Honeywell DPR SERIES, TRUSTABILITY BOARD MOUNT PRESSURE SENSORS Installation Guide

32347060Issue B

1.0 GENERAL INFORMATION

The TruStability™ DPR Series is a piezoresistive silicon pressure sensor offering a ratiometric analog output for reading pressure over the specified full scale pressure span and temperature range. These sensors are fully calibrated and temperature compensated for sensor offset, sensitivity, temperature effects, and non-linearity using an on-board Application Specific Integrated Circuit (ASIC).

CAUTION

PRODUCT DAMAGE FOR SENSORS WITH LIQUID MEDIA OPTION (ONLY AVAILABLE 60 MBAR | 6 KPA | 1 PSI AND ABOVE)

- Ensure liquid media is applied to Port 1 only; Port 2 is not compatible with liquids.

- Ensure liquid media contains no particulates. All TruStability™ sensors are dead-ended devices. Particulates can accumulate inside the sensor, causing damage or affecting sensor output.

- Recommend that the sensor be positioned with Port 1 facing downwards; any particulates in the system are less likely to enter and settle within the pressure sensor if it is in this position.

- Ensure liquid media does not create a residue when dried; build-up inside the sensor may affect sensor output. Rinsing of a dead-ended sensor is difficult and has limited effectiveness for removing residue.

- Ensure liquid media are compatible with wetted materials. Noncompatible liquid media will degrade sensor performance and may lead to sensor failure.

Failure to comply with these instructions may result in product damage.

2.0 CLEANING

CAUTION

IMPROPER CLEANING

Avoid cleaning the sensor; however, if it must be cleaned ensure cleaning fluids, such as appropriate alcohols or fluorinated solvents, are used based on the type of contaminants to be removed. Do not immerse the sensor.

Failure to comply with these instructions may result in product damage.

