TOUCH PANEL SWITCH QUINTOHE-TPS05 USER MANUALV1.0

Overview

This is the user manual for the HELTUN HE-TPS05 Advanced Programmable Touch Panel Switch. The HE-TPS05 brings ‘Impossibly Smart’ capabilities to your home lighting, electric outlets, or motorized blinds, door locks, gates, and valves. It replaces an existing in-wall switch and brings over-the-Internet monitoring, control, and advanced programmability to five connected devices. Quinto is ‘Impossibly Thin’ on the wall yet packed with features to provide the ultimate in control and convenience.

Controls up to five systems with two different power sourcesThanks to Quinto’s five-channel relays it can manage either: 1) up to five On/Off devices, 2) three On/Off devices and one bidirectional motor, or 3) one On/Off device and two bidirectional motors. Two independent relay channel inputs allow control of systems with different power sources or use of relay outputs as dry contacts. Each relay can be loaded up to 5 Amps.

Connects to Z-Wave lights and dimmersQuinto is an excellent choice for managing lighting systems. It allows connection to Z-Wave™ lights and dimmers controlling both On and Off, as well as smooth brighten (Up) and smooth dim (Down) states. Dimmer levels can be tied to Quinto’s button backlights to provide feedback of connected light state (On/Off).

Controls motorized devicesQuinto can also be used to manage motorized systems like shades/blinds, driveway gates, water valves, or window and door locks. It also allows association with relay switches to control the opening and closing of connected motorized devices. If door/window sensors are installed, they may be associated with Quinto backlights, enabling them to indicate device state (Open/Closed).

Touch panel buttons have multiple functionsQuinto has five high sensitivity capacitive touch buttons with two-color backlights (red/blue) for each. 15 backlight brightness levels can be configured manually or set to automatically adjust to ambient light conditions making them always easy to see. Each button can be configured to control the relay output state (#1-5) in any of nine different modes.

Five ways to trigger programmed scenariosAn onboard Real Time Clock (RTC) enables Quinto to trigger scenarios where connected devices are set to a schedule. Another powerful feature lets Quinto trigger connected device scenarios when temperature, humidity, or light sensor values change. Quinto buttons may also directly trigger scenarios on the controller — with each backlight indicating scene status.

Know how much energy you use Quinto can determine how much energy is used by connected devices any particular day, week, or month. Just specify the consumption of the load in watts for each relay channel and the device logic will calculate total consumption relative to the time since the output was in the ‘ON’ state.

Based on the latest Z-Wave platformQuinto integrates a Z-Wave Plus™ v2 700 platform module allowing it to be used with Z-Wave home automation systems. It supports Z-Wave ‘S0’ and ‘S2’ security protocols, SmartStart technology, and can be connected (“associated”) to other Z-Wave devices, such as relays, motor controllers, dimmers, etc.

Technical Specifications

- Front frame (on wall) dimensions: 89mm (H) х 89mm (W) х 9mm (D)

- Rear electronics package dimensions: 53mm (H) х 53mm (W) х 28mm (D)

- Materials: Tempered glass display/body, Flame retardant plastic

- 5 frame colors: White, Gloss Black, Matte Black, Silver, Chrome

- 6 glass colors: White, Black, Yellow, Green, Red, Blue

- 5 capacitive-touch buttons

- Red and Blue LED backlights for each button

- 15 brightness levels (adjustable) for each button backlight

- 5 channel relay outputs, resistive load up to 5A each

- 2 independent relays inputs, dry contact

- Operating temperature: 0°С to +50°С

- Power supply: 85-265VAC 50Hz/60Hz or 24-48VDC

- Power consumption: 1W

- Relay switching with HELTUN Advanced Zero-Cross Technology

- Relay lifetime: 100.000 switches

- Internal ambient light sensor

- Internal temperature sensoro Measurement range: –30°C to +80°Co Accuracy: ±0.5°C

- Internal humidity sensoro Measurement range: 0% to 80%RHo Accuracy: ±3.0%RH

- IP class: IP21

- Z-Wave Plus V2 SDK: V7.11

- Z-Wave module: ZGM130S

- Requires mounting to flush electrical junction box: round or square type – min. depth 40mm

Functions & Features

- Options for Inclusion/Exclusion to/from Z-Wave networko Non-Secureo S0 Secureo S2 Unauthorized, S2 Authorized with Key

- Association control of 20 devices from the network

- Schedule Mode

- Motorized device control (roller shutter mode)

- Each of five buttons can control any relay output

- Up to five different relay channels can be controlled by one button

- Each button can be set up to control devices from associated groups

- Each button backlight & relay outputs can be managed by a gateway or associated device

- Each button can trigger scenes

- Each button backlight can indicate a scene or associated device state

- Any channel may be excluded from the control

- Nine modes for each button:1. Switch-ON2. Switch-OFF3. Timer: ON>OFF4. Timer Reversed: OFF>ON5. Inverse state6. Two-Button Inverse7. Momentary8. Momentary Reversed9. Roller Shutter

- Adjustable periodic measurements from:o Internal temperature sensoro Internal humidity sensoro Internal ambient light sensoro Energy consumption meter

- Calibration of Internal Room Air Temperature Sensor

- Brightness control of button backlight:o Automatic adjustment (depending on ambient light)o Manual adjustment (15 levels).

- Backlight standby mode (different brightness for active and inactive states)

- Backlight blinking function (for easy identification among other Z-Wave devices)

- Backlight colors invert

- Software energy consumption logic

- Factory reset function

- SmartStart technology for a quick addition to Z-Wave networks

- OTA (Over The Air) encrypted firmware update

Installation

HELTUN recommends the HE-TPS05 touch panel switch be installed by a licensed electrician in a manner that conforms to local regulations and building codes. Provide these instructions to the licensed electrician who is installing the HE-TPS05.WARNING: Electrical power must be switched off during installation.

- Placement of the HE-TPS05 is of utmost importance for proper operation and must be away from sunlight and sources of direct heat. We recommend installing the HE- TPS05 approximately 1.5 meters above the floor.

- Remove the touch panel unit and backplate of the HE-TPS05 from the packaging.

