Support you are required to have your model number, serial number, and proof of purchase available upon request. Once an EdgeStar authorized representative has confirmed that your product is defective and eligible for warranty service, the product must be returned to an EdgeStar authorized repair facility. EdgeStar is not responsible for damage resulting from shipper mishandling or improper packaging. Do not return a defective product to the place of purchase. Products received without a return authorization number will be refused.THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TO THE EXTENT ANY IMPLIED WARRANTY IS REQUIRED BY LAW, IT IS LIMITED IN DURATION TO THE EXPRESS WARRANTY PERIOD ABOVE. NEITHER THE MANUFACTURER NOR ITS DISTRIBUTORS SHALL BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF ANY NATURE, INCLUDING WITHOUT LIMITATION, LOST REVENUES OR PROFITS, OR ANY OTHER DAMAGE WHETHER BASED ON CONTRACT, TORT, OR OTHERWISE. IN NO EVENT AND UNDER NO CIRCUMSTANCE OF ANY TYPE OR KIND SHALL THE SELLER, MANUFACTURER, AND/OR DISTRIBUTOR BE LIABLE FOR ANY REASON, UNDER ANY THEORY, FOR MORE THAN THE BASIC COST OF THE PRODUCT TO THE PURCHASER OR END-USER. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

[xyz-ips snippet=”download-snippet”]