Sensors and Switches in MedicalChemistry and ImmunoassayAnalyzersAn Application Note

Sensors and Switches in MedicalChemistry and ImmunoassayAnalyzersAn Application Note

Background

Clinical laboratories conduct many complex and diverse tests in order to diagnose illnesses. Chemical and immunoassay analyzers (which can be combined into one piece of equipment) are used to determine the presence or concentration of a substance in blood, urine, or serum. They are used to test glucose, cholesterol, hormones, drugs, infectious diseases, cardiac markers, tumor markers, etc., which helps diagnose and treat many diseases or other conditions such as cancer, diabetes, fertility, hepatitis, kidney conditions, and thyroid, to name a few.Various test methodologies may be available on a machine, including immunoassay, potentiometric, calorimetric, and enzyme-linked immunosorbent assay (ELISA). While differences in test methodologies exist, the overall operation is similar. Smaller-sized analyzers can be placed bench-top or on carts, while larger-sized equipment requires floor space.

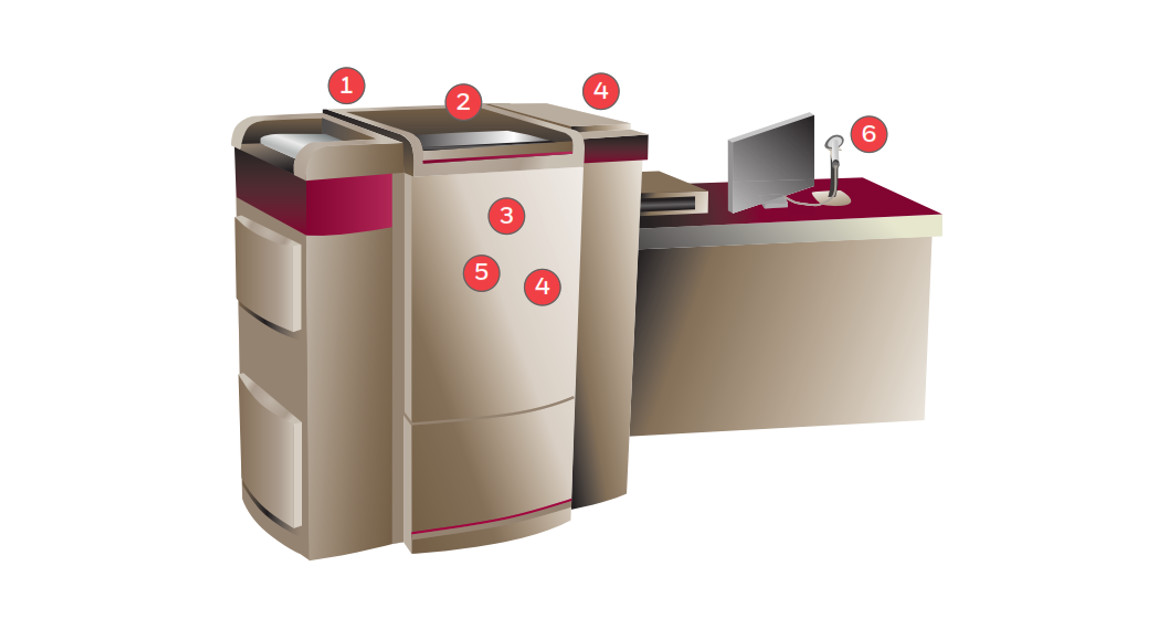

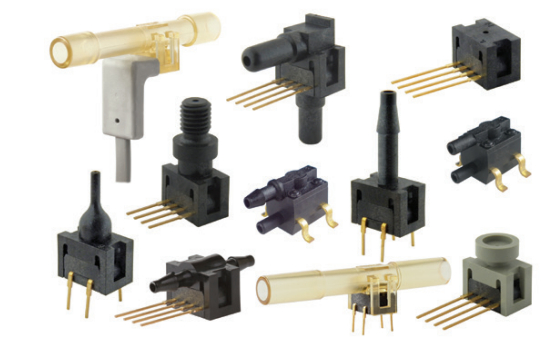

SolutionsHoneywell manufactures many products that may be used to measure fluid volume; detect blockages; heat and cool samples/reagents; open and close covers/doors; humidity detection; filling level detection; sample carriage/reagent position detection; and positive patient confirmation and reading the physician’s test orders off the barcode. (See Figure 1.) y Analyzers

Figure 1. Potential Honeywell Products Used in Chemistry Analyzers

1. Sample/Reagent DispenserMeasurement of fluid volume; detection of air and occlusion in pipetting systemPressure Sensors – Board MountTruStability TM RSC Series, HSC Series, SSC Series, 24PC and 26PC Flow-Through SeriePressure Transducers – Heavy DutyMLH Series, PX2 Series2. IncubatorHeating and cooling of samples and reagents

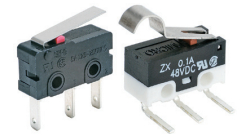

3. Covers/DoorsOpen detectionHall-effect Position Sensor ICsSS351AT, SS451AMICRO SWITCH Snap-in Panel Mount Basic SwitchesDM SeriesMICRO SWITCH Subminiature Basic SwitchesZM Series, ZX Series

