evolutionpowertools.comTWISTEROriginal Instructions

evolutionpowertools.comTWISTEROriginal Instructions

![]()

![]()

(1.4)WEBwww.evolutionpowertools.com

Congratulations on your purchase of an Evolution Power Tools Machine. Please complete your product registration ‘online’ as explained in the A4 online guarantee registration leaflet included with this machine. You can also scan the QR code found on the A4 leaflet with a Smart Phone. This will enable you to validate your machine’s guarantee period via the Evolutions website by entering your details and thus ensure prompt service if ever needed. We sincerely thank you for selecting a product from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEEEvolution Power Tools reserves the right to make improvements and modifications to the product design without prior notice.Please refer to the guarantee registration leaflet and/or the packaging for details of the terms and conditions of the guarantee.

(1.5)Evolution Power Tools will, within the guarantee period, and from the original date of purchase, repair or replace any goods found to be defective in materials or workmanship. This guarantee is void if the tool being returned has been used beyond the recommendations in the Instruction Manual or if the machine has been damaged by accidenneglect or improper service.

This guarantee does not apply to machines and/or components that have been interchanged or modified in any way, or subjectto use beyond recommended capacities and specifications. Electrical components are subject to respective manufacturers’ warranties. All goods returned defective shall be returned prepaid freight to Evolution PoTools. Evolution Power Tools reserves the right to optionally repair or replace it with the same or equivalent item.

There is no warranty – written or verbal – for consumable accessories such as (following list not exhaustive) blades, cutters, drills, chisels or paddles etc. In no event shall Evolution Power Tools be liable for loss or damage resulting directly or indirectly from the use of our merchandise or from any other cause. Evolution Power Tools is not liable for any costs incurred on such goods or consequential damages.

No officer, employee or agent of Evolution Power Tools is authorized to make oral representations of fitness or to waive any of the foregoing terms of sale and none shall be binding on Evolution Power Tools.

Questions relating to this limited guarantee should be directed to the company’s head office, or call the appropriate helpline number.

TWISTER SPECIFICATIONS

| MACHINE SPECIFICATIONS | METRIC | IMPERIAL |

| Product Code UK/EU | 013-0001, 013-0002, 013-0003 | |

| Product Code US | 013-0004 | |

| Motor (220-240V ~ 50Hz) | 1100W | – |

| Motor (110V ~ 50Hz) | 1100W | – |

| Motor (120V ~ 60Hz) | – | 9.5A |

| No Load Speed | 250 – 700min-1 | 250 – 700min-1 |

| Weight | 4.9 kg | 10.8lbs |

| Coupling Thread | M14 – 2.0 | M14 – 2.0 |

| Mix Paddle Length | 120mm | 4-11/16” |

| Dimensions | H: 863mm x D: 240mm x W: 330mm | H: 33-15/16” x D: 9-7/16” x W: 12-31/32” |

| Cable Size | 2m | 6.5ft |

| NOISE & VIBRATION DATA | |

| Sound Power Level (LwA) | 110V: LwA : 96dB(A), KWA : 3dB(A)220-240V: LwA : 98dB(A), KwA : 3dB(A) |

| Sound Pressure Level (LpA) | 110V: LpA : 85dB(A), KpA : 3dB(A)220-240V: LpA : 87dB(A), KpA : 3dB(A) |

| Vibration (m/sec2) | 110V: ah= 2.56 Uncertainty K=1.5m/s2220-240V: ah= 3,16 m/s2, Uncertainty K = 1.5 m/s2 |

(1.6)Note: The vibration measurement was made under standard conditions in accordance with: EN 62841-1+AC:2015 and EN 62841-2-10:2017 in EU market and BS EN 62841-1+AC:2015 and BS EN 62841-2-10:2017 in UK market.The declared vibration total value(s) and the declared noise emission value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.The declared vibration total value(s) and the declared noise emission value(s) may also be used in a preliminary assessment of exposure.

