FMS Pilatus 1100MM Instruction Manual

WARNING

Introductions

High quality anti-collision foam boxFMS invest not only on the airplane design but also on the foam box. CNC molding for the box provides a snug fit for the airplane parts. Extensive work on the 3D graph makes the final work detailed and strong. Before production, crash tests against the four angles and six sides are conducted. As you can imagine, this is a really fun part of our job.

Install in 15 mins with absolutely no glue.Glue is unacceptable to most players. Here we offer you the most thoughtful airplane design, which can be assembled with no glue – just a couple of screws. It takes only 10 mins or less to assemble for an experienced player, and about 15 mins for beginner.

99% scaled appearance.With over one month’s research, the engineers gather the most specific and accurate drawing data from various resources. From there, they go about lovingly recreating it, focusing on every detail, every skin line, every rivet position, every paint color. The five-blade propeller, retractable landing gear, flaps, and scale pilot give this airplane more distinction.

The latest foaming materialMost airplanes in the market are made with low-ratio & high-density foam particles due to the low cost, but it causes the plane to be heavy and not fly well. The PC-21 adopts the latest high-ratio & low-density EPO 52, which reduces the airplane weight by around 15%, greatly optimizing the flying performance without weakening the airplane.

Environmentally friendly, water-based paintOil paint is a low cost paint, which has some disadvantages like high corrosion (which deforms the airplane in the heat of the summer), environmental damage, and harm to human health. Water-based paint is non-corroding, environmentally friendly, and safer to human health. This high cost paint can protect the fragile foam parts under any condition. To bring you a green and safe product, water-based paint is now used on this model.

A nicely-controlled PC-21As a mutual work of engineers all over the world, this model was unceasingly tested and corrected in the past months. Operate stably without gyro and land confidently without flap. As long as you are familiar with the remote control, you will be able fly this model well.

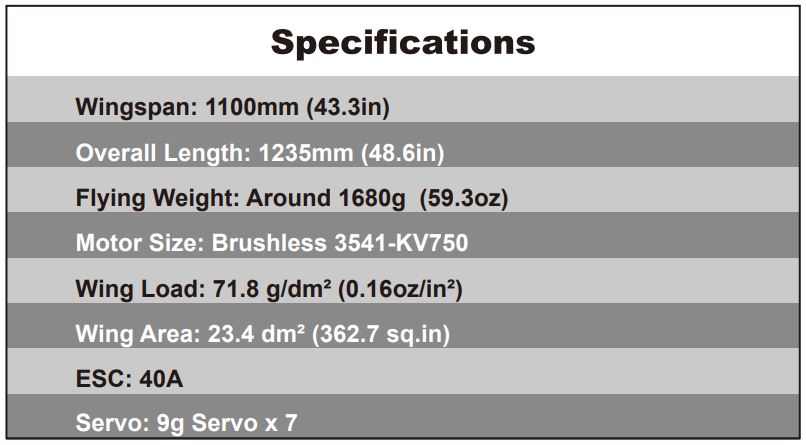

Quality GuaranteeReasonable price, great value: quality guaranteed. All electric parts, like ESC, motor, servos, of this airplane are from first-class suppliers. We offer a 365-day warranty service.

Contents of Kit

Contents of Kit

Before assembly, please inspect the contents of the kit. The photo below details the contents of the kit and labels. If any parts are missing or defective, please identify the name or part number (refer to the spare parts list near the end of the manual) then contact your local shop or email us: [email protected]

- A: Main wing

- B: Main fuselage

- C: Horizontal stabilizer (Left and Right)

- D: Horizontal stabilizer tube

- E: Spinner set

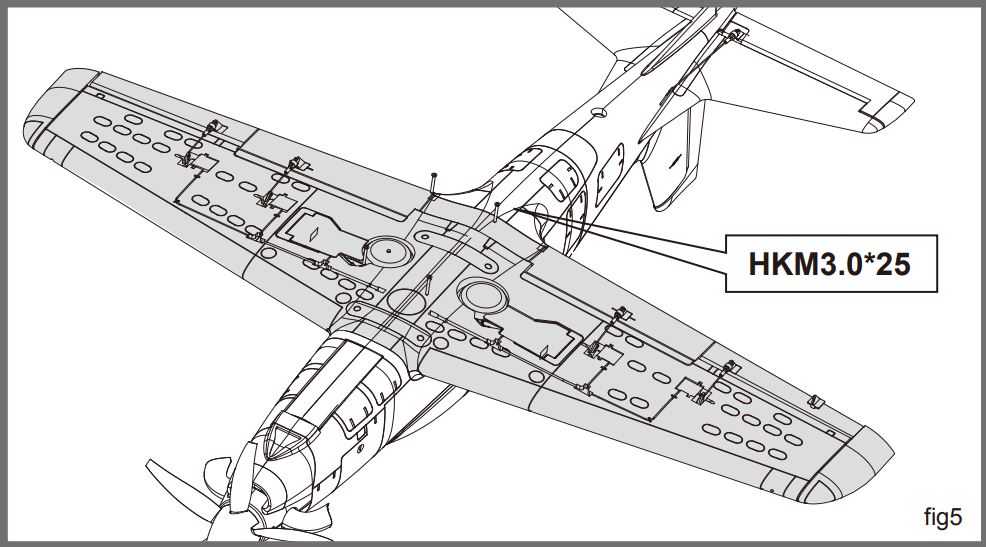

- F: Screws (4-PA2.6*10MM,5-HKM3.0*25MM)

