Honeywell Home T100 Controllers Thermostatic Valve Actuators

DESCRIPTION

The T100 Controller is used with a V100 Radiator Valve to control radiators, convectors or baseboard heating units. The control is self-powered and requires no electrical connections. T100B,C Controllers consist of a valve actuator connected by capillary tubing to the sensor and setpoint dial. The setpoint dial and sensor of the T100B are a single unit, whereas the T100C sensor is separate from the dial (the sensor and dial are connected with a capillary tube). The actuator connects to the V100 valve.

SPECIFICATIONS

Power:Self-powered, no electrical connections.Components:Sensor, setpoint dial and valve actuator.Materials:Body: Industrial grade plastic with low thermal conductivity. Fastening Ring: Plated brass. Internal Parts: Brass thermostat capsule, other metals. Thermal Element: Liquid.

Capillary Length:T100B: 6-1/2 ft (2m) or 16 ft (5m). T100C: Two 4-1/2 ft (1.4m).Sensor Temperature Ratings:Range: 43°F to 79°F (6°C to 26°C). Maximum: 125°F (52°C).

Reference Guide

Table 1 shows setpoint temperatures under ideal conditions. Because factors affecting temperature at the sensor vary for each installation, it may be necessary to adjust the setpoint higher or lower to achieve the desired space temperature.

Table 1. T100B,C Setpoint Temperatures UnderIdeal Conditions.

| Fully cw | * | 1 | 2 | 3 | 4 | 5 | |

| °F | 43 | 56 | 61 | 64 | 68 | 72 | 75 |

| °C | 6 | 13 | 16 | 18 | 20 | 22 | 24 |

INSTALLATION

Location and Mounting

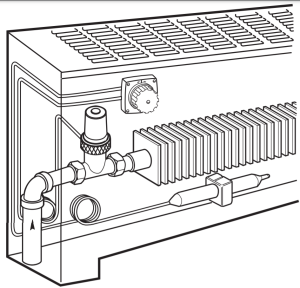

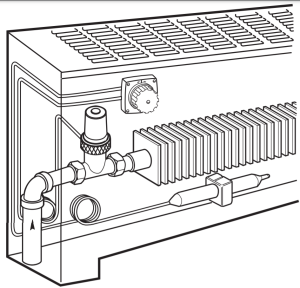

Mount the setpoint dial on a wall. The dial has reference marks (* through 5) and a setpoint of 43°F (6°C) when turned fully cw. The T100C setpoint dial can also be mounted on the enclosure shell, with the sensor mounted a minimum of three inches (75 mm)beneath the heating coils in the cold air return, see Fig. 1.Mount the sensor in a position with unobstructed air circulation. Mount the remote setpoint dial in an area with adequate access.

|

CAUTIONEquipment Damage Hazard.Removal of the knob or taking the T100 apart can result in irreparable calibration loss. Keep the entire T100 intact; the device contains no serviceable parts. |

Sensor

Several things must be considered when choosing the mounting location for the sensor. Avoid the following:

- Direct sunlight on the sensor.

- Mounting the sensor on a cold surface (such as an outside wall).

- Cold air drafts across the sensor.

- Locations consisting of dead air space (such as behind doors or curtains, or inside cabinets).

IMPORTANTThe T100B setpoint dial and sensor are one unit. Mount this unit on a wall where it can sense a representative room temperature

Capillary Tubing

Coil excess capillary tubing beneath and away from the heating coils.

|

CAUTIONEquipment Damage Hazard. Careless handling of the capillary tubing candamage the T100 beyond repair. Take care not to break, kink or sharply bend the capillary tubing. |

ActuatorThe actuator attaches to the valve with a threaded ring.

IMPORTANTImproper mounting of the actuator can cause overheating

- Screw the actuator to the valve body using the threaded ring.

- Firmly tighten the threaded ring to the valve body

TROUBLESHOOTING

| Symptom | Possible Cause | Solution |

| Not all sections of radiator heating | Many radiators are oversized and not all sections heat to maintain the desired room temperature. | System is OK. |

| Underheating | Sensor is in the wrong location. | Change sensor location (see Installation section), or change control type. |

| Capillary tube excess coiled above or too near to the heat source. | Coil below or away from heat source. | |

| Flow through the valve is in the wrong direction. | Check the arrow on the valve body. It should be in the direction of the flow. Change valve direction, or flow direction. | |

| Inadequate system temperature or pressure. | Check operating and limiting controls on the boiler. Check circulating pump and isolating valves. | |

| Steam traps are defective. | Repair or replace traps. | |

| Airlock in hot water system. | Open valve fully to allow air to pass. Install vents. | |

| Scale or debris is blocking flow. | Flush system. Do not use oil base additives. | |

| Heating cabinet dampers closed. | Open or remove dampers. | |

| Overheating | Sensor is in the wrong location. | Change sensor location (see Installation section), or change control type. |

| Control not properly installed. | Reset actuator on valve and tighten threaded ring to valve body. | |

| Capillary tube broken, kinked or bent sharply. | Replace control. | |

| Dirt or scale under seat preventing tight shutoff. | Remove control from valve body, allowing valve to open fully and flush away scale and debris. Reinstall control and turn fully clockwise. If valve does not fully close, remove control and inspect valve seat area using cartridge replacement tool or service socket tool. | |

| Flow through the valve is in the wrong direction, damaging the valve seat. | Check arrow on the valve body. It should be in the direction of the flow. Change valve direction, or flow direction.Remove valve cartridge and inspect for damage to seat disk. | |

| Steam traps are defective. | Repair or replace traps. | |

| Excessive differential pressure is forcing valve open. (Hot water systems.) | Install differential pressure regulator (D146A) to maintain less than 15 psi (103 kPa) differential between the supply and return pipes. | |

| Chattering or knocking. | Flow through valve is in the wrong direction. | Check the arrow on the valve body. It should be in the direction of the flow. Change valve direction, or flow direction. |

| Vacuum in system. | Steam: check traps and vents.Hot water: check expansion tank operation and location. | |

| Excessive differential pressure. | Install differential pressure regulator (D146A) to maintain less than 15 psi (103 kPa) differential between the supply and return pipes. | |

| Bent piping. | Ensure adequate space for piping |

[xyz-ips snippet=”download-snippet”]