FISHER PAYKEL Insert Range Hood User Manual

SAFETY AND WARNINGS

|

WARNING! |

|

|

|

Weight HazardThe appliance is heavy. Please ensure adequate care is taken when installing the appliance to prevent personal injury.Weight of the products are:HPB3011-4 = 36lb (17kg)HPB3011-6 = 36lb (17kg)HPB3019-6 = 46lb (21kg)HPB3611-4 = 41lb (19kg)HPB3611-6 = 41lb (19kg)HPB3619-6 = 51lb (23kg)HPB3619-12 = 68lb (31kg)HPB4819-12 = 77lb (35kg) |

|

WARNING! |

|

|

|

Electric Shock HazardAlways disconnect the appliance from the mains power supply before carrying out any maintenance or repairs.Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards, including fire rated construction. Failure to do so can result in death, electric shock, fire or injury to persons. |

IMPORTANT!READ THE ENTIRE SET OF INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE.Refer to the User guide for more details on safety and warnings. A copy of the installation instruction and user guide for this product can also be found at fisherpaykel.com.

WARNING!For residential use only.

- Use only metal ductwork to reduce the risk of fire.

- Do not use flexible ducting.

CAUTION!Ensure to duct air outside to reduce the risk of fire and to properly exhaust air. Do not vent exhaust air into spaces within the walls or ceilings or into attics, crawl spaces, or garages.

WARNING: Chemical Burn Hazard. Keep batteries away from children.This product contains a lithium button/coin cell battery. If a new or used lithium button/ coin cell battery is swallowed or enters the body, it can cause severe internal burns and can lead to death in as little as 2 hours. Always completely secure the battery compartment. If the battery compartment does not close securely, stop using the product, remove the batteries, and keep it away from children. If you think batteries might have been swallowed or placed inside any part of the body, seek immediate medical attention.Even used cell batteries may cause injury so ensure they are kept away from children and disposed of properly.

PRODUCT INFORMATION

- Please read this manual carefully, and keep it after installation for future reference.

- Keep all packing materials (box, pallet, straps) until the unit has been inspected.

- Inspect the product to check there is no shipping damage. If any damage is detected contact the dealer or retailer you bought the product from to report the damage.

- Fisher & Paykel is not responsible for shipping damage.

User guide and Installation guide

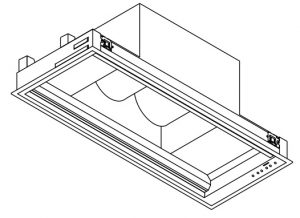

User guide and Installation guide Range hood

Range hood Filters● HPB30 (2)● HPB36 (3)● HPB48 (4)

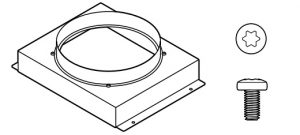

Filters● HPB30 (2)● HPB36 (3)● HPB48 (4) Duct adaptor including 5/16” (8mm) T20 drive screws (4) (selected models)● HPB3619-12, HPB4819-12, have 10” (254mm) outlet

Duct adaptor including 5/16” (8mm) T20 drive screws (4) (selected models)● HPB3619-12, HPB4819-12, have 10” (254mm) outlet Adaptor ring including 5/16” (8mm) T20 drive screws (4)● HPB3011-4/6, HPB3019-6, HPB3611-4/6 and HPB3619-6 have 8’’ (203mm) outlet.

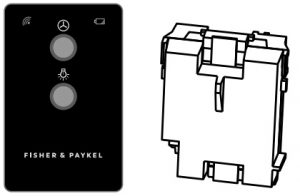

Adaptor ring including 5/16” (8mm) T20 drive screws (4)● HPB3011-4/6, HPB3019-6, HPB3611-4/6 and HPB3619-6 have 8’’ (203mm) outlet. Remote control (selected models)

Remote control (selected models)

Other required materials and tools:

- Metal ducting

- Aluminum tape (DO NOT use duct tape)

- T20 head screw driver

- 1/2” (12.7mm) cULus approved strain relief

- 1/2” (12.7mm) cULus approved wiring conduit and connectors

- cULus listed wire nuts

- Back draft damper(s) if desired

Optional accessories

Remote control kit – Remote control (1), Wireless receiver (1)

Remote control kit – Remote control (1), Wireless receiver (1)

IMPORTANT!SAVE THESE INSTRUCTIONSThe models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our website fisherpaykel.com or contact your local Fisher & Paykel dealer.