- G: Propeller

Assemble the plane

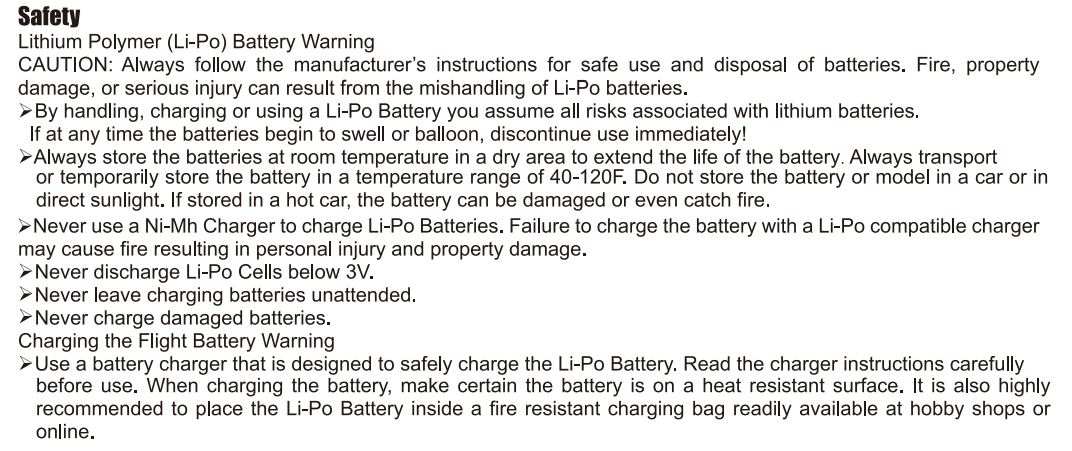

Horizontal Tail Installation1. Slide the horizontal tail into the slot in the rear of the fuselage. Ensure the control horn is face .

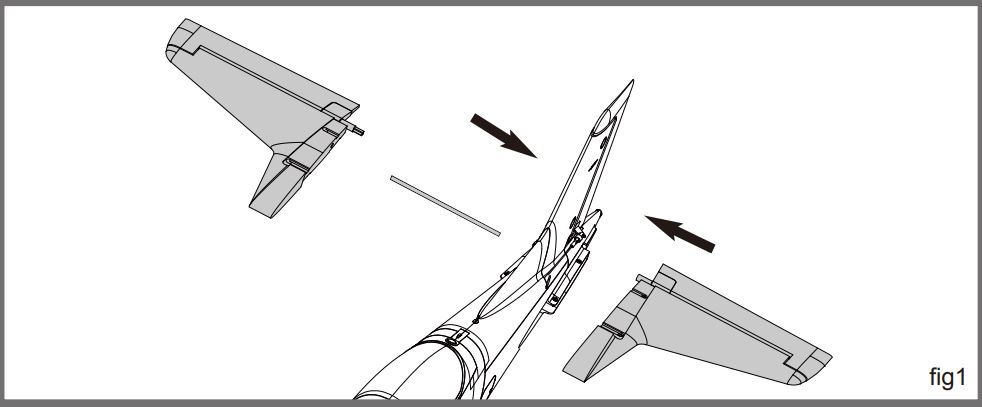

2. Secure the horizontal tail piece in place using the included screw: PA2.6*10. Use caution to avoid over tightening the screw.

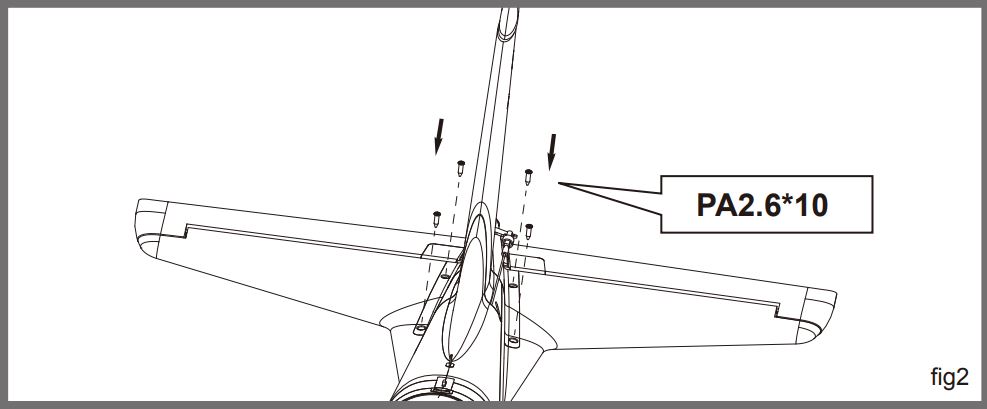

3. Using your radio center, the elevator servo and attach the control arm to the servo then attach the clevis to the elevator control horn. See instruction for clevis connection on page 11.

