Hudson® 99598 & 99599 FOG® Electric Atomizers User Manual

If you have any questions or concerns, or missing parts, Do not return sprayer to the store!

Call our hotline: 1-800-9-SPRAYER (1-800-977-7293)

Common maintenance questions: www.hdhudson.com/FAQS

FOR YOUR SAFETY

This sprayer operates with liquid under pressure.

Failure to observe cautions and follow instructions for use and maintenance can cause tank, hose or other parts to become corroded, weakened, and/or burst. This can result in serious injury or property damage from forcible ejection of parts or high-pressure discharge of spray material. Do not use any flammables or boiling liquids in this sprayer as it is not designed nor intended for such use. Some spray materials can ignite or explode. Do not spray in an enclosed space, near an open flame such as found in a bbq grill or water heater, near an electric motor or open switch, or any source of heat. Do not smoke while spraying. Use of flammables could result in serious injury or property damage from unintended ignition or explosion. Do not use any caustics or acids, bleach, or acetone in this sprayer, since these can damage or weaken the sprayer and its parts, resulting in serious injury or property damage. Keep out of reach from children and pets. Always read and follow directions on the spray material container, including the need for protective clothing. Before using your sprayer, thoroughly inspect both inside and outside of the sprayer and do not pressurize sprayer if tank, hose or other parts appear to be damaged, discolored, brittle, excessively soft or loose. Do not pressurize with any mechanical device such as an air compressor, since this can create dangerous pressure and bursting of parts and result in serious injury. Wear long-sleeved shirt, pants, gloves, goggles or similar protective clothing when spraying. PROP 65 WARNING: This product contains one or more chemicals, including lead, known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

LIMITED WARRANTY

H. D. Hudson Manufacturing Company warrants to the original consumer purchaser of this product at retail that it is free from problems in materials and workmanship for the period of 90 days from the original date of purchase. This warranty does not apply to damage to the product resulting from accident, misuse, neglect, alteration, modification, tampering, or failure to follow instructions supplied with the product. This warranty does not cover normal wear and tear of o-rings or seals, and the warranty shall be void if the product is used commercially. If the product or any part of it should malfunction within the warranty period, call 1-800-977-7293. Valid only in North America.You must retain your sales receipt as proof of the date of purchase and include it with any return of the product.

H. D. HUDSON MANUFACTURING COMPANY EXCLUDES LIABLITY UNDER THIS WARRANTY FOR ANY AND ALL INCIDENTAL AND CONSEQUENTIAL LOSS OR DAMAGES.

DO NOT operate this sprayer in small, enclosed areas, or any where any spray or foreign material could be sucked into the air intake. DO NOT overheat the motor. Be sure air intake is kept open at all times. DO NOT use this sprayer for paint spraying. DO NOT spray gasoline or other flammables. DO NOT alter the sprayer. DO NOT store chemicals in canister. ALWAYS READ AND FOLLOW instructions for chemicals to be applied. IF SPRAY PATTERN BECOMES IRREGULAR, turn sprayer off, remove the intake strainer and clean the screen. IF CORD BECOMES DAMAGED, it must be replaced before further use. DO clean sprayer thoroughly after each use.

SPECIAL NOTICE TO USERS

Damage in transit, wearing of nozzles or other parts, temperature, altitude, climatic factors and manners of use may effect the performance of this equipment. Careful maintenance, approved calibration procedures and repeated testing of output are necessary for safe and satisfactory results. Users must determine that the rate of application is proper for the chemical being used and the conditions under which it is being applied.

