SAFETY MANUALSEARCHLINE EXCEL PLUS™SEARCHLINE EXCEL EDGE™Open Path Flammable Gas Detector

DisclaimerIn no event shall Honeywell be liable for any damages or injury of any nature or kind, no matter how caused, that arise from the use of the equipment referred to in this manual.Strict compliance with the safety procedures set out and referred to in this manual and extreme care in the use of the equipment, is essential to avoid or minimize the chance of personal injury or damage to the equipment.The information, figures, illustrations, tables, specifications, and schematics contained in this manual are believed to be correct and accurate as at the date of publication or revision. However, no representation or warranty with respect to such correctness or accuracy is given or implied and Honeywell will not, under any circumstances, be liable to any person or corporation for any loss or damages incurred in connection with the use of this manual.The information, figures, illustrations, tables, specifications, and schematics contained in this manual are subject to change without notice.Unauthorized modifications to the gas detection system or its installation are not permitted, as these may give rise to unacceptable health and safety hazards.Any software forming part of this equipment should be used only for the purposes for which Honeywell supplied it. The user shall undertake no changes, modifications, conversions, translations into another computer language, or copies (except for a necessary backup copy).In no event shall Honeywell be liable for any equipment malfunction or damages whatsoever, including (without limitation) incidental, direct, indirect, special, and consequential damages, damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss, resulting from any violation of the above prohibitions.WarrantyHoneywell Analytics warrants the Searchline Excel Plus & Edgetm system against defective parts and workmanship and will repair or (at its discretion) replace any components that are or may become defective under proper usage within 12 months from the date of commissioning by a Honeywell Analytics approved representative* or 18 months from shipment from Honeywell Analytics, whichever is sooner.This warranty does not cover consumables, batteries, fuses, normal wear, and tear, or damage caused by accident, abuse, improper installation, unauthorized use, modification or repair, ambient environment, poisons, contaminants or abnormal operating conditions.This warranty does not apply to sensors or components that are covered under separate warranties, or to any 3rd-party cables and components.Any claim under the Honeywell Analytics Product Warranty must be made within the warranty period and as soon as reasonably practicable after a defect is discovered. Please contact your local Honeywell Analytics Service representative to register your claim. This is a summary. For full warranty terms please refer to the Honeywell General Statement of Limited Product Warranty, which is available on request.* A Honeywell Analytics approved representative is a qualified person trained or employed by Honeywell Analytics, or a qualified person trained in accordance with this manual.Copyright NoticeMicrosoft, MS, and Windows have registered trademarks of Microsoft Corp.Other brand and product names mentioned in this manual may be trademarks or registered trademarks of their respective companies and are the sole property of their respective holders.Honeywell is the registered trademark of Honeywell Safety and Productivity Solutions (SPS).Searchline Excel Plus & Edge is a registered trademark of Honeywell (HA).Find out more at www.sps.honeywell.comRevision History

| Revision | Comment | Date |

| Issue 1 | A05530 | July 2021 |

Searchline Excel Plus & Edge™ – Safety Manual

Introduction

This Searchline Excel Plus & Edge Safety Manual contains information, tables, examples and instructions that are crucial and relevant to all areas of system design, development, architecture, approvals, installation and commissioning, and to its ongoing safety, function and fitness for purpose once correctly installed and commissioned.This manual should be read in conjunction with the References listed below, and in conjunction with any associated 3rd-party manufacturer’s technical documents.This manual should be used as a reference source when calculating maintenance and proof-testing periodicity, deferments and concessions, and when writing preventive maintenance and proof-testing procedures.This manual may be used to calculate the probability of Searchline Excel Plus & Edge or component failure (PFD/PFH) for use in risk assessments and other scenarios.

References

IEC 61508: Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems (E/E/PE, or E/E/PES)IEC 61508 has seven parts:

- Parts 1-3 contain the requirements of the standard (normative)

- Parts 4-7 are guidelines and examples for development and are thus informative.

Central to the standard are the concepts of risk and safety function. Risk is a function of the likely frequency of the hazardous event and the likely consequence and severity of an event. The risk can be reduced to a tolerable level by applying safety functions that may consist of E/E/PES and/or other technologies. While other technologies may be employed in reducing the risk, only those safety functions relying on E/E/PES are covered by the detailed requirements of IEC 61508.2017M1220 Searchline Excel Plus & Edge Technical ManualThis manual contains all of the Searchline Excel Plus & Edge specifications, approvals, certifications and core technical information. It is intended for use by authorized technical personnel and OEMs and is available in Technical English only.2017M1225 Searchline Excel Plus Quick Start Guide2017M1230 Searchline Excel Edge Quick Start GuideThese manuals are abridged and translated versions of the Searchline Excel Plus & Edge Technical Manual. They are intended for use by end-users and operators.2017M1270 Fixed Platform App User ManualThis manual contains instructions on the use of the Fixed Platform App for servicing and maintenance of the Searchline Excel Plus & Edge. This manual is available in Technical English only.