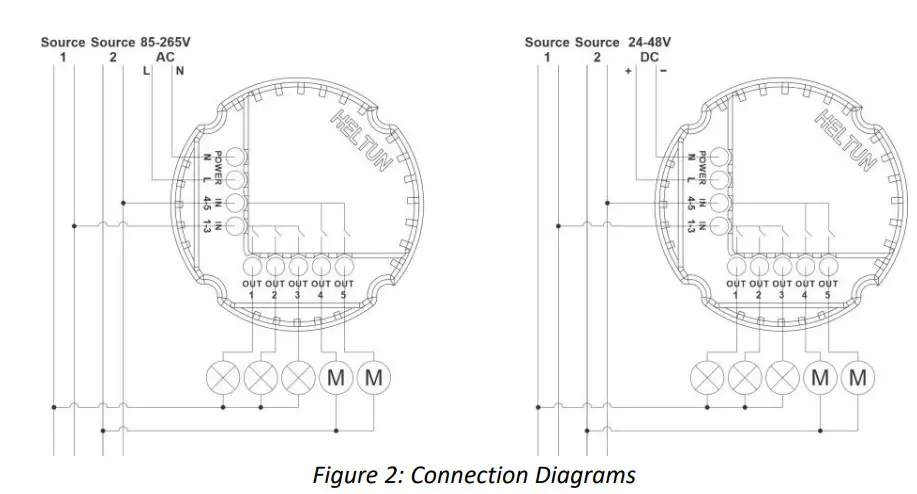

- FIRST ENSURE THE POWER IS OFF at the main circuit breaker (Fig. 1), and then test the wires with a probe or multimeter to verify. Insert the power wires to the HE- TPS05 “POWER” terminal by inserting a small Phillips-head screwdriver in the slot beneath each terminal and unscrew to open. Follow Fig. 2: Connection Diagram and instructions below:• Power wires: for AC power (85-265VAC) connect Line & Neutral wires to L & N terminals labeled “POWER” (Fig 2. left diagram). For DC power (24-48VDC) connect “+” wire to terminal N and “-” wire to terminal L (Fig 2. right diagram).

• Source 1 wire: connect the required power source for relays 1, 2 and 3 to the terminal labeled “IN 1-3”.• Source 2 wire: connect the required power source for relays 4 and 5 to the terminal labeled “IN 4-5”.• Loads: connect the required loads to the relay output terminals labeled “OUT-1”, “OUT-2”, “OUT-3”, “OUT-4”, “OUT-5”.Note: HELTUN recommends installing cord terminals (electric wire ferrule) on the ends of wires before connecting them to the HE-TPS05 outputs (various colors terminals are included in the packaging).

• Source 1 wire: connect the required power source for relays 1, 2 and 3 to the terminal labeled “IN 1-3”.• Source 2 wire: connect the required power source for relays 4 and 5 to the terminal labeled “IN 4-5”.• Loads: connect the required loads to the relay output terminals labeled “OUT-1”, “OUT-2”, “OUT-3”, “OUT-4”, “OUT-5”.Note: HELTUN recommends installing cord terminals (electric wire ferrule) on the ends of wires before connecting them to the HE-TPS05 outputs (various colors terminals are included in the packaging).

- Make sure the HE-TPS05 backplate is oriented on the wall with the word “TOP” pointed upwards. Then secure the backplate onto the electrical junction box using the four screws provided (do not overtighten). Once the backplate is secured onto the wall, assemble the HE-TPS05 touch panel unit onto the backplate by first carefully aligning the two top snap connectors (Fig. 3), and then gently pushing the entire display unit until it ‘snaps’ into position all the way around.

- Next, switch ON the main power at the circuit breaker (see photo above). The HETPS05 will start up with original default factory settings (all button backlights will indicate red).

- Remove the clear protective film from the touch panel unit by pulling on the top right-hand tab.Note: Zero-Cross technology is unavailable if the device operates using DC voltage (24-48VDC).

Disassembly

- ENSURE POWER IS SWITCHED OFF at the main circuit breakerAND ALL BUTTON BACKLIGHTS ARE OFF.

- To remove the HE-TPS05 touch panel unit, grasp firmly at the bottom and pull backward while tilting outwards until all tabs disconnect.

- Remove screws from the backplate and disconnect the wires by inserting a small Phillips-head screwdriver into the slot beneath each wire, then unscrew to release.

Touch Panel Operation

The HE-TPS05 has five relays, five touch buttons, and two-color backlights (red and blue) for each button.

- Each relay can be controlled by any touched button or via a Z-Wave network (using a Z-Wave gateway).

- Each touch button can be configured to control any relay output state (from one to five) in the modes below:1) SWITCH-ON: Press button: relay output switches to ON state (i.e. contacts are closed).2) SWITCH-OFF: Press button: relay output switches to OFF state (i.e. contacts are opened).3) TIMER: ON>OFF: Press button: relay output switches to ON for the specified time, then reverts to OFF.(Tip: This function is useful to open/close garage doors, blinds, curtains, etc.)4) TIMER REVERSED: OFF>ON: Press button: relay output switches to OFF for the specified time then reverts to ON. (Tip: This function is useful for switching off security systems for a short time.)Note: Time can be configured from 0 sec to 43200 sec (12 hours).5) INVERSE STATE: Press button: relay output inverts state: (ON to OFF) or (OFF to ON).6) TWO-BUTTON INVERSE: When two buttons are in Inverse mode, after pressing a button the corresponding relay (connected to that button) inverts its state: (from ON to OFF, or from OFF to ON) and the second relay will be switched OFF.Note: In this mode, both relays cannot be switched ON simultaneously. Can be used for motors direction control.7) MOMENTARY: When the button is held the relay output is ON, as soon as the button is released the relay output state changes to OFF.8) MOMENTARY REVERSED: When the button is held the relay output is OFF, as soon as the button is released the relay output state changes to ON.9) ROLLER SHUTTER: When two relays are connected to the same button, they will operate in ‘roller shutter’ mode. After entering this mode, relays will switch to OFF state, and never switch ON simultaneously. The relay behavior is as follows for this four-touch cycle (in this order):• 1stpress: the first relay will be switched ON, the second relay will be switched OFF• 2 nd press: both relays will be switched OFF• 3 rd press: the second relay will be switched ON, the first relay will be switched OFF• 4 th press: both relays will be switched OFFThe above-mentioned two relays are defined according to parameters 40 & 41 (e.g. if “54” is set as the parameter value, it means the fifth relay and fourth relay will be operated in inverse mode).Note: This can be used to control motor directions with one button only.Each touch button can also be used to run scenarios or change modes in the connected gateway or associated devices.

- Each button’s backlight can be configured as follows to indicate:a) Relay output stateb) Touch button statec) Mode state in the connected gatewayd) Associated device state

Note: It is possible to choose the light color for each state (red for ON and blue for OFF, or blue for ON and red for OFF).If the HE-TPS05 is associated with a Z-Wave gateway, the scene controller, light, temperature & humidity sensor info, and ten binary switches will appear. The scene controller indicates which button was pressed, held, or released and allows the running of scenes on the Z-Wave gateway. The first five binary switches indicate, and allow the control of, the button backlights. The remaining five binary switches indicate and control the relay outputs.

