THE POWER OF CONNECTEDRefrigerantsStorage, Handling, and Use Guidelines for Solstice zd Refrigerant

THE POWER OF CONNECTEDRefrigerantsStorage, Handling, and Use Guidelines for Solstice zd Refrigerant

Before handling the refrigerant, it is essential that you read the Safety Data Sheet (SDS) for Solstice zd refrigerant. Special attention should be given to the section2 on hazards identification, and section 4 on first aid measures.Risk assessment and risk minimization in facilities typically require evaluation on a case-by-case basis since facilities may vary from one another in manyways. To assist you in assessing and minimizing risk in association with the use of Solstice ZD, a number of general guidelines can be applied.

Cylinder Storage

- Store cylinders in a cool, well-ventilated area with a low risk of fire and out of direct sunlight. Ensure that cylinders are properly strapped into place. Avoid dropping, denting, or mechanically abusing containers.

- Store on elevated or concrete floors to avoid tank corrosion, and protect cylinders from moisture and rusting during storage.

- Do not store Solstice ZD cylinders near sources of open flames and do not allow containers to exceed 50°C.

- Smoking should be prohibited in storage, handling, and servicing areas where Solstice ZD is used.

Accidental Spillage

Solstice zd is a liquefied gas with a boiling temperature of 19ºC. In case of accidental spillage, use non-combustible absorbent materials, (e.g., sand, earth vermiculite, diatomaceous earth), to contain and collect spillage (see SDS section 13). Place spilled material in an appropriate container for disposal according to local regulations.

Handling

Personal Protective Equipment (PPE)

- Gloves– Avoid cloth gloves (possible frostbite in contacting liquid)– Incidental liquid contact: wear PVA or neoprene gloves– Avoid repeated exposure or prolonged contact

- Eyewear– Safety glasses for normal operations– If liquid contact is probable, wear chemical safety goggles and self-contained breathing apparatus

- Respiratory Protection– None for adequately ventilated work areas– F or accidents or non-ventilated work situations, wear self-contained breathing apparatus

Personnel Training

A written emergency response plan should exist and be available. In addition, personnel should:

- know product hazards and have access to SD

- be trained to handle refrigerants and hold appropriate certifications

- be properly trained and know his / her responsibility in case of an emergency

Offloading Procedure

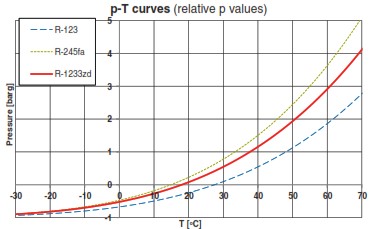

Because of its properties, the use of Solstice zd requires attention in the equipment and setup.The very low vapor pressure values require additional steps for offloading cylinders and tanks, compared to other products:

- Before offloading the product, store the container indoor overnight, if possible

- The use of a heating blanket will facilitate the offloading, alone or in combination with 1

- The use of a pump is required, alone or in combination with 1 and 2• Make sure you always operate in a clean safe area.– Ensure enough clearance to walk around the container– Ensure connections are visible, to allow visual leak check– Keep environment oise low, to allow leaks to be audible– Do not leave connection hoses suspended– Do not step over-pressurized hoses• Continuously check pressure values during the whole process• Read the SDS. A paper copy is included in the shipping documents.• Always use PPE, minimally, chemical resistant goggles (eyes), and gloves (hands).

Offloading from a 100-lb Cylinder

| Package Specifications | 100 lb Cylinder |

| Product weight (kg | 45.3 kg |

| Tare weight (kg) | 31 kg |

| Cylinder dimensions | 1.3m X 0.3m (Tall X Dia) |

| Outlet connection | CGA 660 (1.030” 14NGO RH-EXT) |

- Weigh the cylinder to verify the initial value (tare can vary slightly)

- Position the cylinder in the work area

- An internal dip tube reaches the lowest point inside the cylinder, to extract all liquid

- Connect the transfer hoses to the valve outlet and the pump, and install a pressure gauge

- . Install a sight indicator on the line to process (or pump outlet)

- Open liquid phase valve and start the pump, to start the outlet flow; perform a leak check

- If the liquid flow stops, please check the following:– The cylinder may be empty. This can be confirmed by verifying the weight– Check pressure difference (cylinder compared to process)– Check the pump for cavitation

- Once the product is transferred completely, close the valve on the cylinder

- Depressurise liquid line from cylinder valve to pump

- . DO NOT leave liquid-filled piping blocked with no pressure relief

- Disconnect hoses

- Store in the suitable storage area

- Return the empty cylinder to Honeywell

Offloading from a Ton Cylinder

| Package Specifications | Ton Cylinder |

| Product weight (kg | 900 kg |

| Tare weight (kg) | 645 kg |

| Cylinder dimensions | 2.1 m X 0.8m (Length X Dia) |

| Outlet connection | CGA 660 (1.030” 14NGO RH-EXT) |

- Weigh the ton cylinder to verify the initial value

- Position the ton cylinder in the work area, leveled horizontally, or slightly tilted (lift the end opposite to the valves, about 10 cm)

- Align valves along a vertical line. The valve in the lower position will be the liquid phase

- With the ton cylinder in this position, the dip tubes will reach the lowest and highest points, respectively, for liquid and vapor