(1.7)VIBRATIONWARNING: When using this machine the operator can be exposed to high levels of vibration transmitted to the hand and arm. It is possible that the operator could develop “Vibration white finger disease” (Raynaud syndrome). This condition can reduce the sensitivity of the hand to temperature as well as producing general numbness. Prolonged or regular users of this machine should monitor the condition of their hands and fingers closely. If any of the symptoms become evident, seek immediate medical advice.

- The measurement and assessment of human exposure to hand-transmitted vibration in the workplace is given in: EN 62841- 1+AC:2015 and EN 62841-2-10:2017 in EU market and BS EN 62841-1+AC:2015 and BS EN 62841-2-10:2017 in UK market

- Many factors can influence the actual vibration level during operation e.g. the work surfaces condition and orientation and the type and condition of the machine being used. Before each use, such factors should be assessed, and where possible appropriate working practices adopted. Managing these factors can help reduce the effects of vibration:

Handling

- Handle the machine with care, allowing the machine to do the work.

- Avoid using excessive physical effort on any of the controls of the machine.

- Consider your security and stability, and the orientation of the machine during use.

Work Surface

- Consider the work surface material; its condition, density, strength, rigidity, and orientation.

WARNING: The vibration emission during actual use of the power tool can differ from the declared total value depending on the ways in which the tool is used. The need to identify safety measures and to protect the operator are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle, such as the times the tool is switched off, when it is running idle, in addition to trigger time).

(1.8)LABELS & SYMBOLSWARNING: Do not operate this machine if warning and/or instruction labels are missing or damaged. Contact Evolution Power Tools for replacement labels.Note: All or some of the following symbols may appear in the manual or on the product.

(1.9)

| Symbol | Description |

| V | Volts |

| A | Amps |

| Hz | Hertz |

| Min-1 | Speed |

| ~ | Alternating Current |

| no | No Load Speed |

| Wear Safety Goggles | |

| Wear Ear Protection | |

| Wear Dust Protection | |

| Read Instructions | |

| CE Certification | |

| UKCA Certification | |

| Triman – Waste Collection & Recycling | |

| Waste Electrical & Electronic Equipment | |

| Warning | |

| US Certification |

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a Hand Held Variable Speed Mixer and has been designed to be used with special Evolution mixing paddles. Only use accessories designed for use in this machine and/or those recommended specifically by Evolution Power Tools Ltd.

When fitted with an appropriate paddle this machine can be used to mix:Plaster | Paint | Mortar | Adhesive! Cement | Powder Based Building Products

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a Hand Operated Variable Speed Mixer and must only be used as such. It must not be modified in any way, or used to power any other equipment or drive any other accessories other than those mentioned in this Instruction Manual. This mixer must not be used for the preparation of any food material.(1.13)WARNING: This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge unless they have been given supervision or instruction concerning the safuse of the machine by a person responsible for their safety and who is competent in its safe use.

Children should be supervised to ensure that they do not have access to, and are not allowed to play with, this machine.

(1.14)ELECTRICAL SAFETY

This machine is fitted with the correct molded plug and mains lead for the designated market. If the supply cord of this power tool is damaged, it must be replaced by a specially prepared supply cord available through the service organization.

(1.15)OUTDOOR USE

WARNING: For your protection, if this tool is tobe used outdoors it should not be exposed to rain, or used in damp locations. Do not place the tool on damp surfaces. Use a clean, dry workbench if available. For added protection use a residual current device (R.C.D.) that will interrupt the supply if the leakage current to earth exceeds 30mA for 30ms. Always check the operation of the residual current device (R.C.D.) before using the machine.

If an extension cable is required it must be a suitable type for use outdoors and so labeled The manufacturer’s instructions should be followed when using an extension cable.

(2.1)POWER TOOL GENERAL SAFETY INSTRUCTIONS

(These General Power Tool Safety Instructions are as specified in EN 62841-1+AC:2015 and EN 62841-2-10:2017 in EU market and BS EN 62841-1+AC:2015 and BS EN 62841-2-10:2017 in UK market)

WARNING: Read all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow the warnings and instructions may result in electric shock, fire, and/ or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

(2.2)

General Power Tool Safety Warnings [Work area safety]

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gasses or dust. Power tools create sparks which may ignite dust or fumes.

