ExoWILD MIG-200ie Welding Machine User Manual

Please read the User’s Manual carefully before using the machine.

Safety

In the benefit of you and others, we recommend you to read and fully understand this manual before installation and operation No prior notice will be given in case of any change.

| Please install and use strictly according to the Manual! Electrical connection can be done only after the power supply is turned off. The operation process shall conform to relevant safety operation rules. | ||||

|

An electric shock may hurt or cause severe injury to users. |   |

Welding operation may cause fire or explosion! Welding spatter may ignite combustibles nearby. Combustibles shall be placed at least 10m from the welding site. Prevent the spatter from falling on clothes or body. | |

| Please turn off the power supply before wiring. Do not touch exposed conductive parts | ||||

|

The welding fume is harmful to health. Do not inhale the fume produced during welding.Cleanupthegreasy dirtonwork piece.Keepthewelding site sufficiently ventilated. Smoke and dust extracting facility shall be arranged at the welding station. |   |

Strong arc light may hurt the eyes. The ultraviolet rays produced by the electric arc may hurt the skin and the eyes. Please wear protective clothes and gloves properly during welding. | |

|

Inert gases are harmful to the human body and even cause suffocation. Please choose a well-ventilated environment for welding. If not, do close the gas cylinder valve. |   |

High-frequency arc ignition may cause electromagnetic radiation. Radiation may interfere with other devices! Contact arc ignition can be used to avoid interference. | |

|

The overheated part may burn the skin, and do not touch the overheated welding part. |   |

High-speed moving objects may cause injury. Do not put your hands or a thin objects into the fanhood. | |

|

The gas cylinder may explode. so do not heat it. Itispreferred tokeep the gas cylinder away from the welding site and store it well. |   |

Personal protection. To preventeye and skin injury,please comply with the safety and health rules and wear necessary protective clothing! |

INSTALLATION

The weight of MIG Gasless Flux Shield Wire:0.5~1Kg

TECHNICAL INFORMATIONS

| MIG-200ie | |

| Input voltage | 1 Phase,240VAC |

| Frequency | 50/60Hz |

| Rated Output Current | 200A(For MIG/MAG),200A(For MMA), 200A(For TIG) |

| Rated Output Voltage | 20.0V(For MIG/MAG), 24.8V(For MMA), 14.8V(For TIG) |

| Wire Diameter | 0.8mm, 1.0mm |

| Machine Size | 318×129×220mm |

| Weight | 5.5Kg |

CONNECTION FOR MIG GASLESS FLUX SHIELD WIRE WELDING

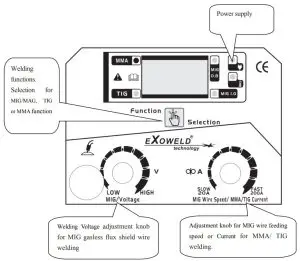

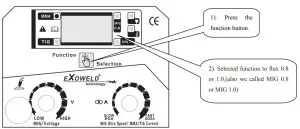

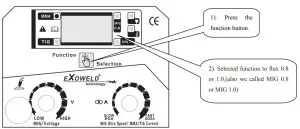

- Press the function button (Function Selection),

- Selected function to wire size 0.8 or 1.0, (also we called MIG 0.8 or MIG 1.0)

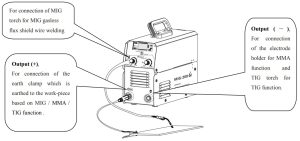

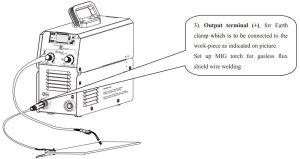

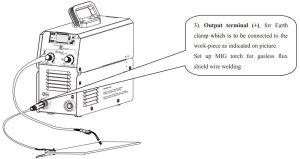

- Output terminal (+), for Earth clamp which is to be connected to the work piece. Connect MIG torch for MIG welding

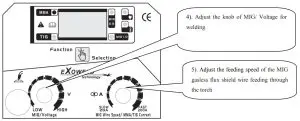

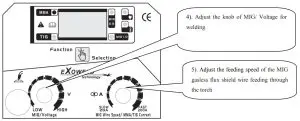

- Adjust the knob of MIG/ Voltage for welding.

