EMERSON Copeland Compressor Electronics Technology

The Copeland compressor electronics technology features a modular design with a base board and plug-in modules with advanced functionalities.Copeland compressor electronics is an innovative technology for Copeland compressors to monitor and interpret data inside the compressor in order to enhance the reliability and operational performance of HVACR systems.Built upon the success of CoreSense Diagnostics introduced a few years ago, Emerson is now introducing the Copeland compressor electronics for semi-hermetic compressors featuring a modular design using state-of-the-art electronics. This modular design with plug-in modules gives the customers the flexibility to choose the advanced features as per their system requirements.

Benefits throughout the value chain

Copeland compressor electronics comes with a great set of features that offer benefits to refrigeration system manufacturers, service engineers and operators. The benefits of compressor electronics goes beyond compressor protection by assisting in system diagnosis and optimization. Providing service engineers with detailed information at the right time, system-related problems can be diagnosed faster or even before they occur.

Compressor electronics optional plug-in modules with advanced control features and factory mounted sensors reduce the system complexity and applied costs for system manufacturers. Supermarket operators benefit from increased system uptime, reduction in food loss and reduced maintenance costs. It is an opportunity for consultants to help their clients to be at the forefront of technology.

Helping manufacturers keep applied system costs under controlCopeland compressor electronics integrates many functionalities of modern refrigeration systems directly into the compressor. A few examples of such features include liquid injection control, dynamic envelope monitoring, discharge gas temperature control, and digital modulation control.

Being able to talk to system controllers via the integrated Modbus® protocol and Bluetooth® for wireless communication, the need for installing sensor cables is greatly reduced. Compressor electronics technology accelerates system manufacturing and eliminates the potential manufacturing errors.

Copeland compressor electronics measures compressor internal data right at the heart of the compressor.It maintains a data and alarm history together with compressor asset information such as model and serial number.A simple LED on the compressor terminals box provides status information through LED colour and flash codes and the compressor electronics software and mobile app enable on-site diagnostic analysis. Information is maintained in onboard EEPROM memory and can be downloaded on-site or remotely. With compressor electronics, the compressor turns into a maintenance engineer’s assistant.

Freeing end-users’ mind to focus on the strategic part of their business

Hard to believe that your operation would not benefit from reduced installed system cost, predictive maintenance or a better understanding of the system’s power consumption.Connectivity has become essential in our personal lives and in commercial applications. Compressor electronics Bluetooth® and Modbus® communication options give end users peace of mind by making sure foodis protected around the clock. Compressor electronics power monitoring provides the right tool to keep refrigeration system operational costs under control.Advanced protection and diagnostics capabilities help ensure system reliability and reduce equipment downtime by guiding service technicians, enabling a quicker troubleshooting in case of failures.With Copeland™ compressor electronics, you enable the team that builds, maintains and operates refrigeration system to leverage on the best available compressor technology.

Technical specifications

- Power supply 115/230VAC

- Communication protocol Modbus RTU and Bluetooth

- Bus to system controller: RS 485

- Discharge temperature sensor

- Current sensor

- Flash memory

- Alarm reset button

Functionality

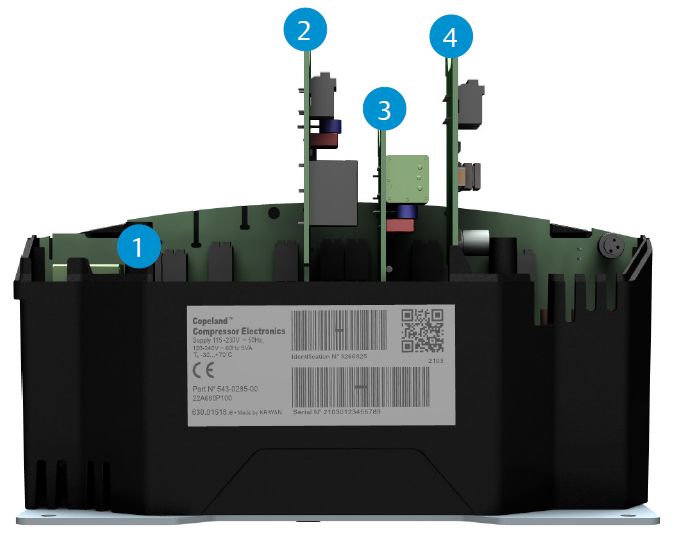

Copeland compressor electronics has a compact design with a base board and optional plug-in modules. The Base board with current, discharge temperature and oil sensor provide advanced protection and diagnostics. The plug-in modules have additional functionalities such as:

- Modbus for remote monitoring

- Head fan and liquid injection control, which is required more and more for future refrigerants

- Digital modulation control and unloaded start

- Base board

- Head fan and liquid injection control

- Digital modulation control and unloaded start

- Modbus

Key Benefits

OEM: Reduced applied system costs by integrating compressor control features System complexity reduction – Modbus® and Bluetooth® communication

Service: Manage on-site compressor data and remote monitoring Quicker troubleshooting and facilitates predictive maintenance

End-User: Increase system uptime / reduce food loss – peace of mind Monitoring of operational costs

For more details, see climate.emerson.com/en-gbEmerson Commercial & Residential SolutionsEmerson Climate Technologies GmbH – Pascalstrasse 65 – 52076 Aachen, GermanyTel. +49 (0) 2408 929 0 – Fax: +49 (0) 2408 929 570 – Internet: climate.emerson.com/en-gbThe Emerson logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.Emerson Climate Technologies GmbH shall not be liable for errors in the stated capacities, dimensions, etc., as well as typographic errors.Products, specifications, designs and technical data contained in this document are subject to modification by us without prior notice. Illustrations are not binding.© 2021 Emerson Climate Technologies, Inc.

References

[xyz-ips snippet=”download-snippet”]