Modbus ServerMitsubishi Heavy Industries Air ConditioningGateway for integration of Mitsubishi Heavy Industries air conditioning systemsinto Modbus (RTU and TCP) systemsUSER MANUALIssue date: 05/2012 r1.0

Intesis™ Modbus Server Mitsubishi Heavy Industries AC

Important User Information

DisclaimerThe information in this document is for informational purposes only. Please inform HMS Industrial Networks of any inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability for any errors that may appear in this document.HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product development. The information in this document shall therefore not be construed as a commitment on the part of HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment to update or keep current the information in this document.The data, examples, and illustrations found in this document are included for illustrative purposes and are only intended to help improve understanding of the functionality and handling of the product. In view of the wide range of possible applications of the product, and because of the many variables and requirements associated with any particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on the data, examples, or illustrations included in this document nor for any damages incurred during the installation of the product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the product is used correctly in their specific application and that the application meets all performance and safety requirements including any applicable laws, regulations, codes, and standards. Further, HMS Industrial Networks will under no circumstances assume liability or responsibility for any problems that may arise as a result of the use of undocumented features or functional side effects found outside the documented scope of the product. The effects caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility issues and stability issues.Gateway for integration of Mitsubishi Heavy Industries air conditioning systems into Modbus (RTU and TCP) systems.

| ORDER CODE | LEGACY ORDER CODE |

| NMBSMHI048O000 | IMH-AC-MBS-48 |

| NMBSMHI128O000 | I MH-AC-MBS-128 |

Description

1.1 IntroductionIntesis™ Modbus Server Mitsubishi Heavy Industries AC is a communication gateway for Mitsubishi Heavy Industries air conditioning (AC) systems to Modbus slave (RTU and TCP).This gateway allows integrating a Mitsubishi Heavy Industries AC system inside a supervision/control/automation system through PLC, SCADA, and, in general, through any device or system with Modbus mastering (TCP or RTU) interface.The aim of this integration is to make accessible several Mitsubishi Heavy Industries air conditioning indoor units communicating with the Superlink protocol as if they were part of a Modbus system. Therefore, the IntesisTM Modbus Server acts as a Modbus slave in the Modbus interface, allowing the Modbus master to read and write in the Modbus registers. Moreover, IntesisTM includes all hardware required to manage/control Mitsubishi Heavy Industries indoor units without extra components needed.1.2 Integration signals*Following is the list of parameters that can be monitored/controlled on the indoor units using Intesis™:

|

|

*Apart from these, the Intesis™also implements some extra signals (functions):

- For all indoor units1 in the system:

- HW Communication Status (read-only)

- On/Off (write-only)

- Operation Mode (write-only)

- SetPoint Temperature (write-only)

- Fan Speed (write-only)

- Remote Controller Lock/Unlock (write-only)

1 These signals work as master signals controlling all connected units at the same time

1.3 FunctionalityEach of the mentioned signals in section 1.2 is associated with a predefined and fixed Modbus address.Therefore, all the system is seen as a single Modbus slave unit with a fixed Modbus address map from the Modbus system point of view.

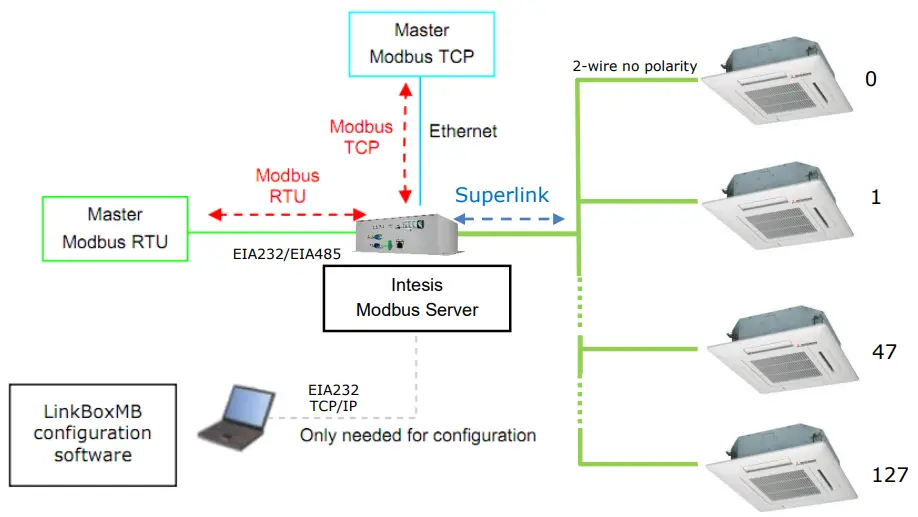

Figure 1.1 Integration of Mitsubishi Heavy Industries AC into Modbus system using Intesis™Two Modbus mode connection types can be active in Intesis™: Modbus RTU or Modbus TCP, or both simultaneously.Intesis™ continuously polls all signals provided by each indoor unit and maintains the updated values to be served in Modbus.In the continuous polling of each indoor unit, if no response of a certain device is detected, the corresponding virtual signal inside the gateway will be activated indicating a communication error between the gateway and that precise device (see 0).When a written order is done from Modbus is a gateway’s write-enabled Modbus address, the corresponding order is sent to the associated Mitsubishi Heavy Industries signal (Superlink).Each Mitsubishi Heavy Industries Indoor Unit has a unique address (0 to 127). These addresses need to be configured inside Intesis™using the LinkBoxMB tool (see 4.2.2).Intesis™ is capable of managing up to two simultaneous Modbus master connections.Intesis™ includes all hardware needed to connect directly with the Mitsubishi Heavy Industries indoor units connecting with the Superlink network.

