Honeywell SLATE Combustion Management System

Candy manufacturing is no piece of cake. For high-quality products, the use of steam is crucial. An efficient steam production depends on quality controls to provide maximum uptime while decreasing fuel and electricity loss. When a Mexican candy manufacturer needed a way to monitor steam consumption on a daily basis and save on electrical costs, they turned to Honeywell.

The NeedsUpdate existing control system and provide operators with tools for critical decision-making.Maximize boiler efficiency and save electricity.Control two fuels in the same valve train and measure steam consumption.

The Solution

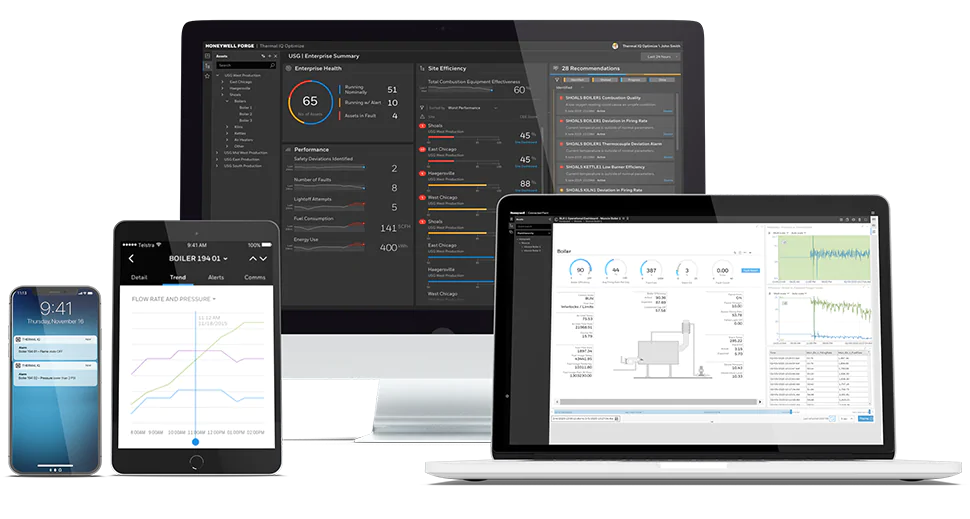

The SLATE Combustion Management System provides all of the components needed to upgrade the candy factory’s boiler system. SLATE’s programming software, the SLATE AX Tool, creates Proportional-Integrate-Derivative (PID) controls and gathers the daily steam consumption information.By utilizing SLATE’s Fuel Air Ratio Control Module, the operators are able to monitor both gas and air, while a Variable Frequency Drive (VFD) ultimately saves on electrical costs. Also, the facility achieves the capability to control two fuels with the same valve train by using SLATE’s Burner Control Module.The 7-inch, full-color touchscreen puts information and control at operators’ fingertips – providing convenient, at-a-glance visibility to analytics, charts, and other key data for diagnostics and tuning. Dynamic screen images also show the status of interlocks, so technicians can see which elements are degrading.The systems also use the standard manifold’s pressure in addition to each boiler’s own pressure to better anticipate changes in steam demand, regulating the steam pressure and improving overall fuel efficiency.

The Benefits

- Controls two fuels within the same valve train while providing operators with the vital information they need to make quick, informed decisions.

- Monitors steam consumption on a daily basis and reduces electrical costs by using a VFD on the combustion blower.

- Adjusts both gas and air levels on the production floor in a convenient, cost-effective way.

- Helps operators zero in on issues instantly, minimizing downtime when hazards occur.

For More InformationThe Honeywell Thermal Solutions family of products includes Honeywell Combustion Safety, Eclipse, Exothermics, Hauck, Kromschröder and Maxon. To learn more about our products, visit ThermalSolutions.honeywell.com or contact your Honeywell Sales Engineer.Honeywell Process SolutionsHoneywell Thermal Solutions (HTS)1250 West Sam Houston ParkwaySouth Houston, TX 77042ThermalSolutions.honeywell.com

References

[xyz-ips snippet=”download-snippet”]