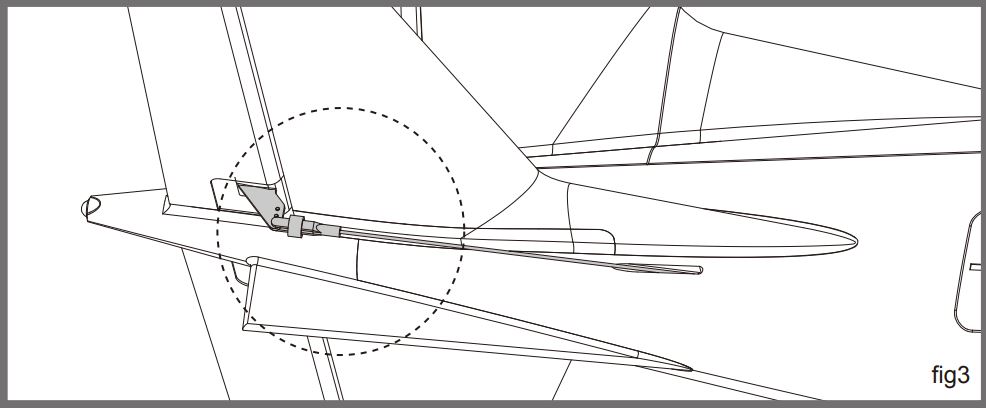

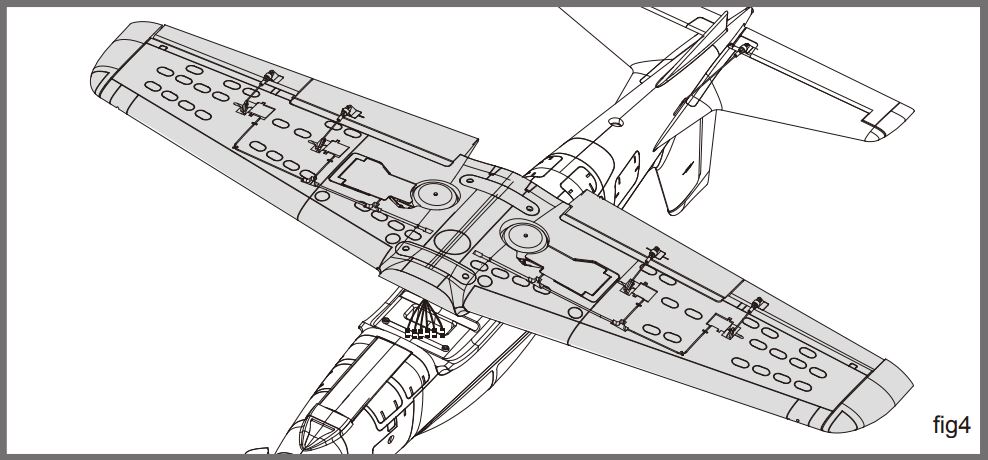

4. Install the winga. Remove the canopy hatchb. Guide the Multi Connector wires through the hole located in the bottom of the fuselage as shown.c. Align the wing with the fuselage and secure into position using screws HKM3.0*25mm as shown.

