Instructions for use and installationCooker Hood

FDW 908 IB XS

RECOMMENDATIONS AND SUGGESTIONS

![]()

![]()

![]()

INSTALLATION

- The manufacturer will not be held liable for any damages resulting from incorrect or improper installation.

- Check that the mains voltage corresponds to that indicated on the rating plate fixed to the inside of the hood.

- For Class I appliances, check that the domestic power supply guarantees adequate earthing. Connect the extractor to the exhaust flue through a pipe of a minimum diameter 120 mm. The route of the flue must be as short as possible.

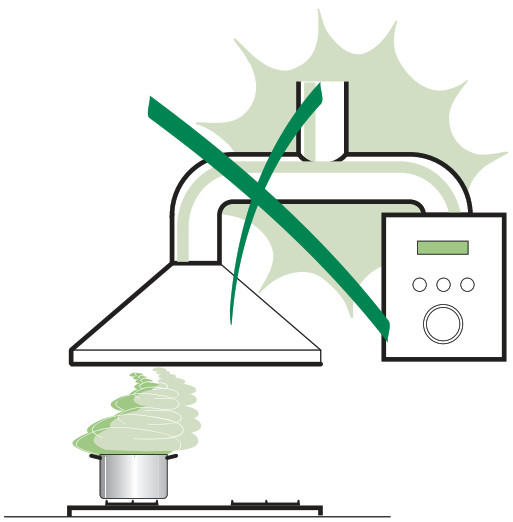

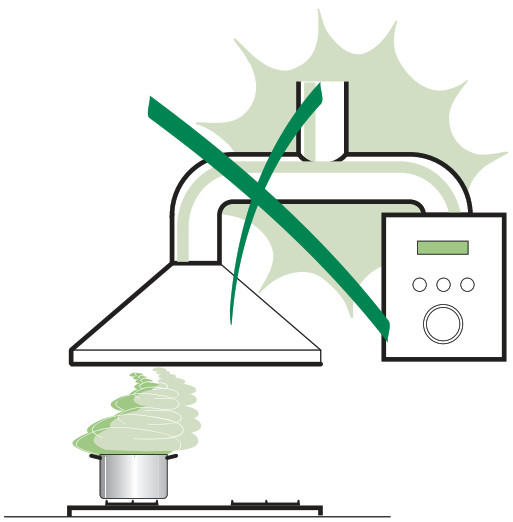

- Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces, etc.).

- If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a sufficient degree of aeration must be guaranteed in the room in order to prevent the backflow of exhaust gas. The kitchen must have an opening communicating directly with the open air in order to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances supplied with energy other than electricity, the negative pressure in the room must not exceed 0,04 m bar to prevent fumes being drawn back into the room by the cooker hood.

- In the event of damage to the power cable, it must be replaced by the manufacturer or by the technical service department, in order to prevent any risks.

- All air ducting regulations must be complied with.

USE

- The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

- Never use the hood for purposes other than for which it has been designed.

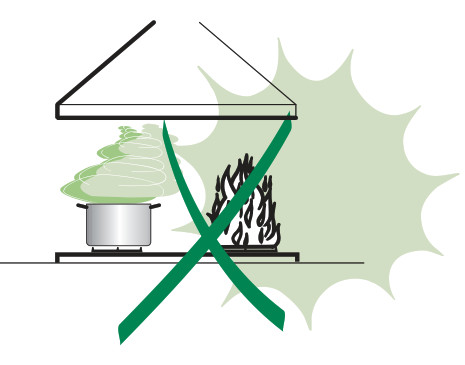

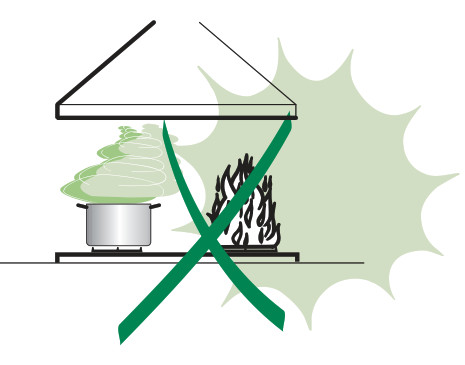

- Never leave high naked flames under the hood when it is in operation.

- Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not engulf the sides.

- Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

- Do not flambè under the range hood; risk of fire

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

- “ CAUTION: Accessible parts may become hot when used with cooking appliances.”.

MAINTENANCE

- Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

- Clean and/or replace the Filters after the specified time period (Fire hazard).

- Clean the hood using a damp cloth and a neutral liquid detergent.

The symbol ![]()

![]()