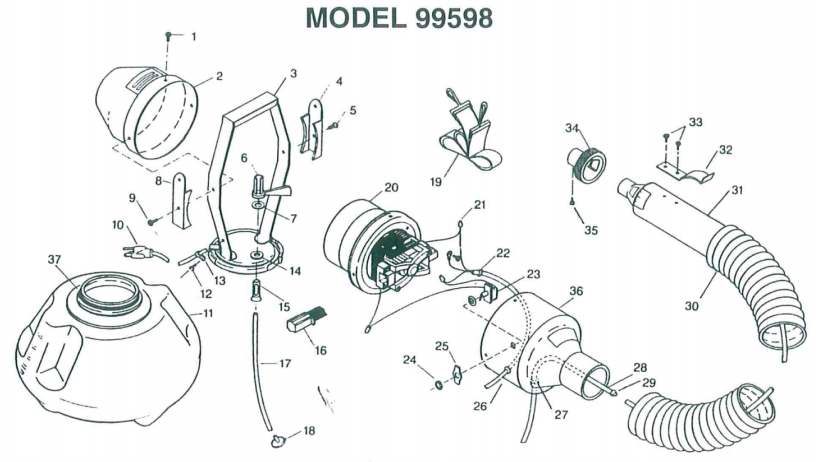

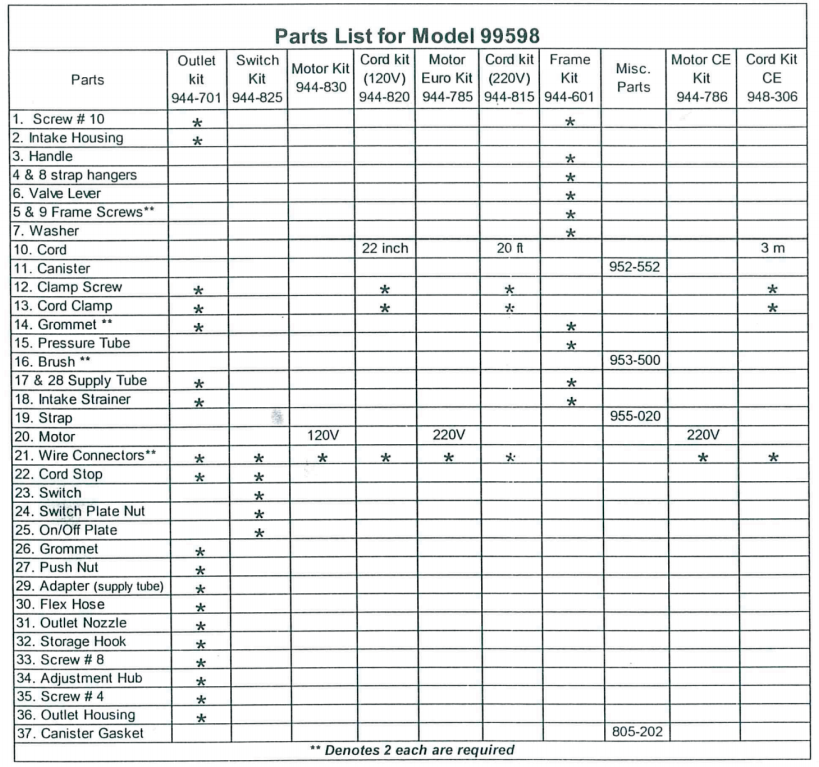

99598 OPERATION

Fill the canister with the desired amount of spray material. Reposition the sprayer on canister top and snap clamp so it fits tightly. Check the switch to make sure it is “off” before plugging into a 110/120 volt AC outlet. Once operating, the discharge rate of the sprayer may be adjusted by turning the discharge control.

Spray Adjustment: The 99598 has an adjustment range of 1.5 to 5.3 gallons/hr. Spray direction is variable through all degrees between 35 upward to 35 downward.

Wettable Powders: The 99598 sprays wettable powders at a maximum discharge rate of 5.3 gallons/hr. Preliminary testing is recommended to insure that desired rate is obtainable. Shake or agitate solution periodically to keep powders in suspension.

Spray Patterns: The 99598 atomizes 95% of its output of less than 50 microns. Average particle size is 20 microns.

After Use: To store the 99598 or change spray materials, detach the sprayer from the canister and turn it “on” to flush out any spray material. The sprayer should be washed after which the unit should be reassembled. After use with wettable powders, detach the canister, immerse the supply tube in clear water and flush until no residue can be seen in the supply tube. Wash the canister thoroughly.