4. Leak Detection SystemMeasurement of high humidity levels to detect leaksHIH6000, HIH6100, HIH7000 Series Honeywell HumidIcon™ Digital Humidity/Temperature Sensors

5. A reagent or Waste ContainerLiquid level and position sensing: filling level detection for magnet and buffer containerHall-effect Position Sensor ICsSS351AT, SS451A

6. Sample IdentificationBarcode scanning for patient confirmation and, sometimes, verification of the physician’s orderUltra-Slim Area-Imaging EngineN6600 SeriesBarcode Decoding SoftwareSwiftDecoder TM

Customer Needs of a Chemical or Immunoassay Analyzer (See Table 1 and Figure 2.)

Laboratory technicians often require the following of a chemical or immunoassay analyzer:

- Provides accurate, repeatable measurement results

- Provides fast delivery of measurement results

- Reduces or eliminates errors in data interpretation

- Contributes to efficient patient health care

- Reduces unscheduled downtime of equipment

- Provides a low MTBF (Mean Time Between Failure) rate

- Improves labor efficiency and effectiveness

Table 1. Operation of a Chemistry or Immunoassay Analyzer

| ReagentLoading | SampleLoading | LiquidHandling | Mixing/Separating | Analyzing | Rinsing/Cleaning | |

| Operation | • Barcoded reagentsare loaded• Reagents/bufferare kept cool at 4°C[39.2°F] for longevity | • Test tubes or vials are loaded• Barcode identification of samples• Samples are kept at ambient temperature or heated to 37°C[98.6°F] | • Draw fluid from sample vial and reagent container• Transfer to pipette ortest tube | Magnetic beads,

for breaking andabsorptionAgitation, centrifuge • Sample maintained at 37°C [98.6 °F] or heated |

• Sample reagent

mix passes through photometer • Optical or electric analysis of fluid |

• Flush between tests

• System test with water |

| Sensor/Switch | • Switches may be used on covers and doors

• Liquid level ofreagent/buffervolume • Optical barcode reader for reagent identification |

• Optical sensors detectposition of vials and carriage movement• Barcode scanengine orsoftwarefor positive patientconfirmation beforesampling | • Capacitive liquidlevel for detection of immersion of pipette tip• Pressure sensor for air or occlusion detection; liquid media compatible• Humidity sensor provides leakagedetection | • Custom heater

• Thermistor or temperature sensor monitors reagent and sample temperature |

• LED light source

• Photodiode |

• Pressure sensor ortransducer for flush monitoring• Liquid level forwaste container |

Figure 2. Operation of a Chemistry or Immunoassay Analyzer

APPLICATION NOTE | Sensors and Switches in Medical Chemistry and Immunoassay Analyzers | sps.honeywell.com/ast

Fluid Handling in a Chemistry Analyzer

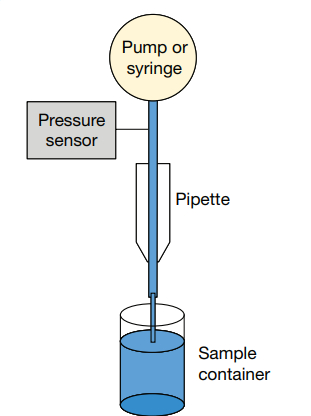

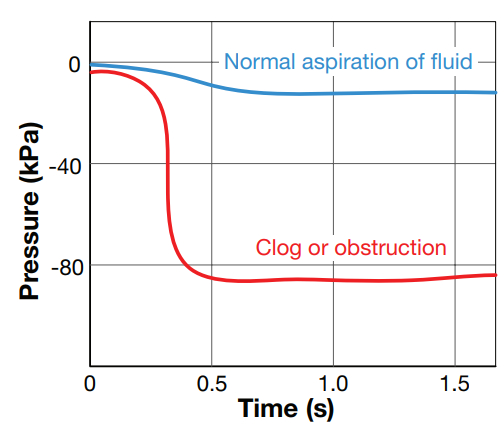

Typically, in a chemistry analyzer, a pipette draws the sample fluid and deposits it into another vial or container for mixing or analysis. (See Figure 3.) Pressure sensors are used to ensure that the right amount of fluid is being measured while the sample is being drawn. They can also be used to detect obstructions or misplacement of the pipette in the sample vial (see Figure 4), and if the air is being drawn instead of fluid.These pressure sensors need to provide consistent accuracy, stability, and repeatability at low-pressure levels. However, in the same systems, they also need to withstand higher pressures that are produced when the fluid pathway is flushed or cleaned. All of this is done while in direct contact with the liquid media being measured.

Customer Needs:

- Accurate sample volumes

- Stable and repeatable

- Eliminate carry-over between tests; thorough flushing

- Fast cycle times

Pressure Sensor Function in the Application:

- Capable of detecting if the probe is clogged

- Capable of detecting if the air is being drawn instead of fluid

Pressure Sensor Needs in the Application:

- Wet media compatibility

- Accuracy and repeatability at low pressures

- Ability to withstand higher pressures from flushing or cleaning

For more information about selecting pressure sensors for potential use in chemistry analyzers, view our white paper.