CHARACTERISTICS

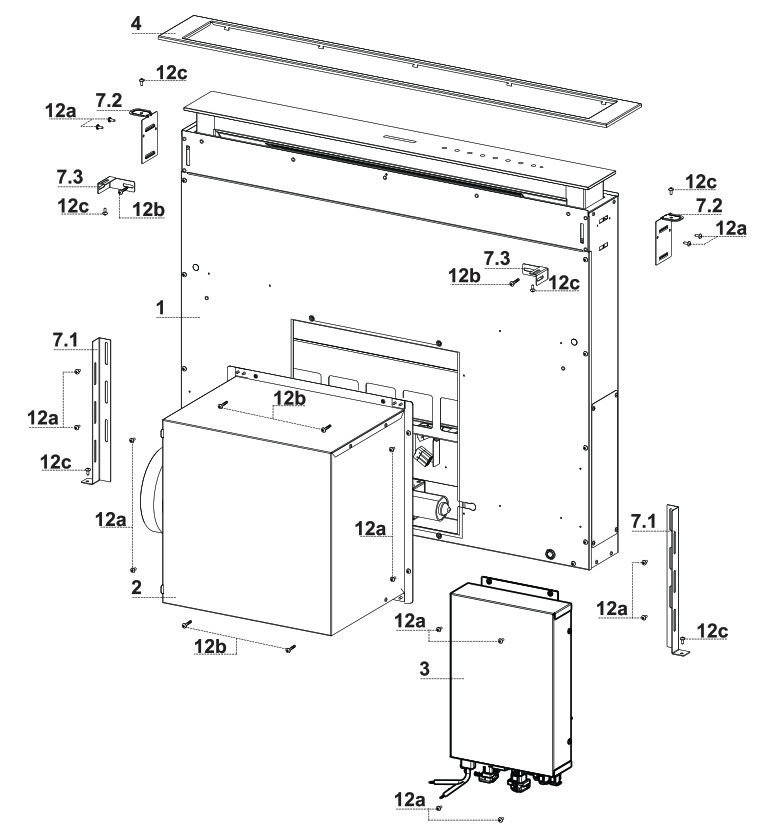

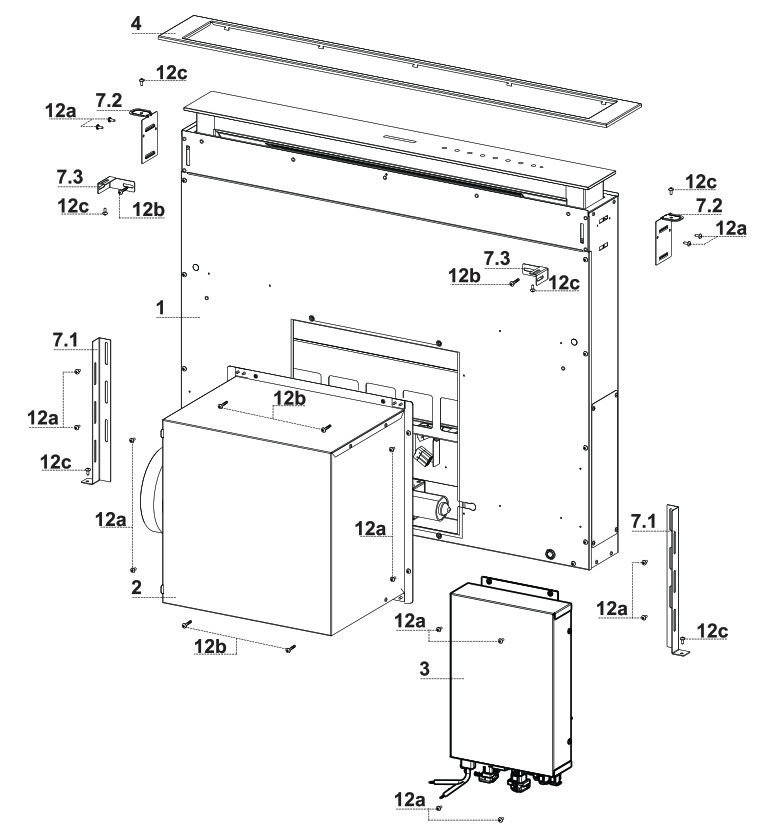

Components

| Ref. | Q.ty | Product Components |

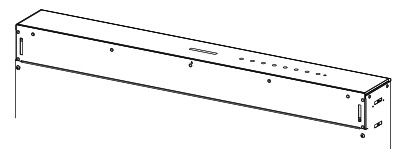

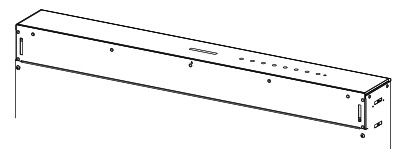

| 1 | 1 | Hood Canopy complete with: Controls, Light, Filters |

| 2 | 1 | Motor unit |

| 3 | 1 | Electric unit |

| 4 | 1 | Front Frame |

| Ref. | Q.ty | Installation Components |

| 7.1 | 2 | Splashback Fixing Bracket |

| 7.2 | 2 | Hob Fixing Bracket |

| 7.3 | 2 | 2 Side Bracket |

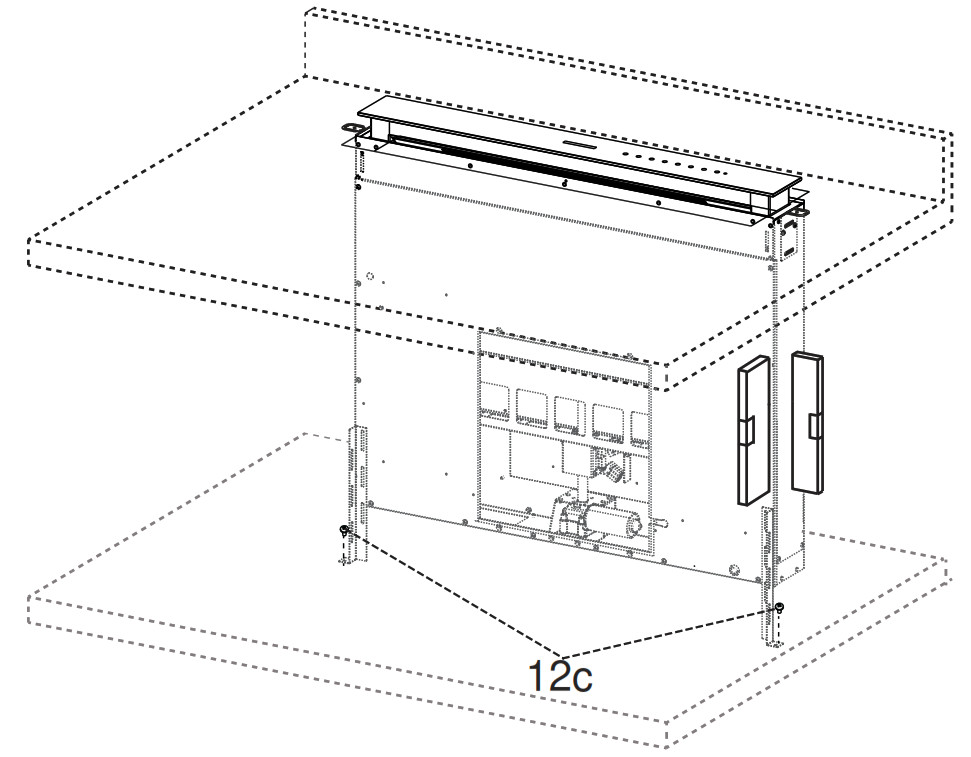

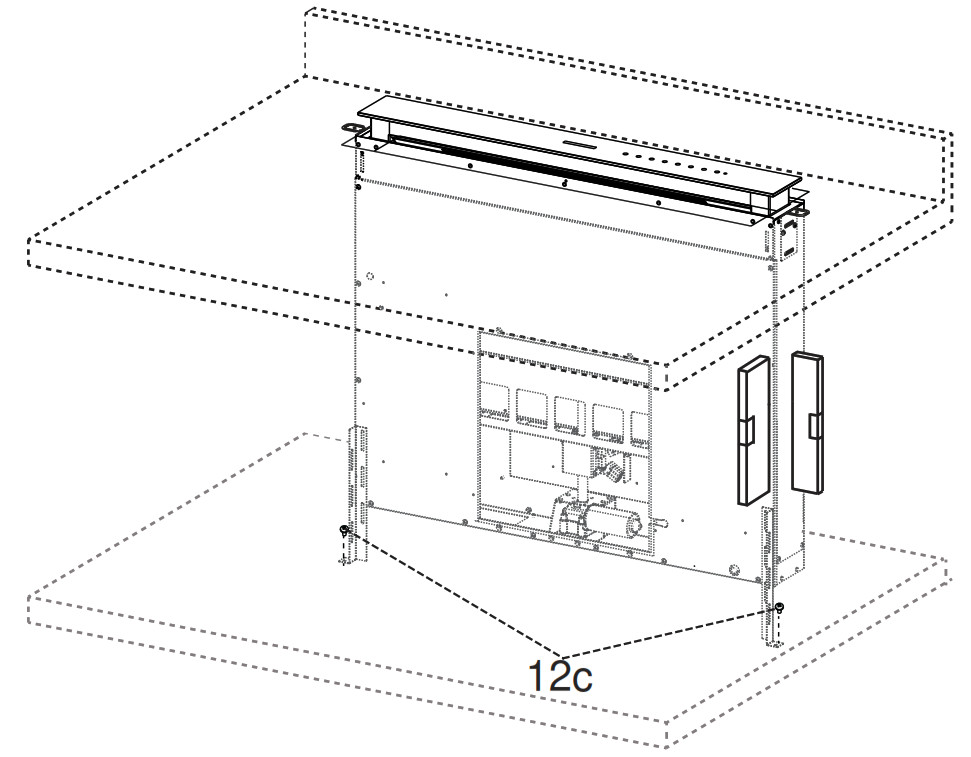

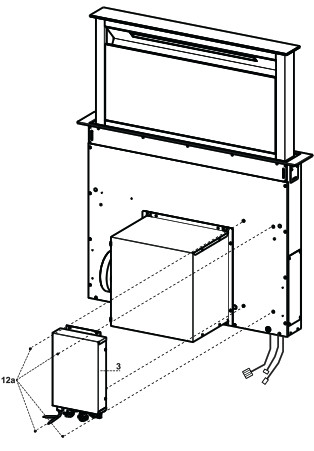

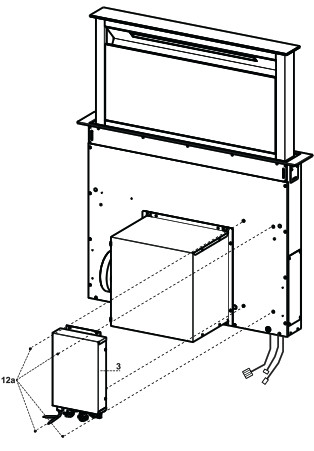

| 12a | 16 | Screws 3.5 x 9.5 |

| 12b | 6 | Screws M4 x 8 |

| 12c | 6 | Screws 4 x 15 |

| Q.ty | Documentation | |

| 1 | Instruction Manual |

