USER MANUALBrushless Electronic Speed ControllerXERUN XR10 Justock G3XERUN XR10 Justock G3-Handout Spec

Disclaimer

Thank you for purchasing this HOBBYWING product! The power of the brushless power system is powerful. Any improper use may cause personal injury and damage to the devices. Please read through this manual before use and strictly abide by the specified operating procedures. We shall not be liable for any liability arising from the use of this product, including but not limited to reimbursement for incidental or indirect losses. Meanwhile, we do not assume any responsibility caused by unauthorized modification of the product. We have the right to change the product design, appearance, performance and use requirements without notice.

Warnings

- Ensure all wires and connections are well insulated before connecting the ESC to related devices, as a short circuit will damage your ESC.

- Ensure all devices are well connected, in order to prevent poor connections that may cause your vehicle to lose control or other unpredictable issues like damage to the device.

- Please carefully check the power devices and manual of the car frame to ensure the power pairing is reasonable. Avoid wrong pairing to overload the motor and damage the ESC.

- Please use a soldering iron with the power of at least 50W to solder all input/output wires and connectors.

- Stop using the ESC when its outer temperature exceeds 90 ℃/194 ℉; otherwise, your ESC will get destroyed and may also get your motor damaged.

- Always disconnect and remove batteries after use, as the ESC will continue to consume current if it’s still connected to batteries (even if the ESC is turned off). Long-time contact will cause batteries to completely discharge and result in damage to batteries or ESC or both. This will not be covered under warranty.

Features

- The timing has been permanently set to 0 degree. With the identical competition motor, this ensures that every driver will have the same power system and have a really just race.

- Aluminum housing top with excellent heat dissipation and great current endurance.

- The built-in capacitor avoids the trouble of finding an installation position for the external capacitor module, saves space and is convenient for layout;

- The built-in reverse connection protection circuit prevents damaging ESC due to the reverse connection of the battery.

- The innovative capacitor overheats protection function can effectively avoid the capacitor explosion caused by overload and finally damage the ESC.

- Multiple protections: battery low-voltage cutoff protection, over-temperature protection, fail-safe (throttle signal loss protection), and motor lock-up protection.

- Supports multifunction LCD program box and OTA programmer to set parameters of ESC, which is convenient for outside use.

- Supports firmware upgrade of ESC (Multi-function LCD program box or OTA Programmer need to be purchased), Enjoy the latest features permanently.

- Supports various RPM limit values to meet the needs of different races. It can be set directly by the program box or OTA programmer, which is simple and convenient.

Specifications

| Model | XERUN XR10 Justock G3XERUN XR10 Justock G3-Handout Spec |

| Cont./Peak Current | 60A / 380A |

| Motor Type | Sensorless/Sensored Brushless Motor |

| Applications | 1/10 、1/12 On-road and Off-road club competition and normal training |

| Motor Limit | ≥10.5T 3650 Motor |

| LiPo Cells | 2S Lipo(Only 2S) |

| BEC Output | 6V/7.4V @ 4A(Switch-mode) |

| Cooling fan | Powered by built-in BEC |

| Connector | Input End: No Connectors; Output End: No Connectors |

| Size/Weight (including wire) | 40.9(L)x33.9(W)x32.1(H)/ 75.4g(Including weight of wire) |

| Programming port | Independent programming port |

Connect ESC

This is an extremely powerful brushless motor system. For your safety and the safety of those around you, we strongly recommend removing your pinion gear before performing calibration and programming functions with this system, and keeping wheels in the air when you turn on the ESC.

This is an extremely powerful brushless motor system. For your safety and the safety of those around you, we strongly recommend removing your pinion gear before performing calibration and programming functions with this system, and keeping wheels in the air when you turn on the ESC.

Please wire correctly according to wiring instructions and wiring diagram.

- Motor WiringThe sensored motor wiring is a little different from the sensorless motor wiring; please make sure that you will strictly follow the introductions below.A. Sensored Brushless Motor WiringThere is strict wiring order from the ESC to the motor, the three A/B/C ESC wires must connect to the three A/B/C motor wires correspondingly and then connect the ESC sensor portand the motor sensor port with the stock 6-pin sensor cable.Note 1: If you don’t plug the sensor cable in, your ESC will still work in sensorless mode. It is like the ESC connects to a sensorless brushless motor.B. Sensorless Brushless Motor WiringThere is no polarity on the A/B/C wires between ESC and motor, so do not worry about how you connect them initially. You may find it necessary to swap two wires if the motor runs inreverse.

- Receiver WiringPlug the throttle control cable (also called Rx cable) on the ESC into the throttle (TH) channel on the receiver. So please do not supply power to the receiver. Otherwise, your ESC may be damaged.

