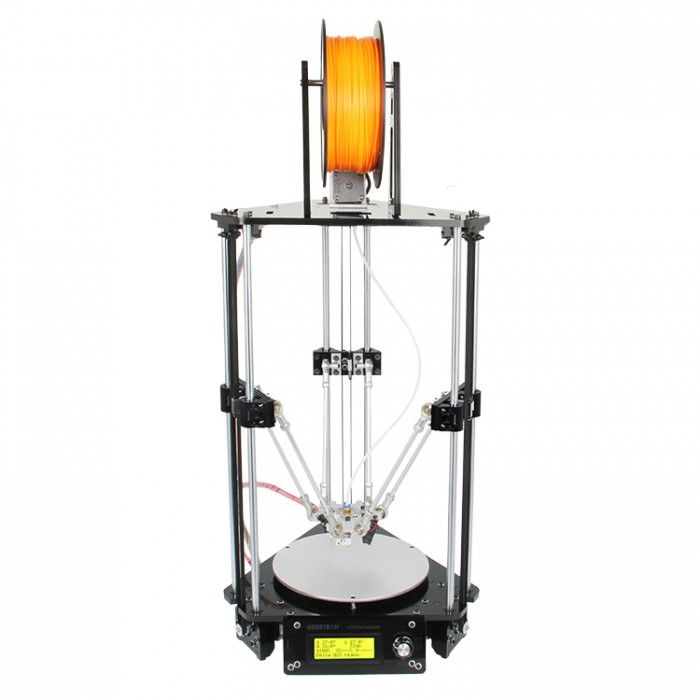

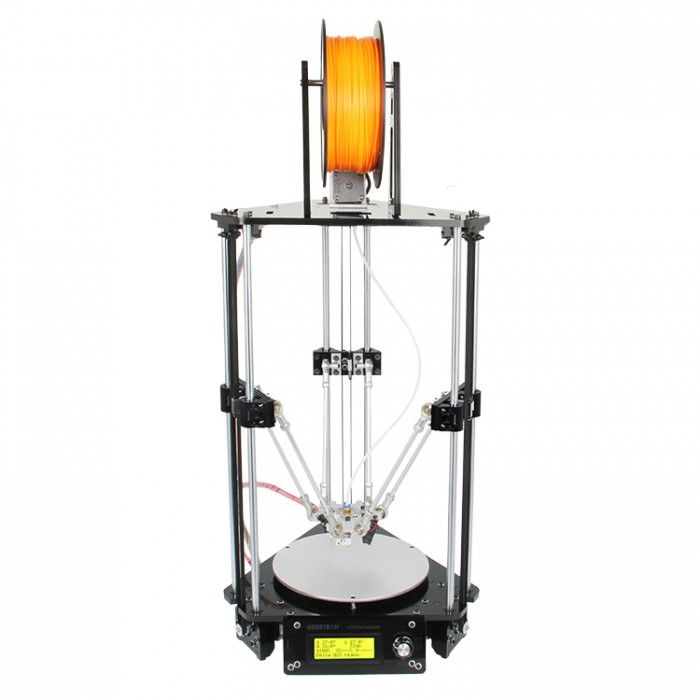

GEEETECH Delta Rostock mini G2 Pro 3D Printer

SUPPROT

Thanks for choosing Geeetech, we strive to provide a satisfied and pleasant shopping experience for you, but we do understand there may be some questions you may encounter in using our product. If so, you can contact us directly or post on our forum, our technique staff will help you resolve it. For more detailed information, please visit Geeetech website.

For detailed instructions, please download here: https://goo.gl/GuP4Sg

For detailed building videos, please check at YouTube: https://goo.gl/5etsos

Subscribe our YouTube channel for more videos. https://www.youtube.com/user/geeetech

Join our geeetech 3D printer user club. https://goo.gl/GhJbe3

Feel free to drop a line at [email protected] .

Copyright Declaration

The copyright of this manual belongs to the Shenzhen GETECH CO., LTD. (hereinafter referred to as the “Geeetech”), and all rights reserved. No part of this specification should be reproduced or extracted in any forms or means without the prior written consent of Geeetech by any company and individuals.

For More Geeetech Products

If you are interested in the technology of 3 D printing, flight control and U-home, welcome to Geeetech, we have series of made-up products, main boards, modules and a variety of peripherals for you. Or if you are looking for relevant information or technical support, please log in our Forum where you can find anything you want about open source. To know more about our new products, please visit www.geeetech.com , we will serve you wholeheartedly.