Abbreviations

The following abbreviations have been used in this manual:

| ACAIMßßDDCDDDIMDuI/OLEDmANCNOPFDPFDavgPFHPOSTPSUSFFSILSISSPCOTÜVUI | Alternating CurrentAnalog Input ModuleBeta Factor – Common Cause Failure Factor for Undetected Dangerous FailuresBeta Factor – Common Cause Failure Factor for Detected Dangerous FailuresDirect CurrentDetected Dangerous FailuresDigital Input ModuleUndetected Dangerous FailuresInput/OutputLight Emitting DiodeMilliampNormally Closed (circuit)Normally Open (circuit)Probability of failure to perform its design function on demandProbability of failure to perform its design function on-demand (Averaged)Probability of a dangerous failure per hourPower-On Self-TestPower Supply UnitSafe Failure Fraction; a percentage of safe failures as compared to all failuresSafety Integrity LevelSafety Instrumented SystemsSingle Pole Change Over (Switch or Relay)TÜV is a leading international body for the certification of safety and quality for products, services, and management systemsUser Interface |

Definitions

| Check | Noun: An examination to test or ascertain accuracy, quality, or satisfactory condition when compared toa known or stated valueVerb: Examine something in order to determine its accuracy, quality, or condition when compared toa known or stated value, or to detect the absence or presence of something |

| Examine | Inspect something thoroughly in order to determine its nature or condition |

| Inspect | 1: Look at something closely, typically to assess its condition or to discover any shortcomings2: Examine something to ensure that it reaches an official standard |

| Test | Noun: A procedure intended to establish the quality, performance, or reliability of something, especiallybefore it is taken into widespread useVerb: Take measures to check the quality, performance, or reliability of something, especially before putting it into widespread use or practice |

Searchline Excel Plus & Edge Safety Function

The intended use of the Searchline Excel Plus & Edge is to alert users to the presence of potentially dangerous gaseous leaks in a defined zone.To achieve this aim, Searchline Excel Plus & Edge provides a safety function with two outputs that may be used simultaneously if required, providing compatibility with different safety integrity levels.An mA output is provided which is compatible with SIL 2 needs. Any output 1.5 mA or below must be treated as a fault condition and is a defined safe state for this safety function. A range below 4 mA can be configured to provide warning indications. Values above 4 mA up to 22 mA can be configured to provide either an analog representation of the leak level or fixed alarm output.A set of relay output is also provided which are compatible with SIL 1 needs. Independent Fault, Suspected Alarm, and Confirmed Alarm relay contacts are provided. A de-energized fault relay must be treated as a fault condition and is a defined safe state for this safety function. The Alarm relay contacts can be configured as either normally energized or normally de-energized depending on the application needs.Compliance to IEC 61508:2010 has been assessed by an independent third party and reference to their certification and test report can be found in the following sections.Bluetooth, Modbus or HART communications are specifically not a part of the Searchline Excel Plus & Edge safety function. These interfaces are non-interfering functions typically used for device setup, commissioning, diagnostics and troubleshooting. They do not interrupt the safety-critical functions of the device.

Searchline Excel Plus & Edge Safety Parameters

The following safety parameters are in alignment with the TÜV report HP94655C. They are valid for Modification State 1 and firmware version 3.20 of the Searchline Excel Plus & Edge.

| Configuration | PFd | PFh | SFF | DiagnosticCoverage | ß | ßd | DD | DU | Safe |

| Relay Output (SIL 1) | 1.71 -03 | 3.89 -07 | 93.50% | 92.10% | 5% | 2% | 4436 | 388.64 | 1069.67 |

| mA Output (SIL 2) | 5.25 -04 | 1.19 -07 | 98% | 97.60% | 5% | 2% | 4594.37 | 119.4 | 976.22 |

The PFD figures quoted above assume a nominal one-year proof test interval and 8-hours repair time (MTTR).The Searchline Excel Plus & Edge internally has an HFT of 0 and is defined as a Type B device as per IEC 61508.The diagnostic test interval for the Searchline Excel Plus & Edge is less than 30 seconds in normal operation.