- Keep children and bystanders away while operating the power tool. Distractions can cause you to lose control.

(2.3)General Power Tool Safety Warnings [Electrical Safety]

- Power tool plugs must match the outlet. Never modify the plug in any way Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power toolwill increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. The use of an RCD reduces the risk of electric shock.

(2.4)General Power Tool Safety Warnings [Personal Safety].

- Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as dust masks, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing the power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or key left attached to a rotating part of a power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure that these are connected and properly used. The use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

(2.5)General Power Tool Safety Warnings [Power tool use and care].

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate at which it was designed.

- Do not use the power tool if the switch does not turn it on or off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the power tool from the power source and/or battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventative safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of moving parts, and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intendedcould result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean, and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

(2.6)General Power Tool Safety Warnings [Service]

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Mixer safety instructions

- Hold the tool with both hands at the intended handles. Loss of control can cause personal injury.

- Ensure sufficient ventilation when mixing flammable materials to avoid a hazardous atmosphere. Developingvapour may be inhaled or be ignited by the sparks the power tool produces.

- Do not mix food. Power tools and their accessories are not designed for processing food.

- Keep the cord away from the working area. The cord may be entangled by the mixer basket.

- Ensure that the mixing container is placed in a firm and secure position. A container that is not properly secured may move unexpectedly.

- Ensure that no liquid splashes against the housing of the power tool. The liquid that has penetrated the power tool can cause damage and lead to electric shock.

- Follow the instructions and warnings for the material to be mixed. Material to be mixed may be harmful.

- If the power tool falls into the material to be mixed, unplug the tool immediately and have the power tool checked by a qualified repair person. Reaching into the bucket with the tool still plugged in can lead to electric shock.

- Do not reach into the mixing container with your hands or insert any other objects into it while mixing. Contact with the mixer basket may lead to serious personal injury.

- Startup and run down the tool in the mixing container only. The mixer basket may bend or spin in an uncontrolled manner.

(2.7)HEALTH ADVICE

WARNING: When using this machine, dust particles may be produced. In some instances, depending on the materials you are working with, this dust can be particularly harmful. If you suspect that paint on the surface of the material you wish to cut contains lead, seek professional advice. Lead-based paints should only be removed by a professional and you should not attempt to remove it yourself. Once the dust has been deposited on surfaces, hand-to-mouth contact can result in the ingestion of lead. Exposure to even low levels of lead can cause irreversible brain and nervous system damage. Young and unborn children are particularly vulnerable. You are advised to consider the risks associated with the materials you are working with and to reduce the risk of exposure. As some materials can produce dust that may be hazardous to your health, we recommend the use of an approved face mask with replaceable filters when using this machine.

You should always:

- Work in a well-ventilated area.

- Work with approved safety equipment, such as dust masks that are specially designed to filter microscopic particles.

(2.8)

WARNING: the operation of any power tool can result in foreign objects being thrown towards your eyes, which could result in severe eye damage. Before beginning power tool operation, always wear safety goggles or safety glasses with side shield or a full face shield where necessary.

ADDITIONAL SAFETY INSTRUCTIONS

- A suitable industrial mixing tub, preferable plastic, should be sourced and sited on a secure and stable horizontal surface.

- The operator should be aware of the routing of the supply cable and ensure that it does not pose a trip or entanglement hazard. Care should also be taken to ensure that the cable is not routed across surfaces that could damage or cut the cable. The cable should not be routed near or through moist, damp, or wet areas.

- The operator should adopt a secure stance with both feet firmly planted and slightly apart. This machine also requires the use of both hands. This machine cannot be used ‘one-handed’.

- The operator should wear close-fitting work clothes or a fitted boiler suit when using this equipment. Loose-fitting clothes pose a hazard as they can become entangled in the rotating parts of the machine.