3.0 SPECIFICATIONS AND MOUNTING DIMENSIONS

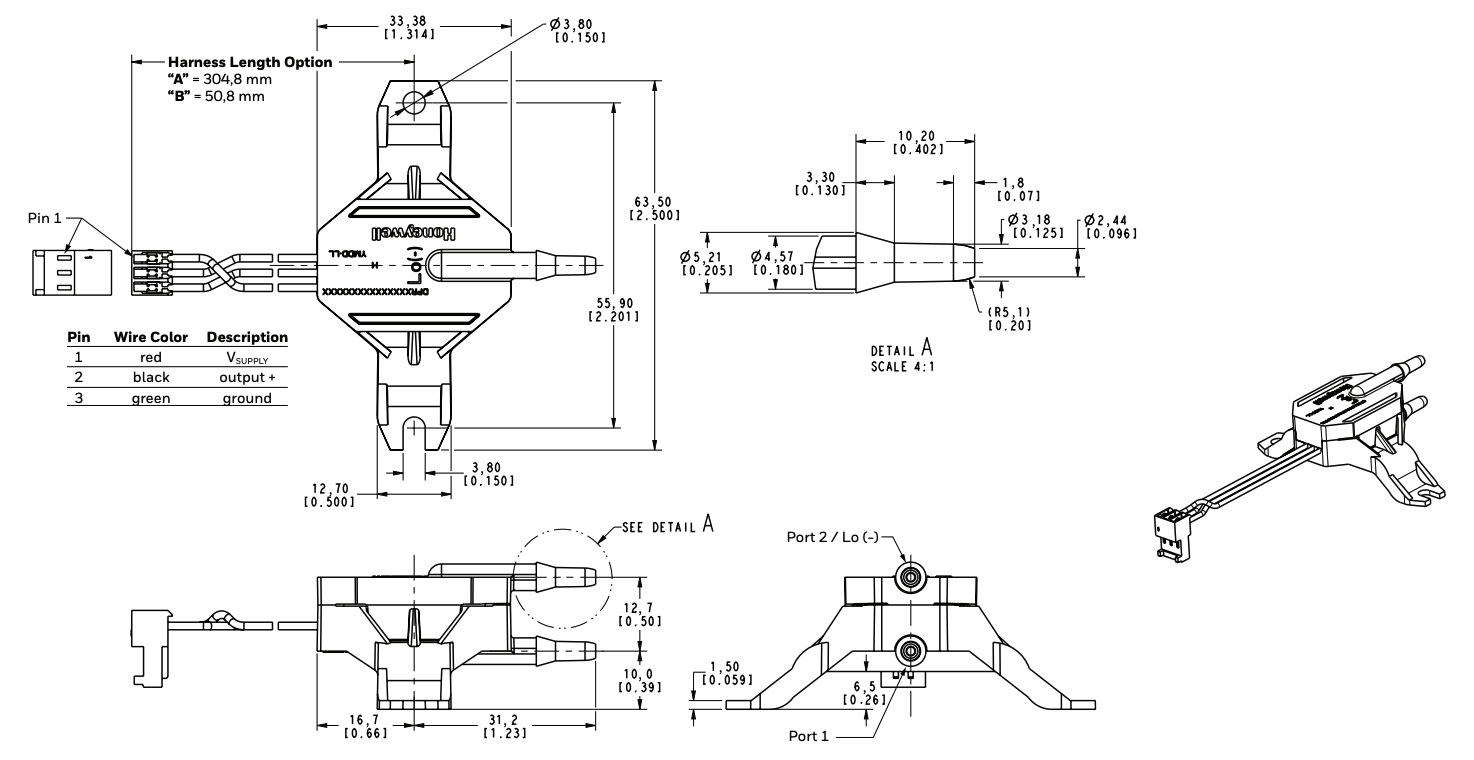

