EMERSON Cooking Oil Tester Installation Guide

Safety

![]() Warning: The company will not be responsible for the safety of the instrument if it is not used properly or if it is not handled in accordance with the instructions in the operating manual.

Warning: The company will not be responsible for the safety of the instrument if it is not used properly or if it is not handled in accordance with the instructions in the operating manual.![]() Warning: Failure to operate the instrument in accordance with the instructions may degrade the safety of the instrument.

Warning: Failure to operate the instrument in accordance with the instructions may degrade the safety of the instrument.![]() Warning: Please use the power cord supplied. Other power cords can affect the safety of the instrument.

Warning: Please use the power cord supplied. Other power cords can affect the safety of the instrument.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Overview

This Cooking Oil Tester is a portable measuring instrument designed to quickly detect the aging of frying oil. The TPM value (total polar component) reflects the deterioration of edible oil due to high temperature during frying process.The sensor uses the change in capacitance value to determine the total polar component content by unit of %. The following measurement tasks can be performed by the Cooking Oil Tester:

- Display the temperature value of the frying oil: accurately indicate the actual oil temperature of frying oil, and correct the accuracy of self-contained thermometer of the frying pan.

- Display TPM value: an indication of degree of deterioration of frying oil.

What kind of oil/grease can this instrument be used to detect? In principle, all oils and fats that are fried can be measured. Vegetable oils such as canola oil, soybean oil, sesame oil, palm oil, olive oil and peanut oil can also be measured.Depending on type of fat, the TPM of fresh oil will fluctuate between a few percent. The maximum use time of frying oil will vary.The acid value is used to evaluate the quality of unfried oil. This instrument is not used for the detection of acid value. The measured frying oil temperature is at least 10° C (the frying oil is liquid and not crystallized), and the maximum is 200° C.When the instrument measures common frying oil, the error is slightly larger when tested at 40° C (104 ° F) or less because of the different freezing points of various oils.The probe is 0.4″ (1 cm) from the measuring tip to probe handle or plastic shell. When it is operated, please follow the immersion depth specified in operating instructions or mark on the probe.Our measuring instruments are inspected before shipment to ensure the accuracy. In order to ensure the high measurement accuracy of instrument, we recommend that you regularly calibrate the instrument.

Calibration

You have the following options:

- Return to Emerson for calibration.

- The user calibrates himself during frying process.

We recommend that you measure the unexpanded edible oil after it is heated to 50°C when first using a new instrument. It is best to perform multiple measurements in succession and repeat, and record the TPM value for each measurement. The average of these readings will be the reference for your future calibration. In the future, when calibrating the instrument, the unfried cooking oil is heated to 50°C and calibrated with the previously recorded calibration reference value.Please note that the reference values described will need to be re-recorded when replacing other types of cooking oil or changing the supplier of cooking oil.The following is used to record your calibration values:The type of measured oil is: ________________________The calibration reference value is: ____________________

Use conditions of instrument

- Power source: polymer lithium battery (3.7V)

- Rated power: 0.45W

- Operating temperature: -20° to 50° C (-4° to 32° F)

- Relative humidity: 30% to 80% (no condensation)

- Storage temperature: -20° to 70° C (-4° to 158°F)

Instrument Appearance And Working Principle

Instrument appearance

Working principle

Edible oil is an important source for energy and nutrition of human beings and an important raw material for processed foods. Fried foods are popular with consumers for their unique flavor. Edible oils used for frying undergo a series of physical and chemical changes during high-temperature frying, which produce substances that are harmful to health.

At present, the traditional detection methods for frying edible oil are mostly chemical methods. These methods must be operated by professionals in the laboratory, which is time-consuming and laborious. The use of chemical reagents may harm the health of the test personnel, and the chemical waste agent may pollute the environment.This instrument is a fast, safe and efficient quality detector for edible oil that quickly detects the content of polar compounds in edible oils. This product can be used in high oil temperature environment and is suitable for quality inspection of various fried edible oils.

Main Performance

Technical indicators

- Measurement parameters – temperature: 0° to 200°C (32° to 392°F) TPM: 0 to 50%

- Measurement accuracy – temperature: ±1°C/±2°F TPM: ±2%

- Resolution – Temperature: 0.1°C/°F TPM: 0.1%

- Power supply: polymer lithium battery (3.7V), charging method USB.