Proof Test Interval

The purpose of a proof test is to return the unit to ‘a new condition in terms of its safety parameters.The nominal proof test interval is 12 calendar months but, as stated in IEC 61508 and always dependent on local conditions, users may vary the proof test interval to meet their system needs. Honeywell allows such variations provided that the proper calculation method for calculating a proof test interval – as defined in IEC 61508 – is used to attain the required SIL level.Proof test variations will depend on the system, hardware architectures, and applications, and should be reviewed annually.Given that relay outputs could be complex to isolate and test, the user may determine that a longer proof test interval would be desirable. The table below can be used to understand the different PFD & PFH values for these differing intervals.Note:The nominal proof test interval should not preclude more frequent maintenance of Searchline Excel Plus & Edge in accordance with the Operating Instructions if site conditions or other factors require it.

The effect of different proof test intervals on the PFDavg :

| Proof Test Interval | Relay | PFdmA Output |

| 0.25 year | 4.32-°4 | 1.33-°4 |

| 0.5 year | 8.58-°4 | 2.63 °4 |

| 1 year | 1.71-°3 | 5.25-1°4 |

| 2 years | 3.41-°3 | 1.05-°3 |

| 3 years | 5.12-°3 | 1.57-°3 |

| 4 years | 6.82-°3 | 2.09 °3 |

| 5 years | 8.53-°3 | 2.62-°3 |

| 6 years | 1/2/02 | 3/14/03 |

| 7 years | 1/19/02 | 3.66-’33 |

| 8 years | 1.36-°3 | 4.19 °3 |

| 9 years | 1.51°3 | 4.71 °3 |

| 10 years | 1.70-°3 | 5/23/03 |

Special Notes

- This safety manual does not address installation, configuration, service, maintenance, or decommissioning tasks.The Searchline Excel Plus & Edge Technical Manual must be read and referred to in order to accomplish these tasks.Read and understand the Searchline Excel Plus & Edge Technical Manual in full as this document also contains important safety information regarding the installation and continued use of the product.It is important to understand and mitigate security risks associated with the day-to-day use of the system in connected IT infrastructures. Refer to the Searchline Excel Plus & Edge Security Guide for information on additional security controls that should be implemented by users.

- Searchline Excel Plus & Edge proof tests shall be carried out strictly in accordance with this manual while referring to the Searchline Excel Plus & Edge Technical Manual as required, and also by including any additional instructions or requirements that may be issued from time to time. Searchline Excel Plus & Edge must not be stored or otherwise exposed to temperatures or conditions outside of the allowable maximums listed in the Technical Manual and/or datasheet.

- It is incumbent on all 3rd-Party OEMs and Partners to enforce these rules on all Searchline Excel Plus & Edge equipment and assemblies manufactured and supplied by Honeywell.

- Modification of settings in the Searchline Excel Plus & Edge shall strictly follow the procedure detailed in the Searchline Excel Plus & Edge Technical Manual or in the Fixed Platform App User Manual. Following modification of any settings in the Searchline Excel Plus & Edge, the entire list of settings must be reviewed to ensure that the product configuration is correct. A proof test should then be undertaken to ensure the functionality of the product is understood and is as expected.

- Access to the product is possible remotely using either the HART or Bluetooth connection. Security is provided on these connections by the use of authentication passwords and tokens. The user must take care to ensure such passwords and tokens do not become known to unauthorized parties. In case of a concern, such passwords should be immediately changed to prevent unauthorized access to the product.

- It is possible to upgrade the firmware in the Searchline Excel Plus & Edge using the Fixed Platform App mobile application. Before performing an upgrade, the user must check that the new firmware has already been certified to the relevant functional safety standard. When performing an upgrade, the procedure listed in the Fixed Platform App User Manual must be followed. Following the upgrade, the version string must be interrogated to ensure it is as expected. Refer to the Fixed Platform App User Manual. A proof test should then be undertaken to ensure the functionality of the product is understood and is as expected.

- Power supplied to the Searchline Excel Plus & Edge or to the 4-20 mA loop of the product shall be of an isolating type (galvanic isolation from mains, providing basic insulation) but does not need to be a Class II (SELV) power supply. At no time should voltages exceeding 60V DC be provided to the product (with the exception of the relay contact connections).

- Searchline Excel Plus & Edge contains relays that may be used to perform executive actions when an alarm is triggered. Ensure that such systems are identified and inhibited/disconnected before carrying out any proof testing, bump testing or sensor calibrations.

- For SIL 2 applications, users must use the mA output to determine both alarm and fault conditions. Configurations for SIL 2 alarm relay outputs are described in point 10d). Relay outputs can be used simultaneously for SIL 1 or non-safety applications.