Scenarios

Scenarios can be created that allows connected devices to be triggered by a sensor or onboard Real Time Clock (RTC). The HE-TPS05 has built-in temperature, humidity, and ambient temperature sensors and includes a very flexible, user-friendly interface for customizing scenarios. In addition to the physical sensors, time may be used as a control source. The user should configure the output number, state, sensor type, state change condition, and threshold in the Parameters (from 42 – 51) which will trigger the scenes.

Factory Reset (RES)

To reset the HE-TPS05 to factory defaults, simultaneously press the two bottom buttons and hold for six seconds. If the reset process is successful, all visible LEDs will turn Off.NOTE: This factory reset procedure will change all parameters to the original factory default values and will also exclude the device from any associated Z-Wave network.Please use this procedure only when the network primary controller is missing or otherwise inoperable.

Power and Energy Consumption

The HE-TPS05 monitors all connected loads active (i.e. ‘real time’) power, and total energy consumption, through software energy consumption logic. This data is periodically reported to the main Z-Wave controller according to Parameter 05.

Total Energy Consumption is the electrical power being used by connected devices in real-time during use. Power usage is calculated by the software using the values that were manually set when configuring Parameters 52-56, multiplied by the time tracked when the HE-TPS05 corresponding output was in an ON state. Using your connected device’s power consumption specification (see associated owner’s manual), set the load in Watts for: “OUT-1” in Parameters 52, “OUT-2” in Parameter 53, “OUT-3” in Parameter 54, “OUT-4” in the Parameter 55, and “OUT-5” in Parameter 56.

Resetting Cumulative Consumption Memory

The HE-TPS05 enables you to erase stored consumption data through the Z-Wave network as follows:

- Make sure the HE-TPS05 is powered.

- If not already done so, include the device into the Z-Wave Gateway network

- Reset memory consumption data using the Reset Command in COMMAND_CLASS_METER (see the Gateway owner’s manual).

Note: Power cycling the HE-TPS05 (On>Off>On) will not erase the consumption data as it is stored in non-volatile memory.

Z-Wave Network

The HE-TPS05 may be operated in any Z-Wave network with other Z-Wave-certified devices from other manufacturers. The HELTUN HE-TPS05 will act as a ‘repeater’ (i.e. ‘range extender’) for other devices regardless of manufacturer or brand to increase the reliability of the overall network.

Adding HE-TPS05 to a Z-Wave network

To add the HE-TPS05 to a Z-Wave Network (i.e. “inclusion”), do the following:

- Start the inclusion mode from the gateway/controller

- To start the inclusion process on the HE-TPS05, simultaneously press the two bottom touch buttons and hold them for three seconds.

- The two upper buttons will then sequentially blink ‘blue-red’

- If the inclusion has been successful, the two upper buttons will turn blue for three seconds.

- If the inclusion was not successful, the two upper buttons will turn red for three seconds. In that case, repeat the inclusion process.

Note: For correct operating in Fibaro gateways the Single Channel Association should be removed from the device LifeLine (EndPoint 0 Group 1).

Removing HE-TPS05 from a Z-Wave network

To remove the HE-TPS05 from a Z-Wave Network (i.e. “exclusion”), do the following:

- Start the exclusion mode from the gateway/controller.

- To start the exclusion process on the HE-TPS05, simultaneously press the two bottom touch buttons and hold them for three seconds.

- Two upper buttons will sequentially blink blue-red.

- If the exclusion has been successful, the two upper buttons will turn red for three seconds.

- If the exclusion was not successful, the two upper buttons will turn blue for three seconds. In that case, repeat the exclusion process.

Note: If the HE-TPS05 has previously been part of a Z-Wave network and has not been excluded, inclusion is not possible without first performing an exclusion or Factory Reset procedure.

Security

S0, S2 unauthorized, and S2 authorized Inclusion Modes are supported. If you use the S2 authorized Inclusion mode, the ‘security key’ (DSK provided on the HE-TPS05 Security Card) should be used during the inclusion process. Note: Be sure to save this key. Without the key, it is impossible to perform an inclusion in S2 authorized mode.

SmartStart

SmartStart-enabled products can be added to a Z-Wave network by scanning the Z-Wave QR Code shown on the product with gateways/controllers that allow for SmartStart inclusion. In this case, no further action will be required and the SmartStart product will be added automatically within ten minutes of being turned on in the vicinity of a network.

To add the HE-TPS05 to a Z-Wave network using SmartStart:

- Input the HE-TPS05 DSK code to the controller’s Node Provisioning List

- Power on the device.

- Wait for the inclusion process to complete.

- A successful “Add” will be confirmed by a message on the Z-Wave controller.

Note: The device DSK and QR code are printed on the HE-TPS05 back panel plus on the additional Security Card included in the HETPS05 packaging.

Firmware OTA Update

To wirelessly update the HE-TPS05 firmware, follow these steps:

- Check the device’s current firmware version in the gateway/controller.

- Start the process from the Z-Wave gateway/controller.

- Download the latest firmware that corresponds to the HE-TPS05 (see https://www.heltun.com/support )

- Set the main controller in Firmware OTA (“over-the-air”) Update Mode (see the gateway/controller manual).

- As soon as the Firmware update begins, all buttons will sequentially blink blue-red (this will take a few minutes).

- When the Firmware has updated, all button backlights will turn off for two seconds and the HE-TPS05 will reboot.

- When the update has been completed, the HE-TPS05 will return to normal operation.

- If desired, verify the update was successful by checking the firmware version from the gateway/controller.

Associations

Association enables the HE-TPS05 to control up to 20 other Z-Wave devices over the network. The HE-TPS05 has 11 Endpoints and 21 Association Groups. Each Association Group (except group 1) may include one other device from different brands and/or manufacturers.