- Battery WiringConnect the battery when the ESC is powered off. Make sure positive (+) of ESC connects to positive (+) of battery, and negative (-) of ESC connects to negative (-) of battery when you plug in your battery! Then turn on the ESC to run it.

ESC Setup

Set throttle range

You must reset the throttle range when you begin to use a new ESC, or the transmitter changes the parameters such as the TRIM, D/R, EPA, and other parameters, otherwise, the ESC cannot work properly.We strongly recommend activating the “Fail-Safe” function of the transmitter and set no signal protection for the throttle channel of a transmitter (F/S) to “OFF” or set its value to the “Neutral Position” to ensure the motor can be stopped when there is no signal received from the transmitter. The throttle calibration steps is as follows:

- Turn on the transmitter, set parameters on the throttle channel like “D/R”, “EPA” and “ATL” to 100% (for transmitter without LCD, please turn the knob to the maximum) and the throttle “TRIM” to 0 (for transmitter without LCD, please turn the corresponding knob to the neutral position).

- Turn off the ESC. Hold the SET button and turn on the ESC, the RED LED on the ESC starts to flash (the motor beeps at the same time), and then release the SET button immediately. (The ESC will enter the programming mode if the SET button is not released in 3 seconds, then you need to restart from step 1.)Note: Beeps from the motor may be low sometimes, and you can check the LED status instead.

- Set the neutral point, the end position of forward and the end position of backward.1) Leave the throttle trigger at the neutral position, press the SET button, the RED LED dies out and the GREEN LED flashes once and the motor beeps 1 time to store the neutral position.2) Pull the throttle trigger to the end position of forward, press the SET button, the GREEN LED flashes twice and the motor beeps 2 times to store the end position of forward.3) Push the throttle trigger to the end position of backward, press the SET button, the GREEN LED flashes 3 times and the motor beeps 3 times to store the end position of backward.Note:• The end position of forwarding: Pull the trigger to the maximum throttle position if it is the pistol-style transmitter. Push the throttle to the top if it is the board-style transmitter.• The end position of backward: Push the trigger to the maximum brake position if it is the pistol-style transmitter. Pull the throttle to the bottom if it is the board-style transmitter.

- The motor can work normally after the throttle range calibration is complete.

Programmable Items

Those “black background and white text” options are the factory default settings.

| Programmable Items | Option 1 | Option 2 | Option 3 | Option 4 | Option 5 | Option 6 | Option 7 | Option 8 | Option 9 |

| 1. Running Mode | Forward with Brake | Forward/Reverse with Brake | Forward /Reverse | ||||||

| 2. Drag Brake Force | 0% | 5% | 10% | 20% | 40% | 60% | 80% | 100% | |

| 3. Cutoff Voltage | Disabled | 2.6V/Cell | 2.8V/Cell | 3.0V/Cell | 3.2V/Cell | 3.4V/Cell | |||

| 4. Start Mode (Punch) | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 |

| 5. Max Brake Force | 25% | 50% | 75% | 100% | |||||

| 6. Max Reverse Force | 25% | 50% | 75% | 100% | |||||

| 7. Initial Brake Force | 0% | 20% | 40% | ||||||

| 8. Neutral Range | 6% | 9% | 12% | ||||||

| 9. ESC Thermal Protection | Disabled | ||||||||

| 10. Motor Thermal Protection | Disabled | ||||||||

| 11. Motor Rotation | CCW | CW | |||||||

| 12. BEC voltage | 7.4V | ||||||||

| 13. RPM Limit | Standard | 25000rpm | 22500rpm | 20000rpm | 17500rpm | 15000rpm | 12500rpm | ||

| Handout | 33500rpm | 30000rpm | 26500rpm | 23000rpm | 20000rpm | 18000rpm |

- Running ModeOption 1: Forward with BrakeThe vehicle can go forward and brake but cannot reverse in this mode. This mode is usually for racing.Option 2: Forward/Reverse with BrakeThis mode provides the braking function, it’s usually for training. “Forward/Reverse with Brake” mode adopted the “DOUBLE-CLICK” method, that is your vehicle only brakes (won’t reverse) when the 1st time you push the throttle trigger from neutral zone to backward zone. If the motor stops when the throttle trigger quickly return to the neutral zone and then re-push the trigger to the backward zone, the vehicle will reverse. If the motor does not stop, then your vehicle won’t reverse but brake, you need to return the throttle trigger to the neutral zone and push it to the backward zone again. The vehicle only reverses after the motor stops. This method is for preventing vehicles from being accidentally reversed.Option 3: Forward/ReverseThis model used the “SINGLE-CLICK” method to make the car go backward. When you move the throttle trigger from neutral zone to backward zone, the car will go backward immediately.