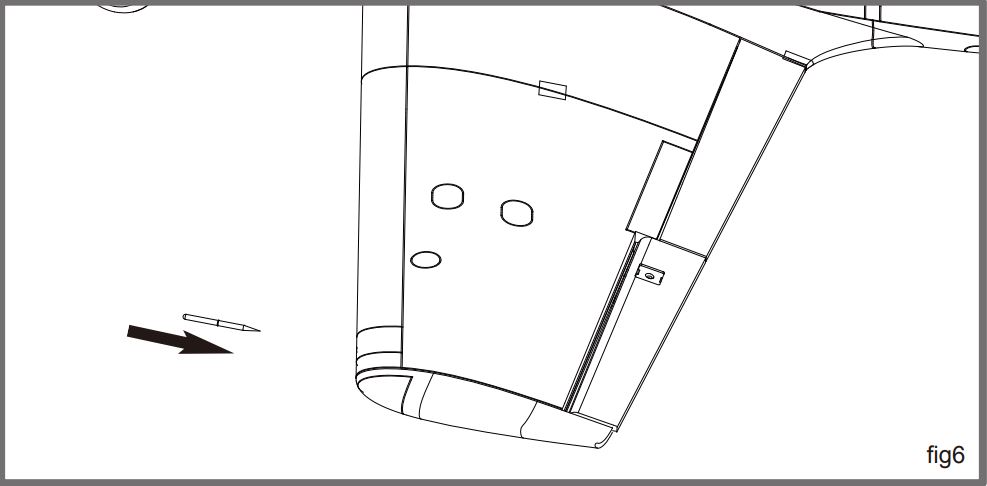

5. Glue the airspeed head and insert it into the wing as shown in Figure 6.

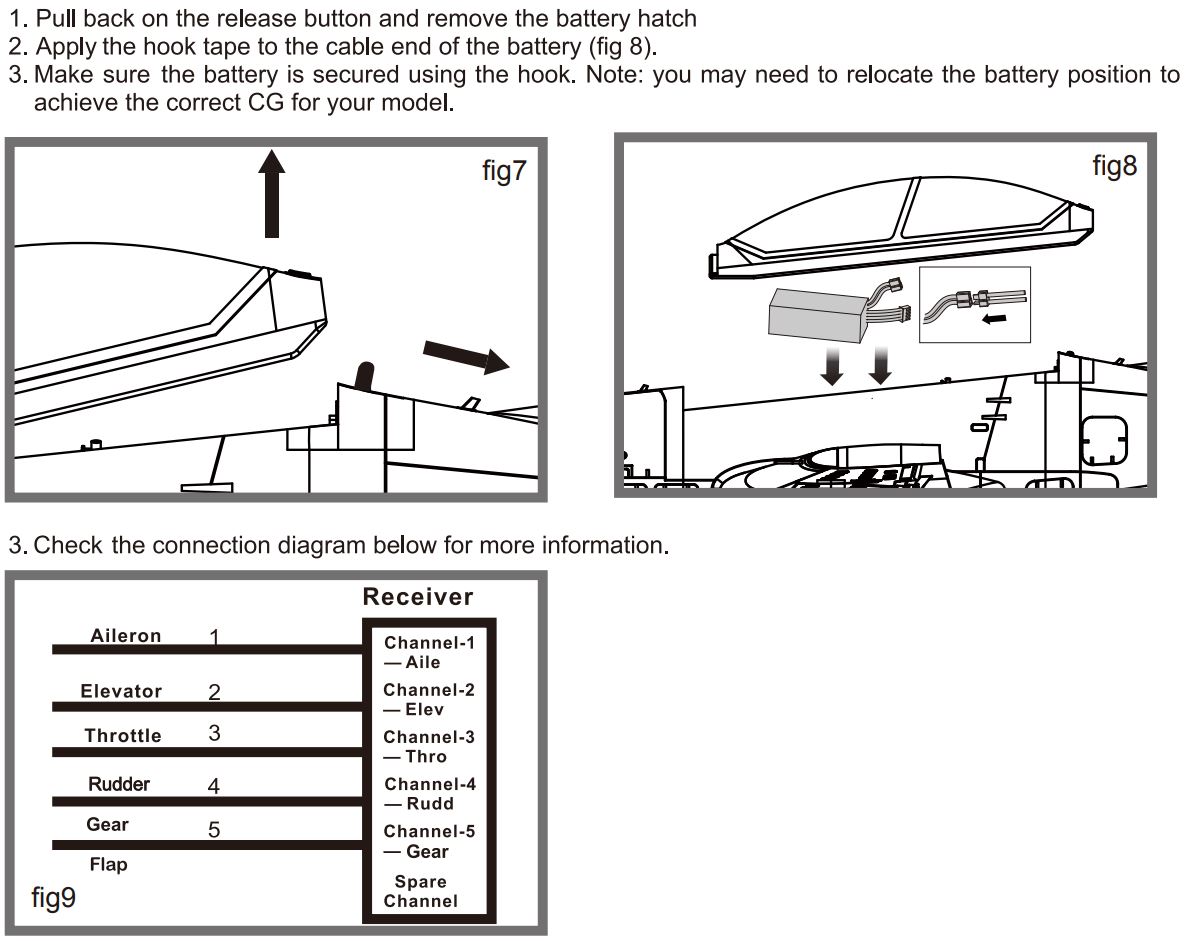

Battery and radio installation

Get your model ready to fly

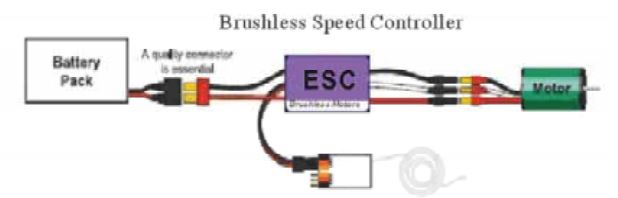

Important ESC and model information

- The ESC included with the model has a safe start. If the motor battery is connected to the ESC and the throttle stick is not in the low throttle or off position, the motor will not start until the throttle stick is moved to the low throttle or off position. Once the throttle stick is moved to the low throttle or off position, the motor will emit a series of beeps. Several beeps with the same tune means the ESC has detected the cells of the battery. The count of the beeps equals the cells of the battery. The motor is now armed and will start when the throttle is moved.

- The motor and ESC come pre-connected and the motor rotation should be correct. If for any reason the motor is rotating in the wrong direction, simply reverse two of the three motor wires to change the direction of rotation.

- The motor has an optional brake setting. The ESC comes with brake switched off and we recommend that the model be flown with the brake off. However, the brake could be accidentally switched on if the motor battery is connected to the ESC while the throttle stick is set at full throttle. To switch the brake off, move the throttle stick to full throttle and plug in the motor battery. The motor will beep one time. Move the throttle stick to low throttle or the off position. The motor is ready to run and the brake will be switched off.