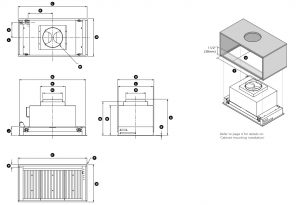

PRODUCT AND CABINETRY CUT-OUT DIMENSIONS

HPB3011-4, HPB3011-6, HPB3019-6, HPB3611-6, HPB3619-6, HPB3619-12 and HPB4819-12 models

| HPB3011-4 HPB3011-6 | HPB3019-6 | HPB3611-4 HPB3611-6 | HPB3619-6 | HPB3619-12 | HPB4819-12 | |

| PRODUCT DIMENSIONS | inches (mm) | inches (mm) | inches (mm) | inches (mm) | inches (mm) | inches (mm) |

| A: Overall height of product | 16 1/4 (412) | 16 1/4 (412) | 16 1/4 (412) | 16 1/4 (412) | 18 3/16 (462) | 18 3/16 (462) |

| B: Overall height of product (excluding duct adaptor) | 16 (407) | 16 (407) | 16 (407) | 16 (407) | 16 (407) | 16 (407) |

| C: Overall width of product | 28 3/4 (730) | 28 3/4 (730) | 28 3/4 (880) | 34 5/8 (880) | 34 5/8 (880) | 46 7/16 (1180) |

| D: Overall depth of product | 11 (280) | 28 3/4 (730) | 28 3/4 (730) | 34 5/8 (880) | 34 5/8 (880) | 46 7/16 (1180) |

| E: Thickness of flange | 1/16 (2.5) | 11 (280) | 18 7/8 (480) | 11 (280) | 18 7/8 (480) | 18 7/8 (480) |

| F: Corner radius of flange | 1/16 (2.5) | 1/16 (2.5) | 1/16 (2.5) | 1/16 (2.5) | 1/16 (2.5) | 1/16 (2.5) |

| G: Width of chassis including louvres | 27 9/16 (700) | 27 9/16 (700) | 33 7/16 (850) | 33 7/16 (850) | 33 7/16 (850) | 45 1/4 (1150) |

| H: Depth of chasis including mounting feet | 10 3/8 (264) | 18 1/4 (463) | 10 3/8 (264) | 18 1/4 (463) | 18 1/4 (463) | 18 1/4 (463) |

| I: Depth of chassis excluding mounting feet | 9 15/16 (252) | 17 13/16 (452) | 9 15/16 (252) | 17 13/16 (452) | 17 13/16 (452) | 17 13/16 (452) |

| J: Height of side of chassis | 4 3/8 (111) | 4 3/8 (111) | 4 3/8 (111) | 4 3/8 (111) | 4 3/8 (111) | 4 3/8 (111) |

| K: Width of blower housing | 13 (330) | 13 (330) | 13 (330) | 13 (330) | 23 1/4 (590) | 23 1/4 (590) |

| L: Offset of duct adaptor — forward of center | 3/8 (10) | 7/8 (23) | 3/8 (10)) | 7/8 (23) | 0 (0) | 0 (0) |

| M: Outside diameter of ducting outlet | 8 1/4 (210) | 8 1/4 (210) | 8 1/4 (210) | 8 1/4 (210) | 9 13/16 (250) | 9 13/16 (250) |

| N: Width of duct adaptor | N/A | N/A | N/A | N/A | 12 3/16 (310) | 12 3/16 (310) |

| O: Depth of duct adaptor | N/A | N/A | N/A | N/A | 12 1/2 (318) | 12 1/2 (318) |

