FESTOOL CARVEX

Safety warnings

General power tool safety warningsWARNING! Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool. Follow the operating manual for the charger and the battery pack.

Machine-specific safety notices

- Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the workpiece by hand or against your body leaves it unstable and may lead to loss of control.

- Festool electric power tools must only be installed on work tables provided by Festool for this purpose. If the tool is installed in another, or self-made, work table, it can become unstable and result in serious accidents.

- Wait until the power tool has come to a complete halt before placing it down. The insertion tool can get caught and lead to a loss of control of the power tool.

- Deformed or cracked saw blades and saw blades with blunt or broken cutting edges must not be used.

- The saw blade on the jigsaw must always be running when it makes contact with the workpiece.

- Wear suitable personal protective equipment: Ear protection, protective goggles, dust mask for work that generates dust, protective gloves for working with rough materials and for changing tools.

- Harmful/poisonous dust may be produced when working (e.g. paint products containing lead and some types of wood). Contact with or inhalation of this dust may pose a risk for the operating personnel or persons in the vicinity. Comply with the safety regulations that apply in your country. Connect the power tool to a suitable dust extractor.

- Always connect the machine to a dust extractor when performing work that generates dust.

- Stroboscopic light can cause epileptic seizures. Do not use this machine if you are susceptible to epileptic seizures.

- Do not look into the stroboscope light. Looking into the light source can damage your vision.

- Do not use power supply units or third-party battery packs to operate cordless power tools. Do not use third-party chargers to charge the battery packs. The use of accessories not expressly authorised by the manufacturer can result in electric shocks and/or serious accidents.

- Only for AS/NZS: The tool shall always be supplied via residual current device with a rated residual current of 30 mA or less.

Metal processingWhen processing metal, the following measures must be taken for safety reasons:

- Connect the machine to a suitable dust extractor.

- Regularly remove dust deposits in the motor housing.

- Use a saw blade specifically designed for the cutting of metal.

- Close the chip guard.Wear protective goggles.

Emission levelsThe levels determined in accordance with EN 62841 are typically:Sound pressure level LPA = 88 dB(A)Sound power level LWA = 99 dB(A)Uncertainty K = 5 dB

CAUTIONNoise generated when working Risk of damage to hearing

Use ear protection.Vibration emission level ah (vector sum for three directions) and uncertainty K measured in accordance with EN 62841: PSC 420 EB PSBC 420 EBSawing wood ah 7.0 m/s2 15.0 m/s2Sawing metal ah 8.0 m/s2 7.5 m/s2Uncertainty K 1.5 m/s2 1.5 m/s2

The specified emission levels (vibration, noise)

- are used to compare machines.

- They are also used for making preliminary estimates regarding vibration and noise load during operation.

- They represent the primary applications of the power tool.

CAUTIONThe emission values may deviate from the specified values. This is dependent on how the tool is used and the type of workpiece being machined.

- The actual load during the entire operating cycle must be evaluated.

- Depending on the actual load, suitable protective measures must be defined in order to protect the operator.

Intended use

Jigsaws are designed for sawing wood and materials similar to wood. With the special saw blades offered by Festool, these machines can also be used for sawing plastic, steel, aluminium, non-ferrous metal and ceramic plates. The user is liable for improper or non-intended use. This power tool is suitable for use with BP Festool battery packs of the same voltage class.

Technical data

- Cordless jigsaw PSC 420 EB PSBC 420 EB

- Motor voltage 10.8–18 V

- Stroke rate 1500–3800 rpm 1000–3800 rpm

- Stroke length 26 mm

- Pendulum stroke 4 settings

- Max. inclination (only with accessory WT-PS 400 angle table) 45° to both sides

- Max. cutting depth (depending on saw blade) Wood 120 mm Aluminium 20 mm Steel 10 mm

- Weight excl. battery pack 1.8 kg

- Weight as per EPTA-Procedure 01:2014 (with battery pack BP 18 Li 6.2 AS) 2.5 kg