- Battery Selection and Installation. We recommend the 14.8V 2600-3300mAh 35C Li-Po battery. If using another battery, the battery must be at least a 14.8V 2600-3300mAh 35C battery. Your battery should be approximately the same capacity, dimension and weight as the 14.8V 2600-3300mAh 35C Li-Po battery to fit the fuselage without changing the center of gravity significantly.

The transmitter and model setup

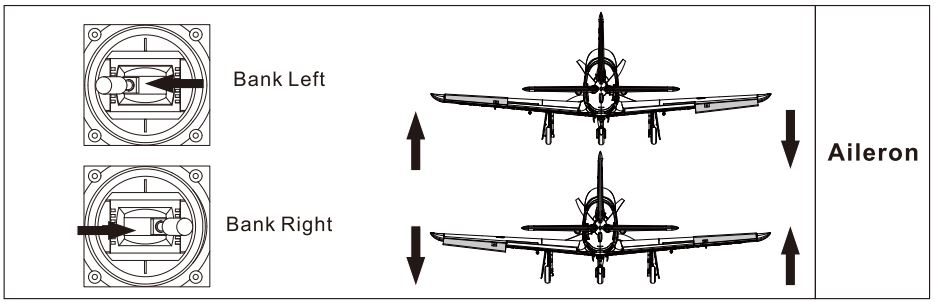

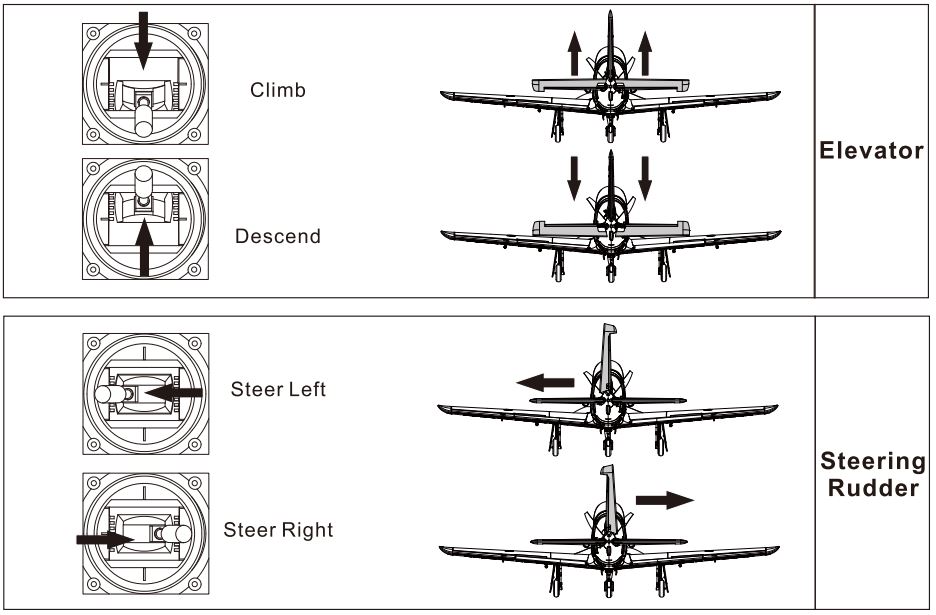

Before getting started, bind your receiver with your transmitter. Please refer to your Transmitter Manual for proper operationCAUTION: To prevent personal injury, DO NOT install the propeller assembly onto the motor shaft while testing the control surfaces. DO NOT arm the ESC and do not turn on the transmitter until the Transmitter Manual instructs you to do so. Tips: Make sure all control sticks on your radio are in the neutral position (rudder, elevator, ailerons) and the throttle is in the OFF position. Make sure both ailerons move up and down (travel) the same amount. This model tracks well when the left and right ailerons travel the same amount in response to the control stick.1. Move the controls on the transmitter to make sure the aircraft control surface moves correctly. See diagrams below.

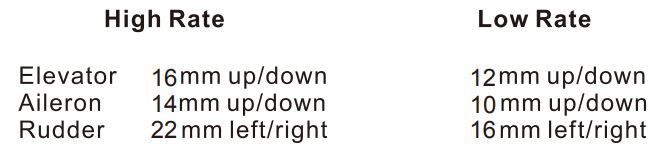

Check the control throws

The suggested control throw setting for FMS MODEL are as follows (dual rate setting):

Tips: At first flight, fly the model in low rate. The first time you use high rates, be sure to fly at low to medium speeds. High rate, as listed, are only for EXTREME maneuvering.

Check the motor rotating direction

The motor should rotate clockwise when viewing the plane from the rear.

Clevis Installation

a. Pull the tube from the clevis to the linkage.b. Carefully spread the clevis, then insert the clevis pin into the desired hole in the control horn.c. Move the tube to hold the clevis on the control horn.