| P: Distance from center of light to front of product | 1 3/8 (35.5) | 1 3/8 (35.5) | 1 3/8 (35.5) | 1 3/8 (35.5) | 1 3/8 (35.5) | 1 3/8 (35.5) |

| Q: Height to top surface of duct adaptor | N/A | N/A | N/A | N/A | 16 7/8 (428) | 16 7/8 (428) |

| R: Offset of junction box knockout from center | 7 5/16 (186)

|

7 5/16 (186) | 7 5/16 (186) | 7 5/16 (186) | 12 7/16 (316) | 12 7/16 (316) |

| S: Offset of junction box knockout from center | 3 5/8 (92)

|

7 9/16 (192) | 3 5/8 (92) | 7 9/16 (192) | 7 9/16 (192) | 7 9/16 (192) |

| CABINETRY CUT-OUT DIMENSIONS | ||||||

| U: Overall width of cutout | 27 3/4 (705) | 27 3/4 (705) | 33 11/16 (855) | 33 11/16 (855) | 33 11/16 (855) | 45 1/2 (1155) |

| V: Overall depth of cutout | 10 1/16 (255) | 17 15/16 (455) | 10 1/16 (255) | 17 15/16 (455) | 17 15/16 (455) | 17 15/16 (455) |

| Thickness of cabinetry surface | Min 5/8 (16) Max 1 ½ (38) | Min 5/8 (16) Max 1 9/16 (38)

|

Min 5/8 (16) Max 1 1/2 (38)

|

Min 5/8 (16) Max 1 1/2 (38) | Min 5/8 (16) Max 1 1/2 (38) | Min 5/8 (16) Max 1 1/2 (38) |

Note:For the larger models we recommend reinforcing your cabinetry. Please ensure that any reinforcing does not prevent access for servicing.For optional recessed installation refer to product dimensions for reference.

IMPORTANT!

- Actual product dimensions may vary by ± 1/16” (2mm).

- Please read the entire instructions before installing the range hood.

INSTALLATION PREPARATION

IMPORTANTThe HPB3011-4, HPB3011-6, HPB3611-4 and HPB3611-6 models are not suitable for use with a high powered professional style cooktops.

Range hood width

- The range hood width is recommended to be no less than the width of the cooktop.

- A wider range hood can be used to increase the capture area if space is not restricted.

- The range hood should ideally be centered above the cooktop for proper performance.

WARNING!To reduce the risk of fire, use only metal ductwork. Do not use flexible ducting

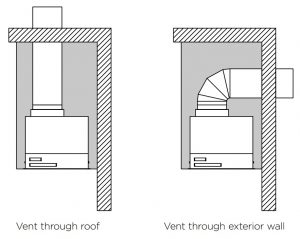

Installation location — Ducting preparationThe range hood is suspended under the cabinetry. The ducting can be configured for both vertical and horizontal discharge. The ducting can terminate either through the roof or wall, to vent through the wall a 90° elbow is needed.

Optional extrasAll optional extras must be installed prior to the range hood being installed.

Remote controlIf an optional remote control was purchased for installation with the range hood the remote control receiver must be assembled into the range hood prior to installation.Installation must be undertaken by an approved service technician. Instructions for installation are provided with the receiver.

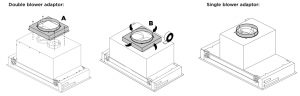

Duct adaptorA 8” (203mm) or 10” (254mm) round duct adaptor is supplied to mount to the top of the range hood to provide a single outlet. This should be installed before the range hood is mounted.

Duct adaptor assembly

- Place the duct adaptor over the range hood exhaust and secure with four 5/16” (8mm) screws provided (refer to A).

- Seal the connection between duct adaptor and range hood with aluminum tape (refer to B).Note: Double blower models have a adaptor ring as shown below. The assembly steps are the same as above.

