Nano SPA HeaterInstallation & Operating Manual

INTRODUCTION

Thank you for purchasing the Nano Spa Heater manufactured to the highest standards in England.

To ensure years of trouble-free service, please read and follow these instructions for proper installation, maintenance and use. Incorrect installation will affect the warranty.

WARNING: Failure to install the unit correctly may result in the warranty being void.Please retain this manual for future reference.

PRODUCT OVERVIEW

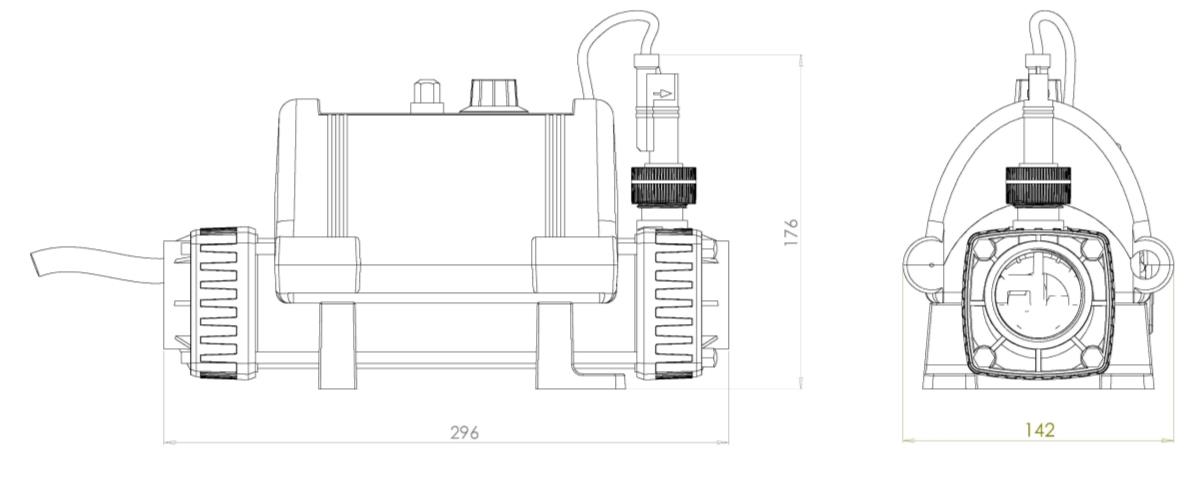

Dimensions:

GENERAL INSTALLATION INSTRUCTION

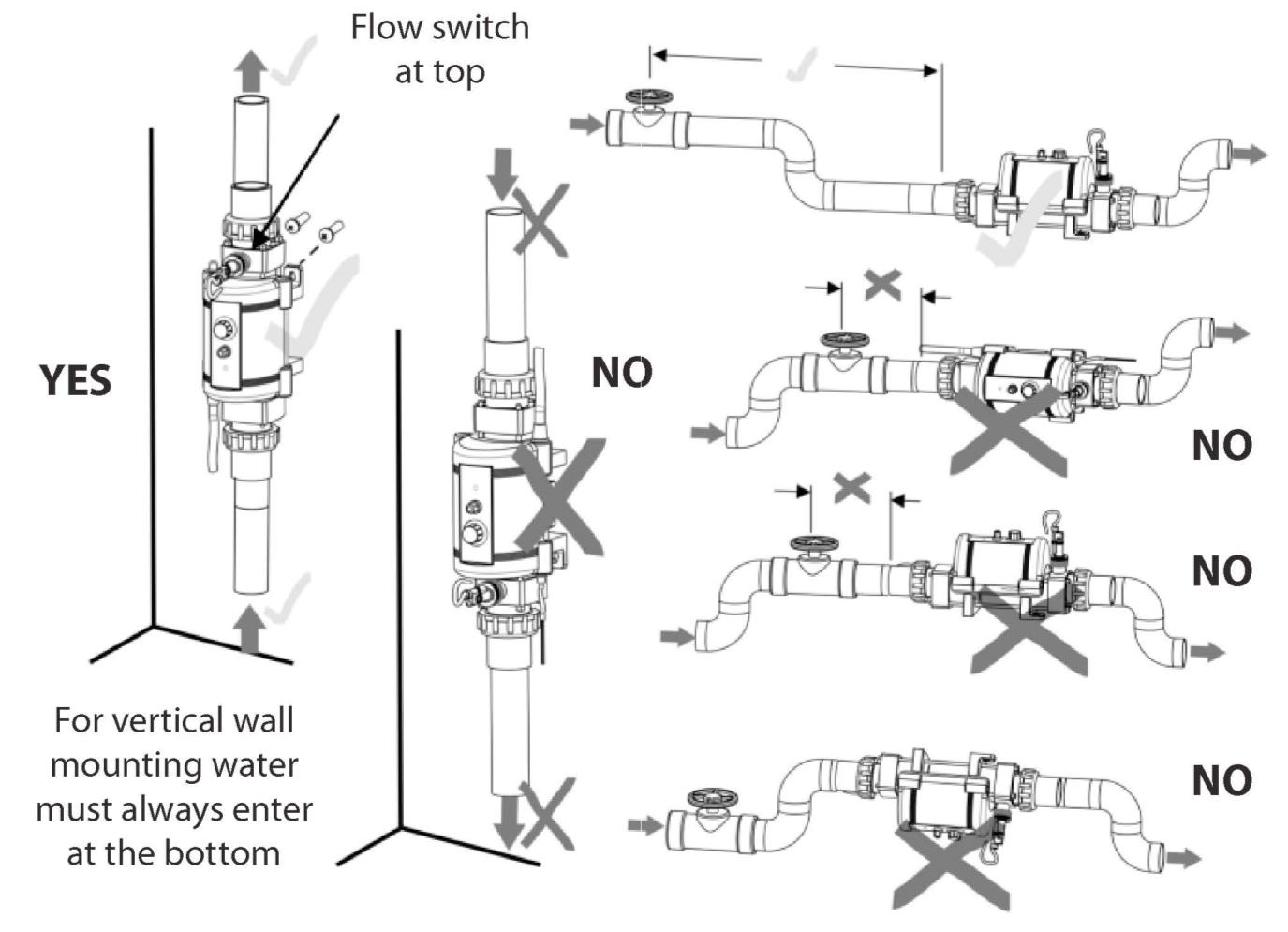

- Mounting instructionThe heater should be either installed horizontally or vertically allowing enough space for the pipe connections and wiring. It should be firmly secured using screws to a firm base or wall.WARNINGS:If the heater is placed against a combustible material a fireproof barrier must be placed between the unit and the wall, this must cover a minimum of 15cm around the outside of the heater. The unit must not be covered to allow adequate ventilation.The heater must be installed within a dry, permanent weather-proof area. In any case where water or moisture enters the enclosure the warranty will be void.Caution:If the heater is unused during the winter months, it must be drained to prevent frost damage. Water must not be allowed to freeze in the heater, as this will cause severe damage.

- PipeworkThe heater should be installed at a low point in the filtration system. It should be positioned downstream of (after) the filter and upstream of (before) any dosing or other water treatment plan. (see Fig. 2).