1.4 Capacity of Intesis™

| Element | Max. | Notes |

| Number of indoor units | 128 * | Maximum number of AC indoor units that can be controlled |

| Number of points per indoor unit | 14 | Modbus addresses per indoor unit |

| Maximum number of points | 1797* | Valid Modbus addresses |

| Maximum TCP master connections | 2 | Maximum number of TCP simultaneousModbus Master connections |

| Maximum RTU master connections | 1 | Maximum number of RTU simultaneousModbus Master connections |

Table 1.1 Intesis™ capacity

* There are two different models of IntesisTM Modbus Server Mitsubishi Heavy Industries AC each one with a different capacity. The table above shows the capacity for the top model (with maximum capacity).

Their order codes are

- INMBSMHI048O000:• Model supporting up to 48 indoor units• For Superlink-I (Previous Superlink) or Superlink-II (New Superlink).• Indoor Unit actual address range is 00 to 47

- INMBSMHI128O000: Model supporting up to 128 indoor units• For Superlink-II (New Superlink)• Indoor Unit actual address range is 000 to 127

Check available combinations of Mitsubishi Heavy Industries Central Control and BMS interface units in the next tables.In the case of SL2NA or SL3NA, it is necessary to erase the registration of the non-connected indoor units. For SL2NA and SL3NA, change is required for the setup deprived of the rights of instruction of Remocon control Lock/Unlock.New Superlink connections:

| INMBSMHI1280000INKNXMHI1280000 | SC-LAGUNA-ASC-BGWNA- A/Betc. | SC-SL3NA-AE/BE etc. | SC-SL2NA-E etc. | SC-SL1N-E etc. | Max Indoor Units | Address No. |

| 1 | Non connect | 2 | 0 | 0-8 | 128 | 000-127 |

| 1 | 0-2 | |||||

| 0 | 0-4 |

| INMBSMHI0480000INKNXMHI0480000 | SC-LGWNA-A SC-BGWNA-A/B etc. | SC-SL3NA-AE/BE etc. | SC-SL2NA-E etc. | SC-SL1N-E etc. | Max IndoorUnits | Address No. |

| 1 | Non connect | 2 | 0 | 0-8 | 48 | 00-47 |

| 1 | 0-2 | |||||

| 0 | 0-4 |

Previous Superlink connections:

| INMBSMHI—0000INKNXMHI—0000 | SC-LAGUNA-ASC-BGWNA-A/Betc. | SC-SL3NA-AE/BEetc. | SC-SL2NA-Eetc. | SC-SL1N-Eetc. | MaxIndoorUnits | AddressNo. |

| 1 | Non connect | Non connect | 1 | 0 | 32 | 00-47 |

| 0 | 1,2 | |||||

| 0 | 0 | 48 |

Modbus interface of Intesis™

2.1 DescriptionIntesis™acts as a slave device in the Modbus interface. The physical interface can be either Ethernet if using Modbus TCP, or the EIA485 (or EIA232), if using Modbus RTU.2.2 Functions supportedThis part is common for Modbus RTU and TCP:

- Modbus functions 03 and 04 (read holding registers and read input registers) can be used to read Modbus registers.

- Modbus function 06 (Single Multiple Holding Registers) must be used to write Modbus registers.

- As per Modbus standard specification, register contents are always expressed in MSB.LSB (Big Endian).

- Modbus error codes are fully supported, they will be sent whenever a non-valid Modbus action or address is required (see section 9).

2.3 Modbus RTUBaud rates can be selected from 1200, 2400, 4800, 9600, 19200, and 38400.Information structure:

- Data Bits: 8

- Parity Bit: Selectable from non, even, odd or second stop bit (2stop).

- Stop Bit: 1

Modbus slave number can be configured.Physical connection (EIA232 or EIA485) can also be selected.Only the lines RX, TX, and GND of the EIA232 connector are used (TX and RX for EIA485).

2.4 Modbus TCPThe TCP port to use can be configured (by default 502 is used).The IP address, subnet mask, and default gateway address to use by Intesis™can be also configured.Address Map2.5 Address map is fixed for each indoor unit and can be consulted as explained in the following tables. Please, remember that in the tables R/W stands for reading and Write, R stands for Read-Only and W stands for Write Only.2.5.1 Modbus addresses related to Intesis™

| Modbus address(base and is 1) | Modbus register type (11/W) |

Signal description and values |

| 2995 | R | 1-1w Communication Status

|

2.5.2 Modbus addresses related to each Indoor Unit1

| I | R | Communication Status

|

|

| 2 | R/W | nit Indoor U On/Off

|

|

| 3 | R/W | Operation Mode

|

|

| 4 | R/W | SetPoint Temperature

|

|

| 5 | R/W | Fan Speed

|

|

| 6 | R/W | emote Controller Lock/Unlock

|

|

| 7 | R/W | Louver Control2

|

|

| 8 | 12 | Room Temperature

|

|

| 9 | k | Filter Sign status

|

|

| 10 | R | Error Code

|

|

|

11 |

R |

Compressor Status

|

|

| 12 | W | Filter Sign Reset

|

|

| 13 | w | Remote Controller Error Reset

|

|

| 14 | R | Thermo On/Off Status (Inverter Type Only)

|

|

| Indoor unit number | Modbus address (base and is 1) | Mod bus register type | Signal description and values |

- The supported number of indoor units varies according to the Intesis™ model

- During the transition between positions, the Swing signal will turn on indicating the Louver is moving 3