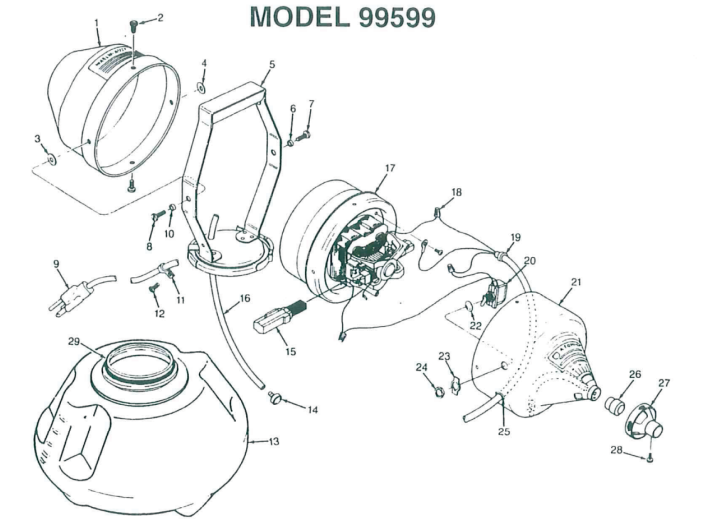

99599 OPERATION

Fill the canister with the desired amount of spray material. Reposition the sprayer on the canister top and snap clamp so it fits tightly. Check the spray selector valve on the tube that extends from the motor housing to the tank cover plate and set it according to the desired spray pattern. “Heavy” setting is achieved with valve lever turned full left (counter-clockwise). This covers the valve opening and pressurizes the canister. “Heavy” setting produces a dense wetting spray, ideal for application of residual or surface type spraying. “Fine” setting is achieved by turning valve lever full right (clock-wise). This opens the valve and allows air not utilized in spray discharge to escape. “Fine” setting produces ultra fine particles, ideal for flying insect control. Check the switch to make sure it is “off” before plugging into a 110/120 Volt AC outlet for 99599. Once operating, the discharge rate may be adjusted by turning the discharge control at end of hose.

Spray Adjustment: The “fine” (unpressurized) setting has an adjustment rate of 1.5 to 3.5 gallons/hr. On “heavy” (pressurized) setting, the adjustment rate is 6 to 14 gallons/hr. Spray direction is variable through manipulation of the discharge hose.

Wettable Powders: Preliminary testing is recommended to insure that desired rate is obtainable. Shake or agitate solution periodically to keep powders in suspension.

After Use: When the unit is turned “off” after spraying, siphoning action may continue for a moment, resulting in a solid stream of spray material. To prevent this, tip the nozzle up straight as you switch “off” the motor, thus flushing any spray solution remaining in the discharge line back into the canister. To store the 99599 or change spray materials, detach the sprayer from the canister, immerse the supply tube in clear water, and flush until no residue can be seen in the supply tube. Wash the canister thoroughly

SERVICE AND MAINTENANCE

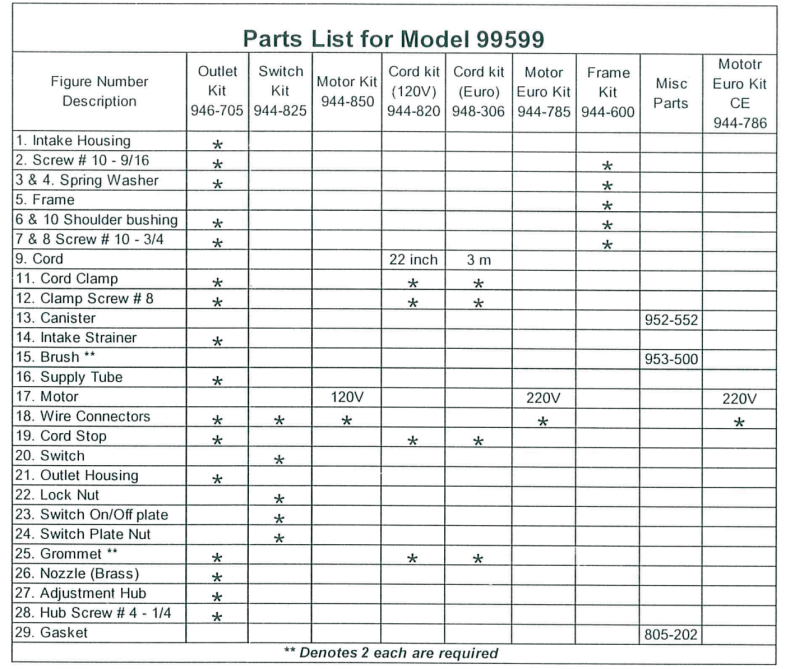

Clean and dry your sprayer after every use to greatly prolong its useful service life. Many spray materials will harden if left in the sprayer and plug up the nozzle, shut-off valve or supply tube. The soft parts, O-rings and gaskets, will ultimately wear out and need replacing, just like the oil filter on your car, for example. How often they need replacing depends on how much you spray, the spray materials you use and whether or not the sprayer is regularly cleaned after use. Call 1-800-9-SPRAYER or visit www.hdhudson.com to obtain genuine Hudson® replacement parts. If you leave your sprayer in the garage over Winter, particularly in northern areas, the soft parts may dry out and need servicing before you use your sprayer for the first time in the Spring.

References

[xyz-ips snippet=”download-snippet”]