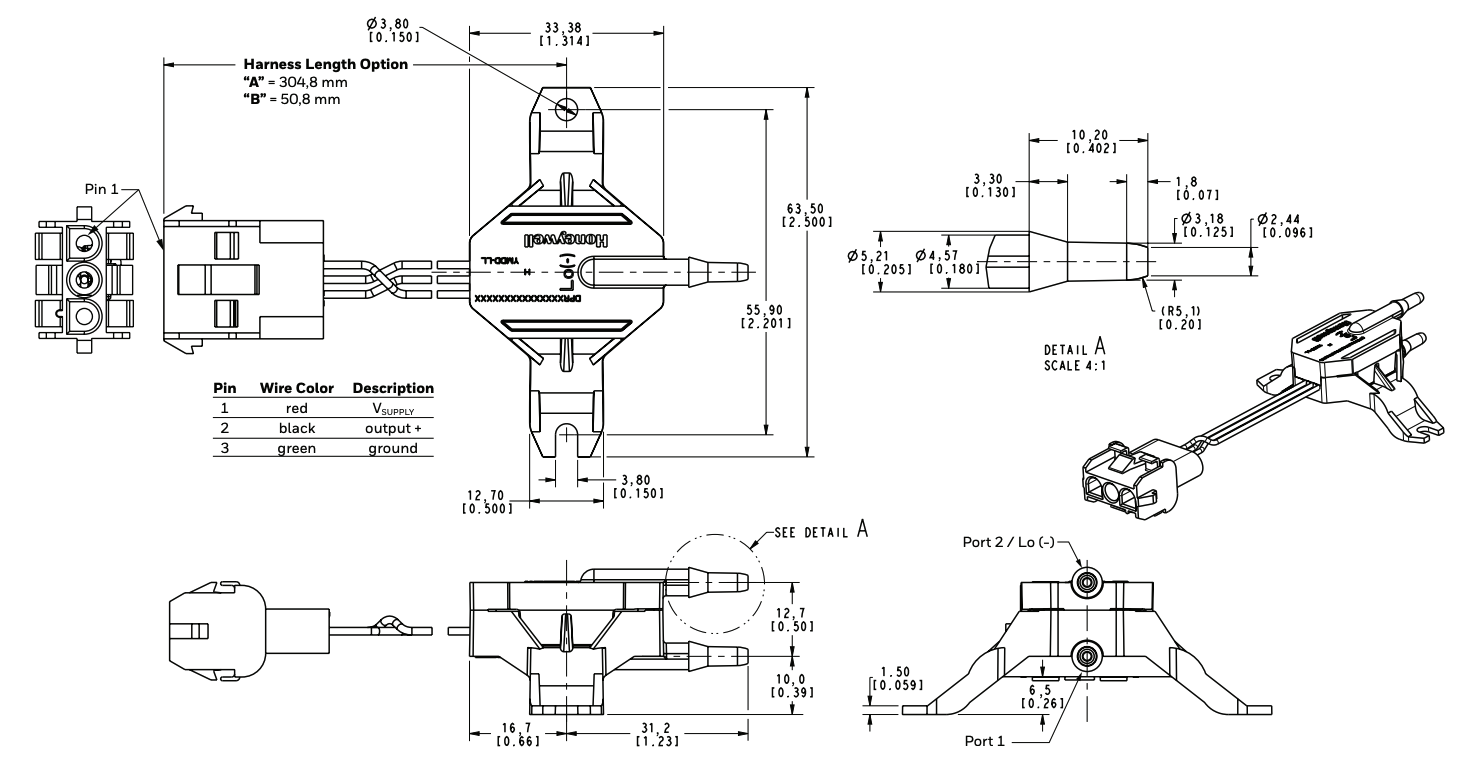

See Tables 1 through 8, and Figures 3 through 6.