- See a list of indoor unit error codes and their meaning in section 9

| (R/W) | |||

| n* | ( n*) x 20 + 1 | R | Communication Status |

| ( n*) x 20 + 2 | R/W | Indoor Unit On/Off | |

| ( n*) x 20 + 3 | R/W | Operation Mode | |

| ( n*) x 20 + 4 | R/W | SetPoint Temperature | |

| ( n*) x 20 + 5 | R/W | Fan Speed | |

| ( n*) x 20 + 6 | R/W | Remote Controller Lock/Unlock | |

| ( n*) x 20 + 7 | R/W | Louver Control | |

| ( n*) x 20 + 8 | R | Room Temperature | |

| ( n*) x 20 + 9 | R | After Sign status | |

| ( n*) x 20 + 10 | R | Indoor Unit Error Code | |

| ( n*) x 20 + 11 | R | Compressor Status | |

| ( n*) x 20 + 12 | W | Filter Sign Reset | |

| ( n*) x 20 + 13 | W | Remote Control Error Reset | |

| ( n*) x 20 + 14 | R | Thermo Status (Inverter Type Only) | |

| … | … | … | … |

| 127 (max number of supported Indoor units depends on Infests model) | 2541 | R | Communication Status |

| 2542 | R/W | Indoor Unit On/Off | |

| 2543 | R/W | Operation Mode | |

| 2544 | R/W | SetPoint Temperature | |

| 2545 | R/W | Fan Speed | |

| 2546 | R/W | Remote Controller Lock/Unlock | |

| 2547 | R/W | Louver Control | |

| 2548 | R | Room Temperature | |

| 2549 | R | Filter Sign status | |

| 2550 | R | Indoor Unit Error Code | |

| 2551 | R | Compressor Status | |

| 2552 | W | Filter Sign Reset | |

| 2553 | W | Remote Control Error Reset | |

| 2554 | R | Thermo Status (Inverter Type Only) |

*n is the indoor unit address number.2.5.3 Modbus addresses related to ALL indoor units

| Indoor unit number | Modbus address (base and is 1) | Modbus register type (R/W) | Signal description and values |

| ALL | 2996 | W | All Indoor Units On/Off

|

| 2997 | W | All Indoor Units Operation Mode

|

|

| 2998 | W | All Indoor Units SetPoint Temperature

|

|

| 2999 | W | All Indoor Units Fan Speed

|

|

| 3000 | W | All Indoor Units Remote Controller Lock/Unlock

|

Intesis™ Device Connections

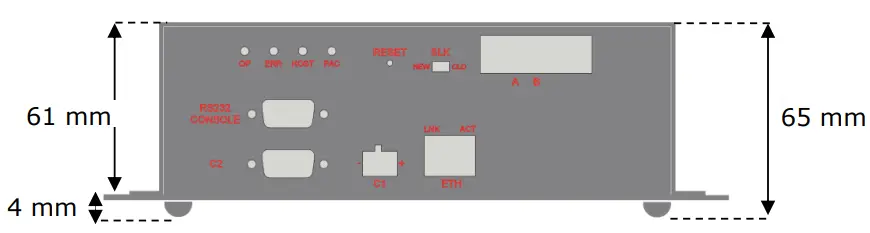

1 Figure 3.1 IntesisTM device front view

1 Figure 3.1 IntesisTM device front view Figure 3.2 IntesisTM device back view

Figure 3.2 IntesisTM device back view

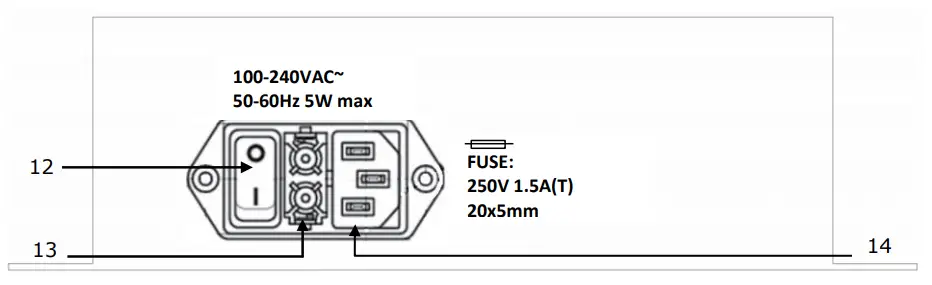

Next, there is the list with the device physical interface connector’s description

| 1.- Modbus RTU master EIA485 (C1)2.- Modbus RTU master EIA232 (C2)3.- Console serial port EIA2324.- Operation LED5.- Error LED6.- Host LED7.- Pac LED | 8.- Reset button (Non supported)9.- Superlink selector (SLK)New: Superlink-II Old: Superlink-I10.- A-B connector (for Superlink, no polarity)11.- Modbus TCP master Ethernet (ETH)12.- Power supply On/Off button13.- Power supply fuse (250V, 1.5A)14.- Power supply connector |

3.1 Connect to Mitsubishi Heavy Industries InterfaceUse the A-B connector in the right top corner of the front side of the Intesis™ device in order to connect the Mitsubishi Heavy Industries network (Superlink) to the Intesis™. Recommended specifications of the cable for the Superlink are shown as follows:

- Size of cable: 0.75 to 1.25 square mm

- Max length of wiring: total 1000m (loop wiring is not allowed)

- Cable materials :

Twisted Vinyl Cabtyre Cable VCTF 2 core 0.75 to 1.25 square mm Twisted Vinyl Cabtyre Cable VCT 2 core 0.75 to 1.25 square mm Twisted Vinyl Cable for Control CVV 2 core 0.75 to 1.25 square mm Table 3.1 Cable types recommended for Superlink connection

- For the prevention of electromagnetic noise malfunctions, parallel wiring with the power line should be avoided

Select the appropriate Superlink mode in the SLK selector. If you are using the latest Air Conditioner of the Mitsubishi Heavy Industries network (New Superlink) select NEW, if not select OLD.

| LED | Status | Intesis™ behavior |

| OP | Blinking | Power supply OK |

| ERR | Off | No error |

| HOST | Blinking | Internal communication OK |

| PAC | Blinking | Communication with the Superlink network OK |

Table 3.2 IntesisTM LED status information

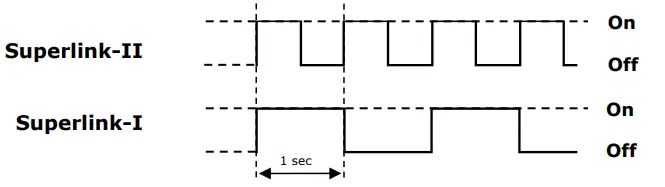

OP LED behavior must defer depending on the Superlink version, as shown in Figure 3.3