- Temperature sensor: PTC sensor

- TPM sensor: capacitive sensor

- Communication interface: Micro USB, Wi-Fi, Bluetooth.

- Data printing: Bluetooth printer (optional).

- Data storage: Supports 10,000 measurement data storage functions.

Technical Specifications

- Dimensions (length × width × height): 14″ x 2″ x 2.5″ (354mm × 53mm × 65mm).

- Net weight: 185g (including probe protection soft cover).

- Shell material: ABS.

Installation adjustment

Unpacking inspectionAfter the instrument is unpacked, check all the complete machines and accessories according to the packing list attached, and check if there is any damage. If there is any damage, please contact Emerson Cooper-Atkins. (Please keep the damaged parts).After unpacking, main components confirm contents:

- Cooking Oil Tester.

- Micro USB cable.

- Instruction manual.

- Probe cover.

Installation conditions

- This instrument should not be installed in places where it is exposed to direct sunlight and cold, excessive heat or humidity. Generally, the indoor temperature should be kept between 10°C and 28°C (50° to 82°F).

- The charging power supply requires a voltage of 5V and a current of at least 1A. You can use the 5V mobile phone charger directly.

- This instrument should be used away from large electrical equipment. There is no vibration, no corrosive liquid, no strong electromagnetic field interference at the work site.

Installation steps

- It is recommended to fully charge the instrument before using it for the first time.

- Remove the probe cover before use and wipe the sensor clean with test paper.

Use and operation

Introduction of function

Power on: Press [power] key(<1 second), the instrument turns on, the display lights up, the boot initialization interface appears, and then automatically counts into the measurement interface, at which point the measurement operation can be started.

Shutdown: Press [Power] key (<1 second) when the power is on, the instrument is turned off.

Security measuresThis instrument should be used away from large electrical equipment, and there is no vibration, no corrosive liquid, no strong electromagnetic field interference at the workplace.

Instrument SettingsAfter the instrument is turned on, it automatically enters the measurement interface. The contents of the measurement interface and its meaning are explained as follows:

| 12:00 | System time, indicating the current time |

| Bluetooth function, when the display indicates that the Bluetooth function is on. | |

| Wi-Fi function indicates Wi-Fi function is enabled. | |

|

Battery indicator, the number on the right indicates the current battery capacity. |

| 20.0% | TPM value showing the current measured TPM value of edible oil. |

| Auto | Display result of holding function can be automatically locked after the data measurement is stable, which is convenient for observing and recording data. |

| Hold | Data lock function indicates that the data is locked and no longer changes. |

| TPM | TPM data indicator. |

| 25.0 ° C | The temperature value shows the temperature of current measurement environment. There are two modes, °C and °F. The temperature display range is 0°-200°C (32°F to 392°F), and the value does not change when the range is exceeded. |

| 2017-6-1 | System date, showing the date and time of the day. |

| 01 | The station number address of the “01” position instrument in the lower right corner indicates the communication address of the instrument. |

| background color | Display the range of TPM value: Green: 0%-20% (lower TPM). Orange: 20% (TPM lower limit) -24% (TPM upper limit). Red: 24% (TPM ceiling) -99%. |

| Return | Select “return” to save the menu setting. Exit, and return to the measurement interface. |

| Auto | Automatic holding setting, [ON] for startup and [OFF] for shutdown. |

| Wi-Fi | Wi-Fi settings, [ON], [OFF] |

| Bluetooth | Bluetooth settings, [OFF], [Printer], [Data Communication]. |

| Data storage | Measured data storage function, [ON] for startup and [OFF] for shutdown.