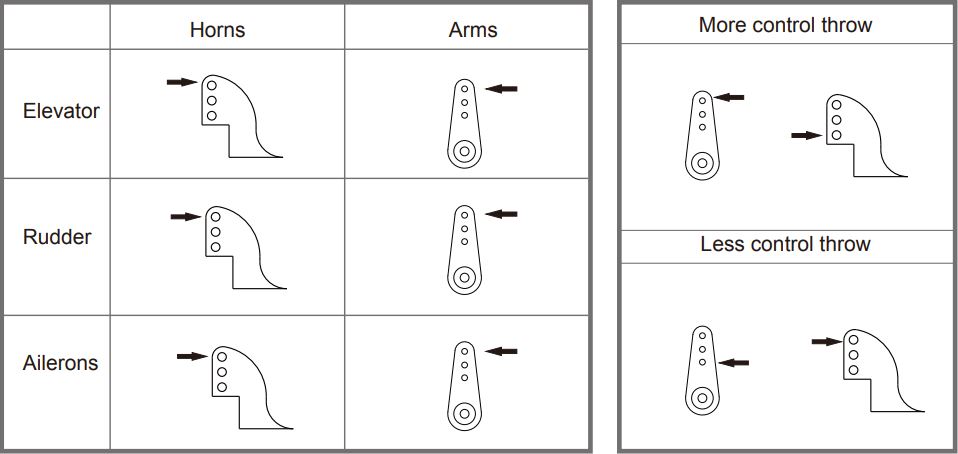

Control Horn and Servo Arm Settings

The table shows the factory settings for the control horns and servo arms. Fly the aircraft at the factory settings before making changes. After flying, you may choose to adjust the linkage positions for the desired control response. See the table to the below

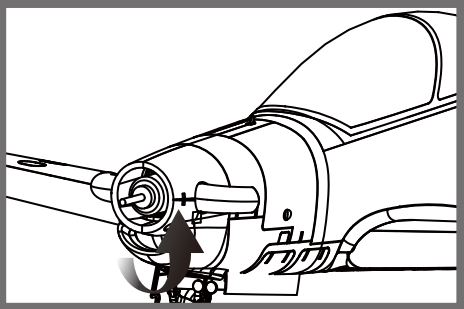

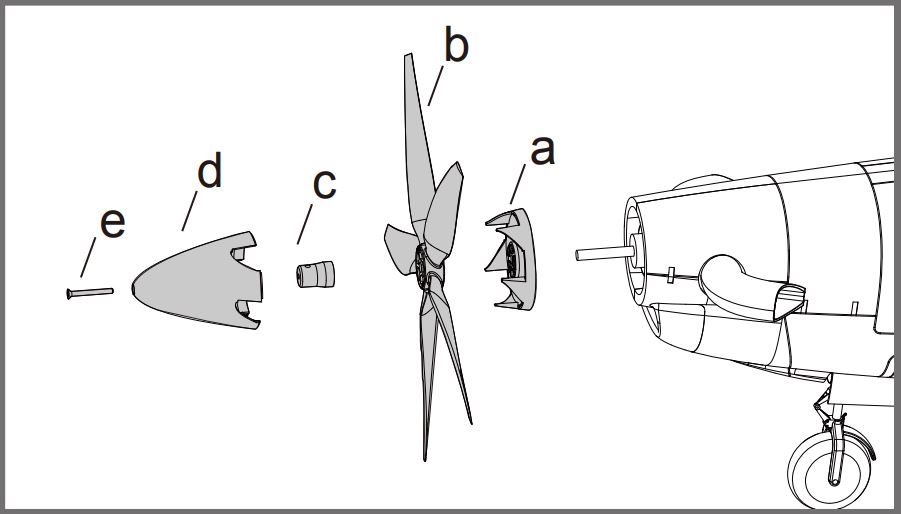

Install the propeller and spinner

Assemble the spinner and propeller as shown below.

Check the C.G. (Center of Gravity)

When balancing your model, adjust the motor battery as necessary so the model is level or slightly nose down. This is the correct balance point for your model. After the first flights, the CG position can be adjusted for your personal preference.

- The recommended Center of Gravity (CG) location for your model is (90-95mm) forward from the leading edge of the main wing (as shown) with the battery pack installed. Mark the location of the CG on top of the wing.

- When balancing your model, support the plane at the marks made on the bottom of the main wing with your fingers or a commercially available balancing stand. This is the correct balance point for your model. Make sure the model is assembled and ready for flight before balancing.

Before flying the model

Find a suitable flying siteFind a flying site clear of buildings, trees, power lines and other obstructions. Until you know how much area will be required and have mastered flying your plane in confined spaces, choose a site which is at least the size of two to three football fields – a flying field specifically for R/C planes is best. Never fly near people especially children, who can wander unpredictably.

Perform the range check for your planeAs a precaution, an operational ground range test should be performed before the first flight each time you go out. Performing a range test is a good way to detect problems that could cause loss of control such as low batteries, defective or damaged radio components, or radio interference. This usually requires an assistant and should be done at the actual flying site you will be using.First turn on the transmitter, then install a fully-charged battery into the fuselage. Connect the battery and install the hatch.Remember, use care not to bump the throttle stick. Otherwise, the propeller/fan will turn and possibly cause damage or injury.Note: Please refer to your Transmitter Manual that came with your radio control system to perform a ground range check. If the controls are not working correctly or if anything seems wrong, do not fly the model until you correct the problem. Make certain all the servo wires are securely connected to the receiver and the transmitter batteries have a good connection.