Figure 3.3 OP LED blinking behavior depending on Superlink version

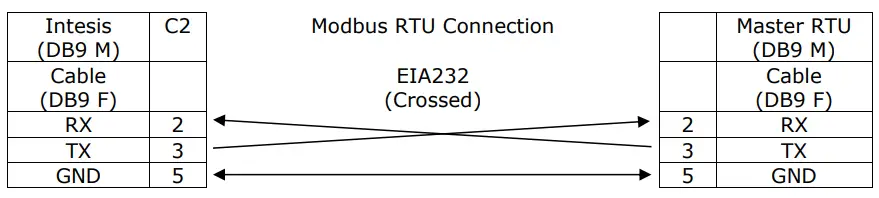

If LEDs (except ERR) are not in the states described above, check section 5.3. For further information about the Superlink network, look up the Mitsubishi Heavy Industries Manual or contact your nearest Mitsubishi Heavy Industries supplier.3.2 Connect to Modbus Interface3.2.1 Connect to Modbus RTU Connect the communication cable coming from the Modbus RTU network to the IntesisTM device (see Figure 3.1). There are 2 existing modes available:

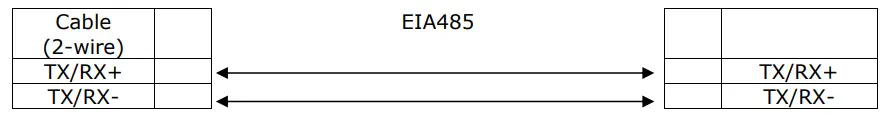

- EIA485 connection: Use the C1 connector (see Figure 3.1) if the Modbus interface is a 2-wire EIA485 connector. Connect the + and to the respective port in the master device and in the Intesis™ device (polarity matters).

- EIA232 connection: Use the C2 connector (see Figure 3.1) if the Modbus interface is point-to-point to one single master.

Table 3.3 EIA232 cable pin assign

Table 3.4 EIA485 cable pin assign

To check the connectivity and correct functioning, use LinkBoxMB software (see LinkBoxMB User Manual).

3.2.2 Connect to Modbus TCPConnect the communication cable coming from the hub, switch, or device of the Modbus Ethernet network to the ETH connector from the Intesis™device (see Figure 3.1). The cable to be used may vary depending on where the Intesis™is being connected:

- Connecting directly to a Modbus TCP master device: Crossover Ethernet UTP/FTP CAT5 cable.

- Connecting to a hub or switch of the LAN of the building: Straight Ethernet UTP/FTP CAT5 cable.

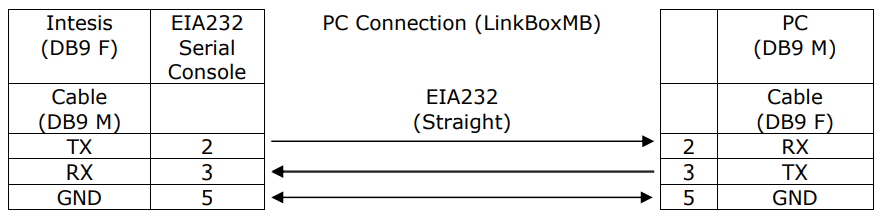

Table 3.5 TCP cable connection

In case there is no communication with the Intesis™, check that the Modbus TCP devices are operative and reachable from the network connection used by Intesis™. You can also check that the Intesis™ Ethernet interface is sending Pings to its IP address using a PC connected to the same Ethernet network.3.2.3 Connect to PC (LinkBoxMB)Connects the Intesis™ device to the PC serial port using the serial cable provided. One end should be connected to the Console EIA232 port of the Intesis™ device (see Figure 3.1) and the other end to the PC serial port.

Table 3.6 EIA232 serial connection pin assign

3.3 Power DeviceTo power up the device, what you need is to plug properly the Power Supply connector to the IntesisTM device using a proper cable and connecting one end to the power supply connector (see Figure 3.2) and the other end to the power line. After that, just press the power supply On/Off button to turn it on.

LinkBoxMB

Configuration & monitoring tool for Intesis™ Modbus Server series

4.1 IntroductionLinkBoxMB is a Windows® compatible software developed specifically to monitor and configure the Intesis™ Modbus Server series.The installation procedure and main functions are explained in the LinkBoxMB User Manual. This document can be found in the Doc folder or can be downloaded from the link indicated in the installation sheet supplied with the IntesisTM device.In this section, only the specific case of Mitsubishi Heavy Industries indoor unit’s integration to Modbus networks will be covered.4.2 Connections configurationTo configure the Intesis™’s connection parameters and to see the points list, press the Config button in the menu bar (see Figure 4.1). The Mitsubishi Heavy Industries Configuration window will open (see Figure 4.2). For integrations with a large number of points, there is available an alternative CSV installation procedure explained in the LinkBoxMB User Manual.