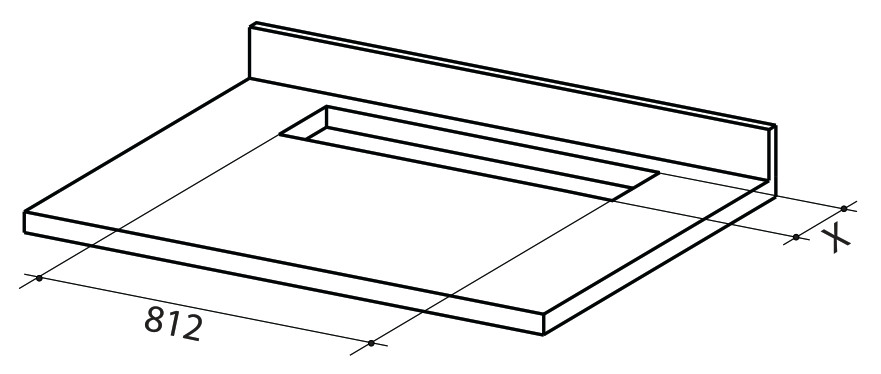

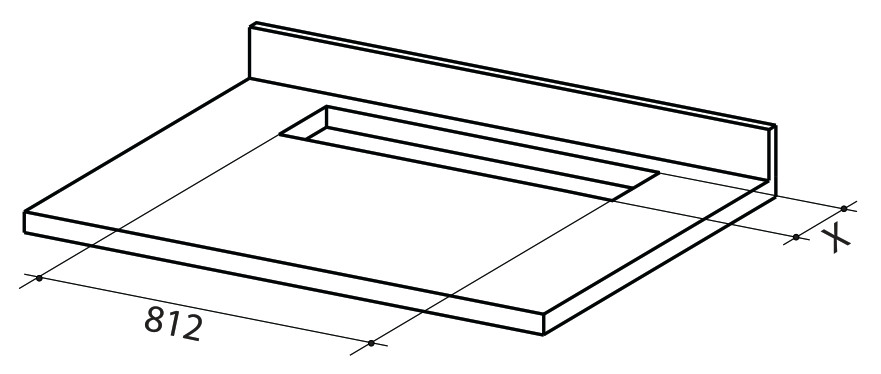

Dimensions

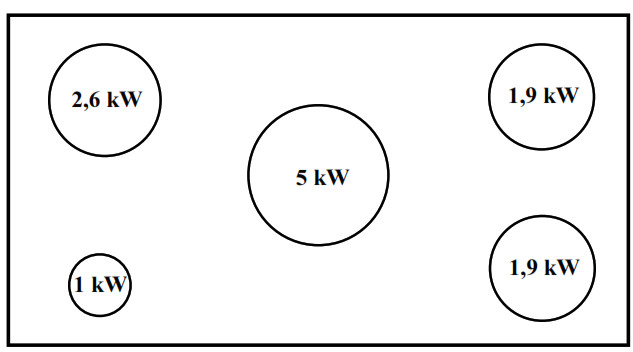

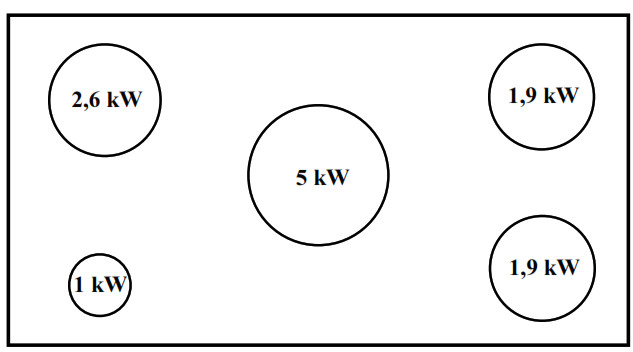

This Cooker hood can be used in conjunction with a Gas Cook Top having the following characteristics:

- Maximum power 12,4 kW

- 5 fire like the picture

INSTALLATION

This Hood is set up to be fitted inside the kitchen unit in:

- Ducting version: Evacuation to the outside.

- Recirculation version: Internal recirculation.

Sequence of operations – Installation

- Drilling the Support Surface and Fitting the Hood

- Connections

- Functional Check

- Disposal of Packaging

Drilling the Support Surface

WarningOnce the Support surface has been drilled the Hood Canopy can be installed in two ways:

- By inserting the Hood Canopy from below ( X = 106 mm ).