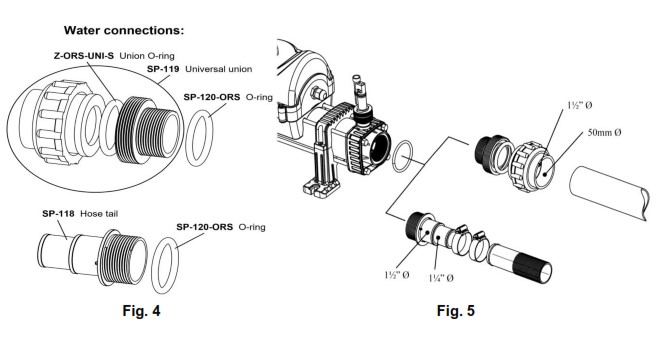

It is essential that the pipework connecting to and from the heater has a minimum bore (internal diameter) of 32mm. To support correct air purging and to ensure the heater remains completely full of water during operation, the return pipe which carries the water back to the pool must incorporate a safety loop or ‘kick-up’ in the pipe as close as possible to the heater (see Fig. 3).NOTE: When coupling to a flexible pipe, a safety loop can easily be formed by directing the pipe up and over an obstacle. Pipe clips should be used to securely fasten all hose connections. If rigid pipework is usedThere is no need to use mastic or PTFE tape to connect unions or hosetails to the heater, use the O-ring supplied which should be slid over the threaded ends (see Fig. 4).All factory unions are made from ABS plastic, when gluing connections to ABS pipe, an ABS cement must be used or when using PVC pipe, a Transition cement must be used (see Fig. 5).NOTE: Be sure to apply the glue evenly and to all surfaces that will be in contact to reduce the risk of leakage.If flexible pipework is usedConnect the pipe to the non-threaded side of the hosetail and secure using two jubilee clips (See Fig. 5).

If rigid pipework is usedThere is no need to use mastic or PTFE tape to connect unions or hosetails to the heater, use the O-ring supplied which should be slid over the threaded ends (see Fig. 4).All factory unions are made from ABS plastic, when gluing connections to ABS pipe, an ABS cement must be used or when using PVC pipe, a Transition cement must be used (see Fig. 5).NOTE: Be sure to apply the glue evenly and to all surfaces that will be in contact to reduce the risk of leakage.If flexible pipework is usedConnect the pipe to the non-threaded side of the hosetail and secure using two jubilee clips (See Fig. 5).

NOTE:• The hosetail may need to be cut depending on the diameter of the pipe.• Wrap PTFE tape or use silicone around the hosetail before connecting the pipe to reduce the risk of leakage.• When using non-standard pipework the first thing to note is that the smooth end of the pipe will not fit into anything other than another fitting of the same brand. You will have to cut it off. The hose tail will push fit into the cut end of the pipe, but it will not be watertight. You can put two jubilee clips on it but because of the ridges in the pipe it will not squeeze down tight. It will need to be sealed with a bathroom-type mastic sealant.

- Flow directionThe heater can accept the flow of water from only one end. The flow switch should always be where the water exits.

- Electrical connection warnings:• This device must be installed by a qualified Electrician following the instructions provided in this manual. The manufacturer will not be liable forany issues caused by poor or improper installation.• Any alterations made to the unit (unless stated) will affect the warranty. This also applies if components are changed for non-standard components acquired anywhere other than direct from the manufacturer.• Incorrect installation may result in serious damage to property/persons.• The heater must be installed in accordance with the country/regional requirements and regulations and an Electrical Installation Certificate mustbe provided on completion of the installation.• The power supply must be fitted with a 30mA RCD.Connections• The Nano splasher comes pre-wired with a plug to allow simple installation.• Make sure not to expose the cable to anything which can cause damage to it i.e. sharp edges, hot surfaces, or crush hazards.• The cable should be fixed to avoid any trip hazard.

- Power requirements

POWER REQUIREMENTS220 – 240V 1Phase-Power Output Load

1-kW 5-Amp 2-kW 9-Amp 3-kW 13-Amp 4-kW 18-Amp 4.5-kW 20-Amp 5-kW 22-Amp 6-kW 27-Amp 400V 3 Phase Phase-Power Output Load 8-kW 20-Amp

OPERATING INSTRUCTIONS

- Flow RequirementsThe flow rate of water into the heater must not exceed 17,000 litres per hour (17m3/hour/3,740 UK gallons per hour). A higher flow rate will require the installation of a by-pass to prevent damage to the heater elements.NOTE: The heater will not operate unless the following minimum flow rates are achieved: 1,000 litres/hour (1m3/hour / 220 UK gallons/hour).