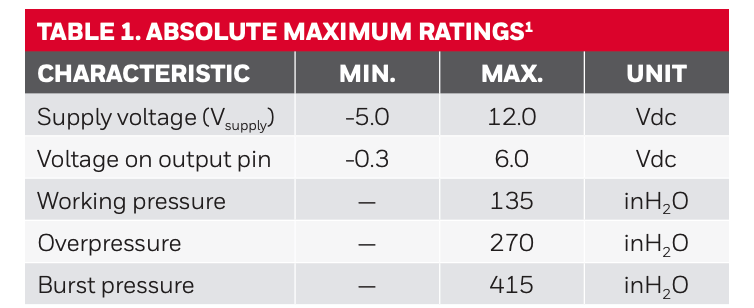

1 Absolute maximum ratings are the extreme limits the device will withstand without damage.

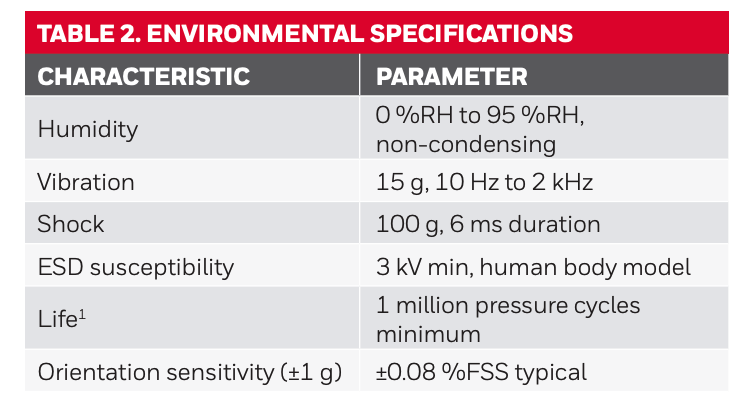

1 Life may vary depending on the specific application in which the sensor is utilized.

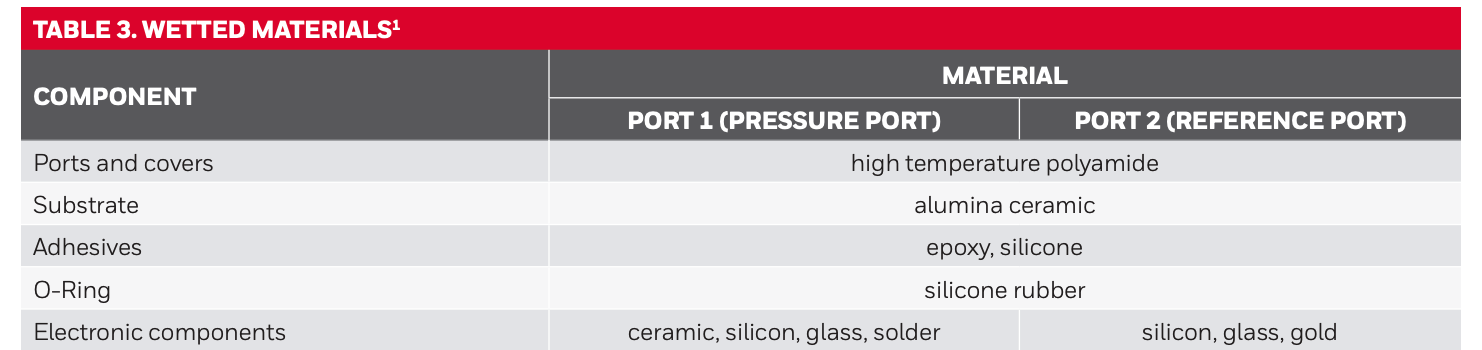

1 Contact Honeywell Customer Service for detailed material information.

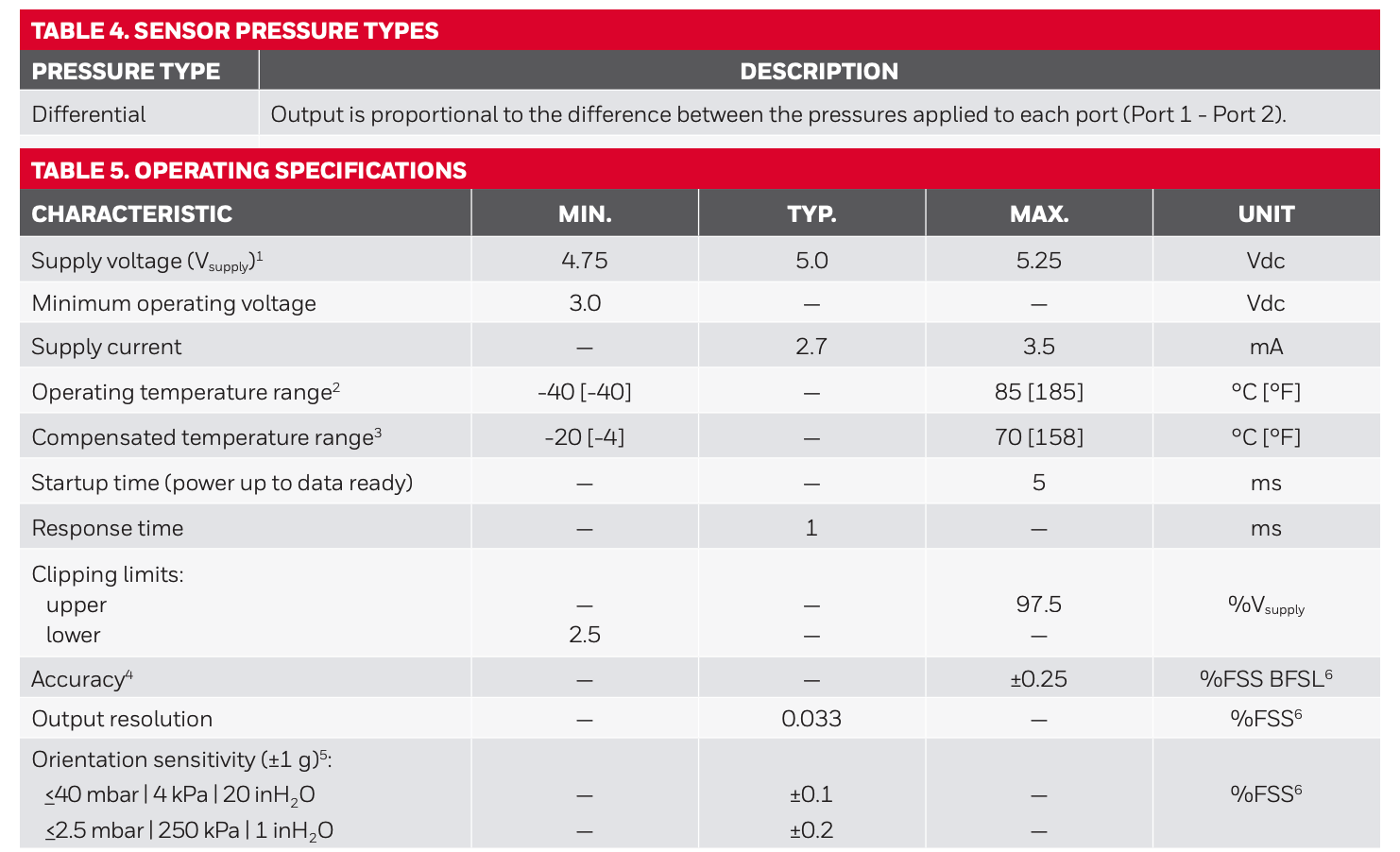

1 Ratiometricity of the sensor (the ability of the device output to scale to the supply voltage) is achieved within the specified operating voltage.

2 Operating temperature range: The temperature range over which the sensor will produce an output proportional to pressure.

