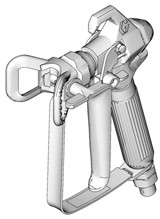

312830MSG2, SG3 Spray GunsModels: 243011, 243012, 246506, 243238, 243382,289843, 257359, 16W431, 16X214, 17J910, 25R553 CAN011, CAN012

312830MSG2, SG3 Spray GunsModels: 243011, 243012, 246506, 243238, 243382,289843, 257359, 16W431, 16X214, 17J910, 25R553 CAN011, CAN012

ti11562a

IMPORTANT SAFETY INSTRUCTIONS.

Refer to your sprayer instruction manual for Pressure Relief, priming, and spray instructions. Keep these instructions.Maximum Working Pressure: 3600 psi (248 bar, 24.8 MPa)

– For the application of architectural paints and coatings –

The following Warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these Warnings. Additionally, product-specific warnings may be found throughout the body of this manual where applicable.

![]() WARNINGS

WARNINGS

- Do not point a gun at anyone or at any part of the body.

- Do not put your hand over the spray tip.

- Do not stop or deflect leaks with your hand, body, glove, or rag.

- Do not spray without a tip guard and trigger guard installed.

- Engage trigger lock when not spraying.

- Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or servicing equipment.

- Use equipment only in well-ventilated areas.

- Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

- Keep work area free of debris, including solvent, rags, and gasoline.

- Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

- Ground all equipment in the work area. See Grounding instructions.

- Use only grounded hoses. · Hold the gun firmly to the side of the grounded pail when triggering into pail.

- If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you identify and correct the problem.

- Keep a working fire extinguisher in the work area.

- Do not operate the unit when fatigued or under the influence of drugs or alcohol.

- Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

- Use fluids and solvents that are compatible with equipment-wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from the distributor or retailer.

- Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

- Do not alter or modify equipment.

- Use equipment only for its intended purpose. Call your distributor for information.

- Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

- Do not kink or over bend hoses or use hoses to pull equipment.

- Keep children and animals away from the work area.

- Comply with all applicable safety regulations.

![]()

![]()

![]()

![]()

- Protective eyewear

- Clothing and respirator as recommended by the fluid and solvent manufacturer

- Gloves

- Hearing protection

Pressure Relief Procedure

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Turn OFF the power and turn sprayer pressure control to the lowest pressure setting.

- Hold the gun against the side of the flushing pail. Trigger gun into the pail to relieve pressure.

If you suspect spray tip or hose is clogged or that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip guard retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Clear hose or tip obstruction.

Gun Trigger Lock

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

| Trigger Locked (no spray) | Trigger Unlocked (spray) |

|

|

Setup

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Attach supply hose to sprayer fluid outlet.

- Attach another end of the supply hose to the gun swivel (5). Use two wrenches (one on the swivel (5) and one on the hose), totighten all connections securely.

- Refer to the sprayer instruction manual for priming instructions.

Installing Tip (26) and Guard (25) on Gun

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- If equipment has recently been operated, relieve pressure. Set trigger lock.