Monitor your flight timeMonitor and limit your flight time using a timer (such as on a wristwatch or in your transmitter if available). When the batteries are getting low you will usually notice a performance drop before the ESC cuts off motor power, so when the plane starts flying slower you should land. Often (but not always) power can be briefly restored after the motor cuts off by holding the throttle stick all the way down for a few seconds. To avoid an unexpected dead-stick landing on your first flight, set your timer to a conservative 4 minutes. When your alarm sounds you should land right away.

Flying course

Take offWhile applying power, slowly steer to keep the model straight. The model should accelerate quickly. As the model gains flight speed you will want to climb at a steady and even rate. PC-21 will climb out at a nice angle of attack (AOA).

FlyingAlways choose a wide-open space for flying your plane. It is ideal for you to fly at a sanctioned flying field. If you are not flying at an approved site always avoid flying near houses, trees, wires and buildings. You should also be careful to avoid flying in areas where there are many people, such as busy parks, schoolyards, or soccer fields. Consult laws and ordinances before choosing a location to fly your aircraft. After takeoff, gain some altitude. Climb to a safe height before trying technical maneuvers, including high speed passes, inverted flight, loops, and point rolls.

LandingLand the model when you hear the motor pulsing (LVC) or if you notice a reduction in power. If using a transmitter with a timer, set the timer so you have enough flight time to make several landing approaches. Recharge the battery and repair the model as needed .The model’s three point landing gear allows the model to land on hard surfaces. Align model directly into the wind and fly down to the ground. Fly the airplane down to the ground using 1/4-1/3 throttle to keep enough energy for proper flare. Before the model touches down, always fully decrease the throttle to avoid damaging the propeller or other components. The key to a great landing is to manage the power and elevator all the way to the ground and set down lightly on the main landing gear. After a few flights you will find the model can be set down lightly on the mains and you can hold the nose wheel off balancing the model on the mains until it slows and gently settles the nose.

MaintenanceRepairs to the foam should be made with foam safe adhesives such as hot glue, foam safe CA, and 5min epoxy. When parts are not repairable, see the Spare Parts List for ordering by item number. Always check to make sure all screws on the aircraft are tightened. Pay special attention to make sure the spinner is firmly in place before every flight.