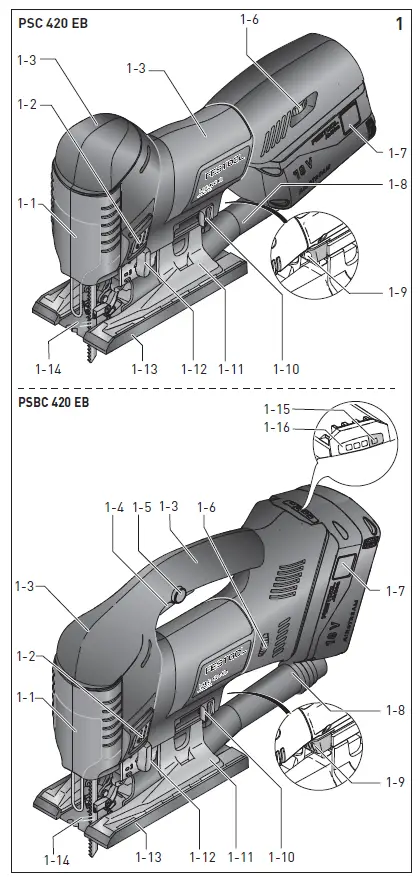

Parts of the machine

- Chip guard

- On/off switch

- Gripping surfaces

- Variable speed trigger (only PSBC 420 EB)

- Safety lock (only PSBC 420 EB)

- Adjusting wheel for stroke rate control

- Buttons for releasing the battery pack

- Extractor connector

- Saw table change lever

- Saw blade ejection

- Replaceable saw table

- Pendulum stroke switch

- Base runner

- Chip ejection opening

- Capacity display button on battery pack

- Capacity display

The illustrations specified are located at the beginning and end of the operating instructions. Accessories shown or described are not always included in the scope of delivery.

INSTALLATION

CommissioningSwitching on/offThe power tool features a switch [1-2] on both sides to turn it on and off. The PSBC 420 EB also has a variable speed trigger [1-4] with a safety lock [1-5]. For continuous operation, use the button [1-2].

Battery pack

- Inserting the battery pack [2a]

- Removing the battery pack [2b] Risk of injury! Always remove the belt clip from battery packs from the BPC series prior to use.

Capacity displayThe capacity display [1-16] indicates the charge of the battery pack for approx. 2 seconds after the button [1-15] is pressed:

70‑100%40‑70%15‑40%< 15%

Recommendation: Charge the battery pack before any further use. Further information about the charger and battery pack with capacity indicator can be found in the corresponding operating manual.

Settings

WARNING Risk of injury, electric shock

- Always disconnect the battery packs from the machine before performing any type of work on the machine!

Changing toolsCAUTIONRisk of injury from hot and sharp insertion\tool

- Do not use any blunt or faulty insertion tools.

- Wear protective gloves when handling an insertion tool.

Selecting the saw blade

Only use saw blades with a T-shank. The saw blade should not be longer than that required for the intended cut. To ensure safe guidance, during the cut the saw blade should emerge at the bottom of the workpiece at every point. Only use cross-set saw blades when using angle tables and base adapters. We recommend the S 105/4 FSG Festool saw blade. Festool saw blades for jigsaws are colour-coded. The colour represents the material for which the saw blade is suited.

Colour MaterialYellow WoodRed PlasticsGreen Building materialsBlue Metal

More information can be found on the packaging, in your Festool catalogue or at www.festool.co.uk.

Inserting the saw blade

Always disconnect the power tool from the power supply before changing blades.

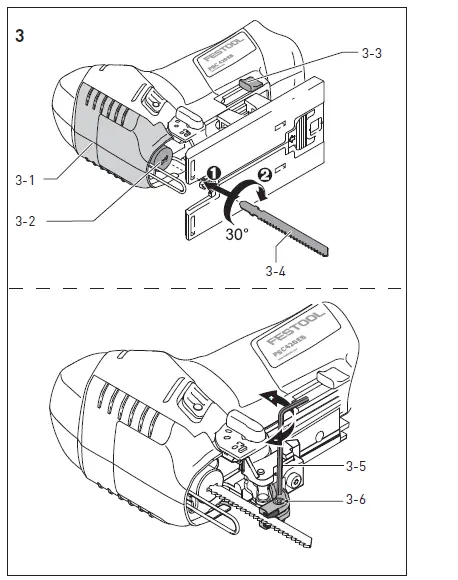

- If necessary, lift up the chip guard [3-1].

- Slide the saw blade [3-4] into the opening [3-2] as far as the stop with its teeth in the cutting direction.

