GO-3D Print Dragon Hotend

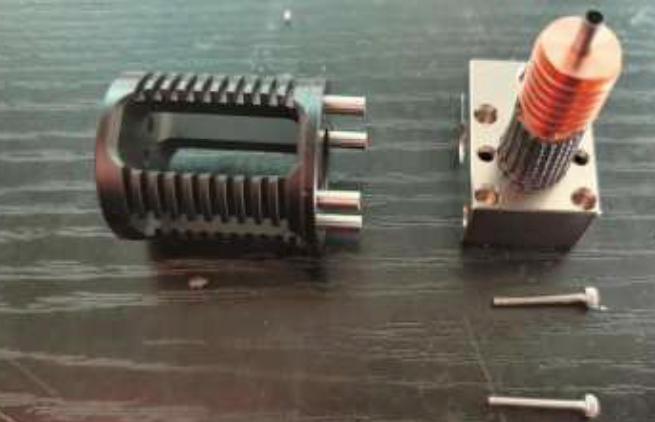

Disassembly

Tools needed:

- 8mm open-ended wrench

- Hex keys

- Use the 1.27 mm hex key to remove the M1.4 socket head cap screws in the bottom of the heater block.

- Once the M1.4 screws are removed, the heater block and heat sink will slide apart with little effort.

- Gently pull up the black insulator tube. The heater block and heat break can be separated using an 8mm open-end wrench.

- If any of the parts are damaged or missing ,replacements can be purchased in our ALI express store.

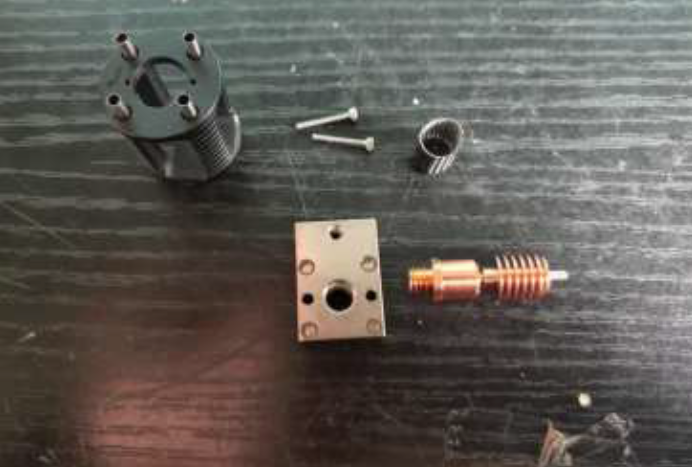

Assembly

Tools needed:

- 8mm open-ended wrench

- Hex keys

- Loctite Threadlocker Red

- Use the 8 mm open-ended wrench to thread the heat break into the heater block. The heat break should be torqued down to approximately 4.5 Nm.

- Install the black insulator tube back make sure that it reached bottom of the heat break.

- Carefully align the heat sink with the 4 stand-off tubes and the heat break tube. Slide the heat sink down until it is fully seated against the tubes and heat break. If heat sink is not properly aligned, it will damage the heat break when tightened down.

After carefully aligning and fully seating the heat sink onto the heater block stand-off tubes and heat break, coat the ends of the M1.4 socket head cap screws with Loctite Threadlocker.

After carefully aligning and fully seating the heat sink onto the heater block stand-off tubes and heat break, coat the ends of the M1.4 socket head cap screws with Loctite Threadlocker.

- Insert the M1.4 socket head cap screws into the bottom of the hot block. Use the 1.27 mm hex key to tighten down the screws to “finger tight”.Warning: Do not overtighten the M1.4 screws, as the threads can be damaged, or the heads stripped out, potentially damaging your hotend.

Hot-Tightening

- Hot-tightening is the last mechanical step before your dragon hotend is ready to go! Hot-tightening is essential to sealing the nozzle and heatbreak together to ensure that molten plastic cannot leak out of the hotend in use.

- Using your printer’s control software (or LCD screen), set the hotend temperature to 285°C. Allow the hotend to reach 285°C and wait one minute to allow all components to equalise in temperature.

- Gently tighten the nozzle whilst holding the heater block still with a spanner and using a smaller 7mm spanner to tighten the nozzle. This will tighten the nozzle against the Heatbreak and ensure that your hotend does not leak.

- You want to aim for 2.5Nm of torque on the hot nozzle—this is about as much pressure as you can apply with one finger on a small spanner.

[xyz-ips snippet=”download-snippet”]

After carefully aligning and fully seating the heat sink onto the heater block stand-off tubes and heat break, coat the ends of the M1.4 socket head cap screws with Loctite Threadlocker.

After carefully aligning and fully seating the heat sink onto the heater block stand-off tubes and heat break, coat the ends of the M1.4 socket head cap screws with Loctite Threadlocker.