- By inserting the Hood Canopy from above ( X = 113 mm ).

ImportantThe minimum distance between the opening for the hob and the one for the hood must be of at least 3-5 cm according to the strength of the material used for the working top.

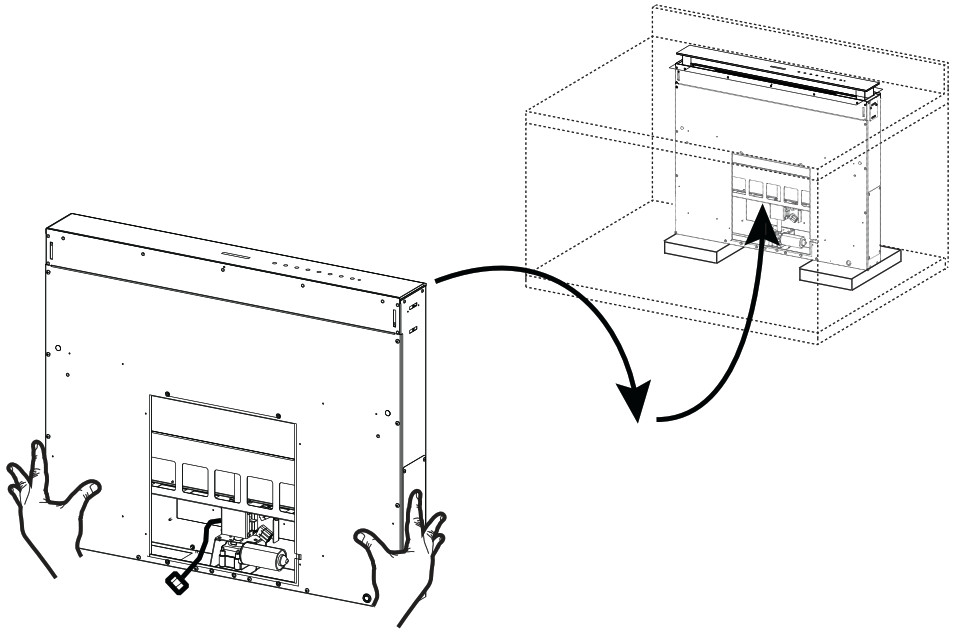

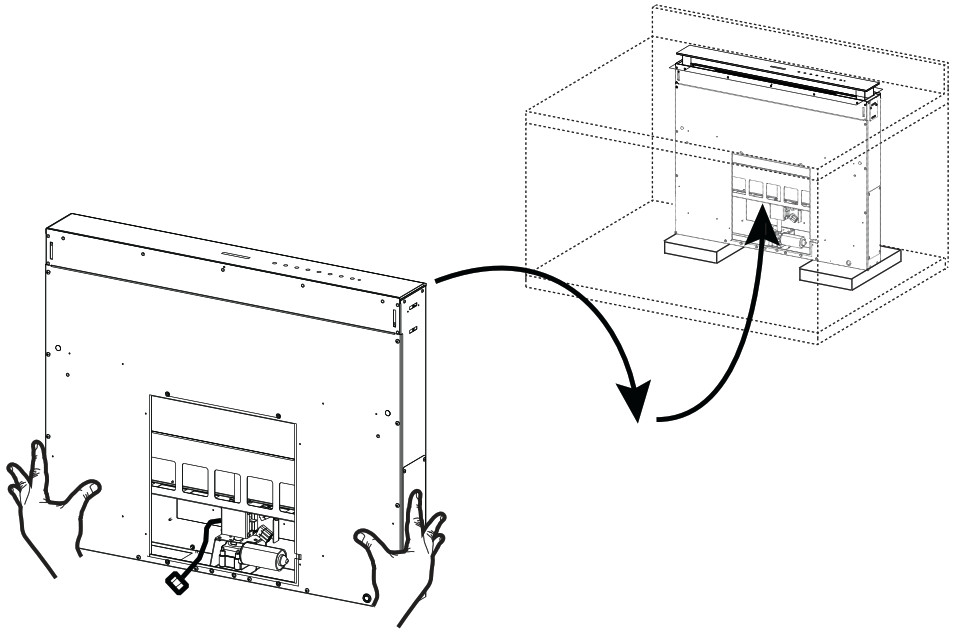

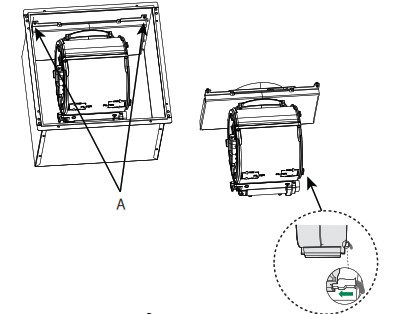

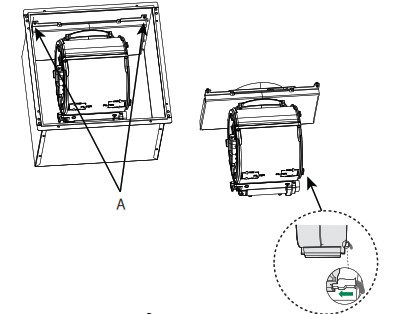

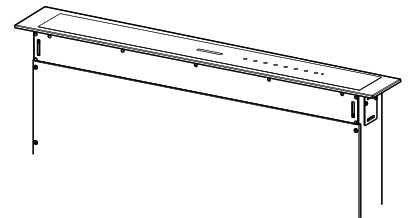

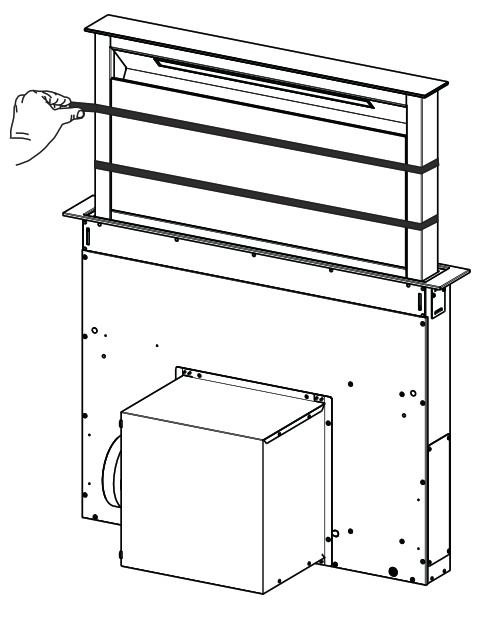

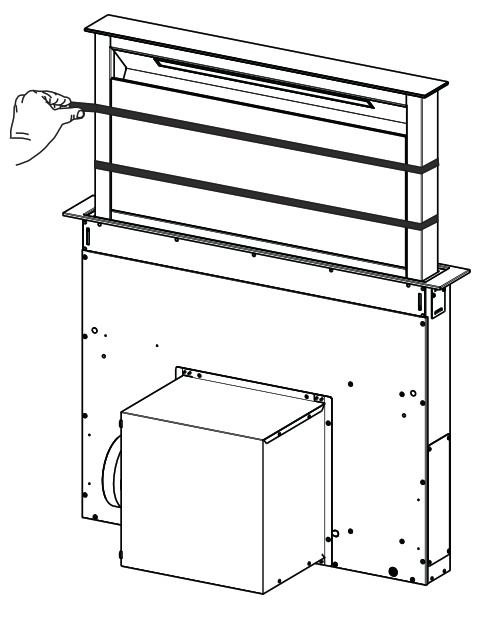

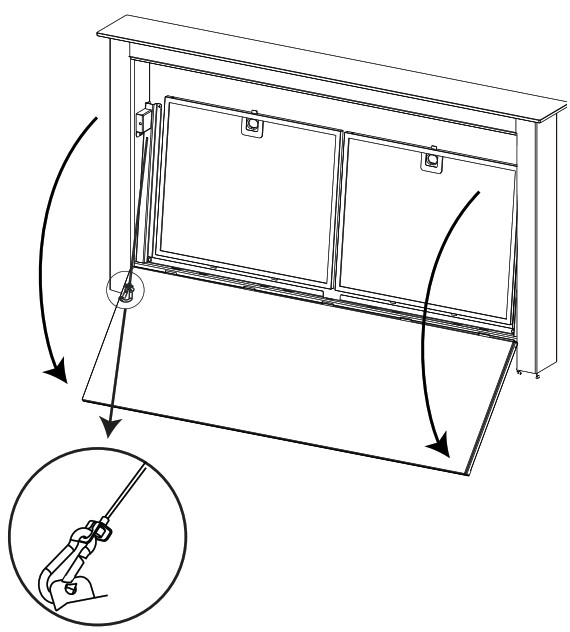

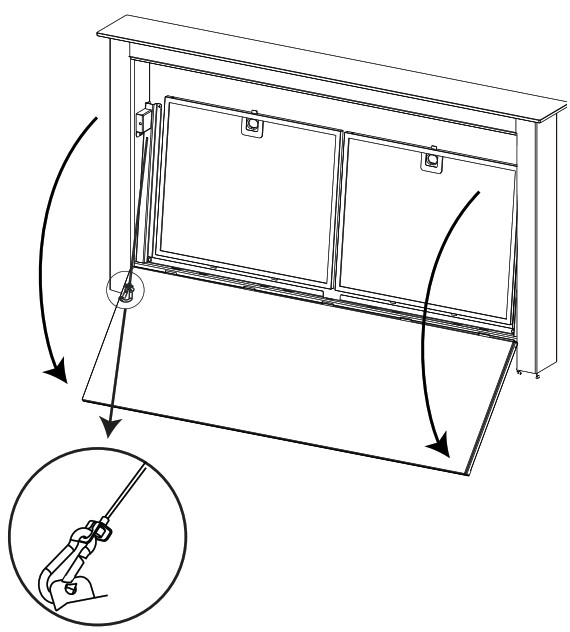

Inserting the Hood Canopy into the support surface from below

- The Hood is built ready for front installation of the Motor Unit.