Figure 4.1 LinkBoxMB menu bar

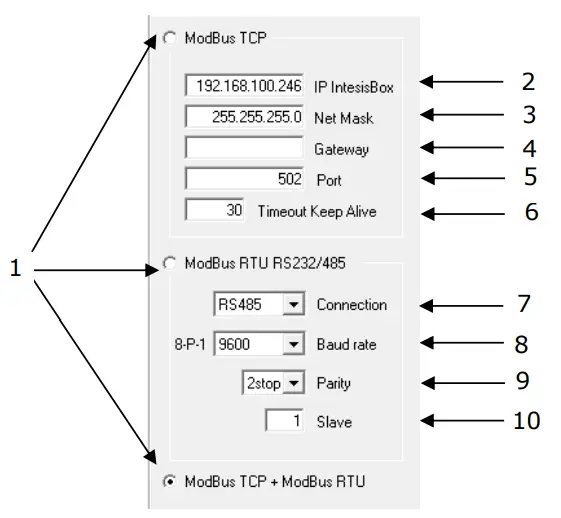

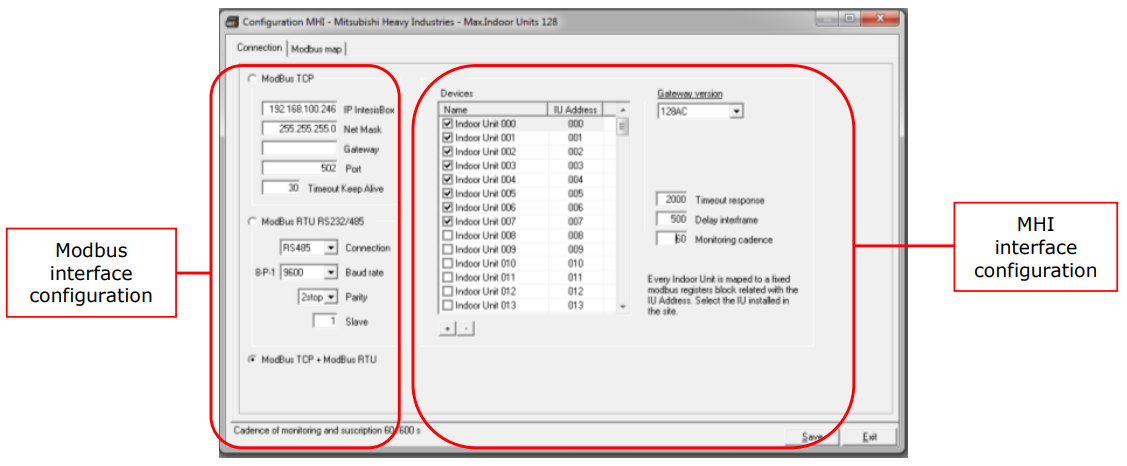

4.2.1 Configuration tabSelect the Connection tab to configure the connection parameters. Two subsets of information are shown in this window: Modbus RTU, Modbus TCP, and Mitsubishi Heavy Industries interfaces parameters (see Figure 4.2).

Figure 4.2 LinkBoxMB configuration tab

Figure 4.2 LinkBoxMB configuration tab

Next, there is an explanation for each of the configuration parameters in each mode.

- Modbus interface configuration parameters:

Figure 4.3 Modbus interface configuration

- Select the type of Modbus communication to use (TCP, RTU, or both).If Modbus TCP is selected, then:

- IP Intesis: Enter the IP address for IntesisTM.

- Net Mask: Enter the IP netmask for IntesisTM.

- Gateway: Enter the default gateway address for IntesisTM; leave it blank if no routeris needed.

- Port: Enter the TCP port to use (default for Modbus TCP is 502).

- Timeout Keep Alive: Enter the time (expressed in seconds) that IntesisTM will wait,upon no TCP activity, to send a Keep-Alive packet. Enter 0 if you don’t want IntesisTM to send any Keep-Alive packet (default 30 seconds).If Modbus RTU is selected, then:

- Connection: Select the physical media (EIA232 or EIA485)1.

- Baud rate: Enter the baud rate of the serial communication.

- Parity: Enter the byte parity of the serial communication.

- Slave: Introduce the Slave number for the Modbus interface.

• Mitsubishi Heavy Industries interface configuration parameters:1 In the LinkboxMB this connection is labeled as RS232 and RS485 respectively.

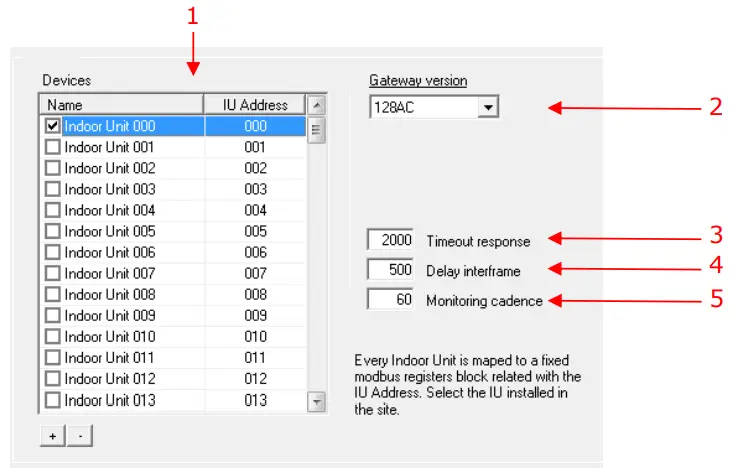

Figure 4.4 Mitsubishi Heavy Industries interface configuration

- Devices: In this list, you can individually enable each of the 128 indoor units available on the system. The index in the column “Indoor unit” (i.e. the number x in “Indoor Unit xxx”) is the reference that will be used later on (in tab “Signals”) to refer to this AC indoor unit. You can also change the name of the indoor Unit to facilitate integration tasks.

- Gateway version: Selection of the Intesis Modbus Server Mitsubishi Heavy Industries gateway you are setting up. (128AC for INMBSMHI128O000, 48AC for INMBSMHI048O000)

- Timeout response: Maximum amount of time permitted before activating the Communication Error signal. It is expressed in milliseconds (ms) and ranges can vary from 2000 ms to 10000 ms.

- Delay interframe: Maximum amount of time permitted between End Of Transmission (EOT) and a new frame. It is expressed in milliseconds (ms) and ranges can vary from 500 ms to 3000 ms.

- Monitoring cadence: Cadence of monitoring and subscription. It is expressed in seconds (s) and ranges can vary from 60 s to 600 s.