When starting up, the data will be held and stored in the instrument |

| Brightness | Screen brightness setting, divided into 1-5 grades, among which the brightest and most energy saving grades are 5 and 1, respectively. |

| Temp unit | Temperature unit setting, [°C] degrees Celsius, [°F] Fahrenheit mode |

| Temp Adjust | For temperature calibration, use the instrument to measure the known standard temperature, modify the value to calibrate the temperature sensor, and adjust the value by [Up] and [Down] key. |

| TPM Adjust | For TPM calibration, use the instrument to measure the edible oil with known TPM value. Modify the value to calibrate the temperature sensor and adjust the value by [Up] and [Down]. |

| TPM Upper | Upper limit value of TPM alarm, when the TPM value reaches this value, the background color of the screen turns red. When TPM value bellows this value, the background color of the screen turns orange. |

| TPM Lower | Lower limit value of TPM alarm, when the TPM value reaches this value, the background color of the screen turns orange, when TPM value below this value, the background color of the screen turns green. |

| Set time | Set the instrument time by setting the year, month, day, hour, minute, and second. After each setting is completed, press [Hold] key (<1 second) to enter the next setting.><1 second) to enter the next setting. |

| Factory Set | This term is used when the instruments is calibrated before its leaves the factory and the use does not need to set it. |

| Reset | When choosing to restore the factory settings, the user settings will be erased and the instrument will be restored to factory settings. |

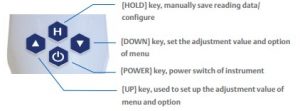

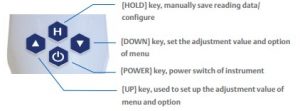

Under the measurement interface, press and hold [Hold] key (>3 seconds) to enter the menu setting interface, adjust the setting contents by [Up] key and [Down] key, then press [Hold] key (<1 second) ) and select the menu mode. After adjusting the menu to be modified by [Up] and [Down] key, press [Hold] key (<1 seconds) to save and exit the menu.

Sample testPlease follow the points below to get the most accurate results in your measurements:

- Turn off the induction frying pan during the measurement because the electromagnetic field will affect the measurement results.

- Please clean the probe before each measurement or before the next continuous measurement. See the cleaning instructions of probe for details.

- Try to avoid touching the probe with metal objects. For example, frying baskets, pot walls, because these things may affect the measurement results, the minimum spacing from metal objects is at least 1cm.

- Uneven oil temperature in the frying oil may cause measurement errors. Please stir the instrument quickly in the frying oil.

- If the measurement result is suspected to be wrong because it contains water: Please repeat the measurement after 5 minutes (do not fry during this period to keep the grease high temperature). If the new reading goes low, measure again after 5 minutes until the reading is stable.

- Please replace the frying oil when it reaches 24% TPM. Different countries have different limit values. Please be sure to replace the frying oil before reaching the limit value.

- When the automatic hold function is turned on, immerse the probe in the frying oil, pay attention to the immersion depth! If the temperature is within the allowable measurement range (0° – 200° C / 32° to 392° F), wait until Auto Hold appears on the screen. After the reading is stable, taking the instrument out of the frying oil will automatically maintain the measured data, which will make it easy to observe and record the data.

Shutdown operation

- After each use of the instrument, press the power key to turn off the instrument.

- After waiting for the probe temperature to cool down (to around room temperature), wipe off the sensor surface and the grease on the probe by test paper. Insert the probe cover onto the sensor to protect the sensor from damage.

- Store the instrument in a box.

- Store it in a dry environment.

Analysis and Elimination of Failure

|

Serial No |

Fault phenomenon | Cause Analysis | Method of exclusion |

Remarks |

|

1 |

Press the power key, the screen does not appear on the screen | 1. The lithium battery is low in power;

2. Instrument failure. |

1. Use the instrument after charging it;

2. It cannot be turned on under charging status. |

|

|

2 |

When using the computer to configure the instrument, there is no COM port. | Poor connection of data lines;

The USB driver corresponding to the computer is not installed

|

Unplug the data cable and reconnect it;

Install the CP2102 driver of the corresponding system, download it yourself or contact our sales staff to request the driver. |

|

|

3 |

Data in the air is abnormal, TPM is not 0 | 1. The sensor cover is not removed;

2. There are stains on the sensor surface. |

1. Remove the sensor cover;

2. Wipe the sensor surface with a test strip. |

|

|

4 |

The data is abnormal when the edible oil in low temperature is measured. | When the temperature is too low, it will cause the edible oil to crystallize or be close to the crystalline state. | After heating the edible oil to 50°C (122°F,) stop heat and re-measure it. | |

|

5 |

Wi-Fi connection is abnormal | Wi-Fi parameters are not set correctly | Configure the Wi-Fi parameters of instrument using the corresponding configuration software.