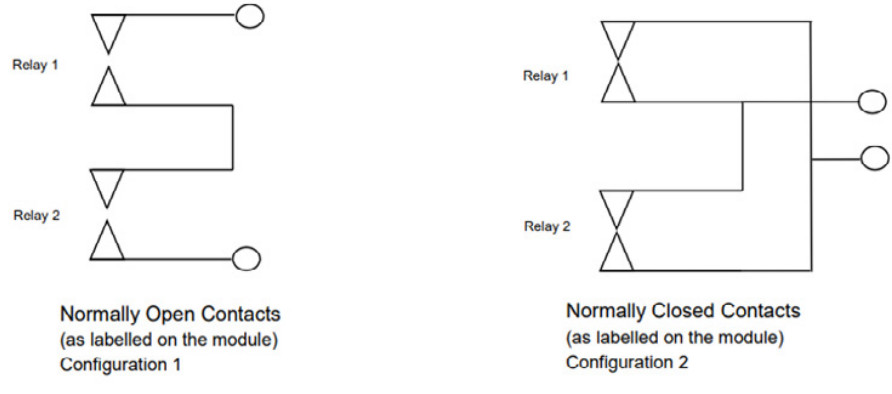

- If relay outputs are used for safety purposes, the following directions must be adhered to:a) The relay contacts must be protected with a fuse rated at a maximum of 3 A.b) Only resistive loads should be connected to the relay contacts.c) The fault relay output must be energized under normal conditions.d) It is possible to realize a SIL 2 relay output for alarm conditions. If such a configuration is required the suspected and confirmed alarm relay outputs must be wired as shown below. Configuration 1 should be used when an “open contact” represents the activation of the safety function whereas Configuration 2 should be used when a “closed contact” represents the activation of the safety function. Configuration 1 requires the addition of a protective fuse rated at a maximum of 3 A to protect the relay contacts from adverse events which may cause contact welding.

Environmental Conditions

The environmental conditions that the Searchline Excel Plus & Edge is designed to operate within are listed below:Voltage: 18 to 32V DCTemperature: -55°C to +75°CHumidity: 0-100% RH CondensingAltitude: 0-1500mEMC: EN 50270, IEC/EN 61000-6-4; Radio Equipment Directive 2014/53/EUIP-Protection: IP 66/67 (Type 4X in accordance with NEMA 250)

Proof Test

To give the user confidence and ensure that proof testing is always carried out on an optimal system, it is recommended the users carry out routine maintenance procedures before carrying out more specific proof tests.Example inspection, testing, and calibration procedures are given below, but users should always refer to the relevant manufacturer’s technical documentation for details appropriate to their installations.

Visual Inspection

- Visually inspect the Searchline Excel Plus & Edge paying particular attention to signs of insecurity, loose connections,damage, corrosion, ingress of moisture, or contamination. Clean and repair as required before proceeding with anyfunctional testing or calibrations.

- Switch off and isolate electrical power, then open the rear enclosure and carry out a visual inspection and clean as listed in in item 1 above. Pay particular attention to the security and condition of electrical connections and terminals.

- Switch on the electrical power. Observe the LEDs for correct operation while the POST is being carried out.

- Record all adverse findings and their remedies to aid future proof testing analysis and fault finding.

Electrical Testing

- Electrically test all external cables, paying particular attention to insulation resistance, shielding and Earthing (Grounding) resistance, and cable continuity and resistance.

- Record all figures to aid future proof testing analysis and fault finding.

Output Testing

Follow the procedures described in the Searchline Excel Plus & Edge Technical Manual and the Fixed Platform App User Manual to accomplish output testing of relays, mA Loop, and status indicator. Ensure that all operate as expected.All relays should be forced both de-energized and energized. The mA Loop should be tested at the extents, at 4 mA, and at mid-range points.

Bump Testing

- Carry out Bump Testing in accordance with the appropriate technical handbooks and manufacturer’s technical specifications.

- Record all figures to aid future proof testing analysis and fault finding.

Find out morewww.sps.honeywell.comContact Honeywell Analytics:Europe, Middle East, AfricaLife Safety Distribution GmbHTel: 00800 333 222 44 (Freephone no.)Tel: +41 (0)44 943 4380 (Alternative no.)Middle East Tel: +971 4 450 5800 (Fixed Gas Detection)Middle East Tel: +971 4 450 5852 (Portable Gas Detection)[email protected]

Please Note:While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions. Data may change, as well as legislation and you are strongly advised to obtain copies of the most recently issued regulations, standards and guidelines. This publication is not intended to form the basis of a contract.

08/20212017M1245 Issue 1 EN A05530© 2021 Honeywell Analytics

References

[xyz-ips snippet=”download-snippet”]