Additional configuration parameters should generally be left to their default value. They only might need to be tuned in some very specific cases (installations with a large number of units, scenarios with large bursts of commands sent at once …)

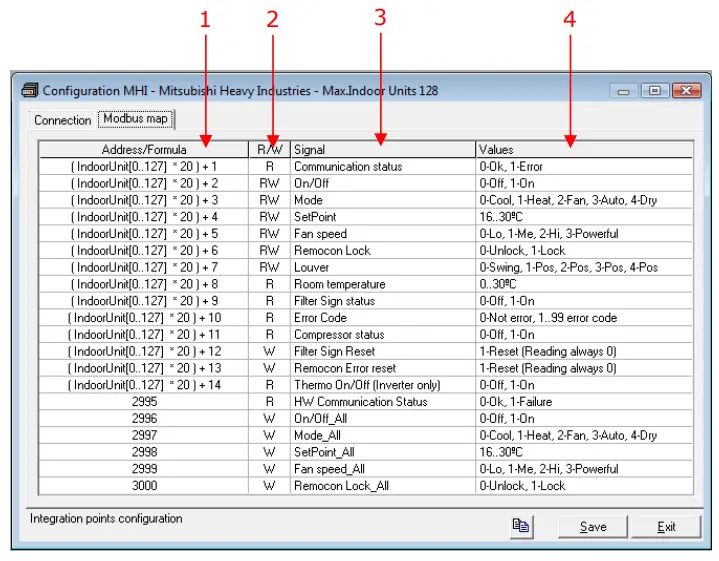

4.2.2 Modbus map tabIn order to know the Modbus map that is going to be used by the interface, the Modbus map tab can be consulted.Content in this tab is just informative: no information has to be set up.

Figure 4.5 Modbus signal list

- Address Formula: Formula used by Intesis™ to define the Modbus address for the point. Use this address (obtained with this formula) to access the point from your Modbus master device.

- R/W: Indicates if the signal is read-only, or if it can be read and written (from the Modbus system point of view).

- Signal: Signal description.

- Values: Possible values for the signal.

See section 2.5 for further detail on address mapping and the possible values on each signal.4.3 Sending the configuration to Intesis™When the configuration is finished, follow the next steps.

- – Click on the Save button to save the project to the project folder on your hard disk (more information in LinkBoxMB User Manual).

- – You will be prompted to generate the configuration file to be sent to the gateway.a.- If Yes is selected, the binary file (MHI.Lbox) containing the configuration for the gateway will be generated and saved also into the project folder.b.- If NO is selected, remember that the binary file with the project needs to be generated before the Intesis™starts to work as expected.

- – Once in the configuration window again, click on exit. The configuration file is ready to be sent to the Intesis™ device.

- – Press the Send File button to send the binary file to the IntesisTM device. The process of file transmission can be monitored in the IntesisTM Communication Console window. Intesis will reboot automatically once the new configuration is loaded.

After any configuration change, do not forget to send the configuration file to the IntesisTM using the button Send File.

4.4 Signals viewerOnce the gateway is running with the correct configuration, to supervise the status of the configured signals, press the Signals button on the menu bar (see Figure 4.1). The Signals Viewer window will open (see Figure 4.6).This window shows all signals active within the gateway with its main configuration parameters and its real-time value1 in the Value column.

Figure 4.6 LinkBoxMB Signals Viewer

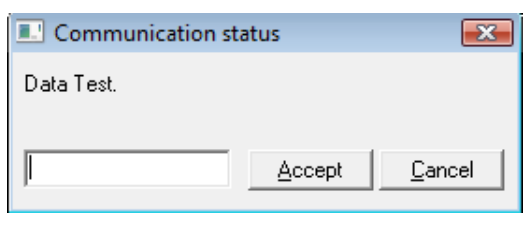

The signals viewer can be used even though only one system is connected to the Intesis™, Modbus, or Mitsubishi Heavy Industries AC. Therefore, it becomes convenient for supervision and testing the system.In order to force a specific value to a signal, double-click its row in the table. This will display a dialog in which the desired value can be entered (see Figure 4.7). Changing its value in this way will make:

- The content of the corresponding Modbus address will be changed to this value.

- If the signal is write-enabled, it will trigger a suitable command to Mitsubishi HeavyIndustries AC system.

1 In case you connect to the IntesisTM when it’s been running for a certain time, you should press the Refresh button to get updated values. After pressing Refresh, all signal values will keep continuously updated until the connection is closed.

Figure 4.7 Signal value change window

4.5 FilesLinkBoxMB saves the integration configuration in the following files inside the project folder:

| PROJECT.INI | INI file containing general information related to the project |

| MHI.INI | INI file containing information related to the values configured through the “Connection” tab in IntesisTM configuration |

| MHI.XBOX | A binary file was created from the information in the files described above. This is the file downloaded to the IntesisTM’ |

Table 4.1 LinkBoxMB generated files during Project creation

It is strongly recommended to back up the project folder containing these files in external media, once the installation process is finished. This way you will be able to do future configuration changes in case of reinstallation of LinkBoxMB due, for example, to a failure of the hard disk in the PC where LinkBoxMB was installed.The configuration cannot be uploaded from the gateway to LinkBoxMB, it can only be downloaded.

The setup process and troubleshooting

5.1 Pre-requisitesIt is necessary to have the Modbus master device operative and well connected to the Modbus port of IntesisTM. If using EIA232 communication, remember to respect the maximum of 15 meters of cable distance.Connectors, connection cables, PC for LinkBoxMB, and other auxiliary material, if needed, are not supplied by HMS Networks for this standard integration. Items supplied by HMS Networks for this integration are:

- IntesisTM Modbus Server device with full Mitsubishi Heavy Industries AC compatibility without extra components.

- Standard plug-in power supply 220Vac 50Hz to power Intesis™ (European plug type).