Figure 3. Fluid Handling in a Chemistry Analyzer

A pressure sensor ensures that the correct amount of fluid is being measured while the sample is being drawn.

Figure 4. Pressure Sensor Detecting Obstruction in a Pipette

Some systems will compare the pressure profile of the aspiration to a known “good” or “bad” profile.

Table 2. Capabilities for Diagnostic and Analytical Equipment

A broad portfolio of products is designed to provide enhanced performance, accuracy, and reliabilit

| HONEYWELL PRODUCT | KEY FEATURES | FUNCTION IN APPLICATION |

PRESSURE – BOARD MOUNT

|

TruStability™ RSC Series,HSC Series, SSC Series | Enhanced stability and accuracy;configurable; liquid media options; digital output; stable; accurate at low pressure; contamination and corrosion-resistant; small size high resolution (RSC Series) | It May be used for flush monitoring duringthe rinsing/cleaning process, and for airor occlusion detection during the liquidhandling process. |

|

24PC Series,26PC Series | Wet/wet capability; a variety of port configurations provide flexibility makingpneumatic connections; miniature package;flow-through configurations; analog output |

PRESSURE – HEAVY DUTY

|

MLH Series | Fully media-isolated for harsh chemicals;pressures up to 8,000 psi; multipleconfigurations simplify design; all metal wetted parts allow for potential use in a variety of fluid applications; rated IP65 or better for protection from most harsh environments | It May be used as an alternative to boardmount pressure sensors for flushmonitoring during the rinsing/cleaningprocess. |

|

PX2 Series | Liquid compatible; pressures up to 1000 psi;compatibility with a variety of harsh media,up to IP69K ingress protection and 100 V/mradiated immunity allow for use in toughenvironments |

POSITION DETECTION

|

DM Series MICROSWITCH Snap-in PanelMount Basic Switches | Compact, lightweight design; accurate;repeatable and consistent performance up toone million lifecycles | It May be used for position detection ofcovers and doors during the reagentloading process. |

|

ZM Series, ZX SeriesMICROSWITCHSubminiature BasicSwitches | Subminiature package size; integral stainlesssteel levers; a variety of electrical terminations | |

|

SS351AT, SS451AHall-effect PositionSensor ICs | Omnipolar; sensitive; flexible use; low voltage3 Vdc capability; built-in reverse polarityprotection; non-contact; long-term reliability,small size; easy to install |

THERMAL MANAGEMENT

|

192 Series, 194 SeriesThermistors | Resistance temperature curve;interchangeability; accurate; enhanced stability; enhanced life; cost-effective; small;can be integrated into the heater assembly | It May be used to monitoring reagent and sample temperature at 37°C [98.6°F] during the sample loading process and the mixing/separation process to provide consistent test results. |

|

Heater Assemblies | Custom flexible heater assemblies with thermal modeling capabilities for optimizing designs in unique applications; thermal modeling; one-stop-shop for assembly | It May be used to monitoring reagent and sample temperature at 37°C [98.6°F]during the mixing/separation process to provide consistent test results. |

|

HIH6000 Series,HIH6100 Series,HIH7000 SeriesHumidIcon DigitalHumidity/TemperatureSensors | Combined humidity and temperature sensor;industry-leading long term stability (1.2 %RH over five years); enhanced reliability; enhanced relative humidity; more energy-efficient; ultra-small package | May be used for leakage detection duringthe liquid handling process. |

BARCODE SCANNING

|

CM Series Compact 2D Imager Module for Kiosk Data CaptureOperations | Self-contained, easy-to-mount 1D and 2Dbarcode scanning solution, whether decodingmobile phone screens or paper; selection of optics allow you to meet the performancerequirements of your application | It May be used for positive patientconfirmation and sometimes verificationof the physician’s order prior to thereagent loading process and the sampleloading process. |

|

N6600 Series UltraSlimArea-ImagingEngine | High-performance barcode imaging; slimand compact; integrates Honeywell Adaptus6.0 technology for unparalleled 1D and 2Dscanning performance | |

|

SwiftDecoder™ BarcodeDecoding and CharacterRecognition Software | Accurate industrial-grade decoding andcharacter recognition; proven in millionsof barcode scanners and OEM productsworldwide |

Warranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is the buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance personally, through our literature and the Honeywell website, it is the buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use. For more informationTo learn more about Honeywell Advanced Sensing Technologies,call 1.800.537.6945, visit our website, or e-mail inquiries to [email protected]To learn more about Honeywell’s scan engines and barcode software, visit our website.

Honeywell Advanced Sensing Technologies830 East Arapaho RoadRichardson, TX 75081sps.honeywell.com/ast

009042-6-EN | 6 | 04/21© 2021 Honeywell International Inc.

[xyz-ips snippet=”download-snippet”]