- Adjust the feeding speed of the welding wire feeding through the fixed MIG torch

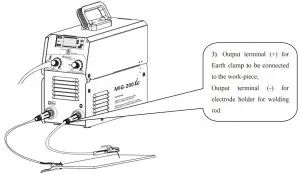

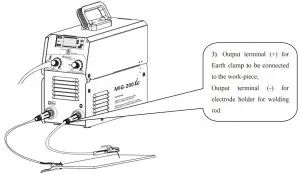

CONNECTION FOR MMA

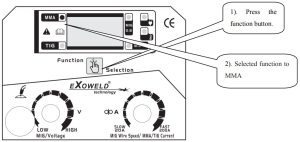

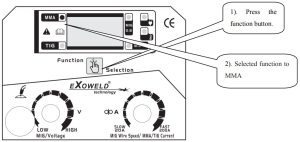

- Press the function button (Function Selection),

- Selected function to MMA,

- Output terminal (+) for Earth clamp to be connected to the work-piece, Output terminal (-) for Electrode holder to be connected for welding rod.

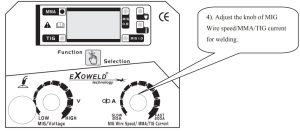

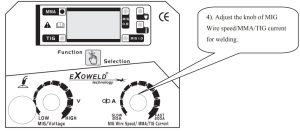

- Adjust the knob of MIG Wire Speed/MMA current for welding.

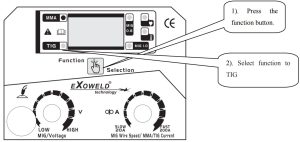

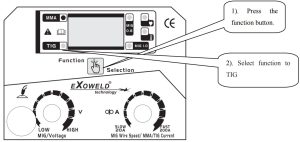

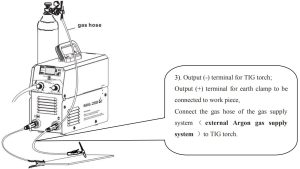

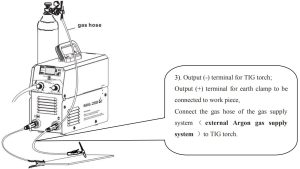

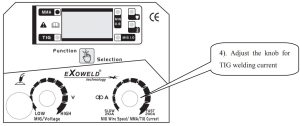

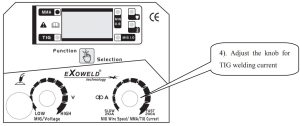

CONNECTION FOR TIG

MAINTENANCE AND TROUBLE SHOOTING

BASIC TROUBLE SHOOTING

| TROUBLE | REASON | REMEDY |

| 1.Machine does not work. | Power source switch is out of order. | Change the switch. |

| Fuse is blown out. | Change the fuse. | |

| PC board is out of order. | Contact your authorized technical service. | |

| 2. The welding machine is turned on, no output, the fan is not running. | Possible failure of power switch. | Check power supply |

| Possible short circuit of input cable. | Check power supply | |

| Fanis out of order. | Change the Fan. | |

| 3. Wire feeder works but wire is not fed. | The drive roll is not appropriate for the wire diameter. | Select the appropriate drive roll. |

| Pressure on the wire roller is not enough. | Adjust the pressure. | |

| 4.Trouble in welding operation. | Contact tip size is wrong or bad. | Change the contact tip. |

| Pressure on the wire roller is not enough. | Adjust the pressure roll. | |

| CO2 heater fuse is blown out. | Check and Replace it if necessary. | |

| Protective gas pressure is not

appropriate. |

Check the gas and adjustment. | |

| 5. While this welding machine is in operation, LED is lighted up, no current output. | It is possible that the over-load protection is activated. | Wait till it is not flashing and the welding

operation will be resumed. |

| It is possible that the over-load protection is activated. | Wait till it is not flashing or switch off the power supply, restart ON/OFF switch of the welding machine. | |

| 6.Welding parameters cannot be adjusted.

7. Welding current or voltage isn’t stabilized. |

The main control PCB is out of order. | Change the control PCB |

| Pressure on the wire roller is not enough. | Adjust the pressure roll. | |

| Gas flow rate is not enough. | Adjust the gas flow rate | |

| Circuits are possibly damaged. | Check and replace them if necessary. | |

| Capacitors are possibly damaged. | Replace them if necessary. | |

| No connection inside this welding machine. | Check and reconnect if necessary. | |

| No connection of the earth cable, or connection of the earth cable and work-piece. | Check and reconnect if necessary. | |

| 8.Heater is not working. | Fuse is blown out. | Change the fuse. |

| Heater is out of order. | Change Heater |

[xyz-ips snippet=”download-snippet”]