HOBO Leaf Wetness Smart Sensor S-LWA-M003 User Manual

Test Equipment Depot – 800.517.8431 – 99 Washington Street Melrose, MA 02176 – TestEquipmentDepot.com

The leaf wetness smart sensor is designed to work with HOBO® stations with its plug-in modular connector. All calibration parameters are stored inside the smart sensor, which automatically communicates configuration information to the station without the need for any programming, calibration, or extensive setup. Unlike other leaf wetness sensors, the HOBO leaf wetness smart sensor does not require any painting or coating—it is ready to use.

Leaf Wetness Smart Sensor

S-LWA-M003

Items Included:

- Mounting bracket

- U-bolt

- Tie wraps

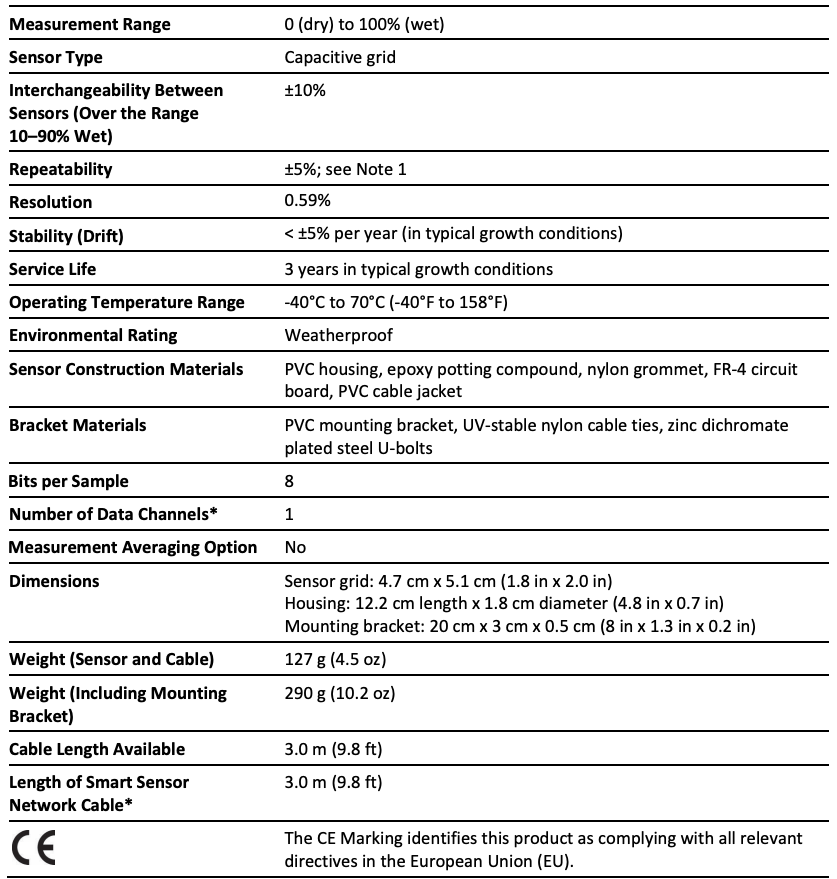

Specifications

* A single station can accommodate 15 data channels and up to 100 m (328 ft) of smart sensor cable (the digital communications portion of the sensor cables).

Note 1

Given the nature of the sensor design and sensor operating frequency, the system has inherent susceptibilities to Radio Frequency signals. The repeatability specification when subjected to certain RFI environments, such as those outlined in IEC 61000-4-3 and IEC 61000-4-6, may be significantly reduced.

The system level repeatability will be particularly affected when placed in an electric field of 3 V/m or greater in the 150 KHz to 1000 MHz range. RFI mitigation practices and physical deployment changes may reduce the system susceptibility. If deployments are planned in high RFI energy environments, Onset recommends on-site testing to determine system level repeatability.

Mounting

Placement and Mounting Considerations

- In most applications, the sensor should be mounted in whichever direction will prolong wetness the longest. For example, in the Northern hemisphere, orienting the sensor to face northwest will minimize exposure to solar radiation in the morning and maximize morning dew exposure.

- The leaf wetness sensor can be tilted to any angle. As the angle becomes steeper, water will run off the sensor more easily, reducing the amount of time the sensor stays wet. The exact angle used is a function of the type of vegetation of interest. Onset recommends using an angle of more than 15 degrees from horizontal to prevent puddles from forming on the sensor.

- The leaf wetness bracket can also be mounted to the cross arm (M-CAA or M-CAB).

- Be sure to secure the sensor cable with cable ties to protect the cable from damage. Wires should be bound tightly to the mast to help protect them from getting damaged in severe weather.

- Do not mount the sensor within two feet of the station case.

- Refer to the station manual and Tripod Setup Guide for more information regarding setting up stations.

Bracket Mounting

Onset recommends that you mount the leaf wetness smart sensor using the included bracket as shown in the figure below. To mount the sensor using the bracket:

- Use the U-bolt to secure the bracket to any 2.5 to 4 cm (1 to 1.6 inch) diameter mast.

- Use two cable ties to secure the sensor to the bracket. Do not fully tighten the cable ties.

- Note that one side of the sensor surface has a visible grid. The grid side should be facing upwards. Typically the sensor is mounted at an angle of 15 to 45 degrees from horizontal.

- Once the desired angle has been set, pull the cable ties tight and cut off the tag ends.

- Secure the sensor communications cable with cable ties between the sensor and data logger.

Typical Mounting of the Leaf Wetness Smart Sensor

Connecting the Sensor to a Station

To connect the sensor to a station, stop the station from logging and insert the smart sensor’s modular jack into an available smart sensor port on the station. See the station manual for details on operating stations with smart sensors.

Operation

The leaf wetness smart sensor measures the percentage of the sensor grid that is wet. A completely dry sensor will record 0% wetness, while a measurement of 100% wetness corresponds to the sensor being completely covered with a thin layer of water.

After prolonged exposure to very hot and wet environments, the sensor may return to only 1 to 3% wet when dried out, but given a day or two in a warm, dry environment, the sensor will recover and return to zero when dry.

IMPORTANT: Do Not Paint the Sensor.

Unlike most other leaf wetness sensors, the leaf wetness smart sensor is ready to use and should not be coated. Some manufacturers of leaf wetness sensors recommend painting their sensors with a flat latex paint to improve the sensor’s characteristics. These manufacturers supply their sensors uncoated and require the user to paint it.

Do not coat the HOBO leaf wetness smart sensor. Onset’s sensor is preconditioned and factory calibrated. Although it is certainly possible to alter the response of the sensor by painting it, applying any sort of coating will only reduce its sensitivity.

Calibration

The leaf wetness smart sensor should be field calibrated to determine the wet/dry transition point. Various types of vegetation will have varying transition points. The best practice is to install a station and the leaf wetness smart sensor in the study area and, while logging data, directly observe the plants to record the time of day that the vegetation makes the transition from wet to dry. Read out the station to determine the percent wetness when the wet/dry transition was observed. In most cases, this is the value that will best represent the wet/dry transition point for your study. You will need to retain this value for use with any third-party software.

Maintenance

The sensor is a capacitive sensor and is less sensitive to contamination than resistive sensors. However, dust, dirt or other contaminants on the sensor will retain moisture and that will ultimately affect the sensor’s performance. You should periodically inspect the sensor and gently clean the sensor grid once per year with a non-abrasive rag, mild soap, and fresh water.

Verifying Accuracy

It is recommended that you check the functionality of the Leaf Wetness smart sensor annually. If the sensor is not providing accurate data, it may be damaged or broken.

© 2010-2017 Onset Computer Corporation. All rights reserved. Onset and HOBO are trademarks or registered trademarks of Onset Computer Corporation. All other trademarks are the property of their respective companies.

9826-F MAN-S-LWA

[xyz-ips snippet=”download-snippet”]