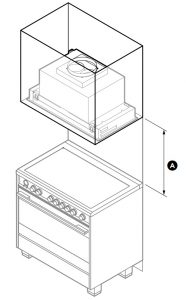

Range hood height

|

INSTALLATION DIMENSIONS |

inches (mm) |

| A Top of cooking surface to base of the range hood | Minimum 30” (762)Maximum recommended 42” (1067) |

The installation height ranges from a minimum height of 30” (762mm) to a maximum recommended height of 42” (1067mm). Consult the cooktop Installation and User guide for details of the required installation height of the range hood.This range hood must be installed no lower than the minimum height indicated in the table above.Minimum installation height may be greater if required by the cooktop manufacturer. Installation at the minimum height will improve the efficiency of capturing cooking odors, grease and smoke. Installation at the maximum recommended height improves user ergonomics by offering increased head room.

IMPORTANT

- Always switch your range hood on when you are cooking.

- Using a powerful gas cooktop or multiple gas burners operating at the same time can cause the range hood surfaces to become hot, this effect can be reduced by:

– Using the maximum speed setting to enable hot air to be extracted quickly.– Installing the range hood at the maximum recommended height. Consult the cooktop Installation and User guide for details on theinstallation height of the range hood.

Cabinet mounting installation

- The cabinet must be of sufficient strength and structurally joined to the wall studs to support the weight of this range hood.

- If support beams are added to cabinetry these must not be more than 1 1/2” (38mm) B high from the underside of the cabinet. Beams that are higher will prevent access for servicing.

- The range hood must be installed into an opening on the underside of the cabinet.

- Cabinet opening dimensions that are shown must be used, see ‘Product and cabinetry cut-out dimensions’ section. Given dimensions provide minimum clearance.

- We recommend the cupboard has a door or service panel that can be easily opened to access the power connection.

Electrical requirementsWARNING!

- Electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards.

- This unit must be grounded/earthed.

- This range hood must be connected with copper wire only.

- A 120 volt, 60Hz AC-only electrical supply is required on a dedicated 15A branch circuit.A time-delay fuse or circuit breaker is recommended.

- Wire sizes must conform to the requirements of the National Electrical Code, ANSI/NFPA 70-latest edition, and all local codes and ordinances.

- Wire size and connections must conform to the rating of this appliance.

- This appliance should be connected directly to the fuse disconnect (or circuit breaker) through flexible, armored or non-metallic sheathed copper cable. Allow some slack in the cable so the appliance can be moved if servicing is required.

- Actually listed strain relief or 1/2” (12.7mm) conduit connector must be provided at each end of the power supply cable (at the appliance and at the junction box).

WARNING!

- To reduce the risk of fire or electric shock, do not use this fan with any solid-state speed control device.

Make-up air (not included)Attention should be given to ensure that any applicable regulations concerning the discharge of exhaust air are fulfilled. Local building codes may require the use of make-up air systems when using ducted ventilation systems greater than specified cubic feet per minute (CFM) of air movement. The specified CFM varies from locale to locale. It is the responsibility of the owner and the installer to determine if additional requirements and/or standards apply to specific installations.

Venting requirements

IMPORTANT!To reduce risk of fire and to properly exhaust air, be sure to duct air outside — Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

- The range hood can be installed to operate with the exhaust air ducted externally from the kitchen.

- Use the shortest and straightest duct route possible, for optimal efficiency.Elbows and transitions increase noise and reduce air flow efficiency.

- For best results:– In ducted installations with internal blowers, use 8” (203mm) or 10” (254mm) round ducting.– For inline blowers use 10” (254mm) round ducting.

Compatible blowers with this range hoodThis range hood may only be used with:

Compatible blowers with this range hoodThis range hood may only be used with: - The provided internal blowers (for HPB30/36/48 range hood models) and/or

- Fisher and Paykel approved Inline blowers which can be purchased separately (for HP30/36/48 range hood models).

To minimize noise in the kitchen, these blowers are mounted along the duct line anywhere between the kitchen and the exterior wall.

CAUTION!To reduce the risk of fire and electric shock, install this range hood only with remote blower models rated maximum 4.8A or integral blowers supplied with the range hood.