- Connect the transfer hoses to the outlet of the valve, and install a pressure gauge on each side:

- Connect the bottom valve (Liquid) to pump suction or process pipe

- Depending on the use, a vapor return line can be connected to the vapor side valve (loop setup)

- Open liquid phase valve to start the outlet flow to process (perform a leak check)

- Install a sight indicator on the liquid line to process (or pump outlet)

- If the liquid flow stops, please check the following:– The ton cylinder may be empty. This can be confirmed by verifying the weight n a scale– Check pressure difference (ton cylinder compared to process)– If using a pump, check for cavitation

- Once the product is transferred completely, close the valves on the ton cylinder

- Depressurize liquid line from roll drum valve to process

- DO NOT leave liquid-filled piping blocked with no pressure relief

- Disconnect hoses

- Store in the suitable storage area

- Return the empty ton cylinder to Honeywell

- DO NOT leave liquid-filled piping blocked with no pressure relief

- Disconnect hoses

- Store in the suitable storage area

Troubleshooting Guide

Inability to Empty Cylinder

- Insufficient pressure in the ton cylinder will cause the liquid flow to stop

- Excessive pressure in the ton cylinder leads to expansion across the outlet valve

- High pressure in the receiving vessel to which the refrigerant is being transferred

- Low ambient temperatures will increase the liquid density, and make the liquid transfer more difficult

- High ambient temperatures will generate possible expansion through the outlet valve

- Pump cavitations, generated by expansion (high temperature) or density increase (low temperature)

- Attempting to achieve excessive flow rate: dip tubes in ton cylinders are small diameter, as well as the orifice in the valve. Excessive flow rate leads to expansion across the valve.

Leak Detection

- Periodic leak checks are required during storage

- In the event of a leak exceeding 1.5 vol%: remove personnel and ventilate the area

- Consstant monitoring for leaks is required during offloading operations

- Continuous refrigerant leak detection equipment– Continuous monitoring systems provide alerts to respond in a timely fashion– Detection levels of 1.5 vol% (15,000 ppm) are acceptable.– Mos t continuous monitoring equipment detect very low levels– Leak detector performance may vary. Consult the manufacturer

- Handheld or portable leak detectors– Valuable for maintenance operations and assembly line workers– Detect at extremely low levels (<4 g/year each size)

- Add to scheduled routine maintenance operations– Check storage containers for leaks– Check to pipe for leaks

Solstice zd properties

| Molar Mass | 130.5kg/kmol |

| Triple point temperature | -78ºC |

| Normal Boiling point | 18.32ºC |

| Critical point | |

| Temperature | 165.6ºC |

| Pressure | 3572.6kPa |

| Density | 478.92 kg/m |

| T [°C] | Vapour p [Mpa] | Liquid Density [kg/m3) |

| -10 | 0.03 | 1339.6 |

| 0 | 0.047 | 1326.7 |

| 10 | 0.072 | 1312.9 |

| 20 | 0.106 | 1298.1 |

| 30 | 0.152 | 1282.2 |

| 40 | 0.212 | 1265.1 |

| 50 | 0.29 | 1246.7 |

| 60 | 0.387 | 1226.7 |

| 70 | 0.508 | 1204.9 |

| 80 | 0.656 | 1181.2 |

| 90 | 0.835 | 1155.1 |

| 100 | 1.048 | 1126.3 |

Solstice zd compared to similar products

| Molar Mass | Critical T [ºC] | Normal Boiling Point [ºC] | GWP | ODP | |

| R-11 | 137 | 197.6 | 23.71 | 4750 | 1.000 |

| R-123 | 153 | 183.7 | 27.82 | 77 | 0.020 |

| R-2451a | 134 | 154.01 | 15.14 | 1030 | 0.000 |

| Solstice zd | 131 | 165.5 | 19.00 | 1 | 0.000 |

For more informationwww.honeywell-refrigerants.com1-800-631-8138Honeywell Specialty Chemicals(Singapore) Pte. Ltd.17 Changi Business Park Central 1Honeywell BuildingSingapore 486073Phone: 65-6355-2828Fax: 65-6783-2947Honeywell IndonesiaMenara Prima, 24th Floor Unit G-HJl. DR. Ide Anak Agung Gde Agung Blok6.2,Jakarta, 12950, Indonesiahone: +6221 2964 0306Although Honeywell International Inc. believes that the information contained herein is accurate and reliable, it is presented without guarantee or responsibility of any kind and does not constitute any representation or warranty of Honeywell International Inc., either expressed or implied. A number of factors may affect the performance of any products used in conjunction with the user’s materials, such as other raw materials, application, formulation, environmental factors, and manufacturing conditions among others, all of which must be taken into account by the user in producing or using the products. The user should not assume that all necessary data for the proper evaluation of these products are contained herein. Information provided herein does not relieve the user from the responsibility of carrying out its own tests and experiments, and the user assumes all risks and liabilities (including, but not limited to, risks relating to results, patent infringement, regulatory compliance and health, safety and environment) related to the use of the products and/or information contained herein.

REF 1953 Asia | October 2017 I v6Solstice is a registered trademark of Honeywell International Inc.© 2017 Honeywell International Inc. All rights reserved.

References

[xyz-ips snippet=”download-snippet”]