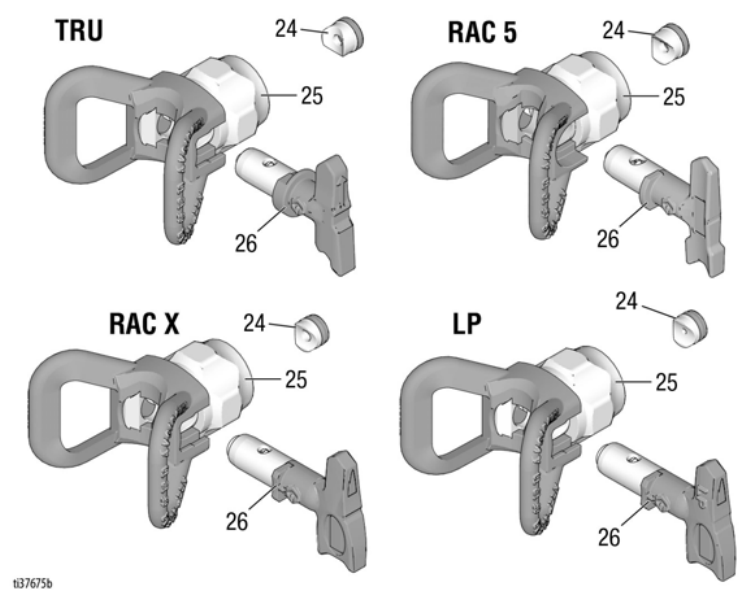

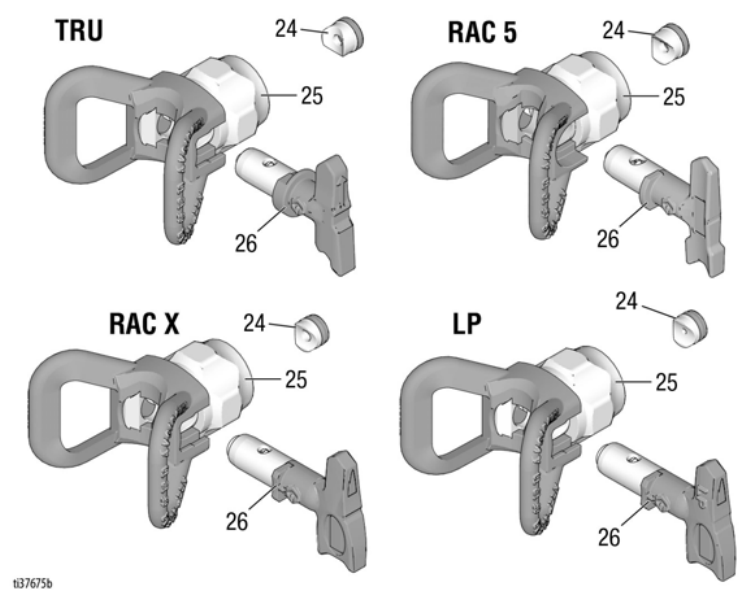

- Using a pencil or similar object, insert a seal (24) into the back of the guard (25).

- Install guard (25) over the end of the gun (1).

- Insert tip (26) in guard (25). Tighten retaining nut.

Operation

Spraying

- Unlock trigger lock.

- Be sure the arrow-shaped tip (26) faces forward (spray).

- Hold the gun perpendicular and approximately 12-inches (30 cm) from the surface. Move gun first, then pull the gun trigger (3) to spray a test pattern.

- Slowly increase pump pressure until coverage is uniform and even (see sprayer instruction manual for additional information).

Aligning Spray![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

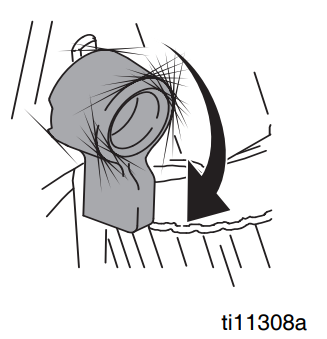

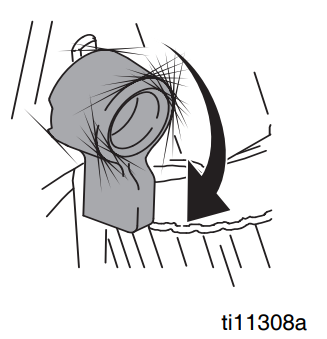

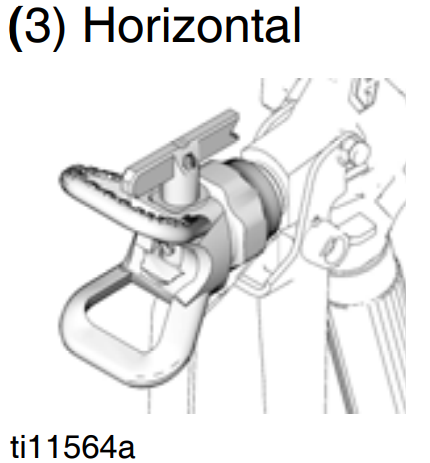

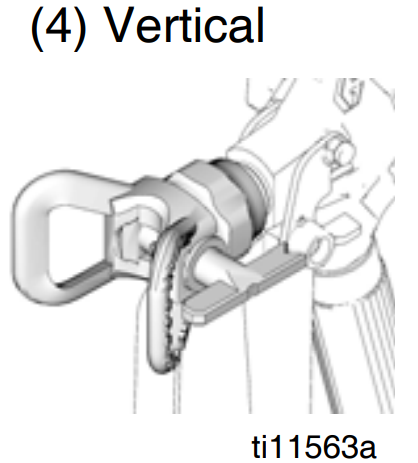

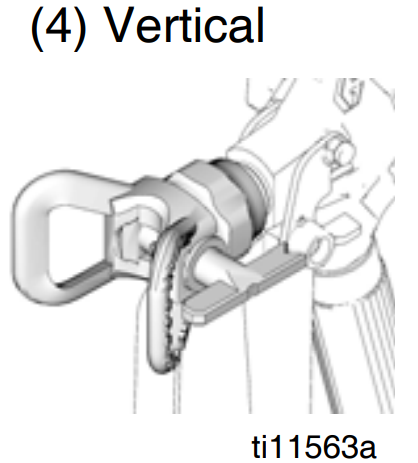

- Relieve pressure. Set trigger lock.