SAFETY INSTRUCTIONS

Building the printer will require a certain amount of physical dexterity, common sense and a thorough understanding of what you are doing. We have provided detailed instructions to help you assemble it easily, please download at geeetech.com

However ultimately we cannot be responsible for your health and safety whilst building or operating the printer, with that in mind be sure you are confident with what you are doing prior to commencing with building or buying. Read the entire manual to enable you to make an informed decision.

Building and operating involves electricity, so all necessary precautions should be taken and adhered to, the printer runs on 12V supplied by a certified power supply, so you shouldn’t ever have to get involved with anything over 12V but bear in mind there can still be high currents involved and even at 12V they shouldn’t be taken lightly.

High temperatures are involved with 3D Printing, the Extrusion nozzle of the hot end can run about 230°C, the heated bed runs 110°C

and the molten plastic extruded will initially be at around 200°C, so special care and attention should be made when handling these parts of the printer during operation.

We wouldn’t recommend leaving your printer running unattended, or at least until you are confident to do so. We cannot be held responsible for any loss, damage, threat, hurt or other negligent result from either building or using the printer.

INTRODUCTION:

This Rostock mini G2 pro is a upgraded delta 3D printer redesigned by Geeetech.

Compared to its predecessor, this G2 pro has two major merits, it looks cooler and it works better.

The printing effector of the G2 pro is upgraded with metal parts, which are more durable and stable than the prints. The whole machine is craft out of high-quality aluminum and laser cut acrylic plate, making it more stable and smooth when printing, improving the printing accuracy and speed to a higher level.

An metal auto-leveling device is also improved on G2 pro; which means you do not have to adjust it every time before you start printing, and with this new metal leveling device, the calibration will be more accurate.

PACKAGE LIST:

This list includes all the parts required to assemble your Delta Rostock mini G2 pro 3D Printer. After you received your package, please check if all the parts listed are included. Also make sure all the components are in good condition and not damaged during shipping. If anything is missing please contact with our customer service straight away, provide us the NO. , Name, and Qty.