- Access to LinkBoxMB software download site to configure Intesis™.

- Console cable needed to download the configuration to Intesis™. · Product documentation.

5.2 Setup procedure

- Install LinkBoxMB on your laptop, use the setup program supplied for this and follow the instructions given by the installation wizard.

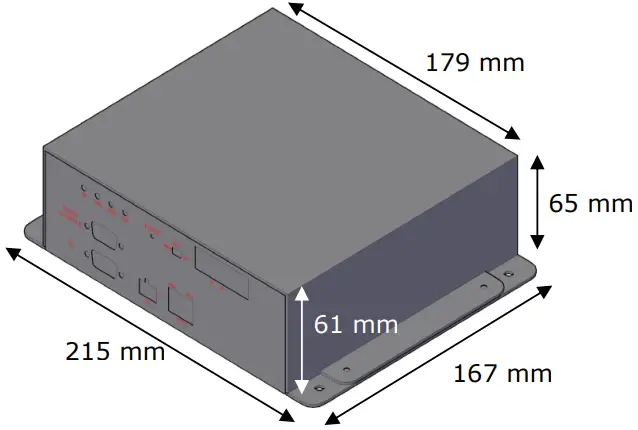

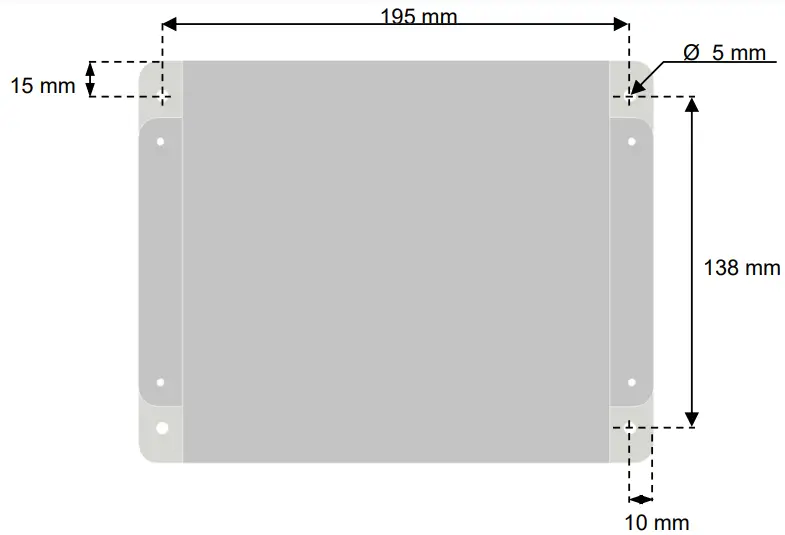

- Install Intesis™ in the desired installation site. For your convenience, check external enclosure measures (see 7) before deciding where to place the Intesis™ device.

- Connect the communication cable coming from the Modbus master device to the Intesis™ port. Depending on the type of communication protocol:• If EIA232 is used, connect it to C2.• If EIA485 is used, connect it to C1.•If Ethernet is used, connect it to ETH.(See 3.2 for more information on connection procedure)Remember that Intesis™ can handle up to two simultaneous Modbus master connections.

- Connect the Superlink network cable to the Intesis port marked as AB (see 3.1).

- Select the appropriate Superlink mode in the SLK selector. If you are using the latest Air Conditioner of the Mitsubishi Heavy Industries network select NEW, if not select OLD. Contact your nearest Mitsubishi Heavy Industries supplier in case of doubt.

- Connect the Intesis™ device to the power line (see 3.3) and press the On/Off button to turn it on.

- Connect the communication cable coming from the serial port of your laptop/desktop PC to the IntesisTM port marked as EIA232 Console (see 3.2.3).

- Open LinkBoxMB and proceed as explained in section 4.

5.3 TroubleshootingIf IntesisTM is not working properly or even not working at all, please check the following conditions to be accomplished.5.3.1 Physical checkingThe first point to look at to make sure that Intesis™ is not working properly is to check physical connections:1.- Make sure that the power plug is correctly connected and the current is available in the power line.2.- Check IntesisTM LED status:

| LED | Status | Explanation | Solution |

| OP | Off | No power reaching the internal device | Check power connectionCheck fuse status (see 13 in Figure 3.2) |

| ERR | Blinking once periodically | Superlink communication failure | Check Superlink cables and terminals (connectors, length of cables, etc.) |

| HOST | Off | Configuration error | Download the binary file again (see 4.3) |

| PAC | Off | Communication error in the Superlink network | Check the Mitsubishi Heavy IndustriesSuperlink network and its connections |

Table 5.1 IntesisTM LED status information

5.3.2 Software checkingOnce physical connections have been checked, if functioning problems still remain, please use the LinkBoxMB tool to monitor the working status of the device.

- To check the Modbus communication status, click on the Modbus button in the menu bar (see Figure 4.1).

- To check the MHI communication status, click on the MHI button, also in the menu bar (see Figure 4.1).

- To check the signal values in the Modbus registers, click on the Signals button, also in the menu bar (see Figure 4.1).

Further information regarding the monitoring procedure and the information provided in each window can be consulted in the LinkBoxMB Manual.