If not resolved, please call our technical staff to solve the problem. |

|

|

6 |

Connection for Bluetooth printer is abnormal | Parameters of Bluetooth printer are not set correctly;

Use it when the printer is not initialized. |

1. Configure the parameters of Bluetooth printer by corresponding configuration software.

2. Turn on the Bluetooth printer first, wait 10 seconds, then turn on the instrument Bluetooth. |

Table 1 Analysis of failure and example of elimination

Daily Maintenance of the Instrument

Cleaning probeDo not touch the hot parts of instrument.

- Allow the instrument to cool sufficiently before cleaning.

- Use a weak detergent, clean it with water or soapy water.

- Gently clean the probe with a soft tissue or rinse it by clean water.

- Carefully dry the probe with a soft tissue.

Cold oil slag cleaning for probe surface:

- Insert the probe into the hot oil.

- Cool the probe and probe rod until there is no risk of burns.

- Repeat the 3-5 steps to clean the probe before the oil residue cools.

Cleaning the outer casingMake sure the instrument is off before cleaning the instrument case.

- Do not use sharp objects.

- Do not use aggressive detergents and solvents.

- Use a weak detergent, rinse with water or soapy water.

- Clean the outer casing with a damp cloth.

- Dry the outer casing.

Calibration instrumentWe recommend unused edible oil for calibration. The instrument should be calibrated regularly with calibration oil. We recommend that you calibrate it every 3 months to ensure accuracy and quality.The calibration steps are as follows:

- Clean the probe before calibration, see the cleaning instructions section of the probe.

- Heat the calibration oil used for calibration in water, and stop heat after heating it to about 50°C (122°F).

- Calibrate the calibration oil in a room temperature environment.

- Immerse the probe in calibration oil, paying attention to the immersion depth.

- In order to get the reading faster, stir the probe in the oil, read the display data and record it after temperature is stable. The TPM adjustment value is calculated by comparing the previously recorded calibration values.

Modify the TPM value to be adjusted by the “TPM Adjustment Value” menu in the setup menu, then press [Hold] key (<1 second) to save and exit the menu.Turn off the instrument, the calibration is completed, and the instrument will take effect after restarting.

Storage and Transportation

- The instrument should be handled gently during handling or movement to avoid violent vibration, collision, impact and drop.

- During transportation, it should be bundled or placed firmly to prevent damage to the instrument caused by slipping or collision.

- It should not be exposed to outside elements during transportation, and for long distance transportation, it should be placed in closed compartment.

- Do not store in areas with strong electric fields, strong magnetic fields and corrosive gases.

- It is strictly forbidden to mix and transport it with other equipment or items that may affect or damage the this instrument.

- The instrument should be maintained or inspected every 3 months during storage. The storage conditions of instrument are as follows:

- Avoid water splashes, rain, and direct sunlight.

- Storage temperature and humidity meet the requirements.

- Avoid corrosive gases and salty air.

- Avoid strong electric fields and strong magnetic fields.

- There is no severe vibration, impact and pests in the storage place.

Out of Factory Instructions

This product can be repaired within one year from the date of sale (it is subject to the date of invoice issued, and there is no extended warranty agreement). The following conditions are not covered by the repair:

- Exceeding the warranty period;

- Damage caused by improper use;

- Damage caused by disassembly without the permission of Emerson Cooper-Atkins;

- Damage caused by improper transportation and storage.

Consumables and Spare Parts

Users need to have a charger, parameter requirements: voltage DC 5V, current at least 1A.The user needs to self-match the test strips of the probe sensor.

Environmental Protection Notice

This electronic device cannot be discarded together with unsorted general waste. Improper handling can harm the environment and human health. Please refer to local regulations for collection and disposal equipment of waste disposal.

Emerson Commercial & Residential Solutions356 Chisholm Road Auburn NSW 2144, AustraliaTel: (612) 9795 2800 Fax: (612) 9738 1699 Climate.Emerson.com/Asia

Cooper-AtkinsEmerson Commercial & Residential Solutions 33 Reeds Gap Road | Middlefield, CT 06455 T +800-835-5011 | F +860-347-2256 www.cooper-atkins.com

References

[xyz-ips snippet=”download-snippet”]