- Water qualityThe water quality MUST be within the following limits:• PH: 6.8 – 8.0• Total Alkalinity (TA): 80 – 140 ppm (parts per million)• Chloride Content MAX: 150 mg/litre• Free Chlorine: 2.0 mg/litre• Total Bromine: Max 4.5 mg/litre• Total Dissolved Solids (TDS)/Calcium hardness: 200 – 1,000 ppmThe permitted salt concentration is dependent on the model of heater purchased:• Incoloy 825 heating element = Zero salt content permitted• Titanium heating element = MAX salt content of 8,000ppm (8g/litre)• For salt concentrations greater than 8,000ppm a Titanium flow tube and Titanium heating element model must be installed.Upon completion of the installation, run the water-circulating pump to purge the system and heater of air(i.e. remove any trapped air in the system and heater).• Switch on the power supply to the heater. This will be indicated by the illuminated Amber light on the panel.• Turn the thermostat to the desired temperature.• The heater will only start heating (red light indicator illuminated) when the following criteria are met:➢ Water circulating pump is ‘On’ delivering more than the minimum flow rate of water (see 3.1 flow requirement).➢ The required water temperature point is set to a higher value than that of the water.Useful advice:To reduce running costs and speed up the heating process, insulate the pool wherever possible. A floating solar cover is an essential minimum to retain heat.

TROUBLESHOOTING

➢ Quick Function TestObserve the main electricity meter when the heater is on (i.e. red light ‘On’) and then observe it again when the heater is in the standby mode. The test should show that the meter is recording more electricity being used by the heater when the red light is ‘On’. It is impossible for an electric heater to waste energy, if it is drawing power then that power will be turned into heat that will be transferred to the water.

➢ Accurate Function TestIf a more accurate test is required to confirm that your heater is delivering the specified heat output, two electricity meter readings will need to be taken from the property’s main electricity meter, at one hourly intervals (i.e. take one-meter reading and then a second reading exactly one hour later). By subtracting the first reading from the second reading the number of units (kilo Watts kW) consumed can be calculated. Note that your heater is also rated in kW hours.

The pool pump and heater will need to be running continuously during the test (i.e. with the heater red light ‘On’. To avoid inaccurate results when performing this test, it is important to refrain from using other high current consuming appliances in the property, such as tumble dryers, showers, cookers etc. A large domestic pool pump of one horsepower will draw less than 1-kW in a one-hour period. The conclusion of the test should prove that for example a 6-kW heater and a half horsepower pump will draw between 6.3-kW to 6.5-kW in one hour.

➢ Heater will not switch from standby to ON (Red light):In most cases this will be the result of one of the following points not being met:

| Possible Cause 1: | The temperature set point has been achieved. To confirm the increase of the temperature set, turn the dial to a value greater than the current water temperature. |

| Possible Cause 2: | Insufficient flow.Make sure circulation pump is powerful enough to deliver min flow required to operate the heater (see 3.1 flow requirement). |

| If using a cartridge filter: | Confirm this by running the system with the cartridge removed from your pump and filter unit, this will supply the heater with the maximum flow rate your unit is capable of. If the heater then switches ‘On’ (i.e. red light ‘On’) a blocked cartridge can be confirmed to be the cause. The cartridge should be cleaned or replaced. |

| If using a sand filter: | Check the pressure indicator on your sand filter and back wash if necessary. |

➢ No light appears on the heater when it is switched ‘On’:Possible Cause: Power failure external to the heaterRemedy: Check any fuses, RCD or other switch components installed in the supply cable.

NOTE: The heater is not fitted with a fuse.

➢ Heater is tripping circuit breaker (MCB) after few minutes/ hours of operation:If the heater is faulty it will instantly trip circuit breaker (MCB). The most likely causes of tripping the breaker after a period of time are:

| Possible Cause 1:Possible Cause 2:Possible Cause 3:Possible Cause 4: | Faulty circuit breaker.Incorrect size of the circuit breaker.Cross section of the cable is not sufficient.Loose connection(s) of the power supply cable. Check both ends of the power supply cable (at the distribution box and at the heater terminal block). |

| Remedy: | Contact an electrician to check installation and protection. |

| ➢ Heater is tripping circuit breaker (MCB) or RCD instantly: | |

| Possible Cause 1: Possible Cause 2:Possible Cause 3: | Short circuit cause by the wiring or faulty components.Heating element is going to ground or is damaged.Moisture inside the heater. |

| Remedy: | Send the heater back to the manufacturer. Use the return form on page 13 or download it from the Elecro website. |

| ➢ Power supply cable is getting very hot: | |

| Possible Cause 1: Possible Cause 2: | Cross section of the power supply cable is not sufficient.Loose connection(s) of the power supply cable. Check both ends of the power supply cable (at the istribution box and at the heater terminal block). |