- Turn the saw blade [3-4] clockwise by approx. 30° until it engages. Check that the saw blade is secure. A loose saw blade can fall out and cause an injury.

- If the saw blade is very short, it is advisable to remove the saw table (see section 8.4) before inserting the saw blade.

Adjust the saw blade guide after every saw blade change

The saw blade guide was designed to improve guidance of the saw blade.

- Remove the saw table (see section 8.4).

- Tighten the screw [3-6] using the hex key [3-5] until the jaws are almost touching the saw blade.

NOTICE

Damage to the machine or saw blade

- Do not tighten the screw [3-6] too much. It must be possible to move the saw blade slightly.Ejecting the saw bladeWhen ejecting the saw blade, hold the power tool such that no persons or animals can be injured.

- Push the saw blade ejection [3-3] forwards as far as the stop. Saw blade ist thrust out mechanically.A tool change is only possible when the tool holder is located in the upper position.When changing the saw blade is not possible: Let the jigsaw run at a high speed for 3–10 seconds. Actuate the saw blade ejection [3-3] again.

Using the chip guardThe chip guard [3-1] prevents chips from flying away and improves the efficiency of the chip extraction system.

- Apply slight pressure to push the chip guard [3-1] downwards.

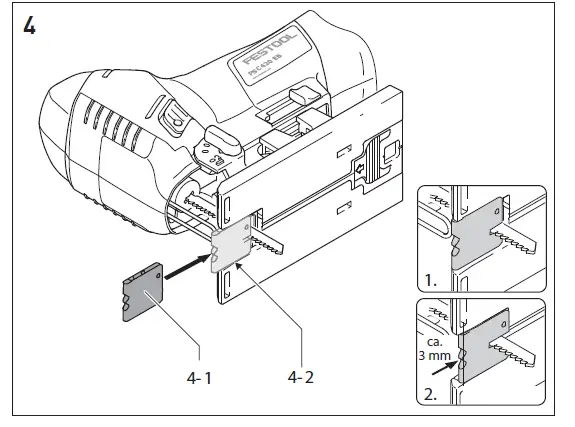

Inserting the splinterguard

The splinterguard prevents the edges of the material from splintering during the cut, even at the end where the saw blade exits the material.

- Switch off the machine and slide the splinterguard [4-1] onto the guide [4-2] and up to the saw blade.

- Switch on the jigsaw.

- On a level surface, slide in the splinterguard (not using your hand!) while the machine is operating until it is flush with the front edge of the saw table (speed setting 5). This cuts into the splinter guard.

- When it is worn, push the splinterguard approx. 3 mm further to the rear and continue using it.

- To guarantee reliable operation of the splinterguard, it must seal tightly on both sides of the saw blade. A new splinterguard should therefore be fitted after every saw blade change to guarantee splinter-free cuts.

Changing the saw table

- Open the change lever [1-9].

- Remove the saw table downwards.Assembly is performed in reverse sequence to removal. Ensure that the saw table is firmly seated in the guide. Instead of the saw table, the WT-PS 400 angle table or ADT-PS 400 base adapter can be installed at the support. Never saw without the saw table, or one of the other tables or adapters offered in the Festool accessories range.

ExtractionWARNINGHealth risk due to dust

- Always work with an extractor.

- Comply with national regulations. The extraction adapter [5-3] allows jigsaws to be connected to a dust extractor (hose diameter 27 mm).

- Insert the extraction adapter in the rear opening of the saw table so that the hook [5-2] engages in the recess [5-1].

- To remove the extraction adapter, press the hook [5-2]. Due to the low power consumption of the machine (low energy consumption), dust extractors with an automatic switch-on function will sometimes only start up when the actual cut is made.

- Set the dust extractor to continuous operation for special applications (e.g. low stroke rate, soft wood).