- Loose jewelry and jewelry chains etc should be removed and safely stored before operating this machine. Loose jewelry can pose a hazard as it can become entangled in the rotating parts of the machine.

- The operator should hold this machine firmly by the insulated handles which have an ergonomic gripping surface incorporated into their upper edge.

- Safety eye goggles or a full face mask should always be worn to provide protection from material that could be accidentally ejected from the mixing tub during mixing operations.

- A dust mask should be worn to provide protection from any material that may be ejected from the mixing tub, especially during the initial mixing process.

- The machine should only be started with the mixing paddle in the mixing tub. Start the machine with the speed set at the lowest speed setting and gradually increase the speed until the optimum mixing performance is achieved.

- Once the mixing process is completed, the operator should use the Speed Adjustment Wheel to set the motor to its lowest speed setting, and then switch ‘off’ the motor with the mixing paddle still in the mixing tub. The mixing paddle should be allowed to come to a complete standstill before the machine is removed from the mixing tub.

- The operator should never reach into the mixing tub or insert any other objects or tools into the mixing tub while mixing is in progress.

- This machine should not be used in environments with a potentially explosive atmosphere. This could include factories, garages, and other enclosed spaces (bakeries, grain silos etc) which may contain significant amounts of airborne dust or other particles.

- This machine should not be used to mix any readily flammable solvents or solvent-containing substances with a flashpoint of below 21°C.

- During operations, if the machine is to be stored temporally (by being placed on a horizontal work surface), the operator must ensure that the machine is placed on its handles with the paddle providing a third contact point. The supply cable must be pointing vertically upwards and not trapped underneath the machine.

(4.1)GETTING STARTED – UNPACKING

Caution: This packaging contains sharp objects. Take care when unpacking. Remove the machine, together with the accessories supplied from the packaging. Check carefully to ensure that the machine is in good condition and account for all the accessories listed in this manual. Also, make sure that all the accessories are complete. If any parts are found to be missing, the machine and its accessories should be returned together in their original packaging to the retailer. Do not throw the packaging away; keep it safe throughout the guarantee period. Dispose of the packaging in an environmentally responsible manner. Recycle if possible. Do not let children play with empty plastic bags due to the risk of suffocation.

(4.2)ITEMS SUPPLIED

| Description | Quantity |

| Instruction Manual | 1 |

| Hand-Held Twister Motor Unit | 1 |

| Mixing Paddle (2 pieces) | 1 |

| Spanner | 1 |

(4.3)ADDITIONAL ACCESSORIES

In addition to the standard items supplied with this machine, the following accessories are also available from the Evolution online shop at www.evolutionpowertools.com or from your local retailer.

| Description | Part No |

| Replacement Paddle | TWISTERPADDLE |

MACHINE OVERVIEW

- TWO-PIECE MIXING PADDLE

- ON/OFF TRIGGER SWITCH

- SPEED CONTROL ADJUSTMENT WHEEL

- GRIPPING HANDLES

- MACHINE ARBOR WITH 14MM INTERNAL THREAD FOR PADDLE CONNECTION

- POWER CABLE

GETTING STARTED

ASSEMBLY

| The Mixing PaddleNote: The Evolution Twister is supplied with a two (2) piece Mixing Paddle.The two pieces of the Mixing Paddle simply screw together (Fig. 1)and should be securely tightened using the spanner supplied. | |

|

The Mixing Paddle to the Twister Motor UnitNote: The machine’s arbor (Fig. 2) projects from the Twister Motor Unit, and has two (2) flats machined on it to accommodate the supplied spanner.The internal hole in the arbor contains a Ø14 mm thread. Thisinternal thread matches the external Ø14 mm thread found onthe Mixing Paddle shaft.The Mixing Paddle should be screwed into the arbor of the machineand securely tightened.Note: The machine’s arbor should be held with a spanner to prevent it from rotating when the Mixing Paddle is attached to the Twister Motor Unit. |

|

TEMPORARY STORAGEEnsure that when the Twister is placed on a work surface etcthe Motor Unit is as shown in (Fig. 3) with the power cordemerging vertically from the handle. |