- Loosen guard retaining nut.

- Align guard (25) horizontally to spray a horizontal pattern.

Align guard (25) vertically to spray a vertical pattern.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Relieve pressure. Set trigger lock.

- Rotate tip (26) 180°. Unlock trigger lock. Trigger the gun into a pail or onto the ground to remove the clog.

- Set trigger lock. Rotate tip (26) 180° back to spray position.

Cleanup

Flush gun after each work shift and store in a dry location. Do not leave the gun or any parts in water or cleaning solvents.

Parts

*Kit 288817 repairs both series A and B guns. 1a replaces these three components of series A.

| Ref. | Part | Description | Qty. |

| 1 | 288817 | KIT, repair, gun (includes 1a, 1b, 1c) | 1 |

| 1a | SEAT, valve | 1 | |

| 1b | NEEDLE, gun | 1 | |

| 1c | 131477 | NUT, lock | 1 |

| 3 | 243639 | TRIGGER, repair kit

includes 10, 32, 33 |

|

| 4 | 195495 | GUARD, trigger | 1 |

| 5 | 238817 | KIT, swivel | 1 |

| 195384 | ADAPTER, gun inlet (SG2) | 1 | |

| 6√ | 288749

CAN085 |

FILTER, gun

FILTER, gun |

1 |

| 7√ | 179733 | SEAL, sleeve | 1 |

| 8 | 195395 | CAP, end | 1 |

| Ref. | Part | Description | Qty. |

| 10 | 115484 | PIN, actuator | 2 |

| 22 | 113409 | RETAINER, guard | 1 |

| 23 | 195393 | HANDLE, gun (SG2) | 1 |

| 195788 | HANDLE, gun (SG3, SG3-E) | 1 | |

| 195920 | HANDLE, gun (SG3-A) | 1 | |

| 24 | 115485 | O-RING | 1 |

| 26 | 17R014 | HOUSING, fluid | 1 |

| 32 | 177538 | STUD, trigger | 1 |

| 33 | 131476 | NUT, lock, hex | 1 |

![]()

![]()

| Ref | Part | Description | Qty |

| 24 | 243004 | Single seal TRU | 1 |

| CAN004 | Single seal TRU | 1 | |

| 243281 | Oneal | 1 | |

| 246453 | ™ | 1 | |

| 17P501 | , RAC 5 (5-pack) | 1 | |

| 25 | 237859 | Oneal | 1 |

| CAN001 | ™ | 1 | |

| 243161 | , RAC X (5-pack) | 1 | |

| 246215 | KIT, gasket, FFLP, LP (5-pack) | 2 | |

| 26 | TRU515 | GUARD, TRU | 1 |

| CAN515 | GUARD, TRU | 1 | |

| 286515 | GUARD, RAC 5 | 1 | |

| LTX515 | GUARD, RAC X, and LP | 1 | |

| TRU517 | TIP, spray 515, TRU | 1 | |

| CAN517 | TIP, spray 515, TRU | 1 | |

| 262515 | TIP, spray 515, RAC 5 | 1 | |

| LP519 | TIP, spray 515, RAC X | 1 |

Maintenance

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Cleaning/Replacing Filter (6)

![]()

![]()

- Relieve pressure. Set trigger lock

- Disconnect fluid hose from a gun at swivel (5).

- Disconnect trigger guard (4) from guard retainer (22).

- Unscrew handle (23) from the gun (1).

- Remove filter (6) through the top of the handle (23).

- Clean filter (6). Use a soft brush to loosen and remove excess debris.

- Insert clean filter (6) into the handle (23).

- Reattach handle (23) to the gun (1). Tighten securely.

- Reconnect trigger guard (4) to guard retainer (22).

Translated Manuals

| French – 312831 | Estonian – 312845 |

| Spanish – 312832 | Latvian – 312846 |

| Dutch – 312833 | Lithuanian – 312847 |

| German – 312834 | Polish – 312848 |

| Italian – 312835 | Hungarian – 312849 |

| Turkish – 312836 | Czech – 312850 |

| Greek – 312837 | Slovakian – 312851 |

| Croatian – 312838 | Slovenian – 312852 |

| Portuguese – 312839 | Romanian – 312853 |

| Danish – 312840 | Bulgarian – 312854 |

| Finnish – 312841 | Chinese – 312855 |

| Swedish – 312842 | Japanese – 312856 |

| Norwegian – 312843 | Korean – 312857 |

| Russian – 312844 |

Translated manuals can be requested through a distributor or at www.graco.com.