- Drag Brake ForceDrag brake is the braking power produced when releasing the throttle trigger to the neutral zone. This is to simulate the resistance applied by the carbon brush of the brush motor to the rotator of the motor while coasting.(Attention! Drag brake will consume much power, so please apply it cautiously.)

- Cutoff Voltage (or Low Voltage Cutoff Threshold)The ESC will monitor the battery voltage all the time, once the voltage is lower than the threshold value, the ESC will reduce the power to 50% and cut off the power output in 10 seconds. When enters into voltage protection, the RED LED will single flash that repeats ( ☆, ☆, ☆, ☆…….). Please set the “Cutoff Voltage” to “Disabled” if you are using NiMH batteries.

- Start Mode /PunchYou can choose the punch from level 1 (very soft) to level 9 (very aggressive) as per the track, tires gripping, your preference and etc. This feature is very useful for preventing tires from slipping in the starting-up process. In addition, “level 7”, “level 8 and “level 9” have strict requirements on the battery’s discharge capability. It may affect the starting-up if the battery discharges poorly and cannot provide large current in a short time. The car stutters or suddenly loses power in the starting-up process indicating the battery’s discharge capability is not good; you need to reduce the punch or increase the FDR (Final Drive Ratio).

- Max. Brake ForceThis ESC provides the proportional braking function; the braking effect is determined by the position of the throttle trigger. The max. brake force is produced when the throttle trigger is at the brake bottom position. Please select the max. brake force parameter as per your car condition and your preference.

- Max. Reverse ForceThe different reverse amounts will bring different reversing speeds. For the safety of your vehicle, we recommend using a low amount.

- Initial Brake ForceIt also called min. brake force. It refers to the brake force applied to the motor at the initial position. It seems like a point brake. The default value is equal to the drag brake force, so as to form a soft brake effect.

- Throttle Neutral RangeAs not all transmitters have the same stability at “neutral position”, please adjust this parameter as per your preference. You can adjust to a bigger value when this happens.

- ESC Thermal ProtectionThe output from the ESC will be cut off with the value you have preset. The GREEN LED flashes ( ☆, ☆, ☆) when the ESC temperature reaches to the preset value. The output will not resume until the ESC temperature gets down.Warning! Please do not disable this function unless you’re in a competition. Otherwise, the high temperature may damage your ESC and even your motor.

- Motor Thermal ProtectionAfter enabling this function, the output will be automatically closed when the motor temperature reaches the preset value. The green light flashes until the temperature drops to restore the output. When the motor is overheated, the green light will flash twice in cycle.Warning! Please do not disable this function unless you’re in a competition. Otherwise, the high temperature may damage your motor and even your ESC. For non-Hobbywing motors, the ESC may get this protection activated too early/late because of the different temperature sensors inside the motor. In this case, please disable this function and monitor the motor temperature manually.

- Motor RotationIt is used to adjust the rotation direction of the motor (in CW or CCW), that is, when the forward throttle is given, and the rotation direction of the motor is reversed, it can be set to the opposite direction.

- BEC VoltageThe BEC voltage can be adjusted at 6.0V and 7.4V. The normal steering servo is generally set at 6.0V, and the high-voltage steering servo can be set at 7.4v. Select the appropriate voltage according to the steering servo used.

- RPM LimitIt is used to set the max. RPM value of the motor. Set corresponding values according to competition rules.This parameter has two choices according to different versions of ESC used:1. If use Hobbywing’s Standard ESC (XR10 Justock G3 ), then select the rpm limit of “Standard” in the table.2. If use Hobbywing’s Handout ESC (XR10 Justock G3-Handout Spec, then select rpm limit of “Handout” in the table.