Functional characteristics summary

| General | |

| Max. Number of Mitsubishi Heavy Industries interfaces | Two different versions of Intesism are available, supporting a maximum of 128 and 48 indoor units respectively. |

| Virtual signals |

|

| Modbus interface | |

| Device type | Slave. |

| Modbus modes supported | TCP, RTU EIA232, or EIA485. |

| Modbus TCP configuration parameters |

|

| Modbus RTU configuration parameters |

|

| Points | |

| Configuration | AC system-related fields.

|

| Supported Modbus function codes | Read functions:

11 poll records are used to read multiple treads, the range of addresses requested must contain valid addresses, otherwise, the corresponding Modbus war ode will be responded to. |

| Modbus data coding | All the point values are coded in 2-byte registers (even if their possible values are 0 and 1). They are expressed in MSB.LSB format (Big Endlan) |

Mechanical & Electrical characteristics

Figure 7.1 External dimensions Perspective view

Figure 7.2 External dimensions Front view Figure 7.3 Top view1 (screw holes size)

Figure 7.3 Top view1 (screw holes size)

1 Device can be installed in any position.

| Enclosure | Industrial sheet metal.Size: 215mm x 167mm x 61mm.Weight: 2.025 Kq |

| Color | Gray metalized. |

| Power | 100 to 240VAC-50 to 60HzSW max.Power connector: C14 (male) ‘ |

| Fuse | 250V1.5ADimensions: 20x5mm |

| Terminal wiring

signals(for low-voltage) |

Per terminal: solid wires or stranded wires (twisted or with ferrule)1 core: 0.75 … 1.25mm22 cores: 0.75 … 1.25mm23 cores: not permitted |

| Mounting | Wall (see Figure 7.3) |

| Modbus TCP port | 1 x Ethernet 10Base-T (R145). |

| Modbus RTU ports | 1 x Serial EIA232 (DB9 male DTE). SELV1 x Serial EIA485 (Plug-in screw terminal block 2 poles). SELV |

| A-B port | 1 x Superlink terminals (Plug-in screw terminal block 2 poles “A” “B”). SELV |

| LED indicators | 2 x Ethernet port link and activity (LNK, ACT).4 x MHI Interface (OP, ERR, HOST, PAC) |

| Pushbuttons | 1 x Reset Device |

| Selectors | 1 x SLK selector |

| Console port | EIA232. (DB9 female DCE). SELV |

| Configuration | Via console port. 2 |

| Firmware | Allows upgrades via console port. |

| Operational temperature range | 0°C to +40°C |

| Operational humidity range | 5% to 95%, non condensing |

| Protection | IP20 (IEC60529). |

| RoHS conformity | Compliant with RoHS directive (2002/95/CE). |

| Norms and standards | CE conformity to EMC directive (2004/108/EC) and Low-voltagedirective (2006/95/EC)EN 61000-6-2EN 61000-6-3EN 60950-1EN 50491-3 |

Table 7.1 Intesis™ Mechanical and Electrical Characteristics

AC Unit Types compatibility

Indoor units compatible with the IntesisTM Modbus Server are those included in the Mitsubishi Heavy Industries XK family and so on.

- A power cable with connector C14 male 1.6 meters long is supplied with the device.

- Standard cable DB9male-DB9female 1.8 meters long is supplied with the device for connection to a PC COM port for configuring and monitoring the device. The configuration software, compatible with Windows® operating systems, is also supplied.

Error codes

This list contains all possible values shown in Modbus registers for “Error Code” for each indoor unit.

| Error Code Modbus | Error in Remote Controller | Error Description |

| 0 | N/A | No active error |

| 1 | El | Remote controller communication error |

| 2 | E2 | Duplicated indoor unit address |

| 3 | E3 | Outdoor unit signal line error |

| 5 | ES | Communication error during operation |

| 6 | E6 | Indoor heat exchanger temperature thermistor anomaly |

| 7 | E7 | Indoor return air temperature thermistor anomaly |

| 8 | E8 | Heating overload operation |

| 9 | E9 | Drain trouble |

| 10 | E10 | Excessive number of indoor units (more than 17) by controlling one remote controller |

| 12 | E12 | Address setting error by the mixed setting method |

| 14 | E14 | Communication error between master and slave indoor units |

| 16 | E16 | Indoor fan motor anomaly |

| 19 | E19 | Indoor unit operation check, drain motor check setting error |

| 28 | E28 | Remote controller temperature thermistor anomaly |

| 30 | E30 | Unmatched connection of the indoor and outdoor unit |

| 31 | E31 | Duplicated outdoor unit address No. |

| 32 | E32 | Open 13 Phase on the power supply at primary side |

| 33 | E33 | Inverter primary current error |

| 35 | E35 | Cooling overload operation |

| 36 | E36 | Discharge pipe temperature error |

| 37 | E37 | Outdoor heat exchanger temperature thermistor anomaly |

| 38 | E38 | Outdoor/Ambient air temperature thermistor anomaly |

| 39 | E39 | Discharge pipe temperature thermistor animal |

| 40 | E40 | High-pressure error |

| 41 | E41 | Power transistor overheats |

| 42 | E42 | Current cut |

| 43 | E43 | Excessive number of indoor units connected, the excessive total capacity of the connection |

| 45 | E45 | Communication error between inverter PCB and outdoor control PCB |

| 46 | E46 | Mixed address setting methods coexistent in the same network |

| 47 | E47 | Inverter over-current error |

| 48 | E48 | Outdoor DC fan motor anomaly |

| 49 | E49 | Low-pressure anomaly |

| 51 | E51 | Inverter anomaly |

| 53 | E53 | Suction pipe temperature thermistor anomaly |

| 54 | E54 | High/Low-pressure sensor anomaly |

| 55 | E55 | Underneath temperature thermistor anomaly |

| 56 | E56 | Power transistor temperature thermistor anomaly |

| 57 | E57 | Insufficient in refrigerant amount or detection of service valve closure |

| 58 | E58 | Anomalous compressor by loss of synchronism |

| 59 | E59 | Compressor startup failure |

| 60 | E60 | Rotor position detection failure / Anomalous compressor rotor lock |

| 61 | E61 | Communication error between the master unit and slave units |

| 63 | E63 | Emergency stop |

Table 9.1 Error codes

In case you detect an error code not listed, contact your nearest MITSUBISHI HEAVY INDUSTRIES technical support service.

© HMS Industrial Networks S.L.U – All rights reservedThis information is subject to change without noticehttps://www.intesis.com

References

[xyz-ips snippet=”download-snippet”]