OPERATING INSTRUCTIONS

|

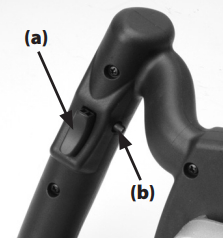

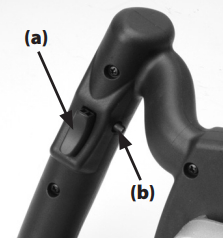

The On/Off Trigger Switch (Fig. 4a)Note: The Trigger Switch is ergonomically located on the underside of the RH handle.Note: For continuous operation, and to provide operator comfort, the trigger switch is fitted with a ‘lock-on button. (Fig. 4b)• For operation press the lock-on button, then squeeze the trigger switch (the trigger switch will not move if the lock-on button is not pressed first).• For continuous operation press the lock-on button in further whilst still pressing the trigger switch.• To switch the machine off from continuous operation gently squeeze the trigger switch and then release. |

|

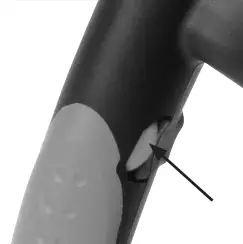

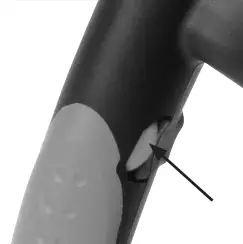

Speed ControlThe Speed Control Adjustment Wheel (Fig. 5) is ergonomically located on the inside of the LH handle where it can be easily accessed by the thumb of a skilled operator.Turning the Speed Control Adjustment Wheel alters the speed of the motor through the range of approximately 250 – 700 rotations per minute (no-load speed). |

MIXING OPERATIONS![]()

![]()

WARNING: This machine requires two (2) handed operations.WARNING: The operator must observe all of the Safety Instructions as outlined in this Instruction Manual. Failure to do so could result in an increased risk of an accident or injury to the operator.

- Position the Mixing Tub on a horizontal, stable and secure surface.

- Place the materials to be mixed in the Mixing Tub in accordance with the recommendations provided by the manufacturer of the materials.

- Check the Twister Unit and particularly the security of the attached Mixing Paddle.

- Place the Mixing Paddle in the Mixing Tub.

- Adopt a secure stance holding the Twister Unit with both hands.

- With the lowest speed setting selected depress the Trigger Switch to start the motor.

-

Be prepared for the impact of the torque forces especially on ‘start up’.

-

Adjust the speed of the motor to give optimum mixing performance.

-

During mixing, guide the Mixing Paddle around the Mixing Tub.

-

Continue mixing until the required material consistency is achieved.

-

Release the Trigger Switch and allow the Mixing Paddle to come to a complete stop.

-

Remove the Mixing Paddle from the Mixing Tub.

WARNING: If the Mixing Paddle comes into contact with the bottom or side(s) of the Mixing Tub during mixing operations ‘kick back’ can be experienced.

MAINTENANCE

Note: Any maintenance must be carried out with the machine switched off and disconnected from the mains power supply.

clean the Twister Motor Unit and the Mixing Paddle immediately after use. Follow the advice given by the material manufacturers regarding equipment cleaning and the disposal of surplus material.

All motor bearings in this machine are lubricated for life. No further lubrication is required. The threads on the Mixing Paddle and in the arbor of the machine should be given an occasional coating of light machine oil.Use a clean, slightly damp cloth to clean the plastic parts of the machine. Do not use solvents or similar products which coulddamage the plastic parts.

WARNING: Do not attempt to clean by inserting pointed objects through openings in the machines casings etc. The machines air vents should be cleaned using compressed dry air.