- If the kitchen unit is arranged differently and the Motor Unit has to be fitted on the back, the Plug already fitted on the back of the Hood Canopy must be removed and replaced at the front, and the Cable with cable raceway for connection of the Motor must also be repositioned using the slot provided on each side (A). Before proceeding, the Motor Unit must be fixed to the Hood Canopy (see paragraph on Fixing the Motor Unit).

- Insert the Hood Canopy from below into the support worktop, drilled as described above.

- With the aid of a support, lift the Hood Canopy until the front comes out of the Worktop.

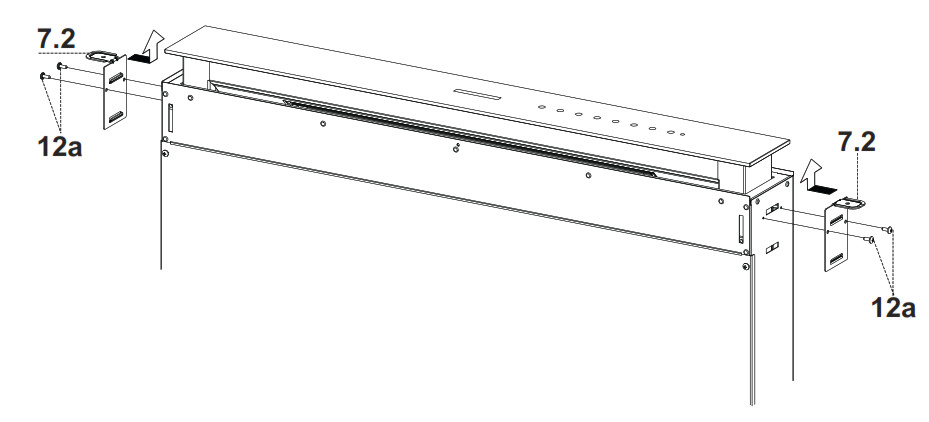

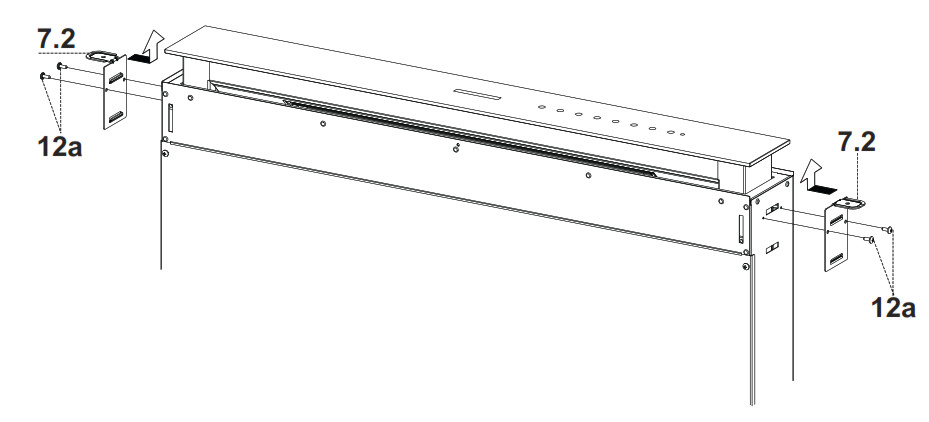

- Insert the Brackets 7.2, as indicated in the figure, into the slots provided and fix them with the screws 12a provided.

- Centre the Hood Canopy with respect to the Cooking Hob slot.

- Using the 2 screws 12c provided, fix the Hood Canopy to the worktop and remove the supports.

