XeRUN

USER MANUALSensored Brushless MotorXERUN 4268/4274 G320201120

Thank you for purchasing this HOBBYWING product! The power of the brushless power system is powerful. Any improper use may cause personal injury and damage to the product and related devices. We strongly recommend reading through this user manual before use and strictly abiding by the specified operating procedures. We shall not be liable for any liability arising from the use of this product, including but not limited to reimbursement for incidental or indirect losses. Meanwhile, we do not assume any responsibility caused by unauthorized modification of the product. We have the right to change the product design, appearance, performance, and use requirements without notice.

Warnings![]()

- Never leave this unit unsupervised when it is powered on.

- All wires and connections should be well insulated. Short circuits can possibly damage the products.

- Avoid incorrect connections between the electronic speed controller(ESC)and the motor.

- Never allow this product to come in contact with water, oil, fuel, or other electro-conductive liquids. If this happens, stop the use of your product immediately and let it dry carefully.

- Please carefully check the power devices and manual of the car frame to ensure the power pairing is reasonable. Avoid wrong pairing to overload and damage the motor.

- Never apply full throttle if the pinion is not installed. Due to the extremely high RPMs without load, the motor can get damaged.

- Always wire up all the parts of the equipment carefully. If any of the connections come loose as a result of vibration, your model RC may lose control.

- Never allow the motor case to get 100 degrees Celsius(212 degrees Fahrenheit) because the magnets may be demagnetized by high temperatures.

Features

- When the built-in chip of the motor is matched with the Hobbywing XeRun XR8 series of ESC, the ESC can automatically identify the motor and build a pure sensor mode power system, providing better manipulating performance and a more delicate manipulating feel.

- When this motor is used together with Hobbywing XERUN XR8 PRO G2 ESC can start more effective turbo timing than the last generation of the system. The motor can release maximum power instantly. The maximum speed can be promoted by 50%. Easily win your rival.

- The motor adopts the patent technology of an “error-free” Hall sensor system, the independent high-speed and high-precision encoder always outputs pure rotor position signal, which effectively avoids the interference of sensor signal and makes the motor work stably in sensor state.

- The mechanical turbo timing of the motor can be adjusted from 20-40°. It is convenient for the driver to calibrate accurately the output power of the motor and meet the power requirements of various applications.

- The motor has a low cogging effect and a small torque pulse. It is very smooth at low speed and has superb manipulating performance.

- The protection grade of an Off-Road motor is IP5X. Its excellent dustproof performance can easy to deal with various Off-Road dusty track environments.

- On the premise of improving the performance, the design of 4268SD G3 is optimized which extremely reduces the weight of the motor. The weight of 1900KV / 2200KV is 20g / 45g lighter than peers. The light motor is convenient for the driver to adjust the balance performance of the vehicle.

Specifications

| PN | Model | KV(No-load) | LiPo | Internalresistance | No-load current |

| 30401906 | XERUN-4268SD-1900KV-G3-Off Road | 1900KV | 2-6s | 0.0075 Q | 4A |

| 30401907 | XERUN-4268SD-2200KV-G3-Off Road | 2200KV | 2-6s | 0.0069 Q | 4.1A |

| 30401908 | XERUN-4268SD-2000KV-G3-0nRoad | 2000KV | 2-6s | 0.0069 Q | 4.2A |

| 30401909 | XERUN-4268SD-2800KV-G3-0nRoad | 2800KV | 2-4s | 0.0035 Q | 6.1A |

| 30405001 | XERUN-4274SD-2250KV-G3 | 2250KV | 2-6s | 0.0037 Q | 5A |

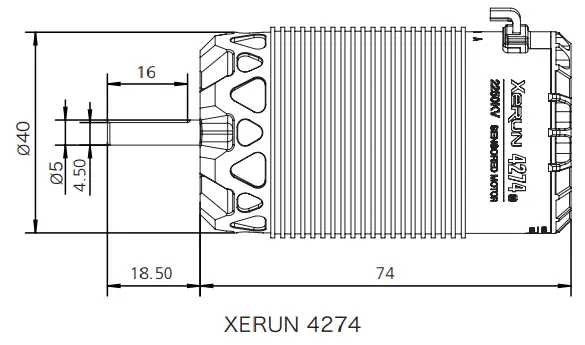

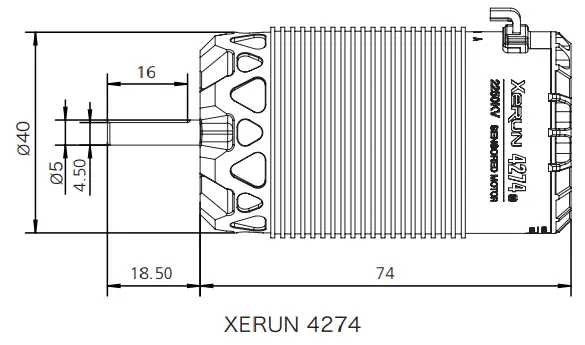

| Outer diameter/Length | Bearing size(mm) | Shaft diameter/ Exposed shaft length | Pole | Weight | Application |

| 42mm (1.654in )

67.8mm (2.669in ) |

Front: D16*D5*T5

Rear: D11*D5*T5 |

5mm (0.197in )18.5mm (0.728in ) | 4 | 315g | 1/8 Off-load |

| 285g | |||||

| 285g | 1/8 On-road | ||||

| 300g | |||||

| 42mm(1.654in) 74mm(2.913in) | 354g | 1/8 Truck, Monster truck |

|

|

Installation & Connection

- Install the motormounting screw specifications are two groups of M3 and two groups of M4. The motor screw hole can be locked into a depth of 5.5mm. Before installing the motor on the vehicle, please carefully confirm whether the specification of the matching screw is appropriate, so as to avoid damaging the motor by using too long or too thick a screw. Generally, it is recommended to use an m3 / M4 screw with a length not longer than 8mm, which is determined according to the thickness of the frame motor mounting base.

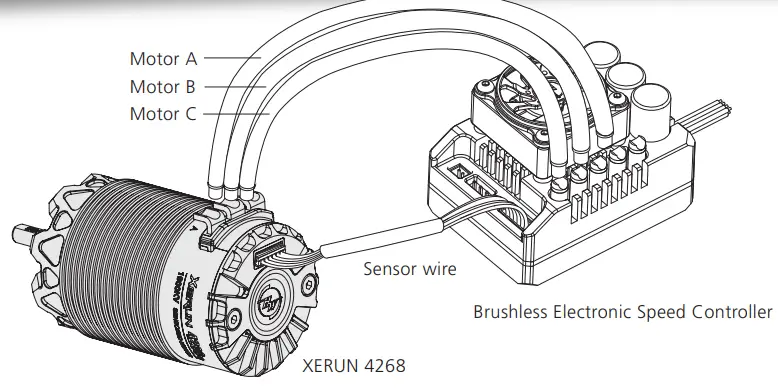

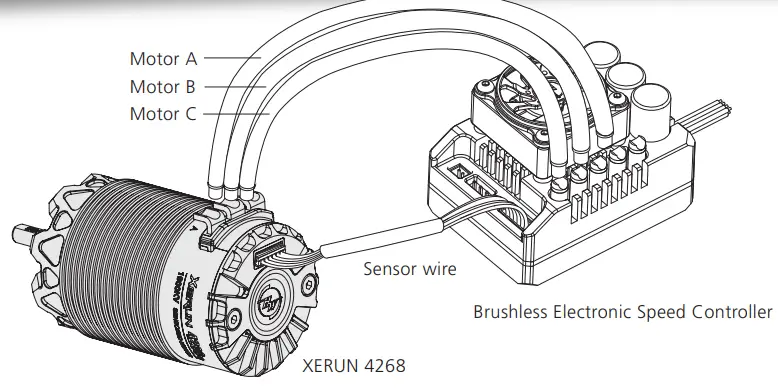

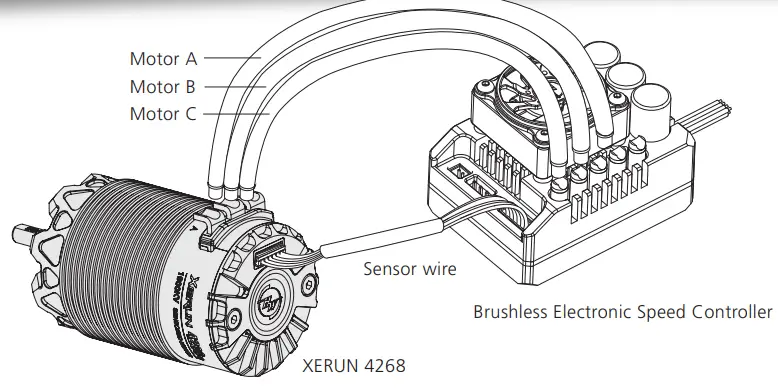

- Motor connection• When welding / connecting the motor and the electronic speed controller (ESC), please pay attention to the ESC marking to ensure that the terminals on the ESC and the motor are one-to-one, that is, wire A of the ESC matches wire A of the motor, wire B of the ESC matches wire B of the motor, wire C of the ESC matches wire C of the motor.• Make sure the sensor wire is clean and undamaged, and pay attention to the orientation of the sensor wire. Connect the sensor wire to the terminal of the motor and ESC in the correct direction.

- InspectionBefore powering on the remote control vehicle, please check the reliability of the motor installation and the correctness of all connections.

Timing Adjustment

- With the motor direction set to CCW, take the graduation/value after “CCW” on the motor case as the starting point when adjusting the timing. With the reversed triangle pointing at a value /graduation, the smaller/bigger the value, the smaller/bigger the timing. The timing is 40 degrees in picture 1.

- With the motor direction set to CW, take the graduation/value after “CW” on the motor case as the starting point when adjusting the timing. (With the reversed triangle pointing at a value/graduation, the smaller/bigger the value, the smaller/bigger the timing. The timing is 20 degrees in picture 1.

- The motor timing is 30 degrees by default (as shown in picture 2). The motor timing should be within 30 to 40 degrees if you want to activate the Turbo timing. And the timing can be within 20 to 40 degrees if you have no intention to activate the Turbo timing.

Gearing

Reasonable selection of gear ratio is very important. Improper gear ratio may bring you great loss. Please according to the following points to select ng, follow the reverse steps.

Parts List

[xyz-ips snippet=”download-snippet”]