EndPoint 0 Groups:

The Root Device (EndPoint 0) of HE-TPS05 has 21 association groups.Group 1 – “Lifeline”: reports state of the device and is used to communicate with the Z-Wave gateway. This group supports one Node.Note: It is not recommended to modify this group.Note: For correct operating in Fibaro gateways the Single Channel Association should be removed from the device LifeLine (EndPoint 0 Group 1).Group 2 – “Touch 1 Basic Set”: is assigned to touch N1. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 3 – “Touch 1 Multilevel Set”: is assigned to touch N1. It sends the MULTILEVEL SWITCH command class frame when touch N1 was held. Is used to send UP/DOWN command to the associated devices. The group supports one Node.Group 4 – “Touch 2 Basic Set”: is assigned to touch N2. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 5 – “Touch 2 Multilevel Set”: is assigned to touch N2. It sends the MULTILEVEL SWITCH command class frame when touch N2 was held. Is used to send UP/DOWN command to the associated devices. The group supports one Node.Group 6 – “Touch 3 Basic Set”: is assigned to touch N3. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 7 – “Touch 3 Multilevel Set”: is assigned to touch N3. It sends the MULTILEVEL SWITCH command class frame when touch N3 was held. Is used to send UP/DOWN command to the associated devices. The group supports one Node.Group 8 – “Touch 4 Basic Set”: is assigned to touch N4. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 9 – “Touch 4 Multilevel Set”: is assigned to touch N4. It sends the MULTILEVEL SWITCH command class frame when touch N4 was held. Is used to send UP/DOWN command to the associated devices. The group supports one Node.Group 10 – “Touch 5 Basic Set”: is assigned to touch N5. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 11 – “Touch 5 Multilevel Set”: is assigned to touch N5. It sends the MULTILEVEL SWITCH command class frame when touch N5 was held. Is used to send UP/DOWN command to the associated devices. The group supports one Node.Group 12 – “LED 1 Basic Set”: is assigned to LED N1. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 13 – “LED 2 Basic Set”: is assigned to led N2. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 14 – “LED 3 Basic Set”: is assigned to led N3. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 15 – “LED 4 Basic Set”: is assigned to led N4. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 16 – “LED 5 Basic Set”: is assigned to led N5. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 17 – “Relay 1 Basic Set”: is assigned to relay N1. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 18 – “Relay 2 Basic Set”: is assigned to relay N2. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 19 – “Relay 3 Basic Set”: is assigned to relay N3. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 20 – “Relay 4 Basic Set”: is assigned to relay N4. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.Group 21 – “Relay 5 Basic Set”: is assigned to relay N5. Is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node.

EndPoints 1-10 Groups:Group 1 – “Lifeline”: reports the state of the device and used to communicate with the Z-Wave gateway. The group supports one Node.Note: It is not recommended to modify this group.Group 2 – “Basic Set”: This is used to send Basic Set ON (value 255) and Basic Set OFF (value 0) commands to the associated devices. The group supports one Node and it is mapped to EndPoint 0 groups.Here is a truth table for EndPoints 1-10 groups mapping to root device (EndPoint 0) groups:

| EndPoints 1-10 groups | Root (EndPoint 0) groups |

| Endpoint 1, Group 2 — “LED 1 Basic Set” | Group 12 — “LED 1 Basic Set” |

| Endpoint 2, Group 2 — “LED 2 Basic Set” | Group 13 — “LED 2 Basic Set” |

| Endpoint 3, Group 2 — “LED 3 Basic Set” | Group 14 — “LED 3 Basic Set” |

| Endpoint 4, Group 2 — “LED 4 Basic Set” | Group 15 — “LED 4 Basic Set” |

| Endpoint 5, Group 2 — “LED 5 Basic Set” | Group 16 — “LED 5 Basic Set” |

| Endpoint 6, Group 2 — “Relay 1 Basic Set” | Group 17 — “Relay 1 Basic Set” |

| Endpoint 7, Group 2 — “Relay 2 Basic Set” | Group 18 — “Relay 2 Basic Set” |

| Endpoint 8, Group 2 — “Relay 3 Basic Set” | Group 19 — “Relay 3 Basic Set” |

| Endpoint 9, Group 2 — “Relay 4 Basic Set” | Group 20 — “Relay 4 Basic Set” |

| Endpoint 10, Group 2 — “Relay 5 Basic Set” | Group 21 — “Relay 5 Basic Set” |

Z-Wave Plus v2 Specifications

Generic Device Class: GENERIC_TYPE_WALL_CONTROLLERSpecific Device Class: SPECIFIC_TYPE_NOT_USEDSupported Command Classes

| Command Class | Version | Required Security Class |

| Z-Wave Plus Info | V2 | none |

| Association | V2 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Association Group Info | V3 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Multi-Channel Association | V3 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Multi-Channel | V4 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Switch Binary | V2 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Central Scene | V3 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Sensor Multilevel | V11 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Meter | V5 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Clock | V1 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Transport Service | V2 | none |

| Security 0 | V1 | none |

| Security 2 | V1 | none |

| Version | V3 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Manufacturer Specific | V2 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Device Reset Locally | V1 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Powerlevel | V1 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Supervision | V1 | none |

| Indicator | V3 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Configuration | V4 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Application Status | V1 | none |

| Firmware Update Meta Data | V5 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

| Basic | V2 | highest granted (S2 Authenticated, S2 Unauthenticated or SO) |

Meter Command Class:

| Meter Type | Scale | Rate Type | Precision | Size |

| Electric [0x01] | Electric kWh [0x00] | Import [Ox01] | 2 | 4 |

| Electric [0x01] | Electric W [0x02] | Import [Ox01] | 0 | 2 |

HE-TPS05 Settings Using Z-Wave Protocol (Gateway)

All configuration parameters are accessed through COMMAND_CLASS_CONFIGURATIONTime ConfigurationParameter 01 – Time correction by the controllerIf this Parameter value = 1 and the HE-TPS05 is connected to a Z-Wave gateway, the HE-TPS05 time and day will be periodically polled and corrected from the gateway. To switch off auto-correction set the Parameter value to 0. The factory default value is 1.Note. When auto-correction is turned off, the gateway will set the time once during the device inclusion to the Z-Wave network time.Parameter 02 – Week Day This parameter allows manual adjustment of the day of the week in case the HE-TPS05 is not connected to any Z- Wave gateway or Parameter 01 (auto-correction) is selected as 0. The factory default value is 1. 1=Monday, 2=Tuesday, 3=Wednesday, 4=Thursday, 5=Friday, 6=Saturday, 7=Sunday.

Parameter 03 – HourThis Parameter allows manual adjustment of Time: Hours.Parameter 04 – MinuteThis Parameter allows manual adjustment of Time: Minutes.

Sensor Configuration

Parameter 05 – Energy Consumption Meter Consecutive Report IntervalThis parameter defines the interval between consecutive reports of real-time and cumulative energy consumption data to the gateway. The value can be adjusted from 1 min. to 120 min. The factory default value is 10 min. Note: If the sensor readings change, the device will send the report to the gateway regardless of this parameter value. In order to not increase traffic on your network, it is not recommended to reduce the value of this parameter.Parameter 06 – Sensor Consecutive Report Interval When the HE-TPS05 is connected to a Z-Wave gateway (controller), it periodically sends the gateway reports from room temperature, humidity, and light sensors even if there are not any changes in those values. This Parameter defines the interval between consecutive reports. The value can be adjusted from 1 min. to 120 min. The factory default value is ten minutes.Note: If the sensor readings change, the device will send a report to the gateway regardless of the parameter value. In order to not increase network traffic, do not reduce the value of this parameter. We recommend reducing the value of this parameter only in cases of poor connection when reports from the device do not always reach the gateway.