Warning:If the cooker top is made from a material that does not allow the screws 12c to be inserted, use a small amount of silicone to glue the Brackets 7.2 to the top and allow it to dry completely before proceeding with installation.

- Insert the Brackets 7.2, as indicated in the figure, into the slots provided and fix them with the screws 12a provided.

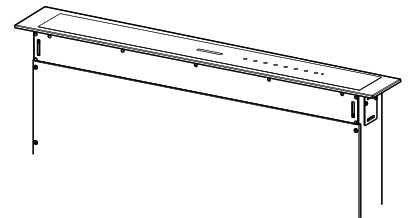

- The Hood is built ready for front installation of the Motor Unit.

- If the kitchen unit is arranged differently and the Motor Unit has to be fitted on the back, the Plug already fitted on the back of the Hood Canopy must be removed and replaced at the front, and the Cable with cable raceway for connection of the Motor must also be repositioned using the slot provided on each side (A).

- Insert the Hood Canopy into the cooker top, drilled as described above.

- Centre the Hood Canopy with respect to the Cooking Hob slot.

- Fix the Hood Canopy with the 2 screws 12c provided.

Warning:If the cooker top is made from a material that does not allow the screws 12c to be inserted, use a small amount of silicone to glue the Brackets 7.2 to the top and allow it to dry completely before proceeding with installation.

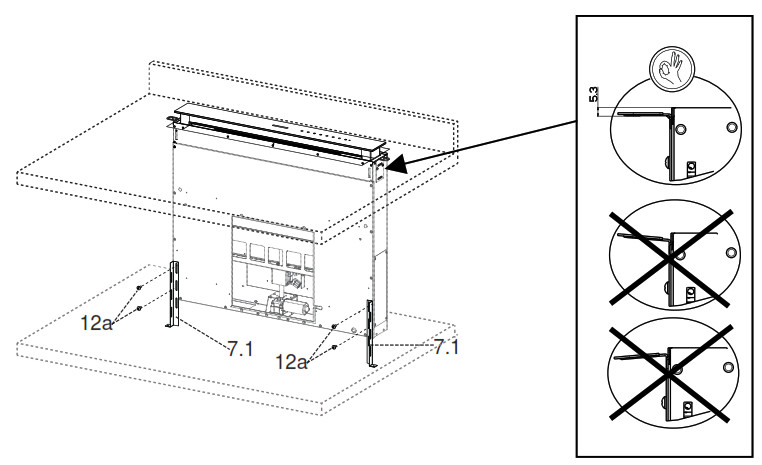

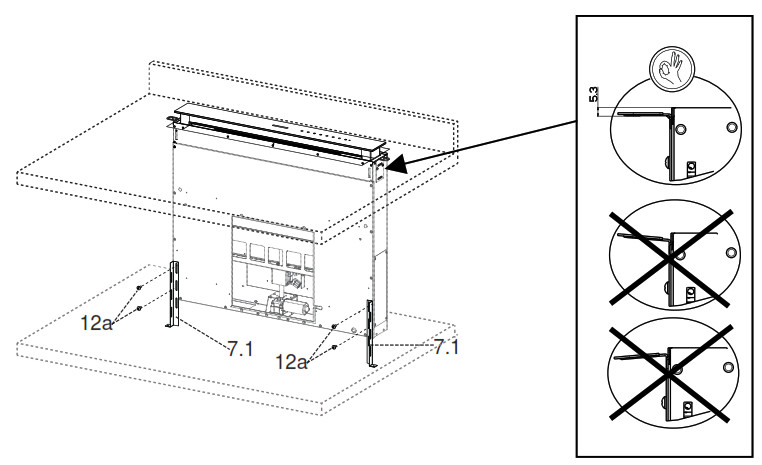

Fixing the Lower Brackets

- Screw the brackets 7.1 to the front of the Hood Canopy using the screws 12a provided.

- Before tightening the Brackets completely, make all the adjustments to allow them to rest on the lower base of the worktop to avoid deformation of the upper brackets 7.2 as shown in the figure.

- With the aid of a spirit level, set the Hood Canopy level vertically and fix it to the Lower Surface using 2 screws 12c provided.

- Tighten the screws 12a completely.

- Screw the brackets 7.3 to the Hood Canopy using the screws 12b provided, without tightening completely.

- Using the screws 12c provided, fasten the other part of the brackets 7.3 either to the side walls of the unit or to the lower part of the cooker top.

- Tighten the screws 12c and 12b completely.

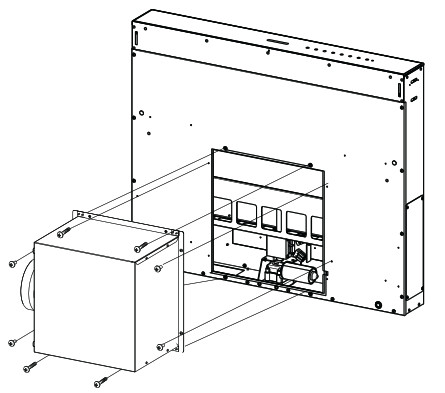

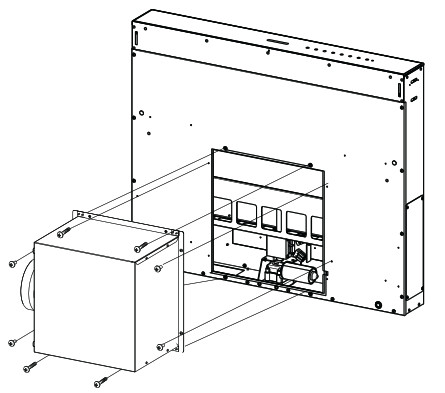

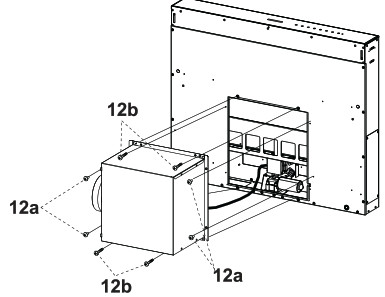

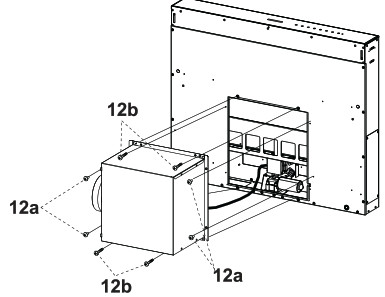

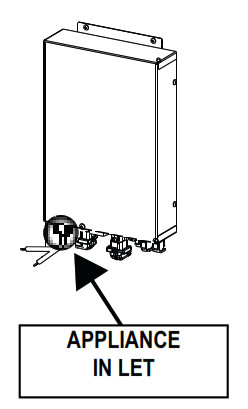

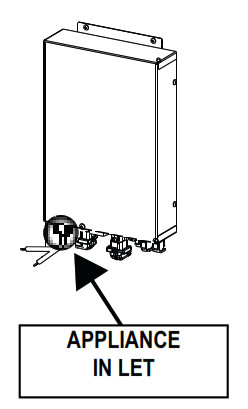

Fixing the Motor Unit

- Installation of the Motor Unit (1) at the front or rear must be decided according to the position of the Kitchen unit, making sure that the plug is properly positioned.