3 Compensated temperature range: The temperature range over which the sensor will produce an output proportional to pressure within the specified performance limits.

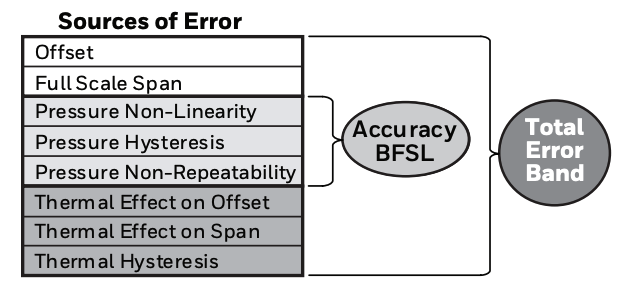

4Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range. Includes all errors due to pressure non-linearity, pressure hysteresis, and non-repeatability.

5 Orientation sensitivity: The maximum change in offset of the sensor due to a change in position or orientation relative to Earth’s gravitational field.

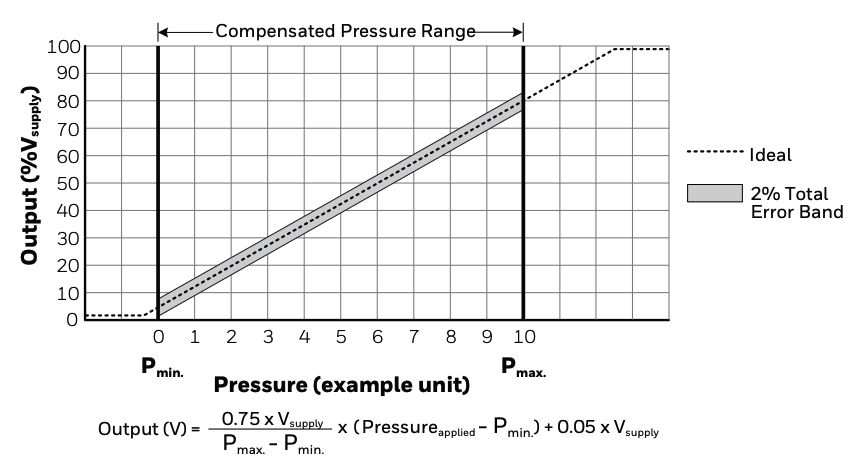

6Full Scale Span (FSS): The algebraic difference between the output signal measured at the maximum (Pmax.) and minimum (Pmin.) limits of the pressure range. (See Figure 7 for ranges).