Parameter 07 – Air Temperature Sensors Report ThresholdThis parameter determines the change in temperature level (in °C) that results in a temperature sensor report being sent to the gateway. The value of this parameter should be x10, (e.g. for 0.4°C, use the value “4”). For example, if the parameter value is 3 and the sensor reading is 24.0°C the HE-TPS05 will send new sensor readings to the gateway only when the temperature reaches 24.3°C and above, or 23.7°C and below. Values from “1” (0.1°C) to “100” (10.0°C) may be selected. Use the value “0” if there is a need to stop sending the reports. The factory default value is “5” (0.5°C).Note: The HE-TPS05 sensor is very sensitive to ambient temperature changes and can often detect shifts as small as ±0.1°C. Therefore, HELTUN recommends setting this parameter at “2” (0.2°C) or above, to reduce the data transfer load across your Z-Wave network.

Parameter 08 – Humidity Sensor Report ThresholdThis parameter determines the percentage (%) change in humidity level that results in a humidity sensor report being sent to the gateway. For example, if the parameter value is 40% and sensor reading is 10% the HE-TPS05 will send a new sensor reading to the gateway only in cases where the humidity is 50% and above, or 30% and below. Values from 1% to 25% may be selected. Use the value “0” if there is a need to stop sending the reports. The factory default value is “2” (2%).Note: The HE-TPS05 sensor is very sensitive to ambient humidity changes and can often detect shifts as small as ±1%. Therefore, HELTUN recommends setting this parameter at 2% or above, to reduce the data transfer load across your Z-Wave network.

Parameter 09 – Light Sensor Report ThresholdThis parameter determines the percentage (%) change in ambient illumination that results in a light sensor report being sent to the gateway. A value from 10% to 90% may be selected. Use the value “0” if there is a need to stop sending the reports. The factory default value is “50” (50%).Note: The HE-TPS05 sensor is very sensitive to changes in ambient illuminance and can often detect shifts as small as ±1%. Therefore, HELTUN recommends selecting a large threshold (between 50% – 90%) to reduce the data transfer load across your Z-Wave network.

Parameter 10 – Touch Buttons Sensitivity ThresholdThis parameter adjusts Touch Button Sensitivity from level 1 (low sensitivity) to 10 (high sensitivity). The factory default value is 6.Note: Setting the sensitivity too high can lead to false touch detection. We recommend not changing this Parameter unless there is a need to do so.

Parameter 11 – Temperature Sensor CalibrationThis parameter defines the offset value for the air temperature sensor. If the internal temperature sensor is not correctly calibrated, then it may be manually calibrated by adjusting the values up to +/- 10.0°C. This offset value will be added or subtracted from the internal air temperature sensor reading. The offset value should be multiplied by 10. For example, to make the offset –1.5°C, set the parameter value to “–15”. The factory default value is “0” (0.0°C).BACKLIGHTThe HE-TPS05 has two brightness levels for its button backlights: 1) Active Level – when a button is touched, its backlight becomes brighter, and 2) Inactive Level – after one second of inactivity all backlights dim. The actual brightness level may be adjusted manually or automatically.Parameter 12 – Active State Backlight ColorChoose the value “1” if you wish the backlight active state to be blue, and the inactive state to be red (default). Choose the value “0” if you wish the backlight active state to be red, and the inactive state to be blue. The factory default value is “1.”Parameter 13 – Backlight Auto-Brightness ControlThe HE-TPS05 can adjust its backlight level automatically depending on the ambient room brightness. If the Parameter value = “0” Inactive Level brightness will be controlled manually and set to the level defined by Parameter 14.If the Parameter value = “1” Inactive Level brightness will be controlled automatically depending on the room illumination.The factory default value is 1.

Parameter 14 – Backlight Brightness (Manual Mode)The Backlight Brightness Level Parameter will take effect when Parameter 13 is set to Manual Control (value = 0).The brightness may then be manually adjusted in Parameter 14 from 1 (lowest) to 10 (brightest).The factory default value is 8.

Parameters 15-19 – Button Backlight Control Source0 – Backlight is disabled (both color LEDs are turned off)1 – Controlled by touch button2 – Controlled by a gateway or associated deviceThe factory-default value: “1”Note: If the LED backlight is disabled (the parameter value is set to “0”) it is also impossible to control it from the gateway

Parameters 20-24 – Touch Button Number for Relays Output Control0 – Controlled by a gateway or associated device1 – Controlled by touch button N1 (Top Left)2 – Controlled by touch button N2 (Top Right)3 – Controlled by touch button N3 (Bottom Left)4 – Controlled by touch button N4 (Bottom Right)5 – Controlled by touch button N5 (Center)Factory default value: Each relay corresponds to its button (e.g. for Relay “3” the default value is touch button “3”)Parameters 25-29 – Hold Control Mode.0 – Hold function is disabled1 – Operate like click2 – When the button is held the relay output state is ON, as soon as the button is released the relay output state changes to OFF (momentary switch).3 – When the button is held the relay output state is OFF, as soon as the button is released the relay output state changes to ON (momentary switch).Factory default value: 1Note: Regardless of this parameter, the device will send to the gateway the touch state (pressed, held, released) by scene notifications.Parameters 30-34 – Click control mode0 – Click function disabled1 – Relay inverts state (toggles ON to OFF, OFF to ON) according to relay state2 – Relay inverts state (toggles ON to OFF, OFF to ON) according to the button backlight state.3 – Relay switches to ON state only4 – Relay switches to OFF state only5 – Timer: On>Off Mode: Relay output switches to ON state (contacts are closed) then after a specified time switches back to OFF state (contacts are open). The time is specified in parameters 35-39.6 – Timer: OFF>ON Mode: Relay output switches to OFF state (contacts are open) then after a specified time switches back to ON state (contacts are closed). The time is specified in Parameters 35-39.Factory default value: 1

Parameters 35-39 – Relay Timer mode durationThese parameters specify the duration in seconds for the Timer mode (value 5 or 6 in Parameters 30-34 respectively). Press the button and the relay output goes to ON/OFF for the specified time then changes back to OFF/ON. This function can be used to open/close garage doors, blinds, curtains, etc. or to turn attached devices like a door lock or security OFF for a short time. The time values can be configured from 0 sec to 43200 sec (12 hours).Factory default value: “0”Note: If the parameter value is set to “0” it will operate as a short contact (about 0.5 sec).