Excessive sparking may indicate the presence of dirt in the motor or worn-out carbon brushes. (>6.2)If this is suspected have the machine serviced and the brushes replaced by a qualified technician. (<6.2)

(6.4)ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your Local Authority or retailer for recycling advice

![]()

![]()

EC DECLARATION OF CONFORMITY

The manufacturer of the product covered by this Declaration is:UK: Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.FR: Evolution Power Tools SAS. 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

The manufacturer hereby declares that the machine as detailed in this declaration fulfills all the relevant provisions of the Machinery Directive and other appropriate directives as detailed below. The manufacture further declares that the machine as detailed in this declaration, where applicable, fulfills the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

| 2006/42/EC. | Machinery Directive. |

| 2014/30/EC. | Electromagnetic Compatibility Directive. |

| 2011/65/EU. & | The Restriction of the Use of certain Hazardous |

| 2015/863/EU. | Substances in Electrical Equipment (RoHS) Directive. |

| 2012/19/EU. | The Waste Electrical and Electronic Equipment (WEEE) Directive. |

And is in conformity with the applicable requirements of the following documents:

EN 62841-1:2015 + AC:15 • EN 62841-2-10:2017 • EN 55014-1:2017+A11:2020 •EN 55014-2:2015 • EN IEC 61000-3-2:2019 • EN 61000-3-3:2013+A1:2019

| Description: | TWISTER ELECTRIC VARIABLE MIXER |

| Evolution Model No: | TWISTER1, TWISTER2, TWISTER2EU013-0001, 013-0002, 013-0003 |

| Brand Name: | EVOLUTION |

| Voltage: | 110V / 220-240V ~ 50Hz |

| Input: | 1100W |

The technical documentation required to demonstrate that the product meets the requirements of directive has been compiled and is available for inspection by the relevant enforcement authorities, and verifies that our technical file contains the documents listed above and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

| Signed: |    |

Print: Barry Bloomer – CEO |

| Date: | 01/09/20 |

UK: Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.FR: Evolution Power Tools SAS. 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

EC DECLARATION OF CONFORMITY

The manufacturer of the product covered by this Declaration is:UK: Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.FR: Evolution Power Tools SAS. 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

The manufacturer hereby declares that the machine as detailed in this declaration fulfills all the relevant provisions of the Machinery Directive and other appropriate directives as detailed below. The manufacture further declares that the machine as detailed in this declaration, where applicable, fulfills the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

| 2006/42/EC. | Machinery Directive. |

| 2014/30/EC. | Electromagnetic Compatibility Directive. |

| 2011/65/EU. & | The Restriction of the Use of certain Hazardous |

| 2015/863/EU. | Substances in Electrical Equipment (RoHS) Directive. |

| 2012/19/EU. | The Waste Electrical and Electronic Equipment (WEEE) Directive. |

And is in conformity with the applicable requirements of the following documents:

EN 62841-1:2015 + AC:15 • EN 62841-2-10:2017 • EN 55014-1:2017+A11:2020 •EN 55014-2:2015 • EN IEC 61000-3-2:2019 • EN 61000-3-3:2013+A1:2019

| UK legislation | Supply of Machinery (Safety) Regulations 2008; |

| UK legislation | Electromagnetic Compatibility Regulations 2016; |

| UK legislation | The Restriction of the Use of Certain Hazardous Substances in Electrical andElectronic Equipment Regulations 2012 |

Name and address of technical documentation holder.The technical documentation required to demonstrate that the product meets the requirements of the directive has been compiled and is available for inspection by the relevant enforcement authorities, and verifies that our technical file contains the documents listed above and that they are the correct standards for the product as detailed above.

| Signed: |    |

Print: Barry Bloomer – CEO |

| Date: | 14/04/21 |

UK: Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.FR: Evolution Power Tools SAS. 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

| UKEvolution Power Tools LtdVenture OneLongacre CloseHolbrook Industrial EstateSheffieldS20 3FR+44 (0)114 251 1022 | USEvolution Power Tools LLC8363 Research DriveDavenportIowa52806+1 866-EVO-TOOL | EUEvolution Power Tools SAS61 Avenue Lafontaine33560Carbon-BlancBordeaux+ 33 (0)5 57 30 61 89 |

References

[xyz-ips snippet=”download-snippet”]