| Remedy: | Contact an electrician to check installation. Inspect for loose connections and upgrade the power supply cable to a bigger size if necessary. |

| ➢ The flow tube does not feel warm: | |

| Due to the high efficiency of your electric heater no warmth should be detectable from the flow tube of the heater.The most likely causes of the flow tube feeling warm are: | |

| Possible Cause 1:Possible Cause 2: | The heater has been positioned in direct sunlight.An air pocket is trapped inside the heater particularly if the tank feels warmer at the highest point of the tank (as air rises). |

| ➢ The water entering the pool does not feel much warmer: | |

| The temperature gain of the water after it has passed through the heater will be directly proportional to the volume of water being pumped in relation to the power output of the heater. | |

| For example: |

A 6-kW heater, when connected to a 4,000 litre/hour pump will produce a lift in temperature of approximately 1.2°C (almost undetectable to the human hand), however, as the water being heated is re-circulated from a single body of water, the time required to heat it remains unaffected by the volume of flow. A popular misconception is that slowing down the flow rate will speed up the heating process. |

MAINTENANCE

We recommend annual maintenance and cleaning of the heater to ensure proper operation.

WARNING: Before performing any maintenance on the unit isolate from the main power supply.

The heater should be drained, the flow tube and heating elements should be cleaned. Removing scale/sludge and any debris or blockages will extend the life expectancy of the heating element(s) and avoid potential failures.Check that electrical cable connections are properly tightened.

DISPOSAL OF ELECTRICAL AND ELECTRONIC EQUIPMENT

DO NOT dispose of this product as unsorted municipal waste.

This symbol on the product or on the packaging indicates that this product should not be treated as household waste. Instead it should be handed over to the applicable collection point for the recycling of electrical and electronic equipment.

By ensuring this product is disposed of correctly you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inappropriate waste handling of this product. The recycling of materials will help to conserve natural resources.

By ensuring this product is disposed of correctly you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inappropriate waste handling of this product. The recycling of materials will help to conserve natural resources.

For more information please contact your local Civic Office, household waste disposal service or the retailer where the product was purchased.

WARRANTY

This product is guaranteed from the date of purchase against faulty workmanship and materials for:– two years within Europe– one year outside Europe• The manufacturer will replace or repair, at its discretion, any faulty units or components returned to the Company for inspection.• Proof of purchase may be required.• The manufacturer will not be liable in cases of incorrect installation of the heater, inappropriate use or neglect of the heater.• Any damages occurred due to shipping must be reported within 48 hours of receipt of the product.• Any claims after this time will be considered as misuse or abuse of the product and will not be covered by the warranty.• Any glass parts, seals and water connections are considered as consumables and are not coveredd by the warranty.

Elecro Engineering LtdRepairs DepartmentUnit 11 Gunnels Wood ParkGunnels Wood RoadStevenageHertfordshire SG1 2BHUnited Kingdom

Customer Information: (ATTACH TO HEATER)Company Name:……………………………………………………………………………Contact Name: ……………………………………………………………………………Daytime Telephone Number: ………………………………………………………………Email Address: ………………………………………………………………………………Return Address: ……………………………………………………………………………Post/Zip Code: ………………………………………………………………………………..Country: ……………………………………………………………………………….

Suspect Fault / Description of problem:

WIRING DIAGRAMS:

Nano SPA 1, 2 and 3-kW Nano SPA 4, 5 and 6-kW

Nano SPA 4, 5 and 6-kW Nano SPA 8-kW

Nano SPA 8-kW

Notes:………………………………………………………………………………………………. Unit 11, Gunnels Wood Park, Stevenage, Herts SG1 2BH[email protected] www.elecro.co.uk +44 (0) 1438 749474© Copyright MANE106-EN-Nano Spa Manual V1-01.01.2020-Elecro

Unit 11, Gunnels Wood Park, Stevenage, Herts SG1 2BH[email protected] www.elecro.co.uk +44 (0) 1438 749474© Copyright MANE106-EN-Nano Spa Manual V1-01.01.2020-Elecro

References

[xyz-ips snippet=”download-snippet”]