FIGURE 1. TEB COMPONENTS FOR TRUSTABILITY™ BOARD MOUNT PRESSURE SENSORS

FIGURE 2. TRANSFER FUNCTION LIMITS

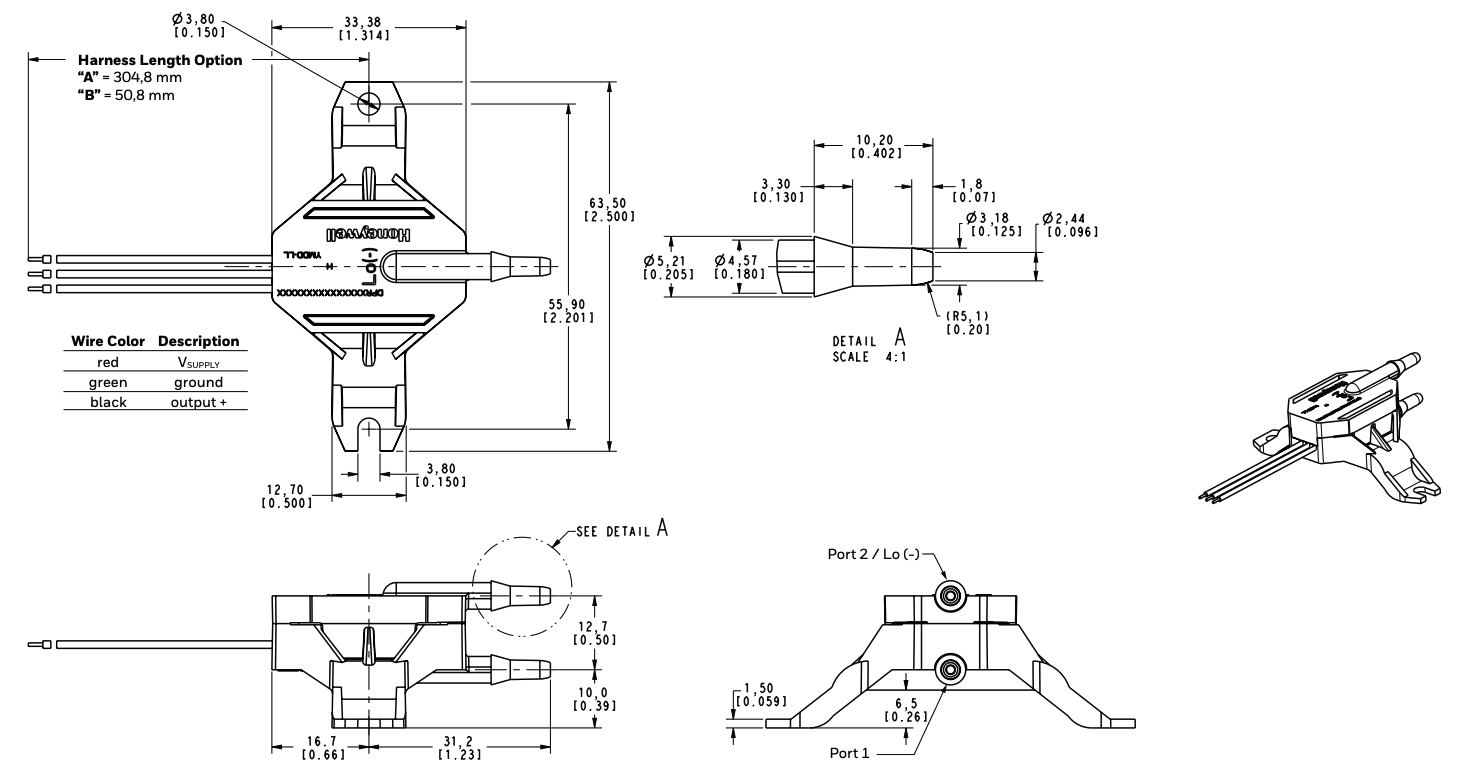

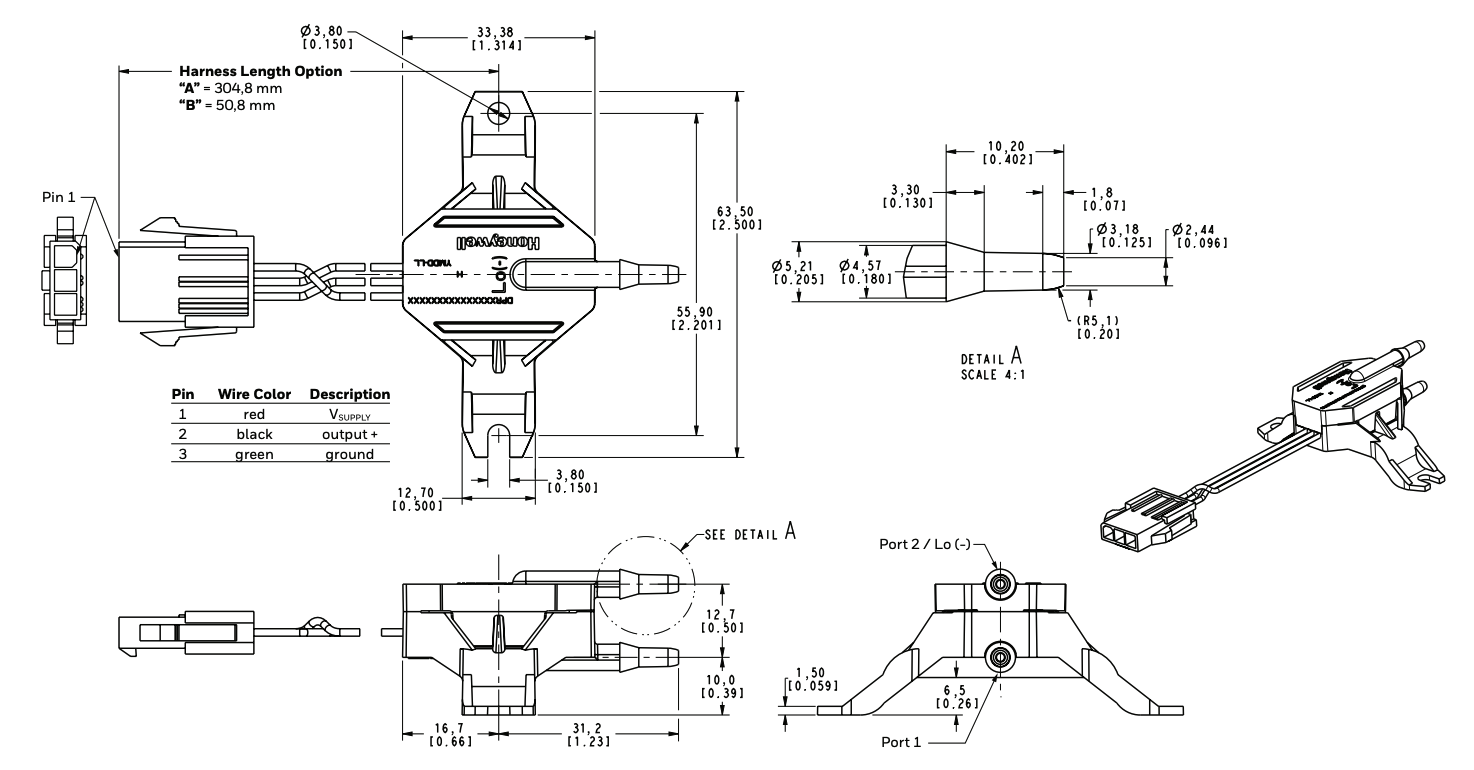

FIGURE 3. MOUNTING DIMENSIONS FOR ELECTRICAL TERMINATION, OPTION “A”: AMP 3-643814-3 (FOR REFERENCE ONLY: MM/[IN].

FIGURE 4. MOUNTING DIMENSIONS FOR ELECTRICAL TERMINATION OPTION “B”: AMP 1-480701-0 (FOR REFERENCE ONLY: MM/[IN].

FIGURE 5. MOUNTING DIMENSIONS FOR ELECTRICAL TERMINATION OPTION “C”: FLYING LEADS (FOR REFERENCE ONLY: MM/[IN].

FIGURE 6. MOUNTING DIMENSIONS FOR ELECTRICAL TERMINATION OPTION “D”: MOLEX 39-01-4033 (FOR REFERENCE ONLY: MM/ [IN].