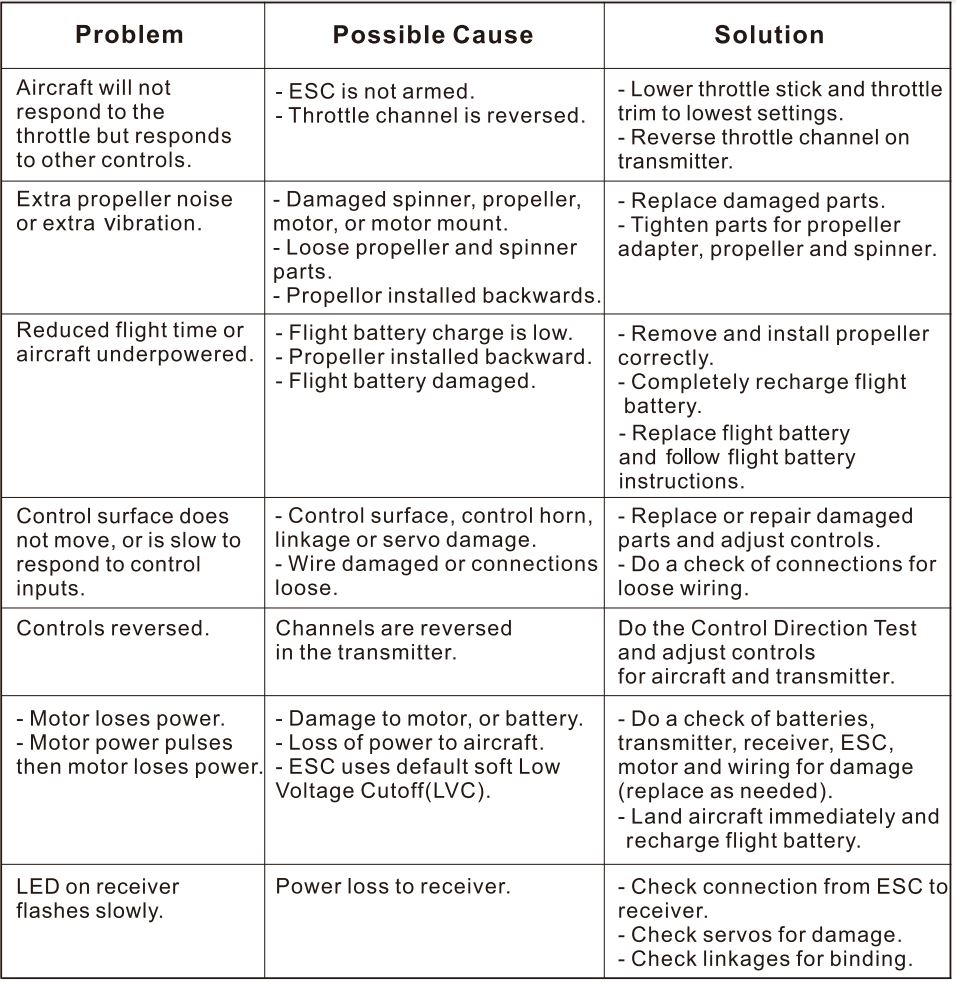

Troubleshooting

Spare parts list content

FMSPP101 — FuselageFMSPP102 — Main Wing SetFMSPP103 — Horizontal StabilizerFMSPP104 — CockpitFMSPP105 — SpinnerFMSPP106 — Air Speed HeadFMSPP107 — Exhaust pipeFMSPP108 — Landing Gear SetFMSPP109 — Main Landing Gear SystemFMSPP110 — Front Landing Gear SystemFMSPP111 — Linkage RodFMSPP112 — ScrewsFMSPP113 — PipeFMSPP114 — Decal SheetFMSPP115 — E-retractFMSPROP015 — PropellerFMSDJ015 — Motor MountFMSDZ022 — Motor ShaftFMSBM028 — Motor BoardFMSCON002 — Multi-connector SetFMSKV750 — MotorPRESC001 — 40A ESCFMSSER9GP — 9g Servo

Visit our website to see photos of this product: www.fmsmodel.com

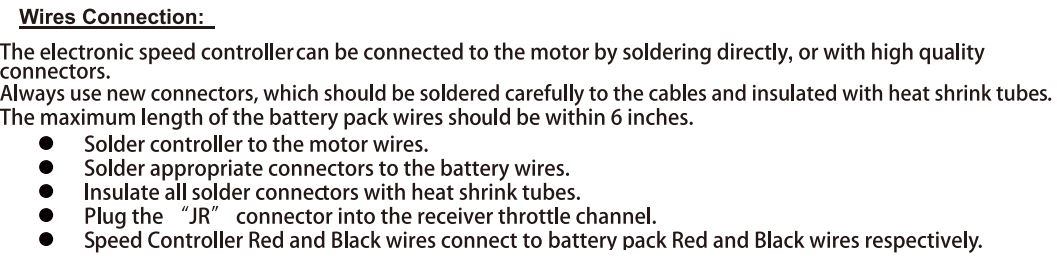

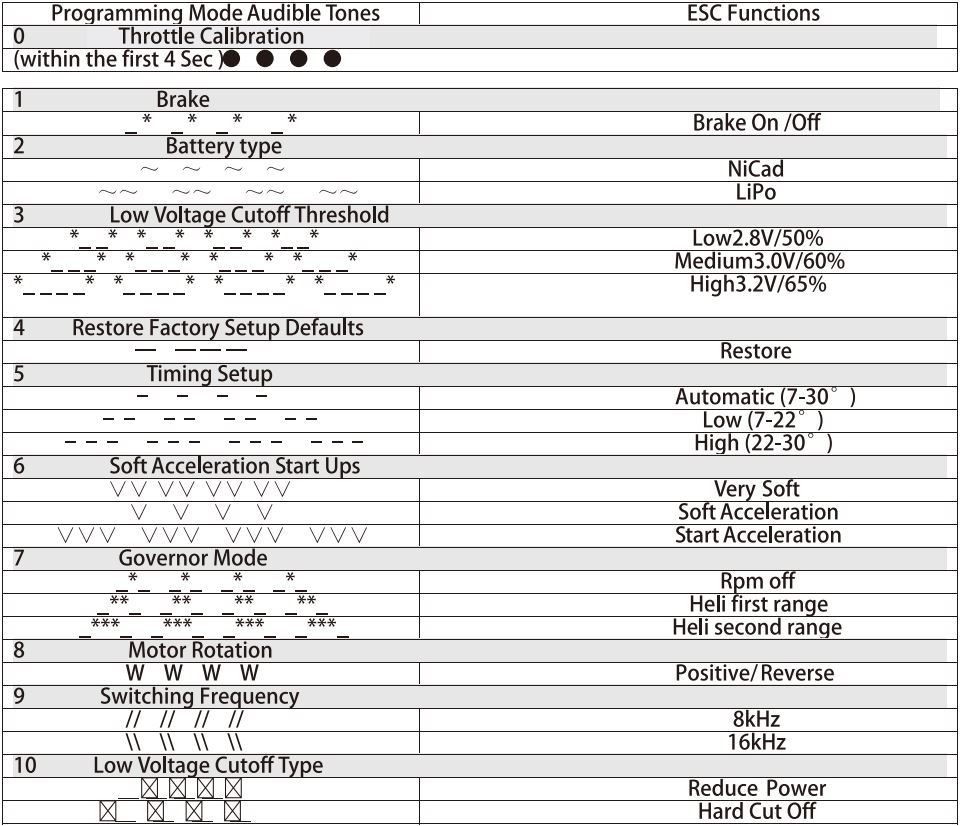

ESC instruction

Programming Mode Audible Tones

MADE IN CHINA

References

[xyz-ips snippet=”download-snippet”]

Contents of Kit

Contents of Kit