Parameters 40, 41 – Relay Inverse ModeThe values in this parameter will specify the relay numbers that will operate in inverse mode. For this purpose, the value will be encoded as a 2-digit number “AB” where “A” is the number of the first relay, and “B” is the number of the second relay. For example, if the parameter value is “35” or “53” it means the relays N3 and N5 will operate in inverse mode. Relays can operate in an inverse mode in two different ways:

- When the first and the second relays are connected to two different buttons. In this case, after pressing a button, the corresponding relay connected to that button will toggle its state (‘ON to OFF’ or ‘OFF to ON’), and the other relay will be switched OFF.

- When two relays are connected to the same button. In this case, the relays will operate in roller shutter mode and their behavior will follow these four cycles:• 1 st press of a button: the first relay will be switched ON, the second relay will be switched OFF• 2 nd press of a button: both relays will be switched OFF• 3 rd press of a button: the second relay will be switched ON, the first relay will be switched OFF• 4 th press of button: both relays will be switched OFF

Note: In this mode, both relays cannot be switched ON at the same time (i.e. simultaneously).Note: Switching OFF one relay will always operate before switching ON another relay to prevent both relays frombeing ON at the same time.Note: Two groups of inverse relays can be specified, one group in Parameter 35 another group in Parameter 36Parameters 42-51- Relays Control by SensorsIn these parameters, the relay state changes depending on a sensor threshold value. For these configurations,parameter values are encoded as 8-digit numbers (ABCDEFGH):A = Relay number (1 through 5)B = Control Mode0-Temperature Sensor,1-Humidity Sensor,2-Light Sensor,3-Time controlC = State change relative to the value in EFGH Condition Value fields (see below)0-Equal or lower than1-Equal or higher thanD: State Change,0-Switch OFF1-Switch ONEFGH: Condition Value“Sensor Value” for Control modes 0, 1, and 2, or “Time” for Control mode 3.If the temperature sensor has been chosen as a source in the control mode, the value should be x10, e.g. for 24.5°C use the value 0245.If Time control has been chosen as a source in the control mode, the device logic will process values EFGH from 0 to 23:59 (in time measure), all other values will be ignored.EF represents Hour (0 through 23),GH represents Minutes (0 through 59).All other numbers are reserved and will not affect the operation. To disable this option simply set this parameter to 0.The factory-default value: “0”Example: Parameter value 12010050 means A=1 (relay 1 output), B=2 (light sensor), C=0 (value lower than), D=1 (switch relay On), EFGH=0050. In this case, if the light sensor reading drops below 50 lums the relay 1 output will be switched On.Note: The relays still can be controlled manually using touch buttons according to Parameters 30-34 or via the gateway.

Note: The logic will implement the operation when the sensor value crosses the value in the Parameter. Meaning, that if the logic Switches on the relay and you manually switch it Off, the relay will switch On next time when the value crosses the set parameter.Parameters 52-56 – Relay Load Power in Watts.You may specify load consumption (in Watts) for each relay channel (1 through 5) in order to calculate total energy consumption relative to the time each relay is ON. The factory default-value: 0Parameters 57-61 – Associations Mode These parameters are intended for use when Multilevel Switch Group Associations (Groups 3, 5, 7, 9, & 11) have been activated. They define the logic of values changing if one of the touch buttons has been held for more than one second. They are useful options for controlling dimmers or roller shutter devices in the following three ways:“0” – On each hold event, “UP (brighten)” and “DOWN (dim)” commands will be alternately sent to associated devices. “1” – On each hold event, the “UP (brighten)” command will be sent to associated devices.“2” – On each hold event, the “DOWN (dim)” command will be sent to associated devices.The factory-default value: 0

Parameter 62 – Frequency RegionThe TPS05 has a Z-Wave 700 series chip inside which allows using of the device in different Z-Wave frequencies. If there is a need to use the device in a frequency different from the factory default change the value of this parameter according to the frequency list below.Note: The factory default frequency differs depending on which region the device was intended for sale in. Check the factory default frequency on the device plate or on the packaging.Note: Do not change this parameter value if there is no special need.Note: The frequency change will be applied only after removing from Z-Wave network and automatic reboot of the device․Note: The change of this parameter will result in an inability to control the device if the device was included in the controller/gateway which supports only one frequency,Note: Resetting the device to factory default settings will revert the frequency to the factory default value.Note: In most of the countries it is not allowed to use a frequency different from the frequency intended for that country.

Frequency list for different regions:

| 0: EU (868.4 MHz, 869.85 MHz)1: US (908.4 MHz, 916.0 MHz)2: ANZ (919.8 MHz, 921.4 MHz)3: HK (919.8 MHz)4: IN (865.2 MHz) | 5: IL (916.0 MHz)6: RU (869.0 MHz)7: CH (868.4 MHz)8: JP (922.5 MHz, 923.9 MHz, 926.3 MHz)9: KR (920.9 MHz, 921.7 MHz, 923.1 MHz) |

The full list of Z-Wave global regions where Z-Wave works is available at the Z-Wave Global Regions SiLabs page.

Parameter 63-67 – Output NO/NC ModeThe device can operate in Normal Open (NO) mode and in Normal Close (NC) mode. If the Parameter value = 0, the device switch operates in NO mode and there is no voltage on output when the device is in OFF state. The output will be powered when the device goes to the ON state. If the Parameter value = 1, the output will be powered in the OFF state, and will be no voltage on output when the device is in the ON state.The factory default value is 0 (NO mode).Parameters 68-80 – Reserved by ManufacturerThese parameters are reserved for future updates and new functionality. Changing these parameters will not have any effect on the device.