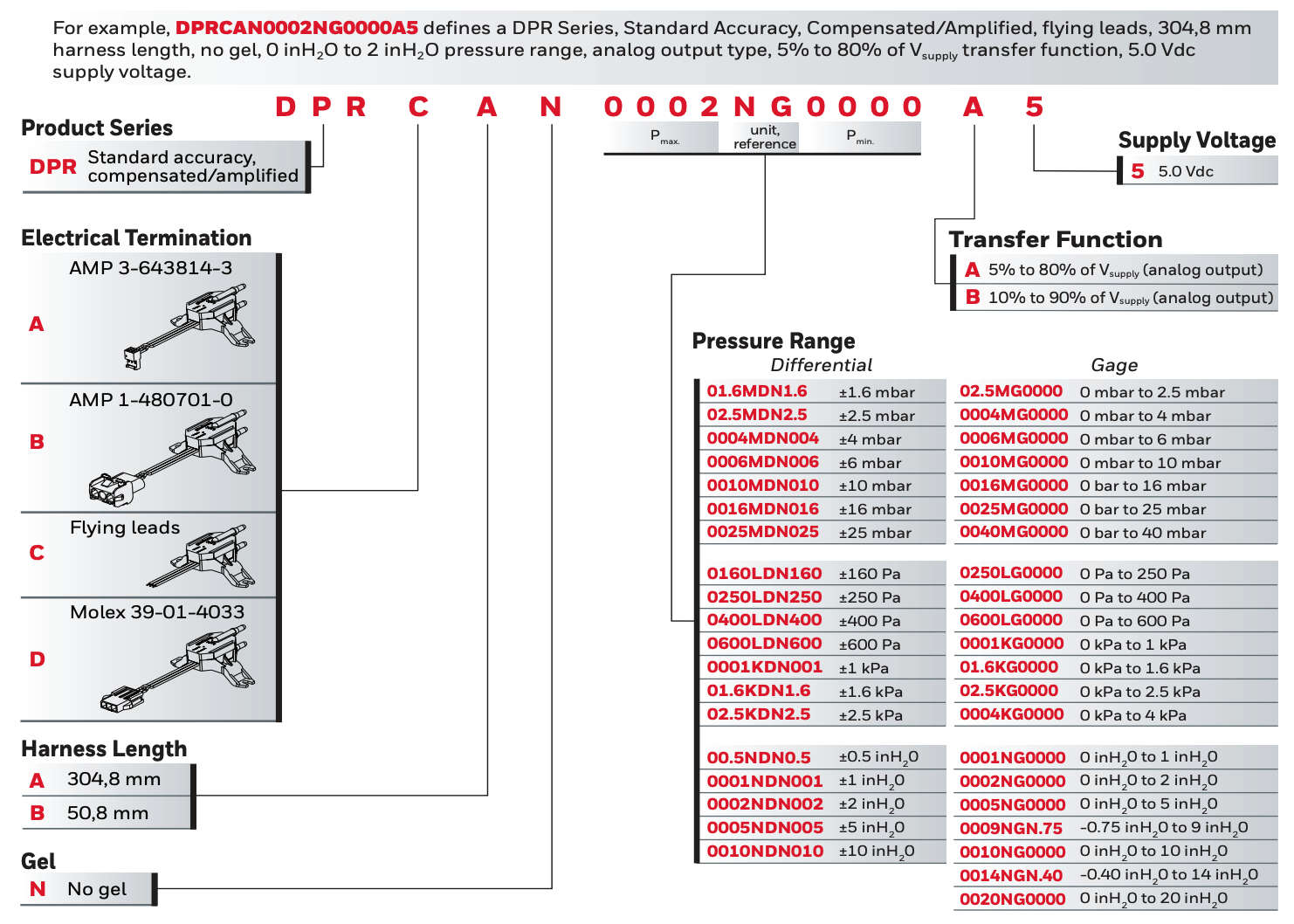

FIGURE 7. NOMENCLATURE AND ORDER GUIDE

![]()

WARNING

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop devices or in any other application where failure of the product could result in personal injury.

Failure to comply with these instructions could result in death or serious injury.

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use.

Honeywell serves its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing or name of the nearest Authorized Distributor, contact your local sales office or:

E-mail: [email protected]Internet: sps.honeywell.com/astPhone and Fax: USA/Canada +1-302-613-4491International +1-815-235-6847; +1-815-235-6545 Fax

HoneywellAdvanced Sensing Technologies830 East Arapaho RoadRichardson, TX 75081sps.honeywell.com/ast

32347060-B-EN | B | 05/21© 2021 Honeywell International Inc. All rights reserved.

References

[xyz-ips snippet=”download-snippet”]