Repair

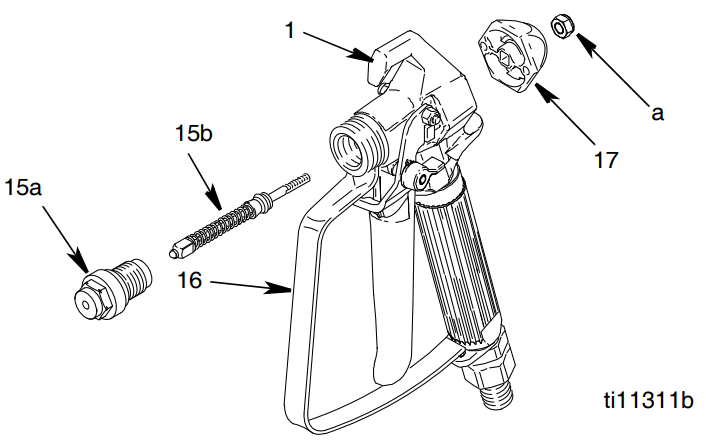

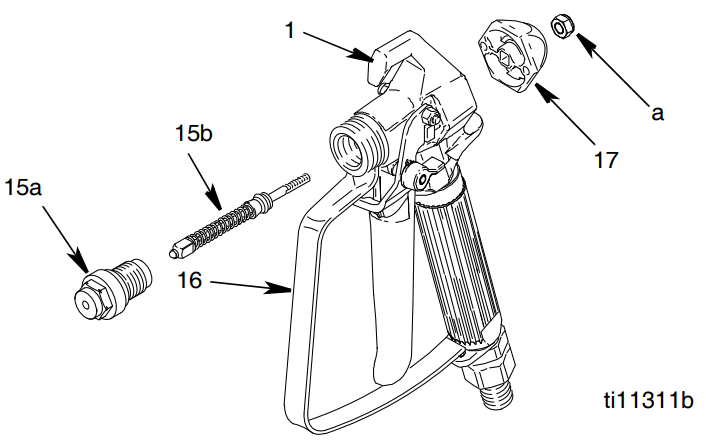

Replacing Needle

- Relieve pressure. Set trigger lock.

- Remove tip (26) and guard (25) from the gun (1).

- Disconnect fluid hose from the gun at swivel (5).

- Squeeze trigger while unscrewing diffuser.

- Remove locknut and end cap.

- Tap out the needle.

- Use a soft brush to clean out the internal passages of the gun.

- Grease o-rings of the new needle using non-silicone grease.

- Guide new needle (15b) through the front of the gun.

- Install end cap and locknut, loosely.

- For needle housing (15a), apply medium strength (blue) thread sealant to threads.

- Squeeze trigger while installing needle housing. Torque to 26-32 ft-lb (35-43 N•m).

- Hold the gun with the nozzle facing up.

- Set trigger lock.

- Turn locknut (a) clockwise until you see and feel trigger (3) raise slightly.

- Turn locknut (a) 3/4 turn counter-clockwise.NOTE: When the needle is properly adjusted, the trigger will move freely.

- Connect fluid hose. Install tip (26) and guard (25).

- Prime sprayer. See sprayer instruction manual.

- Trigger the gun into a bucket until fluid flows from the gun.

- Release trigger (3). Fluid flow should stop immediately.

- Set trigger lock.

- Aim gun into the bucket. Trigger gun. No fluid should flow.

- If the gun fails tests, steps 19 and/or 21, relieve pressure and disconnect the hose. Readjust needle. Repeat tests.

Technical Data

| Maximum working pressure | 3600 psi (248 bar, 24.8 MPa) |

| Fluid orifice size | 0.125 in. (3.18 mm) |

| Weight (with tip and guard) | 22 oz. (630 g) |

| Inlet | |

| Maximum material temperature | 120 F (49 C) |

| Wetted Parts | Stainless steel, polyurethane, nylon, aluminum, tungsten carbide, brass |

| *Noise Level: Sound power | 87 dBa |

| Sound pressure | 78 dBa |

| *Measured at 3.1 ft (1m) while spraying water-based paint, specific gravity 1.36, through a 517 tip at 3000 psi (207 bar, 20.7 MPa) per ISO 3744 |

For complete warranty information contact your local Graco distributor, call Graco customer service:1-800-690-2894 or visit our website: www.graco.com.All written and visual data contained in this document reflects the latest product information available at the time of publication.Graco reserves the right to make changes at any time without notice.For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312830Graco Headquarters: MinneapolisInternational Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES• P.O. BOX 1441• MINNEAPOLIS MN 55440-1441• USACopyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.www.graco.comRevised M, August 2020

References

[xyz-ips snippet=”download-snippet”]