Factory Default Parameters

| Number | Size | Name | Description | Default Value | Available Values |

| 1 | 1 byte | TIME CORRECTION | Time correction by the controller | 1 | O. 1 |

| 2 | 1 byte | WEEKDAY | Week Day | 1 | 1. 2. 3. 4. 5. 6. 7 |

| 3 | 1 byte | HOUR | Time Hour | 0 | 0 to 23 |

| 4 | 1 byte | MINUTE | Time Minute | 0 | 0 to 59 |

| 5 | 1 byte | METER REPORT INTERVAL | Energy Consumption Meter Consecutive Report Interval. minutes | 10 | 1 to 120 |

| 6 | 1 byte | SENSORS REPORT INTERVAL | Sensors Consecutive Report Interval | 10 | 1 to 120 |

| 7 | 1 byte | TEMPERATURE REPORT THRESHOLD | Temperature difference to send to controller, value X 10 | 5 | 0. 1 to 100 |

| 8 | 1 byte | HUMIDITY REPORT THRESHOLD | Humidity to send to a differencecontroller. value X 10 | 2 | O. 1 to 25 |

| 9 | 1 byte | LIGHT REPORT THRESHOLD | Luminance to send to a differencecontroller in % | 50 | O. 10 to 90 |

| 1° | 1 byte | TOUCH SENSITIVITY | Touch buttons sensitivity: 1 = lowest sensitivity10 = highest sensitivity. | 6 | 1 to 10 |

| 11 | 1 byte | TEMP SENSOR CORRECTION | Temperature sensor calibration. x10 | 0 | -100 to +100 |

| 12 | 1 byte | 3ACKLIGHT ACTIVE COLOR | Active state backlight color | 1 | O. 1 |

| 13 | 1 byte | BACKLIGHT AUTO BRIGHTNESS | Backlight auto-brightness control | 1 | 0.1 |

| 14 | 1 byte | BACKLIGHT MANUAL BRIGHTNESS LEVEL | Backlight brightness in manual mode | 8 | 1 to 10 |

| 15 | 1 byte | BACKLIGHT1 CONTROL SOURCE | Backlight 1 control source | 1 | 0. 1. 2 |

| 16 | 1 byte | BACKLIGHT2 CONTROL SOURCE | Backlight 2 control source | 1 | 0. 1. 2 |

| 17 | 1 byte | BACKLIGHT3 CONTROL SOURCE | Backlight 3 control source | 1 | 0. 1. 2 |

| 18 | 1 byte | BACKLIGHT4 CONTROL SOURCE | Backlight 4 control source | 1 | 0. 1. 2 |

| 19 | 1 byte | 3ACKLIGHTS CONTROL SOURCE | Backlight 5 control source | 1 | 0. 1. 2 |

| 20 | 1 byte | RELAY1 CONTROL SOURCE | Relay 1 control source | 1 | 0. 1. 2. 3. 4. 5 |

| 21 | 1 byte | RELAY2 CONTROL SOURCE | Relay 2 control source | 2 | 0. 1. 2. 3. 4. 5 |

| 22 | 1 byte | RELAY3 CONTROL SOURCE | Relay 3 control source | 3 | 0. 1. 2, 3. 4. 5 |

| 23 | 1 byte | RELAY4 CONTROL SOURCE | Relay 4 control source | 4 | 0. 1. 2, 3. 4. 5 |

| 24 | 1 byte | RELAYS CONTROL SOURCE | Relay 5 control source | 5 | 0. 1. 2. 3. 4. 5 |

| 25 | 1 byte | HOLD CONTROL MODE | Hold control mode for touch button 1 | 1 | 0. 1. 2. 3 |

| 26 | 1 byte | HOLD2 CONTROL MODE | Hold control mode for touch button 2 | 1 | 0. 1. 2. 3 |

| 27 | 1 byte | HOLD3 CONTROL MODE | Hold control mode for touch button 3 | 1 | 0. 1. 2. 3 |

| 28 | 1 byte | HOLD4 CONTROL MODE | Hold control mode for touch button 4 | 1 | 0. 1. 2. 3 |

| 29 | 1 byte | HOLDS CONTROL MODE | Hold control mode for touch button 5 | 1 | 0. 1. 2. 3 |

| 30 | 1 byte | CLICK1 CONTROL MODE | Click control mode for touch button 1 | 1 | 0. 1. 2. 3.4. 5.6 |

| 31 | 1 byte | CLICK2 CONTROL MODE | Click control mode for touch button 2 | 1 | 0. 1. 2, 3. 4. 5.6 |

| 32 | 1 byte | CLICK3 CONTROL MODE | Click control mode for touch button 3 | 1 | 0. 1. 2. 3. 4. 5.6 |

| 33 | 1 byte | CLICK4 CONTROL MODE | Click control mode for touch button 4 | 1 | 0. 1. 2. 3. 4. 5.6 |

| 34 | 1 byte | CLICKS CONTROL MODE | Click control mode for touch button 5 | 1 | 0. 1, 2. 3. 4. 5.6 |

| 35 | 2 bytes | RELAY1 TIMER DURATION | Timer mode duration for button 1 | 0 | 0 to 43200 |

| 36 | 2 bytes | RELAY2 TIMER DURATION | Timer mode duration for button 2 | 0 | 0 to 43200 |

| 37 | 2 bytes | RELAY3 TIMER DURATION | Timer mode duration to button 3 | 0 | 0 to 43200 |

| 38 | 2 bytes | RELAY4 TIMER DURATION | Timer mode duration to button 4 | 0 | 0 to 43200 |

| 39 | 2 bytes | RELAYS TIMER DURATION | Timer mode duration to button 5 | 0 | 0 to 43200 |

| 40 | 1 byte | RELAY INVERSE GROUP1 | Group 1 relay inverse mode | 0 | 0, 12, 13, 14, 15,21, 23, 24, 25,31, 32, 34, 35,41, 42, 43, 45,51, 52, 53, 54 |

| 41 | 1 byte | Group 2 relay inverse mode | 0 | 0, 12, 13, 14, 15,21, 23, 24, 25,31, 32, 34, 35,41, 42, 43, 45,51, 52, 53, 54 | |

| RELAY INVERSE GROUP2 | |||||

| 42 | 4 bytes | RELAY CONTROL SCENARIO? | Relays control by sensors Group 1 | 0 | 0. 10000000 to53112359 |

| 43 | 4 bytes | RELAY CONTROL SCENARIO2 | Relays control by sensors Group 2 | 0 | O. 531110000000 to53112359 |

| 44 | 4 bytes | RELAY CONTROL SCENARIO3 | Relays control by sensors Group 3 | 0 | 0. 10000000 to53112359 |

| 43 | 4 bytes | Relays control by sensors Group 4 | 0 | 0. 10000000 to53112359 | |

| RELAY CONTROL SCENARIO4 | |||||

| 46 | 4 bytes | RELAY CONTROL SCENARIOS | Relays control by sensors Group 5 | 0 | 0. 10000000 to53112359 |

| 47 | 4 bytes | RELAY CONTROL SCENARIOS | Relays control by sensors Group 6 | 0 | 0. 531110000000 to2359 |

| 48 | 4 bytes | RELAY CONTROL SCENARIO7 | Relays control by sensors Group 7 | 0 | 0. 10000000 to53112359 |

| 49 | 4 bytes | RELAY CONTROL SCENARIOS | Relays control by sensors Group 8 | 0 | O. 531110000000 to2359 |

| 50 | 4 bytes | RELAY CONTROL SCENARIO9 | Relays control by sensors Group 9 | 0 | 0. 10000000 to53112359 |

| 51 | 4 bytes | Relays control by sensors Group 10 | 0 | 0. 10000000 to53112359 | |

| RELAY CONTROL SCENARI010 | |||||

| 52 | 2 bytes | RELAY LOAD POWER | , ower of the Relay 1 load in Watts | 0 | 0 to 1100 |

| 53 | 2 bytes | RELAY2 LOAD POWER | , ower of the Relay 2 load in Watts | 0 | 0 to 1100 |

| 54 | 2 bytes | RELAY3 LOAD POWER | , ower of the Relay 3 load in Watts | 0 | 0 to 1100 |

| 55 | 2 bytes | RELAY4 LOAD POWER | , ower of the Relay 4 load in Watts | 0 | 0 to 1100 |

| 56 | 2 bytes | RELAYS LOAD POWER | , ower of the Relay 5 load in Watts | 0 | 0 to 1100 |

| 57 | 1 byte | TOUCH1 ASSOCIATION MODE | Touch control mode for associations with touch button 1 | 0 | 0. 1. 2 |

| 58 | 1 byte | TOUCH2 ASSOCIATION MODE | Touch control mode for associations with touch button 2 | 0 | 0. 1. 2 |

| 59 | 1 byte | TOUCH3 ASSOCIATION MODE | Touch control mode for associations with touch button 3 | 0 | 0. 1. 2 |

| 60 | 1 byte | TOUCH4 ASSOCIATION MODE | Touch control mode for associations with touch button 4 | 0 | 0. 1. 2 |

| 61 | 1 byte | TOUCHS ASSOCIATION MODE | Touch control mode for associations with touch button 5 | 0 | 0. 1. 2 |

| 62 | 1 byte | FREQUENCY REGION | frequency region | 0 | 0…9 |

| 63 | 1 byte | RELAYS OUTPUT MODE | Relay1 output NO/NC mode | 0 | 0.1 |

| 64 | 1 byte | RELAY2 OUTPUT MODE | Relay2 output NO/NC mode | 0 | 0.1 |

| 65 | 1 byte | RELAYS OUTPUT MODE | Relay3 output NO/NC mode | 0 | 0.1 |

| 66 | 1 byte | RELAY4 OUTPUT MODE | Relay4 output NO/NC mode | 0 | 0.1 |

| 67 | 1 byte | RELAYS OUTPUT MODE | Relays output NO/NC mode | 0 | O. 1 |

| 69-80 | Reserved by the manufacturer |

Limited Warranty

HELTUN warrants this product to be free from defects in workmanship or materials, under normal use and service, for a period of one (1) year from the date of purchase by the consumer (“Warranty Period”). HELTUN will extend this Warranty Period to three (3) years from the date of consumer purchase for any consumer who registers their warranty with HELTUN at this website page: bonus.heltun.com. This Limited Warranty applies only to the first end-user of the product and is not transferable.

If during the Warranty Period the product is determined to be defective or malfunctions due to workmanship or materials, HELTUN, at HELTUN’s option, shall either repair or replace the defective product. If the product is defective, (i) return it with dated proof of purchase to the place it was purchased; or (ii) contact HELTUN Customer Care by email at [email protected]. HELTON Customer Care will make the determination whether the product should be returned or whether a replacement product will be sent to you.

EXCEPT AS MAY BE OTHERWISE PROVIDED BY APPLICABLE LAW, THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER COVENANTS AND WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. HILTON MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THIS LIMITED WARRANTY DOES NOT COVER REMOVAL OR REINSTALLATION COSTS. THIS LIMITED WARRANTY SHALL NOT APPLY IF IT IS SHOWN BY HELTON THAT THE DEFECT OR MALFUNCTION WAS CAUSED BY DAMAGE DONE BY A CONSUMER INCLUDING DURING INSTALLATION. THIS LIMITED WARRANTY IS VOID IF DEFECT(S) RESULT FROM A FAILURE TO HAVE THIS PRODUCT INSTALLED PROPERLY.HELTON’S SOLE RESPONSIBILITY AND THE CONSUMER’S SOLE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE TO REPAIR OR REPLACE THE PRODUCT WITHIN THE TERMS STATED ABOVE. HELTUN SHALL NOT BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING, DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF ANY WARRANTY, EXPRESS OR IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. IN NO EVENT SHALL HELTUN’S LIABILITY EXCEED THE AMOUNT ACTUALLY PAID FOR THE PRODUCT WHETHER SUCH LIABILITY ARISES FROM A CLAIM BASED ON WARRANTY, TORT, OR CONTRACT. THESE LIMITATIONS ON LIABILITY SHALL REMAIN IN EFFECT EVEN IF HELTON WAS ADVISED OF THE POSSIBILITY OF SUCH INJURIES, LOSSES, OR DAMAGES.

SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THIS LIMITATION MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY IS THE ONLY EXPRESS WARRANTY HELTUN MAKES ON THIS PRODUCT.

If you have any questions concerning this limited warranty, please write HELTUN Customer Care at [email protected].

HILTON, INC. A USA DELAWARE CORPORATION.2/5 ARMENAKYAN STR., YEREVAN, 0047, ARMENIAWWW.HELTUN.COM [email protected]

References

[xyz-ips snippet=”download-snippet”]

• Source 1 wire: connect the required power source for relays 1, 2 and 3 to the terminal labeled “IN 1-3”.• Source 2 wire: connect the required power source for relays 4 and 5 to the terminal labeled “IN 4-5”.• Loads: connect the required loads to the relay output terminals labeled “OUT-1”, “OUT-2”, “OUT-3”, “OUT-4”, “OUT-5”.Note: HELTUN recommends installing cord terminals (electric wire ferrule) on the ends of wires before connecting them to the HE-TPS05 outputs (various colors terminals are included in the packaging).

• Source 1 wire: connect the required power source for relays 1, 2 and 3 to the terminal labeled “IN 1-3”.• Source 2 wire: connect the required power source for relays 4 and 5 to the terminal labeled “IN 4-5”.• Loads: connect the required loads to the relay output terminals labeled “OUT-1”, “OUT-2”, “OUT-3”, “OUT-4”, “OUT-5”.Note: HELTUN recommends installing cord terminals (electric wire ferrule) on the ends of wires before connecting them to the HE-TPS05 outputs (various colors terminals are included in the packaging).