- Subsequently, according to where the air outlet opening has been created on the unit, the Motor Unit can be turned by 90° at a time so as to allow the air to come out on all 4 sides in correspondence with the opening in Unit (2).

- Remove the Motor Unit from the support by unfastening the 2 screws (A).

- Connect the connector from the Hood Canopy to the Motor Unit connection.

- Replace the Motor Unit in the support using the 2 screws removed as described above.

- Screw the Motor Unit to the Hood Canopy using the screws 12a and 12b provided as shown in the figure.

- Connect the Electric cables that come out of the lower right-hand part of the Hood Canopy to the Connectors on the Electric unit.

- Each cable connector has a corresponding connector on the Electric Unit, so take care not to make mistakes when connecting up.

- Fix the Electric Unit to the Hood Canopy using the screws 12a provided.

- The position indicated in the figure is only an option, as if necessary it may also be fitted on the left of the Hood Canopy or even left free on the base of the unit if there are no structural or safety problems involved.

![]()

![]()

![]()

Connections

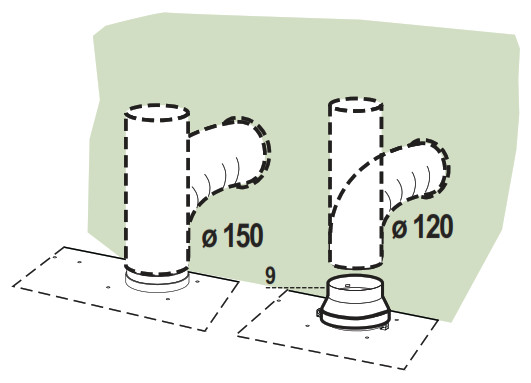

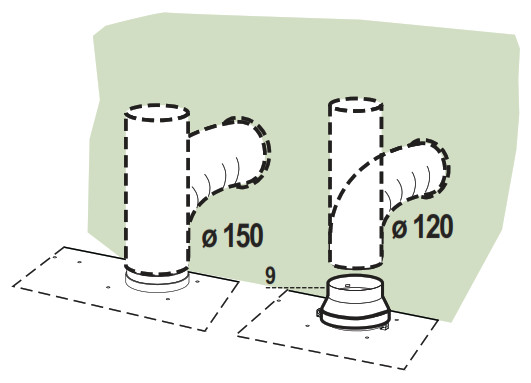

DUCTED VERSION AIR EXHAUST SYSTEMWhen installing the ducted version, connect the hood to the chimney using either a flexible or rigid pipe ø 150 or 120 mm, the choice of which is left to the installer.

- To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the hood body outlet.

- Fix the pipe in position using sufficient pipe clamps (not supplied).

- Remove any activated charcoal filters.

AIR OUTLET – RECIRCULATION VERSION

- Connect the Flange to the air outlet opening using a rigid or flexible pipe of ø120 or 150 mm.

- To connect using a ø120 mm pipe, insert the reduction Flange 9 onto the Hood canopy outlet.

- Fasten the pipe using suitable pipe clamps. The materials required to do so are not provided.

- Fix the directional Grid 8 on the outlet, using 2 screws 12e (2.9 x 9.5) provided.

- Make sure that the activated charcoal filters are present (see paragraph on Activated Charcoal Filter Maintenance).

ELECTRICAL CONNECTION

- Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm..

Fitting the Front element

- Lift the mobile hood canopy (see paragraph on Use) by just a few centimetres.

- To stop movement, simply press down on the mobile canopy as it lifts up.

Warning: Never block the sliding door when it is opening or closing, except during the operations required to fit the frame.

- Remove the sponge guards from the corners of the glass.

- Take the front Frame and insert it from above, making sure that its tabs insert into the slots provided on the Hood and sliding it to the left.

Warning..: All the tabs must be inserted.

- Use a tool (hammer) to tap all along the front Frame from right to left until it is completely flush.A piece of wood or similar element can be inserted between the hammer and the front Frame to prevent any damage.

- Please refer to the paragraph on Use for indications of how to return the mobile canopy to the Standard position.

Surround Suction Panel

- Open the Hood Door (see USE).

- Remove the 2 strips of adhesive tape fastening the panel during transport.