Adjusting the pendulum stroke

In order to saw different materials with the proper rate of advance the pendulum stroke can be adjusted. Set the required stroke via the pendulum stroke switch [1-12]: Position 0 = pendulum stroke disabled Position 3 = maximum pendulum stroke

Recommended pendulum stroke setting

- Softwood, chip board, wood fibreboard 1 – 3

- Blockboard, plywood, plastic 1 – 2

- Ceramics 0

- Aluminium, non-ferrous metals 0 – 2

- Steel, hardwood 0 – 1

Stroke rate control

Using the adjusting wheel [1-6], the stroke rate can be continuously adjusted between 1500 and 3800 rpm (PSBC 420 EB: 1000–3800 rpm). This enables you to optimise the cutting speed to suit the respective material. Automatic load detection is activated in positionA: The stroke rate drops when idling and is adjusted to the highest setting when the workpiece is introduced. Recommended stroke rate (position of the adjusting wheel)

- Hard and soft wood, blockboard, plywood, chipboard A

- Fibreboard 4–A

- Plastic 3–A

- Ceramic, aluminium, non-ferrous metals 3–5

- Steel 2–4

Working with the electric power tool

CAUTIONMaterials which produce a lot of dust Damage to the machine due to the ingress of dust, risk of injury

- Do not work overhead. When working on small or thin workpieces, always use a stable base, or the CMS module (accessory).

When working, hold the electric power tool by the handle and guide it along the desired cutting line. For precise cuts and smooth running, use two hands to guide the electric power tool.

9.1 Free saw guidance along a scribe markThe triangular pointer on the splinterguard[4-1] indicates the cutting line of the saw blade. This facilitates sawing along a scribe mark.

LightingWARNINGStroboscopic light could lead to misjudgement of the saw blade positionRisk of injury

- Ensure the work area is well illuminated. A steady light or stroboscopic light is installed to illuminate the cutting line: Up to approx. 2100 rpm: Steady light From approx. 2100 rpm upwards: Stroboscopic light In the overhead position (+/- 45°), the lighting is switched off completely. If required, you can adjust the lighting:

- Plug in the electric power tool.

- Press both buttons [1-2] simultaneously and hold for approx. 10 s until a beep sounds.

- Release both buttons [1-2].

- Press the left button (on the pendulum stroke side) the specified number of times to set the desired mode:

Mode Indication during configuration Behaviour during operation

- Light flashes With stroboscope (standard)

- Light on Steady light without stroboscope

- Light off Light switched off.

Press the right button to save the setting.

Acoustic warning signalsAcoustic warning signals sound and the machine switches off in the following operating states:

Battery flat or machine overloaded.

- Change the battery.

- Place the machine under reduced stress.

Machine is overheating.

- You must allow the machine to cool beforeusing again.

LiIon battery pack is faulty or has overheated.

- Once the battery pack has cooled, perform a functional check using the charger.

Service and maintenanceWARNINGRisk of injury, electric shock

- Always remove the battery pack from the power tool before performing any maintenance or service work.

- All maintenance and repair work which requires the motor housing to be opened should always be carried out by an authorised service workshop.

Customer service and repairsmust only be carried out by the manufacturer or service workshops. Find the nearest address at: www.festool.co.uk/service Always use original Festool spare parts. Order no. at: www.festool.co.uk/service

Observe the following information

- Check the guidance roller regularly for wear.

- Regularly remove dust deposits from the chip guard.

- Regularly clean the base runner to prevent scratches and cores on the surface.

- Damaged safety devices and components must be repaired or replaced in a recognised specialist workshop, unless otherwise indicated in the operating instructions.

- To ensure constant air circulation, always keep the cooling air openings in the motor housing clean and free of blockages.

- Keep the contacts on the power tool, charger and battery pack clean.

Cleaning the chip ejection openingClean the chip ejection opening [1-14] regularly to prevent blockages:

- Remove the chip guard.

- Use a brush or vacuum cleaner to clean the chip ejection opening.

- Reinsert the chip guard.

AccessoriesThe order numbers of the accessories and tools can be found in the Festool catalogue or on the Internet at “www.festool.com“.

Saw blades, other accessoriesIn order to saw different materials quickly and cleanly, Festool offers saw blades for all applications that are specially designed for your Festool jigsaw.

Sawing with special base runnersThe special base runners protect high-quality surfaces against scratches and scores.

- Press in the base runner at position [6-1].

- At the same time, push the base runner forwards.

- Mount another base runner and push it to the rear until it engages.

Sawing with the angle table

The WT-PS 400 angle table is used for cutting pipes or interior and exterior angles up to 45°. Dust extraction is not possible when sawing with the angle table!

Installing the angle table

- Remove the saw table [1-11] (see section 8.4).

- Position the angle table against the saw base support.