Mechanical parts |

||||

|

No |

Name |

Specifications |

Qty |

Pic |

|

1 |

Smooth Rod |

D10 L500mm |

6 |

|

|

2 |

Spool |

D8 L120mm |

1 |

|

|

3 |

Rod-end bearing holder |

D6.5 23mm |

12 |

|

|

4 |

Diagonal Rod |

With rod-end bearing |

6 |

|

|

5 |

M3 Washers |

M3 |

101 |

|

|

6 |

M4 Washers |

M4 |

15 |

|

|

7 |

M5 Washers |

M5 |

4 |

|

|

8 |

M8 Washers |

M8 |

12 |

|

|

9 |

Nut |

M2.5 |

6 |

|

|

10 |

Nut |

M3 |

8 |

|

|

10A |

Nut |

M5 |

24 |

|

|

11 |

Lock nut |

M4 |

3 |

|

|

12 |

Wing nut |

M3 |

6 |

|

|

13 |

Square nut |

M3 |

27 |

|

|

14 |

Hex Counter- sunk-head screw |

M3x30 mm |

3 |

|

|

15 |

Round head screw with pad |

M3 x 8 mm |

12 |

|

|

16 |

Screw |

M2.5x8mm |

2 |

|

|

17 |

Screw |

M2.5x16mm |

8 |

|

|

18 |

Screw |

M3x8mm |

18 |

|

|

19 |

Screw |

M3x12mm |

32 |

|

|

20 |

Screw |

M3x16mm |

32 |

|

|

21 |

Screw |

M3x20mm |

2 |

|

22 |

Screw |

M3x25mm |

8 |

|

|

23 |

Screw |

M3x40mm |

3 |

|

|

24 |

Screw |

M4x8mm |

12 |

|

|

24A |

Screw |

M4x12mm |

4 |

|

|

25 |

Screw |

M4x16mm |

2 |

|

|

26 |

Screw |

M4x25mm |

3 |

|

|

27 |

Screw |

M5x16 |

12 |

|

|

27A |

Screw |

M5x20 |

12 |

|

|

28 |

Spring |

4.0x 20(for heat bed) |

3 |

|

|

29 |

Spring |

3.5*30(for endstop trigger) |

4 |

|

|

30 |

locking ring |

M8 With Jimmy bolt |

1 |

|

|

31 |

Ball Bearing |

MR84zz(Placed in No.32) |

6 |

|

|

32 |

Driven wheel |

3 |

|

|

|

33 |

Driven wheel holder |

Sheet metal part |

3 |

|

|

34 |

Pulley |

20 tooth |

3 |

|

|

35 |

Linear Bearing |

PCS10UU |

6 |

|

|

36 |

Timing Belts |

2GT L=1200mm |

3 |

|

|

37 |

Spacer |

With Aircraft type end |

8 |

|

|

38 |

Nylon ties |

20 |

|

|

|

39 |

Feeding pipe |

PTFE L=600mm |

1 |

|

|

40 |

Spiral Coil |

3 meters |

1 |

|

|

41 |

Sticker |

2 |

|

|

|

42 |

Heat sink |

9*10*5mm |

4 |

|

|

43 |

Probe |

Φ3 L60mm |

1 |

|

|

Electronic parts |

||||

|

44 |

End stop |

2-pin Blue–1pcs, Red 2pcs Black-1pcs |

4 |

|

|

45 |

Fan |

40x40x10mm |

1 |

|

|

46 |

Extension wire |

3Pin Male-3Pin Female |

1 |

|

|

47 |

Fan |

30x30x10mm (with 1200mm extend wire) |

1 |

|

|

48 |

Knob |

For LCD control |

1 |

|

|

49 |

LCD 2004 |

LCD2004+ cable |

1 |

|

|

50 |

Control board kit |

GT2560+4 A4988 |

1 set |

|

|

51 |

USB cord |

A-BA |

1 |

|

|

52 |

Thermometr y wire |

2pin(pasted on heatbed) |

1 |

|

|

53 |

Heating Wire |

30cm(soldere d on heatbed) |

2 |

|

|

54 |

Heatbed |

Round |

1 |

|

|

55 |

Stepper motor |

Nema 17 |

3 |

|

|

56 |

Extruder |

1 |

|

|

57 |

Hotend |

MK8 hotend |

1 |

|

|

58 |

Power Supply Unit |

AC Input: 115V/1.5A 230V/0.75A |

1 |

|

|

DC Output: 12V/0-15A |

||||

|

59 |

3D printer Power Cable |

With plug |

1 |

|

|

60 |

Power Cable |

Connect board to PSU |

1 |

|

Acrylic parts

|

A1 |

Top plate |

RK-01 |

1 |

|

|

A2 |

Base plate |

RK-02 |

1 |

|

|

A3 |

Motor holder |

RK-03 |

3 |

|

|

A4 |

Motor holder support |

RK-04 |

6 |

|

|

A5 |

Drive wheel mount |

RK-05 |

3 |

|

|

A6 |

Endstop mount |

RK-06 |

3 |

|

|

A7 |

Fan mount |

RK-07 |

1 |

|

|

A8 |

LCD frame |

RK-08 |

1 |

|

|

A9 |

LCD support |

RK-09 |

2 |

|

|

A10 |

Spool holder Side panel |

RK-10 |

1 |

|

|

A11 |

Spool holder Side panel |

RK-11 |

1 |

|

|

A12 |

Carriage mount |

RK-12 |

3 |

|

metal parts |

||||

|

M1 |

Spider |

1 |

|

|

|

M2 |

Fan mount |

1 |

|

|

|

M3 |

Probe Lock ring |

with M3*3 screw |

1 |

|

|

M4 |

Probe mount |

1 |

|

|

M5 |

Belt mount |

3 |

|

|

|

M6 |

Endstop trigger mount |

3 |

|

|

|

M7 |

Diagonal Rod joint |

6 |

|

|

|

M8 |

Building platform |

Round aluminum plate |

1 |

|

Free add-on |

||||

|

F1 |

Ejector pin |

1 |

|

|

F2 |

File |

1 |

|

|

|

F3 |

Screw- driver |

1 |

|

*The acrylic plate for the spool holder and the LCD frame are 5mm.

GENERAL CARE AND MAINTENANCE

As with all the electronic equipment, it is important to keep your printer clean to extend its life. Regularly remove dust and debris with a microfiber cloth or compressed air. Dredge the tube and the nozzle after use every time to ensure fluent performance.

- Don’t leave the heaters on the printer turned on for a long periods of time when not used.

- Don’t leave your printer in shady and moist places, which may exacerbate the problems associated with erosion.

- The three axes of the GEEETECH I3 Pro B are lubricated with grease for smooth operation and can last for a long time. Grease may need to be re-applied to your printer to maintain smooth performance.

- Avoid positioning your power supply unit in such a way that the brick is hanging, pulling, or putting any unnecessary stress in the electrical wires and components.

References

geeetech 3d printers onlinestore, one-stop shop for 3d printers,3d printer accessories,3d printer parts

geeetech 3d printers onlinestore, one-stop shop for 3d printers,3d printer accessories,3d printer parts

Geeetech – YouTube

📧[email protected]

Geeetech G2&G2s Pro & Rostock 301 Assembly instruction – YouTube

Geeetech 3D Printer User Club

geeetech 3d printers onlinestore, one-stop shop for 3d printers,3d printer accessories,3d printer parts

[xyz-ips snippet=”download-snippet”]