ESC Programming

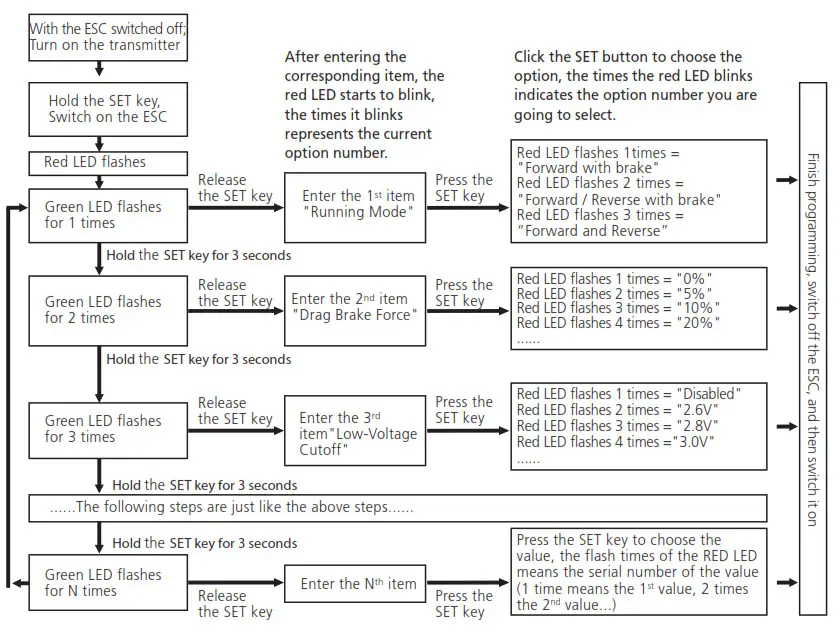

- Programming your ESC with the SET button

• For easy recognition, the motor beeps at the same time when the LED flashes.• When “N” (the number) is equal to/bigger than 5, we use a long flash to represent “5”. For example, the GREEN LED flashes a long flash (and the motor beeps a long beep at the same time) indicating you are in the 5 programmable item; if the GREEN LED flashes a long flash and a short flash (and the motor beeps a long beep and a short beep at the same time) indicating you are in the 6 the programmable item; a long flash and two short flashes ( a long beep and two short beeps at the same time) indicating you’re in the 7th programmable item and so on.

• For easy recognition, the motor beeps at the same time when the LED flashes.• When “N” (the number) is equal to/bigger than 5, we use a long flash to represent “5”. For example, the GREEN LED flashes a long flash (and the motor beeps a long beep at the same time) indicating you are in the 5 programmable item; if the GREEN LED flashes a long flash and a short flash (and the motor beeps a long beep and a short beep at the same time) indicating you are in the 6 the programmable item; a long flash and two short flashes ( a long beep and two short beeps at the same time) indicating you’re in the 7th programmable item and so on. - Program your ESC with a LCD program box(For detailed information, please refer to the user manual of the LCD program box.)You can use LCD program box to set parameters, or connect LCD program box with a computer to set parameters (use HOBBYWING USB LINK software). Connect the ESC and LCD program box via a cable with two JR male connectors. Then power on the ESC, the LCD setting box will display the boot interface. Press any key on the LCD program box to set up communication between the LCD program box and the ESC, and displaying “CONNECTING ESC”. After several seconds, the current mode name will be displayed, and the first setting parameter will be displayed after that. Press “ITEM” and “VALUE” button to change the parameters. Press “OK” button to store the parameters to your ESC.

- Program your ESC with an OTA ProgrammerPlug the programming cable of OTA Programmer to the programming port of ESC. Then use the mobile phone to install HOBBYWING HW LINK App to set parameters.

Factory Reset

- Restore the default values with the SET buttonPress and hold the SET button for over 3 seconds anytime when the throttle trigger is at the neutral position (except during the ESC calibration and programming) can factory reset your ESC. RED & GREEN LEDs flash simultaneously indicating you have successfully restored all the default values within your ESC. Once you power the ESC off, and then back on, your settings will be back in the default mode.

- Restore the default values with a multifunction LCD program boxAfter connecting the program box to the ESC, continuously press the “ITEM” button on the program box until you see the “RESTORE DEFAULT” item, and then press “OK” to factory reset your ESC.

- Restore the default values with an OTA Programmer(Use HW LINK mobile phone App) Connect OTA Programmer to the ESC, enter into 【Parameters 】, click “reset” to factory reset your ESC.

Explanations for Different Status LED

- The throttle is in a neutral zone1) In normal Blinky mode (non-rpm limit mode), the red LED flashes rapidly.2) In the RPM limit mode, there are two different flashing modes due to two versions of XR10-Justock G3 and XR10-Justock G3 Handout Spec, the details are as follows:XR10-Justock G3:In RPM limit mode, when RPM limit is 25,000, the red LED long flashes once and the green LED flashes once.In RPM limit mode, when RPM limit is 22,500, the red LED long flashes once and the green LED flashes twice.In RPM limit mode, when RPM limit is 20,000, the red LED long flashes once and the green LED flashes three times.In RPM limit mode, when RPM limit is 17,500, the red LED long flashes once and the green LED flashes four times.In RPM limit mode, when RPM limit is 15,000, the red LED long flashes once and the green LED flashes five times.In RPM limit mode, when RPM limit is 12,500, the red LED long flashes once and the green LED flashes six times.XR10-Justock G3 Handout Spec:In RPM limit mode, when RPM limit is 33,500, the green LED long flashes once and the red LED flashes once.In RPM limit mode, when RPM limit is 30,000, the green LED long flashes once and the red LED flashes twice.In RPM limit mode, when RPM limit is 26,500, the green LED long flashes once and the red LED flashes three times.In RPM limit mode, when RPM limit is 23,500, the green LED long flashes once and the red LED flashes four times.In RPM limit mode, when RPM limit is 20,000, the green LED long flashes once and the red LED flashes five times.In RPM limit mode, when RPM limit is 18,000, the green LED long flashes once and the red LED flashes six times.