INSTALLATION INSTRUCTIONS

IMPORTANT!Venting directly into the cabinet with no vent is not permitted.

WARNING!

- This appliance is heavy and requires two persons for unpacking and installation.

- Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards.

- Failure to install the screws or fixing device in accordance with these instructions may result in electrical hazards

- When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

IMPORTANT!

- Wear gloves to protect against sharp edges.

- The manufacturer is not liable for any damage caused by not following these instructions.

Before you start installation

- Ensure you have read the ‘Installation preparation’ section of this guide.

- Unpack the range hood.

- Ensure the voltage (V) and the frequency (Hz) indicated on the serial plate match the voltage and frequency of the installation site.

- Check all functions of the range hood are working.

- Check that the area above and behind the installation surface is clear of any electrical cables or pipes and there is proper clearance for the ducting etc.

- The range hood surfaces can be damaged during installation if grazed or knocked by tools. Please take care to protect the surfaces during installation.

- Remove protective wrappings that will not be accessible after installation.

- Protect the cooktop to prevent damage occurring whilst the range hood is being installed above.

- The wall or cabinet used for mounting the range hood should have sufficient strength and a flat surface.

WARNING!

- Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards.

- This unit must be earthed/grounded. Improper earthing/grounding can result in a risk of electric shock.

- Ensure the cabinetry has the required cutout for insertion of the range hood.Refer to the ‘Cabinetry cutout dimensions’ section of this installation book.

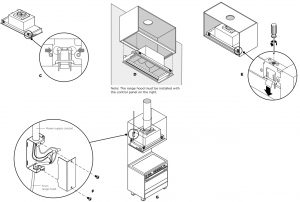

- If you are using a duct adaptor this must be installed to the range hood prior to the range hood being mounted. Please refer to ‘Duct adaptor assembly’ for details on how to install your duct adaptor.

- Ensure the mounting brackets are set to the correct position for installation by checking the top of the foot lines up with the notches (refer to C). Note: Adjusting the mounting bracket up or down from this position prior to installation could cause the range hood to be difficult to install and/or damage the cabinetry.

- Lift the range hood into the opening until the spring loaded mounting brackets click into place and support the weight of the range hood (refer D). For larger size range hoods this will require two people. Note: Depending on the cabinetry base panel thickness the range hood will be protruding below the cabinetry until tightened.

- Secure the range hood into the cabinetry by tightening each of the mountingbrackets in a counterclockwise direction (refer to E). Tighten each bracket in succession around the range hood to close the gap incrementally for each bracket.

- Remove the junction box cover by removing the two screws (refer to F).

- Remove the electrical knockout and install a cULus listed 1/2” (12.7mm) wiring conduit and strain relief in the junction box.

- Run three wires through the conduit from the power supply to the junction box.

- Connect the power supply wires to the range hood wires using suitable cULus listed wire nuts:– black to black– white to white– green/yellow to green/yellow

- Close the junction box cover and secure with screws.

- Complete the installation

- Install the filters as described in the ‘Cleaning and maintenance’ section of your User guide.

- Remove all protective wrapping from range hood.

- Turn the power on at control panel.

- Check the operation of the range hood as described in the ‘Operating instructions’ section of your User guide.

- Refer to G for an image of a completed installation

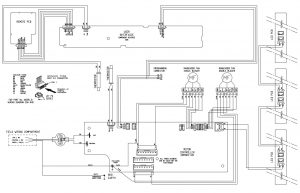

WIRING DIAGRAM

FISHERPAYKEL.COMFisher & Paykel Appliances 2019. All rights reserved.The product specifications in this document apply to the specificproducts and models described at the date of issue. Under our policyof continuous product improvement, these specifications may changeat any time. You should therefore check with your Dealer to ensure thisbooklet correctly describes the product currently available.

US CA105305B 02.19

References

[xyz-ips snippet=”download-snippet”]

Compatible blowers with this range hoodThis range hood may only be used with:

Compatible blowers with this range hoodThis range hood may only be used with: