Honeywell AQ25A42B Programmable Boiler Relay Control Panel

INSTALLATION JOB RECORD

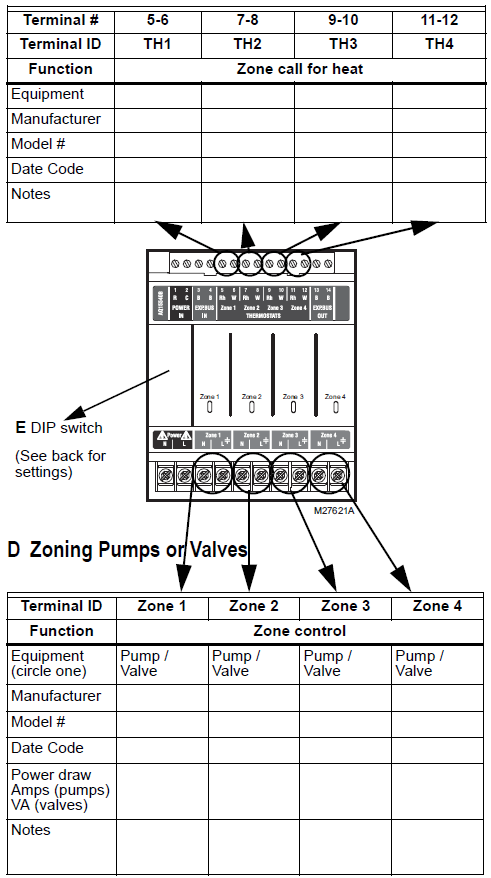

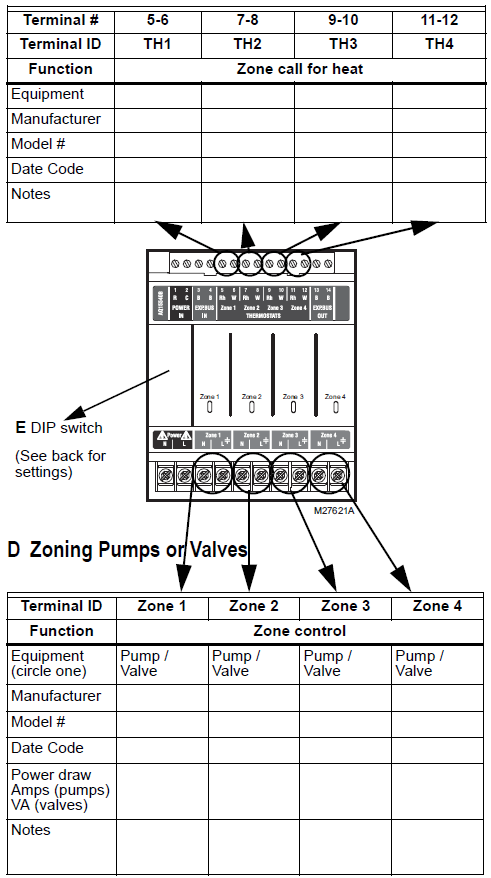

Fill in the details of the equipment connected to the control module and the zoning module:

A Low voltage control module wiringB Low voltage zone thermostatsC Line voltage zone pumps or low voltage zone valves without end switchesD Line voltage Boiler pump, DHW pump and AUX outputE Review and set DIP switch settings – once DIP switches for the zoning module (AQ15540B) have been set, complete the “Installer Settings” diagram by filling in the circles to indicate the DIP switch position set during installation

File this with other installation records for equipment used on this installation.

A Boiler Control Module

B Zoning Thermostats

E Zoning Module DIP Switch Settings

| DIP Number | Description |

| 1 | Zone Address

Slide the DIP switch to the right-hand (ON) position to indicate which group of zones this is: The correct DIP switch settings for each zone module are: • First Zone (1-4) Module:1 = ON position; 2, 3, and 4 = OFF position • Second Zone (5-8) Module:2 = ON position; 1, 3, and 4 = OFF position • Third Zone (9-12) Module:3 = ON position; 1, 2, and 4 = OFF position • Fourth Zone (13-16) Module: 4 = ON position; 1, 2, and 3 = OFF position For each zone group, there can be only one DIP switch in the right- hand (ON) position. |

| 2 | |

| 3 | |

| 4 | |

| 5 | • If set to SYNC, zone synchronization is enabled.

• If set to NOT, zone synchronization is disabled. |

| 6 | • If zone valves are normally closed (N.C.), set the NC/NO DIP switch to the OFF position.

• If zone valves are normally open (N.O.), set the NC/NO DIP switch to the ON position. |

| 7 | • If set to Group (ON position), the AUX Pump contacts on the Control Module are switched when any of the zones on this Zoning Module are active.a

• If set to – (OFF position), the AUX Pump contacts are not affected by activity on these zones. |

| 8 | • If set to 2-Stg (ON position), then 2-stage operation is activated on thermostat inputs. The zoning module operates as two 2-stage zones or 3 zones (one 2-stage and two 1-stage).

• If set to 1-Stg (OFF position), then operates as four 1-stage zones. |

The EQUIPMENT SETUP > AUXILIARY I/O > AUX PUMP menu option on the AQ25A must be set to “GROUP”

EQUIPMENT SETTINGS

The Installer Menu is used to establish and modify the system’s equipment and option settings. These include equipment settings for boiler operation, DHW management, zoning, auxiliary input/output operation, and option settings such as pump/valve exercise, and freeze protection. Use Table 1 to record the equipment settings for this installation.To record the equipment and option settings:

A Press the Home button to return to the Home Page display.B Press and hold the OK button for 3 seconds until the message, INSTALLER MODE – ARE YOU SURE?, displays.C Select YES, then press and release the OK button to display the Installer Menu.D Select the Equipment Setup sub-menu.E Record the configured settings in Table 1.F Exit Installer mode by selecting the Installer Exit menu option.

Table 1. Installer Menu – Equipment Setup Sub-menu.

| EQUIPMENT SETUP SUB-MENU | ||||

| Sub-Menu and Option | Range | Factory Default | Equipment Settings Used | |

| BOILER SETTINGS | ||||

| HIGH LIMIT | 120°F to 225°F (49°C to 107°C) | 190°F (88°C) | ||

| LOW LIMIT | 60°F to 180°F (15°C to 82°C) | 150°F | ||

| BOILER DIFF | 2°F to 41°F (1°C to 23°C) / AUTO | AUTO | ||

| W.W.S.D. | – –

35°F to 100°F (2°C to 38°C) |

70 °F (21°C) | ||

| MIN. RETURN | – – / 80°F to 180°F (27°C to 82°C) | 140 °F (60°C) | ||

| BOILER OPERATION | ||||

| CYCLES/HOUR | 2 to 6 | 4 | ||

| FIRE DELAY | 0 seconds to 3 minutes (in 5 second increments) | 10

(seconds) |

||

| PURGE TIME | OFF, 10 seconds to 30 minutes (in 10 second increments) | 30

(seconds) |

||

| EXERCISE | YES / NO | YES | ||

| FREEZE PROT | YES / NO | YES | ||

| 10V MOD. SELECT | ||||

| 10V MOD | 0-10V / 2-10V | 0-10V | ||

| USAGE | NONE / BOILER | NONE | ||

| DOMEST.HOT WATER | ||||

| DHW | ENABLE / DISABLE | ENABLE | ||

| DHW PRIO | YES / NO | NO | ||

| PRIO.OVER. | YES / NO | YES | ||

| DHW DEVICE | PUMP / VALVE | PUMP | ||

| DHW VLV.OP | 0 – 230 seconds (in 5 second increments) | 15

(seconds) |

||

| DHW PURGE | YES / NO | YES | ||

| DHW SENSOR | YES / NO | NO | ||

| DHW SETPOINT | 60°F to 160°F (16°C to 71°C) | 140°F (60°C) | ||

| DHW DIFF | 5°F to 40°F (2.5°C to 22°C) | 20°F (-7°C) | ||

| DHW VACANCY | [41°F + DHW DIFF] to 160°F ([5°C + DHW DIFF] to 71°C) | 45°F (7°C) | ||

| ZONING | ||||

| HT DMND PRIO | YES / NO | NO | ||

| PRIO.OVER | YES / NO | NO | ||

| ZONING VALVES TIME TO OPEN | 5 – 230

(seconds) |

15

(seconds) |

||

| HT DMND PRIO | YES / NO | NO |

| EQUIPMENT SETUP SUB-MENU | ||||

| Sub-Menu and Option | Range | Factory Default | Equipment Settings Used | |

| AUXILIARY I/O | ||||

| AUX.IN

(optional) |

SETBACK / VACANCY / EM. SHUT / NONE | SETBACK | ||

| AUX.OUT

(optional) |

BOILER / SETBACK / ZONE OP. / ALARM /

AUX.IN / DHW IN / HEAT IN / HT DMND / COOL / NONE |

BOILER | ||

| AUX.PUMP

(optional) |

BOILER / GROUP / OCC / BYPASS / FAN / NONE / AUX.IN / DHW IN / HEAT IN / HT DMND | BOILER | ||

| A/C SETTINGS | ||||

| CYCLES/HOUR | 2 / 3 / 4 / 5 / 6 | 4 | ||

| MIN.OFF TIME | 2 to 10 (minutes) | 5M | ||

| C.W.S.D. | 32°F to 100°F (0°C to 38°C) | 65°F (18°C) | ||

| FAN MODE | AUTO / ON | AUTO | ||

| A/C EQUIP CONFIG | ||||

| ZONE | A-1 to D-16 | A-1 | ||

| A/C UNIT | NONE / 1 | 1 | ||

| COOLING | ENABLE / DISABLE | ENABLE | ||

| ENVIRACOM (not used at this time – reserved for future use) | ||||

| Modules ID: | n/a | n/a |

Automation and Control SolutionsHoneywell International Inc.1985 Douglas Drive NorthGolden Valley, MN 55422customer.honeywell.com

® U.S. Registered Trademark© 2013 Honeywell International Inc.69-2121—05 L.L. Rev. 10-13Printed in United States

References

[xyz-ips snippet=”download-snippet”]