- The throttle is in a non-neutral zone1) The RED LED turns on solid when moving forward. Green LED is also on when the throttle trigger is at the end position of forwarding (100% throttle ,on non-speed limit mode).2) The RED LED turns on solid when you brake. The GREEN LED will also come on when pushing the throttle trigger to the full brake endpoint and setting the “Max. Brake Force” to 100%.3) The RED LED turns on solid when you reverse your vehicle.

- LED status when some Protection is Activated:1) The RED LED flashes a short, single flash that repeats ( ☆ -, ☆ -, ☆ -) indicating the low voltage cutoff protection is activated.2) The GREEN LED flashes a short, single flash that repeats ( ☆ -, ☆ -, ☆ -) indicating the ESC thermal / overheat protection is activated.3) The GREEN LED flashes a short, double flash that repeats ( ☆ - ☆ -, ☆ - ☆ -, ☆ - ☆ -) indicating the motor thermal /overheat protection is activated.4) The GREEN LED flashes a short, five times flash that repeats ( ☆ --☆☆--☆☆--☆☆--☆☆--, ☆ --☆☆--☆☆--☆☆--☆☆-) indicating the capacitor thermal /overheat protection is activated.

Trouble Shooting

| Trouble(s) | Possible Causes | Solution(s) |

| The motor was unable to start and the LED is not on after power on, and the cooling fan does not work. | 1. No power was supplied to the ESC.2. The ESC switch was damaged. | 1. Check if all ESC & battery connectors have been well soldered or firmly connected.2. Replace the broken switch. |

| The ESC was unable to start the motor after it was powered on, but the motor emitted a short, double beep (BB, BB, BB…) that repeats with GREEN LED on the ESC blinked. (The interval between two beeps was 1 second.) | The battery voltage was beyond the normal operating voltage range of the ESC. | Check the battery voltage. |

| ESC was unable to start the motor after it was powered on, but the red LED flashes quickly. | The throttle signal is not detected. | Check if the transmitter is turned on and bound, check if the throttle wire is reversely plugged in or whether the receiver is good (Insert the throttle wire to the channel of the servo to debug) |

| The motor suddenly stopped or significantly reduced the output in operation. | 1. The receiver was influenced by some foreign interference.2. The ESC entered the LVC protection.3. The ESC entered the thermal shutdown protection. | 1. Check the cause of interference on the receiver, and check the battery power of the transmitter.

2. The RED LED keeps flashing indicating the LVC protection is activated, please replace your pack.3. The GREEN LED keeps flashing indicating the thermal protectionis activated, please let your ESC cool down before using it again. |

| The motor stuttered but couldn’t start. | 1. The wire connections between the motor and ESC were not A-A, B-B and C-C.2. Some soldering between the motor and the ESC was not good.3. The ESC was damaged (some MOSFETs were burnt). | 1. Check the connections;2. Check all soldering points, please re-solder if necessary.3. Contact the distributor for repair. |

| The vehicle could run forward (and brake), but could not reverse. | 1. The throttle neutral position on your transmitter was actually in the braking zone.2. Set the “Running Mode” improperly.3. The ESC was damaged. | 1. Re-calibrate the throttle neutral position. The LED on the ESC is not on when the throttle trigger is at the neutral position.2. Set the “running mode” to “Forward/Reverse with Brake”.3. Contact the distributor for repair. |

| The car ran forward/backward slowly when the throttle trigger was at the neutral position. | 1. The neutral position on the transmitter was not stable, so signals were not stable either.2. The throttle range is not calibrated properly. | 1. Replace a transmitter with stable signal.2. Re-calibrate the throttle range or fine-tune the neutral position on the transmitter. |

| The setting of the throttle range cannot be completed. | The ESC did not receive the correct throttle signal. | Check if the transmitter is turned on and bound, check if the throttle wire is reversely plugged in or plugged in the wrong channel, whether the receiver is damaged (Insert the throttle wire to the channel of the servo to debug) |

[xyz-ips snippet=”download-snippet”]