- Close the lever [1-9]. Ensure that the angle table is firmly seated in the guide.

Setting the angle

- Turn the adjusting wheel [7-1] to select the required angle. You can select the angles -45°, 0° and +45° on the scale [7-2].

WARNINGSawing cutting depthsRisk of injury

- Select the saw blade length and cutting depth so that the saw blade remains plunged in the workpiece. For 0° cuts, we recommend setting the angle table to a small negative angle to guarantee smooth operation.

Sawing with the base adapterThe ADT-PS 400 base adapter is used for attaching your jigsaw to the Festool guide rail and the KS-PS 400 core maker. With guide rail and core maker: Observe the max. material thickness of 20 mm and only use cross-set saw blades (FSG).

Installing the base adapter

- Remove the saw table [1-11] (see section 8.4).

- Position the base adapter [8-1] against the saw table support.

- Close the lever [1-9]. Ensure that the base adapter is firmly seated in the guide. Also use the extractor connector [1-8] with the base adapter.

Adaptation to the FS 2 guide railThe FS 2 Festool guide system (Fig. [9]) makes it much easier to produce straight and precise cuts.

- Place the jigsaw with attached base adapter [8-1] on the guide rail.

Adaptation to the core makerThe core maker can be used to create circular cuts with a diameter between 120 and 3000 mm. The core maker can be installed from both sides on the base adapter.

- Place the jigsaw with attached base adapter on the adapter [10-1] on the core maker.

- Insert the centring mandrel [10-2] in the hole [10-4] on the core maker aligned with the saw blade.

- Clamp the measuring tape to the core maker using the rotary knob [10-5]. Recommended settings when using the core maker:

- Cut in an anticlockwise direction.

- Work at a slow rate of advance.

- Set the pendulum stroke [1-12] to 0–1.

- Set the stroke rate [1-6] to 1–5. Store the centring mandrel in the depot [10-3].

Semi-stationary sawing with the Festool CMS system

When combined with the Festool CMS system, the jigsaw becomes a semi-stationary bench saw for profiled cuts. See the CMS brochure for more information.

- Install your jigsaw with base adapter in the CMS as described in the operating manual for the CMS-PS.

EnvironmentDo not dispose of the device in thehousehold waste! Recycle devices, accessories and packaging. Observe applicable national regulations.EU only: In accordance with the European Directive on waste electrical and electronic equipment and implementation in national law, used power tools must be collected separately and handed in for environmentally friendly recycling. Information on REACH: www.festool.com/reach

General informationImported into the UK byFestool UK Ltd1 Anglo Saxon WayBury St EdmundsIP30 9XHGreat Britain

Bluetooth®The Bluetooth® word mark and the logos are registered trademarks of Bluetooth SIG, Inc.; they are used by TTS Tooltechnic Systems AG & Co. KG, and therefore by Festool, under licence.

References

Festool Suomi

Festool United Kingdom

Festool customer service | Service for you and for your tool

Festool Worldwide – Tools for the toughest demands

Festool Polska

Festool-asiakaspalvelu | Sinun ja työkalusi palveluksessa

Service

Nuestros Servicios Personalizados | Rendimiento sin concesiones ? Festool

Festool-klantenservice | Service voor u en uw gereedschap

Festool Kundservice | Service för dig och dina verktyg

Festool Services | Le service après-vente pour vous et votre machine

Servizio clienti Festool | Assistenza per te e per i tuoi utensili

Festool Kundenservice | Service für Sie und Ihr Werkzeug

OdpowiedzialnoÅÄ za Årodowisko w Festool

Festool Italia

Responsibility for the environment at Festool

Festool España

Elektrowerkzeuge für professionelle Handwerker | Festool Deutschland

Festool Äeská republika

Festool РоÑÑиÑ

Festool Sweden

Festool kundeservice | Service til dig og dit værktøj

Festool España

Elektrowerkzeuge für professionelle Handwerker | Festool Deutschland

Festool Worldwide – Tools for the toughest demands

Festool France

Festool Suomi

Os nossos grupos de produtos | Ferramentas da Festool ?

Festool Netherlands

ObsÅuga klienta Festool | Serwis dla Ciebie i Twojego narzÄdzia

Festool Äeská republika

stool.com

[xyz-ips snippet=”download-snippet”]