USE

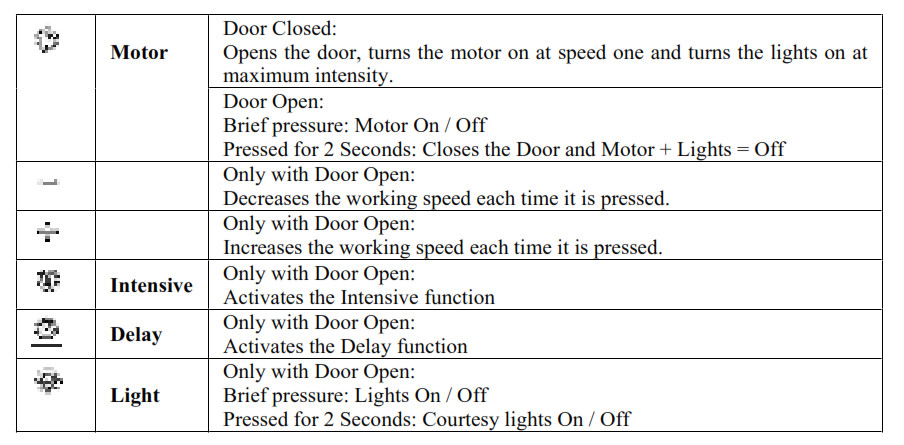

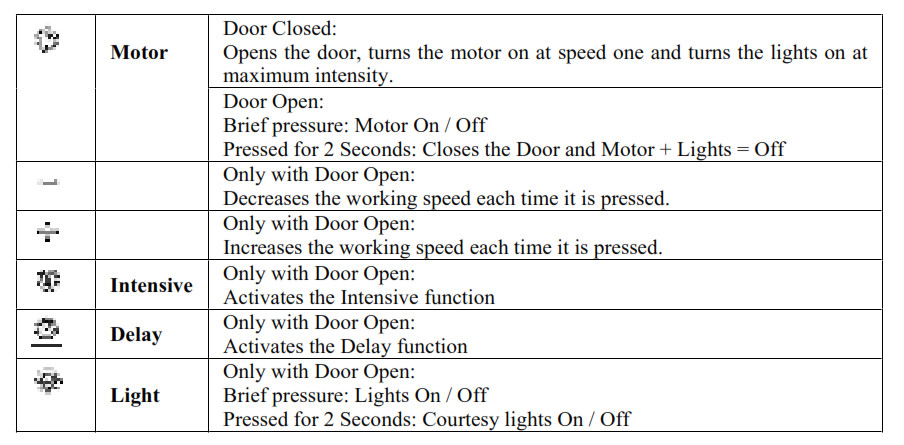

Control panel

| Button | Function | LED button |

| A | The button only works when the door is open. | |

| Press Briefly = Turns the Lights On/Off at maximum intensity. | ||

| Press and hold for 2 Seconds = Turns the Courtesy Lights On/Off. | ||

| B | Door Open or ClosedPress briefly = Pe foam a Reset of the Filter saturation alarm. | After 100 hours in operation the Drop symbol isdisplayed to indicate saturation of the MetalGrease Filters.After 200 hours in operation the letter C is displayed to indicate saturation of the Activated Charcoal filters. |

| Door Open or ClosedPress and hold for 2 Seconds = Enables/Disables the Activated Charcoal Filter Alarm with the Motor turned off and no Filter Alarm triggered. | Symbol C flashes twice = A.C. Filter Alarm Activated Symbol C flashes once = A.C. Filter Alarm Deactivated | |

| C | Door Open.Press briefly = Activates/Deactivates Delay mode, causing automatic shutdown of the Motor and the Lighting system from any speed with a 30′ delay. It is disabled by pressing the same button again, turning the motor off or closing the door. | Displays the Clock symbol. |

| Works both with Door Closed and Open with Motor + Lights = Off.Press and hold for 4 Seconds = Enables/disables the Keyboard lock. | All the LED buttons flash twice. During the Lock the LEDs light up in sequence. | |

| D | Only works with the Door Open.Press briefly = Enables/Disables Intensive speed. This speed is timed to run for 10 minutes. At the end of this time the system will return to the speed set previously.It is disabled by pressing the same button again, turning the motor off or closing the door. | Displays the symbol I. |

| E | Only works with the Door Open = increases the operating speed. | The number of lighted segments increases. |

| F | Only works with the Door Open = decreases the operating speed. | The number of lighted segments decreases. |

| G | Only works with the Door Open. Press briefly = Turns the Motor off | LEDs go out |

| Door Open or ClosedPress and hold for 2 Seconds with Motor and Lights Off = Enables/Disables the Remote control. | LED buttons flash twice = Remote control EnabledLED buttons flash once = Remote control Disabled | |

| H | Door Open = Closes the Door + Lights and Motor Off Door Closed = Opens the Door + Lights and Motor On. Warning: If the Door remains partially open for any reason, press the Button to complete the opening or closing cycle. |

REMOTE CONTROL (OPTIONAL)The appliance can be controlled using a remote control powered by a 1.5 V carbon-zinc alkaline batteries of the standard LR03-AAA type (not included).

- Do not place the remote control near to heat sources.

- Used batteries must be disposed of in the proper manner.

Remote control panel

Warning..: The remote control receiver is deactivated when first supplied. To activate it, see the paragraph Use Function of Button G.

MAINTENANCE

Cleaning the Comfort Panels

- Open the Comfort Panel by pulling it at the top.

- Unhook the security chain by opening the spring catch.

- Disconnect the panel from the hood canopy.

- The comfort panel must never be washed in the dishwasher.

- Clean the outside with a damp cloth and neutral detergent.

- Clean the inside using a damp cloth and neutral detergent; do not use wet cloths or sponges, or jets of water; do not use abrasive substances.

- On completing the operation, hook the panel and the spring catch up to the hood canopy again and close it.

Metal grease filtersThese can also be washed in the dishwasher, and need to be cleaned whenever the “drop” symbol lights up or at least once every 2 months use, or more frequently if use is particularly intensive.Resetting the alarm signal

- Turn the Lights and the Suction Motor off.

- Press button B (see paragraph on Use).

Cleaning the Filters

- Open the Door (see USE).

- Open the Comfort panel by pulling it.

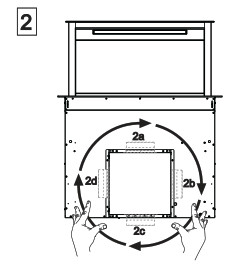

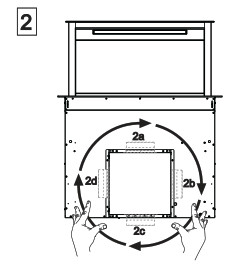

- Remove the Filters one at a time, pushing them towards the back of the unit and at the same time pulling downward.

- Wash the Filters without bending them, and leave them to dry completely before replacing. (If the surface of the filter changes colour as time goes by, this will have absolutely no effect on the efficiency of the filter itself.)

- Replace, taking care to ensure that the handle faces forwards.

- Close the Comfort panel.

Activated Charcoal Filter (Recirculation Version)

Can be washed in the dishwasher. It must be washed when button “C” lights up or at least once every 4 months, or more frequently if use is particularly intense. Guaranteed to operate after washing for up to a maximum of 5 times before requiring replacement. The Alarm signal, if it has been activated, only appears when the Suction motor is turned on.

Activating the alarm signal

- In Recirculation Version Hoods, the Filter Saturation Alarm must be activated on installation or at a later date.

- Turn the Lights and the Suction Motor off.

- Press and hold button B for 2 seconds:

- Symbol “C” flashes twice – Activated Charcoal Filter saturation alarm ACTIVATED.

- Symbol “C” flashes once – Activated Charcoal Filter saturation alarm DEACTIVATED.

CHANGING THE ACTIVATED CHARCOAL FILTERResetting the alarm signal

- Turn the Lights and the Suction Motor off.

- Press button B (see paragraph on Use).

Changing the Filter

- Remove the comfort panel.

- Remove the Metal grease filters.

- Remove the metal filter stops from the grease filter and clean the saturated activated charcoal odour filter.

- Replace the clean activated charcoal filter, hooking it back up to the grease filter using the metal filter stops.

- Replace the Metal grease filters.

- Close the comfort panel.

Lighting unit

Warning: This appliance is fitted with a white LED lamp classed as 1M according to EN 60825-1: 1994 + A1:2002 + A2:2001 standards; maximum optical power emitted @439nm: 7µW. Do not look directly at the light through optical devices (binoculars, magnifying glasses…).

- For replacement contact technical support. (“To purchase contact technical support”)

Franke S.p.a.Via Pignolini,237019 Peschiera del Garda (VR)www.franke.it991.0266.342_ver 4

References

[xyz-ips snippet=”download-snippet”]